REBUILDING

THE MORGAN FRONT SUSPENSION

by Lorne Goldman September

22, 2011

SOME DEFINITIONS

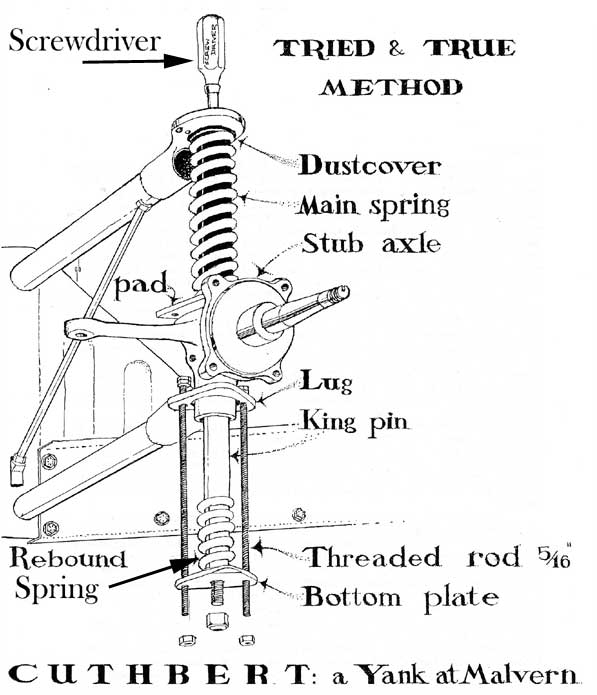

Wheel Spindle or Stub

axle: the front axle component to which the front wheel, brake caliper

and rotor, shocks and road springs attach. Slides up & down on the

kingpin. One per front wheel.

Brake Caliper: on

cars with front wheel disk brakes, the clamshell shaped component housing

the brake pads, to which the brake line attaches. Bolts to the back

of the wheel spindle. One per front wheel. (Replaces front

brake drum technology on older models)

Brake rotor: again

on cars with front wheel disk brakes, the round flat plate like device

which turns with the front wheels. Secured to the wheel spindle by the

wheel bearings. Straddled by the brake caliper, with a brake pad

residing on either side of it at approximately 2:00 o'clock. One

per front wheel.

Track Rod: the rod

connecting the left wheel spindle to the right spindle, and also the steering

arm from the steering box. Each end terminates in a ball joint, which will

need to be separated where it attaches to the wheel spindle.

IN PDF FORMAT (old version) CLICK Morgan

Front Suspension Rebuilding.pdf

There are VERY few jobs on

a Morgan that present a danger to the operator. Of course, as with anything

on a car, there is always the possibility of damaging a component or getting

the job wrong but few Morgan tasks present a personal danger to the home

mechanic who takes standard safety precautions. The Morgan front end disassembly

and assembly is an exception to this. There are dangers. Yet it draws amateurs

as this task, specific to Morgans only, has become an icon of what the

accomplished home mechanic can do. An Everest to climb. That is not altogether

a good thing. Without a study of what is entailed and the watchpoints,

sadness can result.

Recently, a Morgan internet

forum publicly posted how-to instructions prepared by a new owner who attempted

the job without advice or research. Sadly, aside from technical errors

that will require the job to be redone, his method is inherently dangerous

and caused concern amongst those who have done this job before. Word arrived

from France last week that a mogger had been very badly hurt following

his instructions. Please beware!

We have had a spotless record

for 28 years. We used to provided three (3) methods here to do the job,

depending on the reader's skill level and experience with a Morgan front

end. There has NEVER been a come-back or mishap on any of them in all that

time. However, I have decided to remove the more expert methods and concentrate

on the one considered the safest. The method below has the least risk.

It has been used with uneventful success by hundreds of first-timers for

a decade. PLEASE BE CAREFUL ABOUT WHAT INSTRUCTIONS YOU CHOOSE TO USE.

To avoid confusion, I have

made these instructions as detailed as possible. If you have questions

or comments, Please contact me. (webmaster@gomog.com)

READ THE SAFETY NOTES

FIRST. The ignorance of one of these elements in the other instructions

caused the accident referred to above.

SAFETY

COMMENTS AND WATCHPOINTS

PRIORITY. The bottom line to this job (which becomes super simple after 5-10 times) is safety. But someone at home, if they use the right components, will only have to do this job once on

their car. There are aftermarket components and maintenance,

popularized by eMog, that can make a Morgan front suspension last a

life time. The issue is that the spring pressures involved are

enough to cause great damage to anything adjacent and one of those

things adjacent is YOU. The detail I employ here is a function of that

caution. This method is not the fastest one, it is merely the safest

one.

