The Roller Bearing Conversion

(The whys and wherefors)

by Lorne Goldman, John Sheally II, Peter Mulberry

& Bill Button

June 2005 updated May 2020 updated, May 2022 updated

1. The Whys

2. John H. Sheally II/eMog Pub Version

3. Mulfab Version & Their Fitting Instructions

4. The Morgan Motor Company Version & Caution

5. Wolf Performance Version (my current favourite)

6. Watchpoint for Post-2008 MMC System

7. Watchpoint2 for Earlier Morgans

8. Watchpoint For All Morgans (read first)

9. When All Else Fails

THE WHYS

by LORNE GOLDMAN

As

the stub axles move up the kingpin when the car goes over a bump,

the large kingpin springs compress (obviously) and produce a twisting motion

(not so obviously). All other things being equal, this twisting motion

would be relayed to the spindle and would result in a slight turning of

the wheel. When this occurs and a certain speed, it sets up a harmonic

bounce which can express itself in a violent shimmy.

To avoid this, HFS Morgan placed a bronze plate between

the spring and where its sits on the spindle. The bronze plate then is

held steady (and untwisting) by being bolted to the damper blade which,

in turn,

is

held at the frame. With all this, the spring's motion is now transferred

to the immobilized bronze plate rather than the spindle. Of course, since

the spindle moves up and down the damper blade cannot be bolted to the

frame as it must move in and out to follow to the spindle's movement up

and down. Ergo the blades are "sandwiched" into a slot made of small metal

plates and the damper blade shims.

is

held at the frame. With all this, the spring's motion is now transferred

to the immobilized bronze plate rather than the spindle. Of course, since

the spindle moves up and down the damper blade cannot be bolted to the

frame as it must move in and out to follow to the spindle's movement up

and down. Ergo the blades are "sandwiched" into a slot made of small metal

plates and the damper blade shims.

This system has worked for almost 3/4 of a century. Its

drawbacks are the maintenance it requires (as the blades get loose they

allowing twisting to occur at the spindle unless the shims are readjusted

and the blades and shims deteriorate. It handles the twisting movement

in a less efficiently manner than other solutions. The roller bearings

are one of these "other solutions" and a good one.

RESISTANCE

With the standard Morgan setup, the twisting action of

the spring is the twisting action of the spring is dissipated on the bronze

plate (attached to the damper blade). As the bronze plate is, in effect,

fixed, there is some resultant resistance to the twisting on the plate.

In the roller bearing system, the twisting is on the collar

and washer which are seated on the bearings and turn on these..ergo no

resistance and lighter steering.

CLEANING

As the bearings are closed to the elements by the washers

under them and the other washer atop them (with the collar and spring pressure

to hold it all sandwiched, there is nothing that can get in and dirty those

bearings. (Second) ergo, though the area would require normally cleaning,

it would be not susceptible to road dust as it is fully enclosed in the

stainless washers and I would find it hard to see how wear would be a factor.