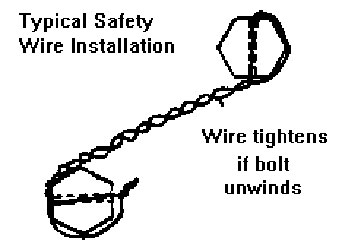

1. When working on the front

suspension,

the cross-axle must be seated on jack stands or their equals. Don't work

on the car with it resting on a jack only.

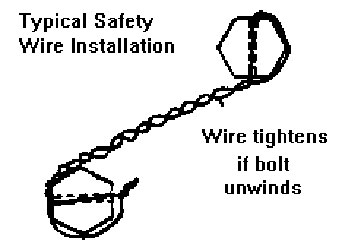

2. Make sure the caliper

securing bolts have been safety wired such that the wire will tend to tighten

the bolts (see sketch).

2. Make sure the caliper

securing bolts have been safety wired such that the wire will tend to tighten

the bolts (see sketch).

3. After the job, check every

nut and bolt again after you have put about 100 miles on the car. Also

check for wheel bearing play and take up if required.

4. Make sure you have all

the parts of the assemblies in the order so that you do NOT forget something

and be forced to deassemble again.

5. ASSURE that the hubs have

not been reversed. Look at each knock-off and make sure it threads in the

same direction as the rear wheel on the same side. If you have removed

the hubs, and install them in the reversed direction (threads going the

wrong way), you will loose a wheel. It is no fun --- so check!

6. Be sure to bleed

the brakes if the pipes have been disconnected.

7. Make sure you understand

which front system you have. From 2000 on, the MMC has been changing the

front and you must be aware of the changes to do the job right. Check with

the greasing

methods in this Manual to ascertain the necessary watchpoints for

each or contact the webmaster.

|

Pros

and old timers have all learned to shun

spring compressors to assist in this task. Yet recently, a first timer

installer, considered a guru on one anglo-Morgan forum, published

a how-to method that relied on them. The queries to GoMoG about

it precipitates this note. Because of the (obscured) presence of the

kingpin dust protector inside the main spring, NO pre-made compressor

can

be made to hold with any confidence. The clamp sections of a compressor

do NOT have sufficient space to seat

properly. But unknown to the enterprising first timer, who sadly never

asks advice of anyone, a store bought spring compresor only

precariously holds the Morgan main springs

inadequately until, at high tension, they can slip, allowing the spring

to expand suddenly

with enough power to kill or cause great damage. SO NEVER USE A SPRING COMPRESSOR. I

can report to you that a mogger in France who followed the bad advice,

crushed his jaw and eye socket, losing 6 teeth as well. HE

asked me to post this warning.There are others. PLEASE do not listen to people who tell you that the compression force of a Morgan front main spring is negligible.

Plus 8s anfd Plus 4s were 140ftlbs/inch for the main spring and double

that for the rebounds and if you compress them..that increases their

force.

There are also excellent copies of the GoMoG

method for amateurs on the internet. This one is

very good. http://morganrebuild.co.uk/SusRebuild.html

(sadly the writer is less-than-perfect in other areas and has (so far)

been unresponsive to contacts). Lovely diagrams for old Morgans!) Please, my fellow owner, be wary of

anything you hear on some forums. In fact, please beware of everything

you hear, period! There are also excellent copies of the GoMoG

method for amateurs on the internet. This one is

very good. http://morganrebuild.co.uk/SusRebuild.html

(sadly the writer is less-than-perfect in other areas and has (so far)

been unresponsive to contacts). Lovely diagrams for old Morgans!) Please, my fellow owner, be wary of

anything you hear on some forums. In fact, please beware of everything

you hear, period!

UPDATE 2020

The quintessimal pros, with more than their fair share of such work, and

extensive metal work abilities, occasionally fasion their own (safe!) proper spring compressors for Morgans. Cain Poulton (aka Wolf

Performance) also sells his to dealers and (plush) enthusiasts at a VERY reasonable price. If one is looking for safe shortcuts..this is what to buy. I am thinking of buying one myself as it makes front end experimentation very easy.

|

PARTS

NEEDED

1. Two hardchrome

(preferably) kingpins

2. Two new main springs

3. Two rebound springs.

4. Four bronze bushes. (See

bush types.) (The new ones have a grease groove cut in them and should

only be pressed in one way which is more or less obvious in examining them.)

5. Two new damper plates.

(The damper blades and shims can be changed at any time.)

6.

You should change

the main spring top bolts, (I do not advise the use of a oiler

bolt and the lock nuts below. Use a graded top bolt. These parts, even

more than head bolts, weaken and stretch with usage.

7. You will need wire to

re-wire the brake caliper bolts.

8. Pack the assemblies with bearing grease.

TOOLS

NEEDED

1. Rubber gloves (if

wanted)

2. Small trolley jack

(borrow one if need be)

3. Spanners, 21 mm,

14 mm, 13 mm, 11 mm,

4. Spanners, ¾

in., 9/16 in, 7/16" and 1/2"

5. 11/16 in socket

6. At least one if

not two ratcheting 1/2" (or 13mm) spanners. The job is a pain without one.

7. Small handheld sledge

hammer

8. Lead knockoff hammer

9. Two needlenose

pliers

10. Jackstands and/or blocks

11. 2 wire coat hangers or

empty boxes

12. 12 inch pry bar (flat

type used by burglars, available at any hardware store)

13. You may need a tie rod

end remover.

14. A cut down Phillips screw

driver.

15. Two lengths of 1/4 inch-

20 threaded rod approximately 4.5 to 5.0 inches long. (Cut the rods with

a nut already on. Then slowly thread it over the newly cut ends to repair

the threads and make sure it is easy to put the nuts on.)

16. A MORGAN spring compressor or none at all. I have never used a spring compressor

l

STEP BY STEP - DISASSEMBLY

1. Clean your front suspension.

Use a high pressure hose or brake spray cleaner. The front end can become

unbelievably greasy due to oil from the one-shot lube, grease and road

dirt. It builds up. This is a much easier job for those who keep their

front end cleaned.

2. Jack up the front of the

car and place it on stands. You will need about 18" of height.

3. Remove the spinners

and wheels.

4. Have little boxes or hangers

at the ready and remove the calipers by cutting their lock wire, removing

it, and then undoing the caliper bolts. Slip the caliper off the rotor

and place it on the little box with the brake line still attached or hang

it under the wing with the wire coat hangers.

5. Remove the dampers from

their bottom posts only.

6. Detach the tie-rod

ends. I do so by removing the nuts and then a sharp whack or two at the cast joint

itself and it falls off.

|

Some of you may require a tie-rod end puller. Leave the nut on loosely. With the Snap-on, slip the

puller "C" disk between the rubber seal and spindle arm and install the

puller. Screw bolt end of puller onto the rod end bolt. Things will separate

with a loud snap.

|

7. Remove the damper blades

(if you have any) by unscrewing them from the spacers at the chassis and damper plate.

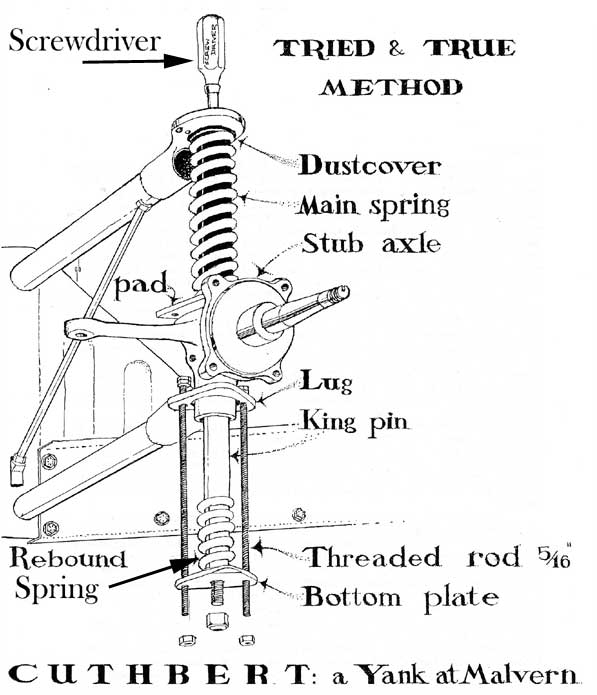

8.

Now... see the two little

fittings at the bottom plate on either side of the larger nyloc nut in

the middle? (At the bottom of the diagram above.) Remove ONE of these

little bolts and replace it with the threaded

rod (1/4 inch-20 cut to approximayely 4 to 5 inches long) with 2 nuts

locked at the top and one at the bottom, snuggled up against

the bottom of the plate. Then do the same with the other little

fitting.