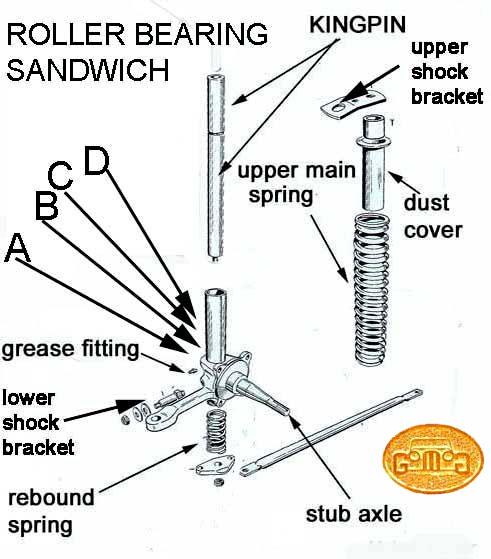

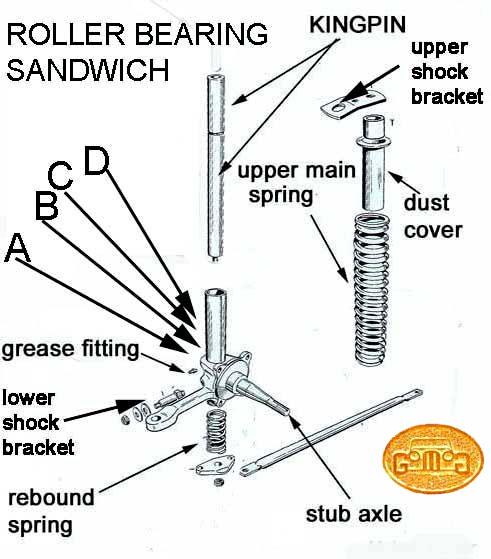

I have attached a diagram the reflects my understanding.

A 4-story sandwich. After removing the kingpin assembly and stub axles,

the bronze plate that attaches to the damper blade is removed from its

position around the stub axle tube (where the kingpins are placed). A washer

is placed on then the thrust roller bearing is pressed fit. Another washer

is placed loose on the bearing ..diagram "C", then the top hat cover is

placed on top of the assembly. The kingpin is re-installed and the large

kingpin spring fits down over the kingpin and sits on the top hat. The

top hat is used to properly position the spring and the sandwich and keep

the grease in the bearing assembly and debris out. The top hat must turn

freely. If it is too tight, use some sandpaper on the inner edge until

it slides loosely.

I have attached a diagram the reflects my understanding.

A 4-story sandwich. After removing the kingpin assembly and stub axles,

the bronze plate that attaches to the damper blade is removed from its

position around the stub axle tube (where the kingpins are placed). A washer

is placed on then the thrust roller bearing is pressed fit. Another washer

is placed loose on the bearing ..diagram "C", then the top hat cover is

placed on top of the assembly. The kingpin is re-installed and the large

kingpin spring fits down over the kingpin and sits on the top hat. The

top hat is used to properly position the spring and the sandwich and keep

the grease in the bearing assembly and debris out. The top hat must turn

freely. If it is too tight, use some sandpaper on the inner edge until

it slides loosely.

JOHN H. SHEALLY II & the eMOG PUB & GRILLE

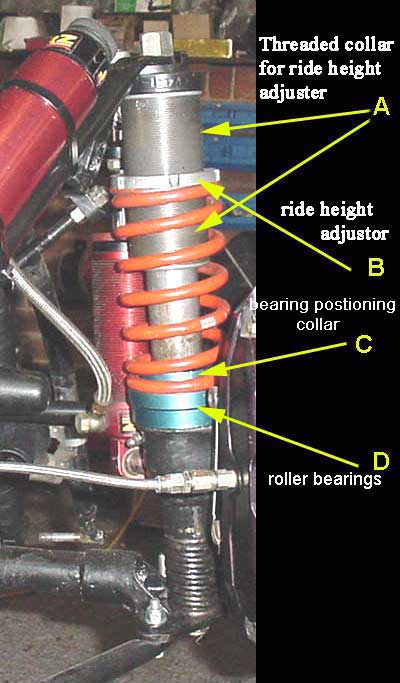

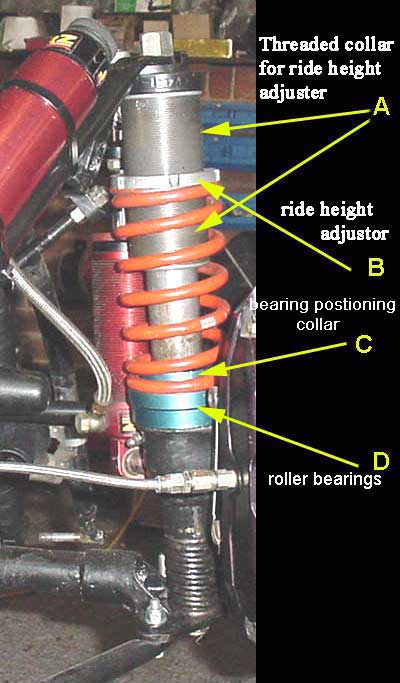

Here is the "Sheally Setup". It is quite simple. The views included are

of it on John's new Plus 8 Morgan Racer. If you look close under the bottom

of the red main spring you will just see the stainless washers sandwich

with bearing in between.