Push the strut attached to the rear fitting to the side. No need to

remove

it from the chassis side.

| WATCHPOINT: When

cutting a threaded rod, (with a hack saw or an angle grinder ), you

will often damage the thread. By putting on a nut first, you can repair

the damage by spraying the end with a bit of penetrating lubricant and

threading off the nut. |

9. Now go to the top of

the assembly. If you have and are still using the old one-shot

oiler, detach it. This is a delicate operation as the brass coupling

which screws into the top of the large bolt holding the top of the kingpin

in place rounds off very easily with usage. Use lots of penetrating oil before

hand, and unscrew it carefully. Taking care not to bend the copper oil

tube, gently push the assembly to the side once it is removed.

| NOTE: In

2002, When the MMC switched to stainless kingpins they also changed the

thread and the top bolt to 1/2" unf. I recommend you have choose the better hardchromes which you can merely buy from any savvy dealer. |

10. Take a small screw

drivers and see if you can get them into the top hole when the big

bolt is removed from it. I use a medium size Phillips screw driver and cut off

part of the handle to make it fit. The point of this is that 3 inches or

so of the

little screwdriver, when placed down the top bolt hole, will

actually hold the assembly together without you holding it and

will allow you

to pivot the assembly to straighten it, and important factor. The

danger is loosing control of the of the kingpin and spring during

assembly or disassembly.

11. Now, while making sure the rods

do NOT pivot (I put my vice grips on the bottom of the rods and hold that to stop the pivoting) I ratchet

down the nuts at the bottom of these rods, and go from one to the other to keep them evenish and the kingpin will start to drop

SLOWWWLLLLLYYYY. Keep a hammer nearby to make the main spring stay

in place if needed.

12. When you have about 3

inches between the now dropped bottom plate and the lower frame it was

bolted to..the assembly will become looseish. Keep ratcheting down until you see little

or no tension at the little nuts you are turning on the threaded rods.

13. At this point, I take

something I have around (I used a deflated folded swimming pool raft).

and place it above the kingpin assembly to cushion any impact. I remove the little screwdriver and knock

the kingpin and spring off the top. Don't worry TOO much about it hitting the inside

of the front fender when extended– its rest position is only 2 inches (approx.)

longer than its length when compressed.

(BTW, the kingpin is not only held by the bolts.There is a little 1 inch

diameter détente in its upper frame spot that the kingpin fits into.)

14. Remove the threaded rods

by removing their top nuts. Remove the assembly by lifting it up. You can

also slip the kingpin out.

| NOTE: At this point

some people remove the rotors. This makes the other work easier but it

is more work and not strictly necessary. (See Bearing

and Rotor Removal) |

| NOTE: You can leave

the hubs in place if you have a Devol bush car. The ones with the resultant

fit blue nylon bushes as the bushes are that easy to fit. Drive them out

with a socket and extension and bang the new ones in with a a hammer and

a flat piece of wood. Once in, the fit should be fine without any reaming

or other adjustment. |

| NOTE: Have a beer. You deserve

one. |

REMOVAL

AND REPLACEMENT OF THE NEW FOR OLD BUSHES

i. After degriming

my friend's stub axles, I went to one of the machine shops in the village

and used their hydraulic press. With the help of some blocks of wood, I

got the tube in position and pressed out both bushes from one side. (This can also be done at home with a poor-man's drift. Nonetheless,

I advise the first timers to find a machine shop to do this task!

ii. Then I pressed the four

bushes in separately, taking care to get them oriented properly so that

the bush "lip" is facing outward..(bottom at the bottom and top and at

the top).

Mating New Bushings to the

Kingpins (updated 2014)

by Lorne Goldman

Morgan stub axles are not consistent. In welding the kingpin

tubes to the axles, they warp the tube. And, save for the Devol bushed

cars made between late 2001 and 2006. (scroll down for more information

under Devol), Morgan does not address the anolmalies they create by this

welding. This would require honing or reaming the tubes themselves to a

common ID and alignment of both ends. Without a common ID and alignment,

resultant fit bushes are not possible. One cannot simply press the bushes

in and expect, automatically, a correct clearance and/or alignment. In

layman's terms, without aligning the bushes at each end, you can have one

bush askew one way and the other end askew another way, making the kingpins

bind and sieze, regardless of whether their individual clearance to the

kingpin is correct. So properly mating new bushings to the kingpins is

absolutely key to the success of the job. Once the old bushings have been

removed and the new ones forced in, they will have to be mated (aligning

the bushes with each other and the kingpins and also machined so that the

interior diameter of the bushes has the right clearance for the kingpins).

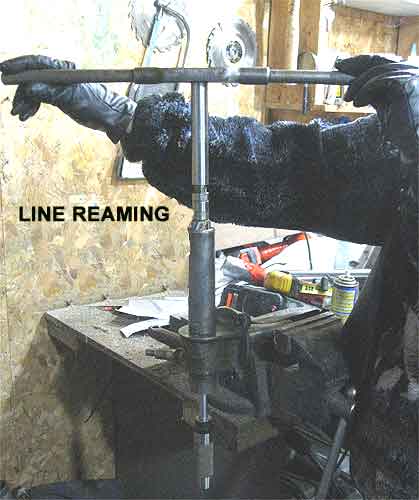

This will require either that you purchase some special tools a line reamer)

or find a machine shop that will do the work with more sophisticated equipment.

I once had mine done at a machine shop with a laser-guided Sunnen honer

for about $20 per axle. I admit to using a line reamer since....more

convenient.

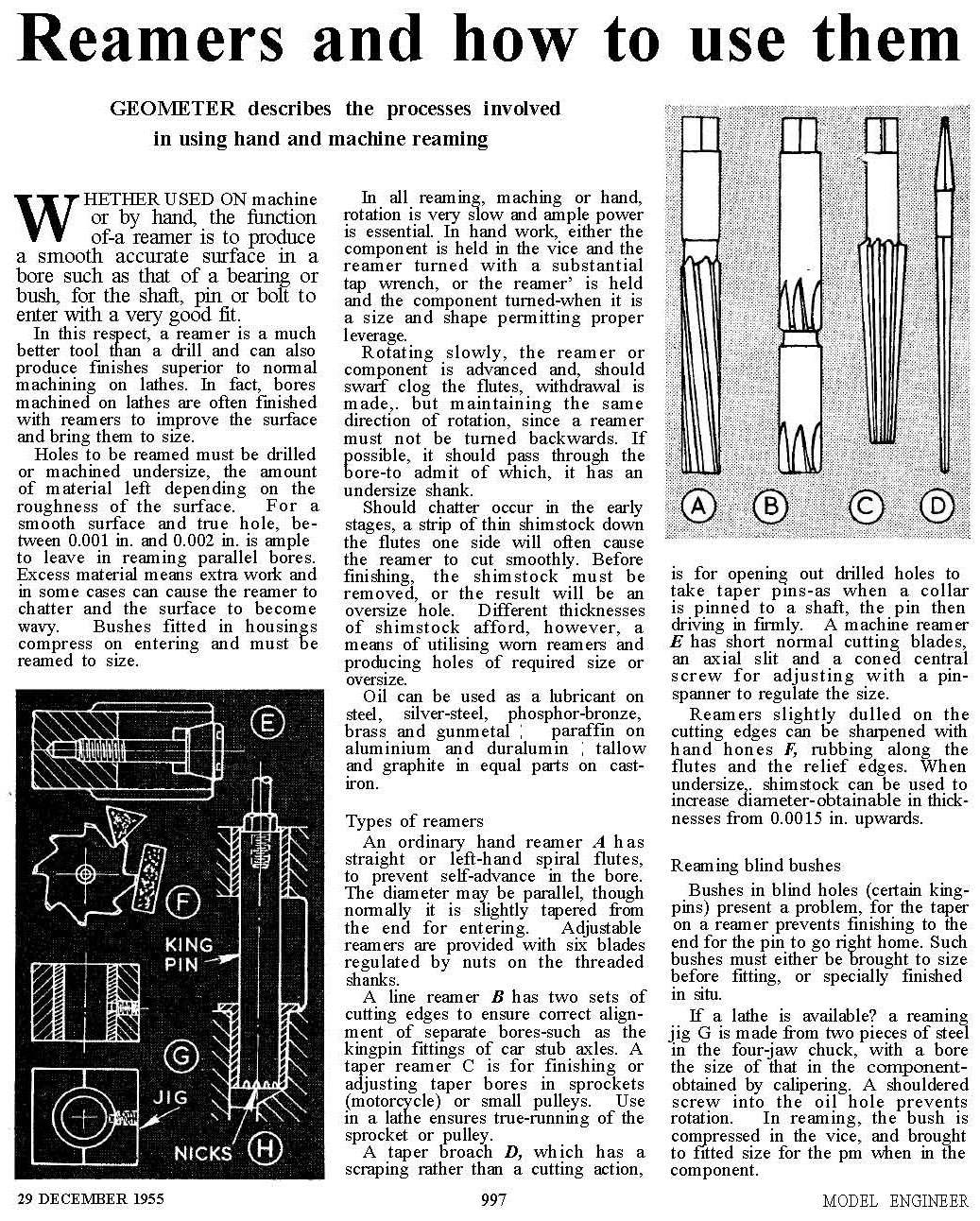

There are two methods of obtaining this fit. One is to

use a line reamer, the other is to have them honed. The consensus of opinion

is that the honing is preferred as a better and a computer-consistent precision

fit can be attained every time. I have not noticed a difference.

As well, honing allows for improved lubrication of the bushes on the same

principle that encourages the honing of engine cylinder walls. Knowledgeable

owners simply use hardchromed kingpins and forget such niceties.