What you can not see is the machined collar pressed over

the kingpin tube to center the bearing and washers. The collar or collet

is drilled to match the grease fitting hole so that the existing fitting

can be used to grease the bearing from inside to outside serving also to

clean it each time it is greased via gun.

The bearing is a FEDERAL MOGUL/NTA 2840 and the stainless

washers are FEDERAL MOGUL/ TRA 2840 (total of approximately $30US collars

extra). Toss the damper blades and bronze thrust plate and enjoy quick

smooth steering at a small cost with my applied "KISS PRINCIPAL" I have

found that the setup is too simple for a lot of folks to comprehend.

You have to make your own from round steel stock or good

quality steel pipe. It is very simple, you are making a steel "ring" to

press fit over your spindle bushing tube. make the ID tight to press fit

over the tube and press fit all the way down to where your bronze plate

would sit. make the OD to be a snug fit to the ID of your thrust roller

bearing. put the stainless washer over the tube and slide down over the

ring "collar" followed by the bearing and the second washer (lube the bearing

well on both sides) and make sure your grease will feed to the bearing

from your existing (grease nipple/zerk) by drilling a small hole in the

ring and line it up with the oil hole on the spindle. Place your main spring

in place and assemble spindle and kingpin, etc. and enjoy your Morgan.

Sincerely, John H. Sheally II

top hat right side up | Kits of the Sheally set up were machined and assembled

through the efforts of Roger Shawyer. Roger had the collar produced and

used a grease ring to spread the grease evenly about the bearing. Care

should taken to ensure that the collar freely turns about the tube. These

assemblies, made as an eMog Pub

initiative, are no longer available. However, they can be reproduced

by a machine shop to order along with the other parts are listed above.. |

top hat upside down

|

PETER MULBERRY

Peter Mulberry extends the thrust roller bearing principle ..using

different ball bearings within a housing as can be seen by the picture.

As well, the main spring is changed. For racers, there is an interesting

adaptation (shown in the picture) of a treaded collar at the top with an

adjuster. This  allows the ride height to be changed quickly and conveniently.

allows the ride height to be changed quickly and conveniently.

Peter adds a worthwhile note on the reasons for vibration

AFTER this mod.

"Probably the most likely cause of wheel wobble when fitting

roller bearings is removing the damper blade. Strange to believe but every

Morgan is different, some will 'wobble', some not at all. Why could

that be? What use is fitting rollers when the Mog is going to shake her

head along the road?

The advantages have been commented several times, lighter

steering, smoother action, disadvantages as far as I believe are capital

outlay to buy the bits and getting your hands dirty to fit said parts.

So this still does not answer the problem of wheel wobble. So why take

away the damper blade?

Trying not to get too technical, the blade fulfills two

functions. Without the bronze thrust pad the road spring would sit directly

upon the stub axle. When the steering was turned the spring would turn

as well, but the top of the spring is hard against the top of the crosshead

which does not want to turn so the end result is akin to winding up a large

spring in one direction and unwinding in the other. Very strange. So we

have the bronze thrust pad between the spring and stub axle which stops

the spring winding up. The second function is a friction damper to give

it its correct name. Two key words here, first was friction, hard work

and effort, roller bearings take all that away, second word was damper.

It is damping the oscillation that is wheel wobble.

If

you still have the dreaded wheel wobble after the bearing installation,

look to your castor angle. A few will be conversant with the term, but

basically it is the angle that the kingpin leans backward as you look at

your car from the side. It is what gives your steering its self-centering

effect. Too little and no self-center, too much and grossly heavy steering.