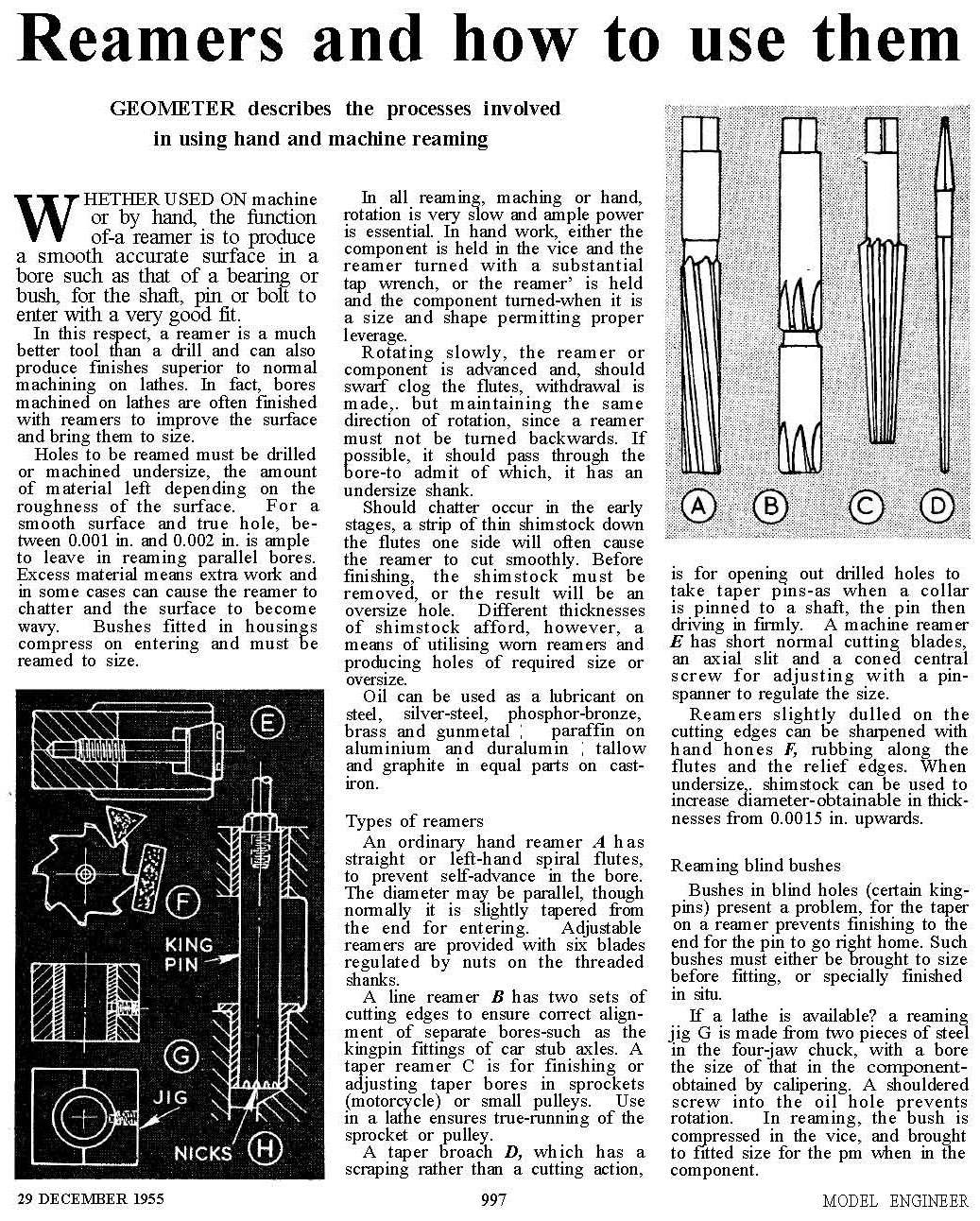

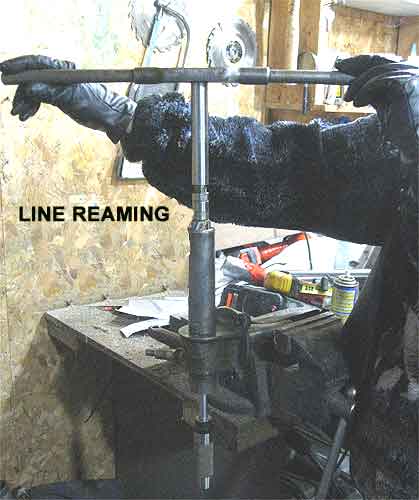

REAMING THE BUSHES

This is my wife Audrey showing how easy

it is. She was able to ream her first set of Morgan bushes

from these

instructions without my assistance. |

| DEVOL

cars only, you need not go through this process. Their blue bushes

are a resultant fit and VERY easy to press out and install without causing

damage. Drive the old ones out with a socket and extension and bang the

new ones in with a light hammer and a flat piece of wood. Once in, the

fit should be fine without any reaming or other adjustment. |

NOTE: With other,

bronze

bushes This part of the job requires specialized equipment. It can

be left to your local machine shop if you wish. The job can be done with

a reamer (it has been done this way for 100 years) but for precision a

Sunnen laser guided honer is technologically perfect..merely unnecessary. Here are instuctions for DIYers like

me.