Everybody

must have pushed a shopping cart sometime. Ever

had one that the wheels do their own war dance? The factory

measurement

for castor is 4 degrees, give or take a bit for allowance. If yours is

a bit less you have lost the self-centering ability and gained wheel

wobble,

if you have a bit more than 4 degrees you have one of those delightful

drivers that track straight and true with hands off the wheel. I always

set mine up at six degrees and have no problems at all. Unfortunately

the

factory have made it all non adjustable. But it can be tweaked if you

know

what to do. If you are not sure where yours is visit an auto align

center

and they will give you a read out of your front suspension. Then you

know. I use these..two Morgans, 170,000 miles, no problems in 24

years.

WATCHPOINT2 FOR EARLIER CARS (posted 2006): Within

the eMog community, many (100s) performed this modification.

Overwhelmingly, they were successful and without

issue. However, we DID find that earlier cars were far more

susceptible to

the dreaded Malvern Dance, akja an uncontrollable wobble at the front

end that appears at the vibration point of the wheels/tyres they use.

There was speculation that the thinner tyres

and less castor (the modern

era began with 4 degrees) or some other element of earlier front end

geometry made those cars more vulnerable than later cars. One

of the

best home Morgan mechanics I know, the well-respected Bob Nogueira,

found this to be the case with his 1960s Plus 4. I wish I had time to

solve this quandary, but I allocate my time according to the

number of owners effected. What is posted in the Manual is merely 25%

of what I have in archives. Of course, I am always willing to

help if you contact me directly. WATCHPOINT2 FOR EARLIER CARS (posted 2006): Within

the eMog community, many (100s) performed this modification.

Overwhelmingly, they were successful and without

issue. However, we DID find that earlier cars were far more

susceptible to

the dreaded Malvern Dance, akja an uncontrollable wobble at the front

end that appears at the vibration point of the wheels/tyres they use.

There was speculation that the thinner tyres

and less castor (the modern

era began with 4 degrees) or some other element of earlier front end

geometry made those cars more vulnerable than later cars. One

of the

best home Morgan mechanics I know, the well-respected Bob Nogueira,

found this to be the case with his 1960s Plus 4. I wish I had time to

solve this quandary, but I allocate my time according to the

number of owners effected. What is posted in the Manual is merely 25%

of what I have in archives. Of course, I am always willing to

help if you contact me directly.

Bob found that he could eliminate the sad effect by re-installing the damper blades along with the damper blade system.

Damper Blades seem to some (not all) earlier trads as

a method

for divorcing the influences of the road from the main spring while

steering bearing/races, which should accomplish the same divorce

theoretically ease steering and limit the need for maintenance and

blade fiddling. Using the combination should cause

no prejudice harm whatsoever (though it adds back the original

hassles). Damper blade plates (the thick bronze plates the blades

attach to at the stub axle) do not add sufficient height to

pre-load (aka unduly stiffen) the main springs as the Mulberry and Factory bearing/races might do without compensation in main spring height.

(I installed shortened Main Springs with my Mulberry bearing system/ These can

be had at any spring rate you might want

to try merely shortened in length.) I favor the traditional Plus 4 spring rate on my muscly Plus 8 (140). They were marked by the Works with a "Morgan Plus 4" script (to the right)

|

THE MORGAN MOTOR COMPANY (PostScript in 2009) (another in 2020)

The bearing systems do make the cars much easier

to steer but also more likely to vibrate and wobble if all is not as it

should be. When anomalies (ie.vibration) were experienced with older Morgans

(pre-1968) we were forced to examine more closely and found and corrected

other problems, after which all was well.

If

wobble/vibration is experienced by later cars (post 1980), it normally

indicates a damaged, very poorly set up or poorly maintained front end

which should

If

wobble/vibration is experienced by later cars (post 1980), it normally

indicates a damaged, very poorly set up or poorly maintained front end

which should  be brought to the attention of your mechanic. In such cases,

if this seems too much of a hassle, you can rebuild your front again with

the damper blades, with or without the bearings. We do not recommend you

increasing your castor without resort to an expert who has done so before.

When

all else fails you can try the Mercedes damper.

be brought to the attention of your mechanic. In such cases,

if this seems too much of a hassle, you can rebuild your front again with

the damper blades, with or without the bearings. We do not recommend you

increasing your castor without resort to an expert who has done so before.

When

all else fails you can try the Mercedes damper.

After

this article was posted, the Morgan Motor Company copied the system designed by Peter

Mulberry. Like the Mulberry

system, the height of the bearing assembly requires the use of shorter

main springs. (Be careful which spring rate you get!). After a period without,

the Company began using drilled kingpins with grease nipples. This is

NOT the one shot oiler system that was happily removed some years ago.

The new passage is not for oil, but rather made larger for grease and is

drilled further down to feed the steering bearing assembly which, unlike

the other systems described above, it seems the Factory did not pre-pack their assemblies with grease on installation.

WATCHPOINT FOR POST 2008 CARS

From

the eMog Pub in January 2004 and updated January 2011 and in June 2020.All these bearing assemblies NEED grease. This was provided,

in pre-2008 cars with retrofits, by the little grease exit hole the MMC used to drill

at the junction of the stub axle shelf and the stub axle tube. (see

image) For these

bearing assemblies, this exit was perfect as it

comes up under the housing at a place where it flows easily into the

whole

assembly and the bearings. After a short delay, the MMC drilled three

holes in the stub axle tube to feed their bearing assemblies.

However, ever more frequently, when owners DO open up this area, it is found that the MMC bearing assemblies are bereft of grease, dry, with signs of rust and often seized. This results in the opposite effect that these systems are supposed to address. Rather

than easing steering, these bearings make steering harder and can

have other sad expressions...they must be addressed. Why did this

happen. A number of our favourite gurus have added their speculations

to my own below. Any of these or a combination of them could be causing the problem.

1. It seems the Factory does not pre-pack their assemblies with grease on installation. It

has long been thought that with an exclosed system, pressured closed by

the immense force of the compressed mainspring, that once packed, these

bearing assemblies would NEVER lose any grease. That has been the case

when I have had the occasion to disassemble my Mulfab front

end.

1. It seems the Factory does not pre-pack their assemblies with grease on installation. It

has long been thought that with an exclosed system, pressured closed by

the immense force of the compressed mainspring, that once packed, these

bearing assemblies would NEVER lose any grease. That has been the case

when I have had the occasion to disassemble my Mulfab front

end.

2. On disassembly, we have discovered that the seal the MMC uses, has a hole in it.

3.

Owners are, as a rule, pretty timid front end greasers. Improper

greasing is rampant, even among those who are concientous about

it. The grease gun becomes dislodged, or they give up far too

prematurely rather than waiting until they see the grease coming out

the right place.

Any of these things might be causing the evidence we are seeing..but regardless of the cause, IT MUST BE ADDRESSED.

WOLF PERFORMANCE June 2020

Wolf

Performance (aka Cain Poulton) is a relatively new entry into steering

bearings sweepstakes. Cain has come up with two versions, one based on

roller bearings and the other on thrust bearings. Frankly, both

have advantages..it is a matter of which of their charcteristics you

favour. No complaints or feedback has yet to be heard.

| I am

always pleased to see new and honest suppliers enter the Morgan

community. Too many old stalwarts have retired or moved on to other

things since the Company began purloining their ideas outright

rather than encouraging their ingenuity as Peter Morgan did for

decades. :( As well, in the last 15 years there has been much super

expensive silliness promoted, discouraging owner learning and ideas as

well, prejudicing the cars and culminating in the lack of real

development of the trad for the last two decades, a factor in its

recent demise. |  |

I am now giving THESE bearings my highest recommendation for this genre of components. It

is not merely their price, it is the quality of their manufacture and

design. As well, with their lower height, they can be swapped in

without requiring shortened main springs.

Rebound Spring Length Watchpoint: In

each of these cases, when retro-fitting thse bearings, one compresses

the springs by the height of the height of the top hat cover of the

bearing. The amount of this compression varies from system to system,

negligibly with the Sheally method above and the most with the Mulberry system,

which is undoubtely the strongest and the most widely used before the

MMC copied the system into its stock cars. The other systems compress

the springs somewhere between Shally and Mulberry methods. Proper Plus

8 springs have 140s or 140lbs per inch

but these were changed to a lower rate (along with the Morgan Plus 4s

and Roadsters) which is why they feel "wallowly" to cogniescenti and

steering precision appreciaters. Dealers, racers and agressive drivers in-the-know swap them out on arrival.