I am looking for a line reamer source at a reasonable price. At the

moment, one suitable for a Morgan is in the range of £150. I

think they can be had for $35 USD. When successful, I will post an

advisory to the GoMoG New Additions Page. June 2020 |

|

|

A. Then I went home and fit

the axles to be held by a large table vice (the best garage friend of the

home mechanic).

B. I then took the Morgan

line reamer Norm Patterson lent me 27 years ago. (wry smile) This is a

1" reamer with an attached rod and a removable tapered end that slides

on the rod and fits into the other end of the stub axle tube. The rod and

taper aligns the reamer and therefore guarantees that your bushes will

also be aligned with each other. That is key. You then adjust and turn

gently through each bush until the kingpin can just slide through snugly.

Don't worry too much about measuring the clearance. Feel is better than

measurements here. I greased the bushes by filling the spiral bush grooves

with my finger. Frankly, in most cases the reamer, once it has done a Morgan once, need not be adjusted at all.

C.

I increase the reamer OD until the kingpin will JUST slide in the bush

(4-5 thous clearance or 0.1020mm) with no effort. The

check is done by putting light oil (vaseline for instance) on the

kingpin. Insert it in the tube all the way, put the palm of the hand

at the far end of the slider and pull the kingpin, if the vacuum thus

created

sucks the kingpin back, good enough for me, job done. White lithium or

molybdenum sulphide (water repellants and low friction) give excellent

results as front end grease.

BUSHING REMOVAL

Removal requires a bushing

tool (see sketch) that will push out the bushings and clear the ID of the

spindle. Use a jack stand to hold the spindle, and a drift (rich man's

or poor man's) to drive out the bushing. A brass knock off hammer is about

the right weight. Both bushings are driven out from the same side.

Here

is an alternate method from Downunder.

BUSHING INSTALLATION

Installation is best done

using a hydraulic press (any machine shops and many garages can do this).

In a pinch you can, with care, use the poor man's drift and drive them

in. Here

is an alternate method from Downunder.

ASSEMBLY

OF THE FRONT SUSPENSION

DO NOT forget parts

and the order they go on! You need the little plate that attaches to the

kingpin bottom, the kingpin, the rebound spring, the stub axle, the damper

plate (or bearing thingie if you are using one), the dust cover and the

main spring.

A. Remove the little plates

from the old kingpins and fit them on the new kingpins. In case you forget,

the sloped edge of the plate is on the bottom and outboard.

B. Gather the parts needed

in the right order. Place the correct stub axle assembly (right and left

stub axles are different) on top of the opening on the lower arm of the

crosshead and then slide the kingpin into the stub axle tube from the bottom.

(This is the point were many people add gaiters or steering

bearing thingies or O

Rings .)

| WATCHPOINT: Do not

forget the damper plate! And do not forget to place the dust cover inside

the top of the main spring before you slide the main spring on. |

C. Go find the threaded rods

you sued to remove the assembly and set them up again, through the little plate and through their

bolt holes in the crosshead. Two nuts each (locked together) on the top and

one nut each at the bottom.

D. Tighten the lower nuts

until most of the slack is taken up but before the kingpin starts rising.

E. Now here is the hardest

part..for me at least. You will find that the main spring does not politely

slip into its place under the top of the cross frame. It won't do that

unless it is compressed.

Here is how I did it the first time (though I have fashioned a three sided

funnel to help me out since). I put a jack under the "nose" of the

stub axle. I angle a strong (3/16" thick) metal plate (about 4" x 15")

under the spot I want the top of the spring to go. The main spring top

may/will be facing outboard. I use my hammer to force the top flush with

the plate and inward. As I am doing this, I use the jack to straighten

the end of the

axle and that forces the

entire spring to straighten. You cannot do this before you start, because

you need the angle outward to give you more length to deal with the spring.

This spring will curve and then straighten as you use the jack and get

closer to the near the springs happy home.

Keep banging inward until

the plate is sandwiched between the top of the main spring and its place

under its crosshead position. Once in place, Scott Lankton suggests (wisely) that we tie spring to the subframe with a bit of nylon rope so it cannot get away as we wiggle the steel piece out. Good idea.