Rebound springs and the rebound section here in section 8,

are already too long, and all have spring rates double that of the Main

Springs. That means that the top hat flange compresses the springs and

extra, for example,1/2 Inch or adds another 60 pounds of pressure if

the same length spinrgs are used. Along with the rebound problem from

the Factory, this will prejudice handling and comfort even more. Astute

installers will notice that they must compress the Main Spring more to

re-install the stub axle or that the bolt on top must be longer. What

they are do is make the front end stiffer when their goal was to

make their steering easier. Sadly, some of the suppliers who copied Peter Mulberry, mention nothing

to their buyers. Peter Mulberry used to receommnded buying the same

Main Springs but shorter ones or to cut the existing main springs down.

That is what I did for all my Morgans.

|

BACK

is

held at the frame. With all this, the spring's motion is now transferred

to the immobilized bronze plate rather than the spindle. Of course, since

the spindle moves up and down the damper blade cannot be bolted to the

frame as it must move in and out to follow to the spindle's movement up

and down. Ergo the blades are "sandwiched" into a slot made of small metal

plates and the damper blade shims.

is

held at the frame. With all this, the spring's motion is now transferred

to the immobilized bronze plate rather than the spindle. Of course, since

the spindle moves up and down the damper blade cannot be bolted to the

frame as it must move in and out to follow to the spindle's movement up

and down. Ergo the blades are "sandwiched" into a slot made of small metal

plates and the damper blade shims.

I have attached a diagram the reflects my understanding.

A 4-story sandwich. After removing the kingpin assembly and stub axles,

the bronze plate that attaches to the damper blade is removed from its

position around the stub axle tube (where the kingpins are placed). A washer

is placed on then the thrust roller bearing is pressed fit. Another washer

is placed loose on the bearing ..diagram "C", then the top hat cover is

placed on top of the assembly. The kingpin is re-installed and the large

kingpin spring fits down over the kingpin and sits on the top hat. The

top hat is used to properly position the spring and the sandwich and keep

the grease in the bearing assembly and debris out. The top hat must turn

freely. If it is too tight, use some sandpaper on the inner edge until

it slides loosely.

I have attached a diagram the reflects my understanding.

A 4-story sandwich. After removing the kingpin assembly and stub axles,

the bronze plate that attaches to the damper blade is removed from its

position around the stub axle tube (where the kingpins are placed). A washer

is placed on then the thrust roller bearing is pressed fit. Another washer

is placed loose on the bearing ..diagram "C", then the top hat cover is

placed on top of the assembly. The kingpin is re-installed and the large

kingpin spring fits down over the kingpin and sits on the top hat. The

top hat is used to properly position the spring and the sandwich and keep

the grease in the bearing assembly and debris out. The top hat must turn

freely. If it is too tight, use some sandpaper on the inner edge until

it slides loosely.

allows the ride height to be changed quickly and conveniently.

allows the ride height to be changed quickly and conveniently.

WATCHPOINT2 FOR EARLIER CARS (posted 2006):

WATCHPOINT2 FOR EARLIER CARS (posted 2006): If

wobble/vibration is experienced by later cars (post 1980), it normally

indicates a damaged, very poorly set up or poorly maintained front end

which should

If

wobble/vibration is experienced by later cars (post 1980), it normally

indicates a damaged, very poorly set up or poorly maintained front end

which should  be brought to the attention of your mechanic. In such cases,

if this seems too much of a hassle, you can rebuild your front again with

the damper blades, with or without the bearings. We do not recommend you

increasing your castor without resort to an expert who has done so before.

be brought to the attention of your mechanic. In such cases,

if this seems too much of a hassle, you can rebuild your front again with

the damper blades, with or without the bearings. We do not recommend you

increasing your castor without resort to an expert who has done so before.