Now here is where life gets

exciting. With hammer in one hand and plate grabbed in the other, wiggle

the plate out while keeping the main spring in place by banging/positioning

it with the hammer. As you wiggle out the plate, you may find that you can

slip in your trusty cut down screwdriver. In any event, as you can slip

that screwdriver in and once in, you will be considerably safer.

F. Now start ratcheting up

the bottom threaded rod nuts. You can measure you progress (it is slow)

by seeing the space between the lower plate the kingpin is held to and

the crosshead flange which is its destination. You will need the hammer

to make sure the main spring behaves and stays aligned as you want.

WATCHPOINT: Be very

careful not to crush the dust covers with the stub axle tube (it is hard

to see inside the Main spring).The dust cover fits over the tube as a very

tight fit and it is easier to crush it than not. When they approach the

point of contact, make SURE the cover slides over the tube. see

here

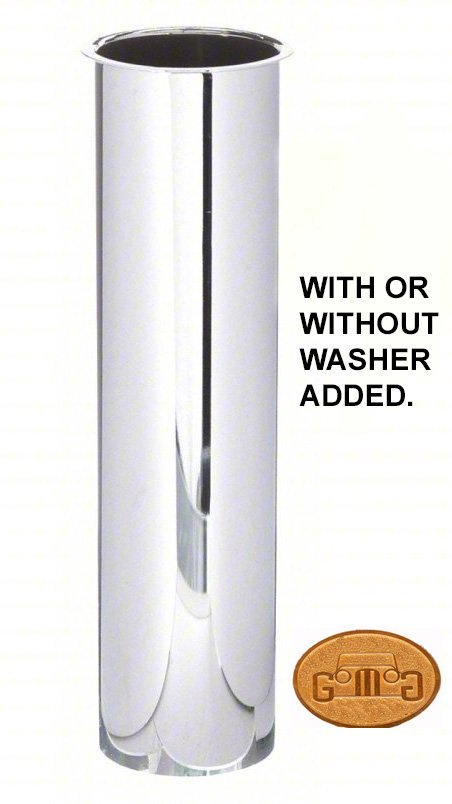

NOTE: The dustcover to

the right is a plumbing extension found in any plumbing or hardware

store. The reason to switch (when convenient) is not because it is

cheaper and prettier. It is because it a much higher quality part for

the purpose it serves as it does not rust and one can see its condition

and any debris at a glance. |

G. I find that my

top kingpin

bolts cannot thread properly if the kingpins are raised fully into

their final

position. Perfect alignment of bolt and threads is unlikely when they

are that close. So I leave the kingpin about 25-35mm from the top. I

then feel for the kingpin

position with the cut down screw driver. If necessary I use a small

mirror, flashlight and hammer

to carefully center the pin under the bolt hole. Then I search for the

kingpin hole with the bolt. Finding the thread can be difficult

and could require a number of tries! (PLEASE place the cut down

screwdriver

back when you are not trying!!!!!!!!) When the center pin is under the

hole, thread the bolt (with loctite) home. It is not necessary to

tighten

it completely.

H. Once you have the bolt threaded, finish ratcheting up the nuts on the threaded rods

and then tightendown the big bolt on top.

I. Now remove one of the

threaded rods and replace with its bolt and nut. Now do the second one, Don't forget to put the strut back on.

J. Put the tie-rods back

on.

K. Fit back the calipers.

If it won't slide onto the rotor, pry the pads apart with a big screw driver

and try again. In extremis, remove the pads, fit the calipers and then

install the pads. Make sure you don't twist the brake lines. Use the wire

to lock the caliper bolts..they both have holes for that in them.

L. Fit the shocks on their

bottom posts.

M. Refit the damper

blades and spacer and attach them to the damper plates. You can allign

the plate with a few knocks of a small hammer. You can bend the damper

blades to fit them back into their slot on the frame but I usually remove

the shims and lengths of metal, clean them and reassemble after examining

them for wear. Adjust the shims (part of the damper blade assembly on the

car frame) to ensure that the assembled damper blades have no lateral motion

where they attach to the body. See HERE.

N. Install the one

shot oil pipes. (if you have them and still use them)

O. Pump the stub axles full

of grease.

P. You now need a professional

wheel alignment.

and another beer!

Q.As a word of caution, ensure

that you recheck the tightness of all fittings and bolts after your first

few kilometers, and again several times after driving longer distances

(I suggest 50, 100, and again at 200 Kms.).

EPILOGUE

My apologies to the pros

in our midst, but this article is written for Morgan-owning lay persons.

2. Make sure the caliper

securing bolts have been safety wired such that the wire will tend to tighten

the bolts (see sketch).

2. Make sure the caliper

securing bolts have been safety wired such that the wire will tend to tighten

the bolts (see sketch).

There are

There are