"The Damper Blades were not fitted to three wheelers

I believe because the large wheels, light weight, and low speeds did not

result in front wheel shimmy.

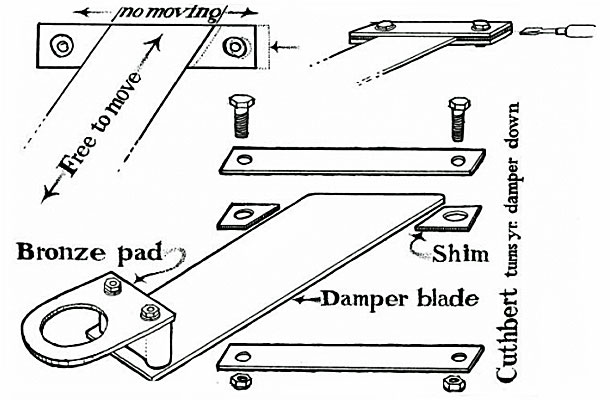

As the spindle moves up the kingpin over a bump, the spring

will have a twisting motion, this is relayed to the spindle and results

in a slight turning of the wheel. If this occurs at a certain speed. It

sets up a harmonic bounce which becomes a violent shimmy. This usually

occurs at between 55 and 65 mph. The damper blade is bolted to a bronze

plate fitted between the spring and spindle and, via the blade, is held

to the chassis. Thus the spring can rub on the bronze plate and move but

the plate is held still and none of the springs motion is transferred to

the spindle. Since the spindle moves up and down the length of the blade

can not be fixed. The blade is held to the chassis by being sandwiched

between two flat bars so that the blade can move in and out. At each end

of the approximately 1" by 4" bars are shims which are the same thickness

and material as the blade. These are positioned and pressed up to the blade's

side as guides and the bolts hold them tight so they can not move fore

or aft thusly preventing unwanted (side to side) lateral movement of the

blades.

Both the shims and blade wear since the blade rubs on

the shims every time the wheel moves up or down. As the blades and shims

become worn, their edges lose the height necessary to act as a stop and

they pinch rather than guide (stopping movement entirely). To test for

wear, grab the blade and push forward and back. If a click or movement

can be heard or felt the shims need to be pushed tight against the blades.

There should be free movement in and out, from the center line of the car,

but no movement otherwise. I check mine every time I grease the car, and

adjust the slack out."

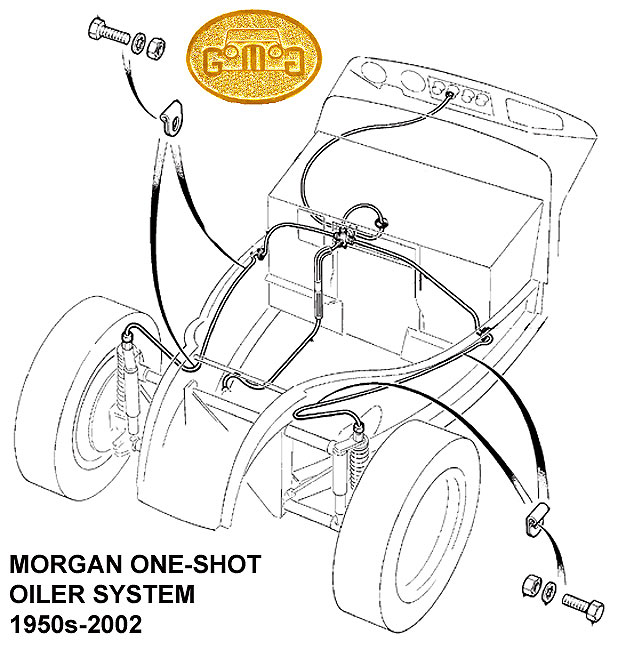

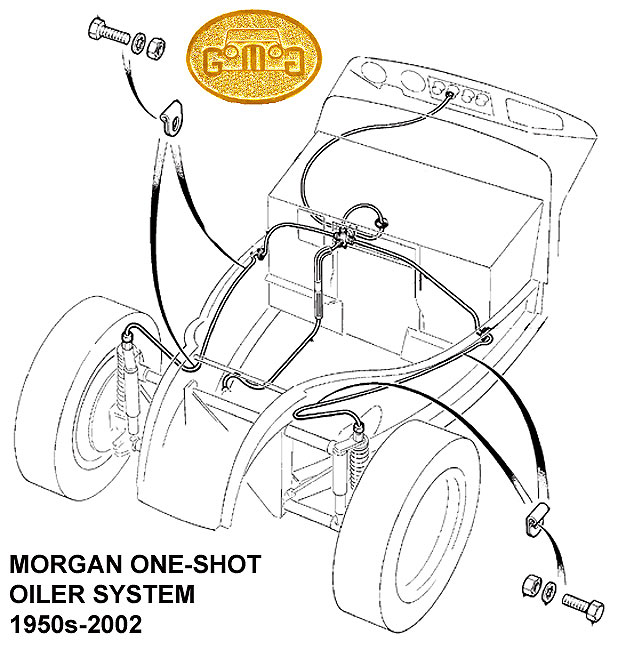

The One

Shot Oiler

The One

Shot Oiler

This is one of the more intriguing (and sadder) stories

of Morgan design. It remained unique only to Morgan as part of the front

suspension from the 1950s to 2002 when it was finally removed. The manuals

of the day suggested that the front suspension be given a regular shot

of oil from the one-shot pedal immediately at start up every 100 mi. In

fact, it did and can not lubricate the suspension as its kingpin exit hole

does not reach the reservoir section within the stub axle. Others suggest

that it is there to lubricate the damper blade plate, but the MMC was quite

clear in their 1920s articles that this plate was a FRICTION damper. Oil

would prejudice that. In any event, all stub axles grease that plate automatically

from a drilled passage coming up from below.

The only thing that testing and experience has proven

is that use of the one shot oiler;

1. can dangerously foul the brakes

2. cover that area of the car with dirty oil

3. offer the opportunity for a broken one shot oiler valve

and/or lines and void the car in minutes of motor oil..to disastrous effect.

4. Dirty the floor around it.

5. Has no remedial effect

| WATCHPOINT: Replacement of the old oiler system with a

grease zirk sadly makes no sense at all. The older passages are not made

for the passage of grease and the grease will NOT go far enough down to

reach anything of significance. The exit hole exits too high to serve the

stub axle grease reservoir. The result of using the oiler passage to feed

grease is to create grease gobs next to your brake disc. |

So why is the one-shot oiler there? It was placed at the

insistence of Peter Morgan (NOT HFS!) who had seen something similar with

Bentley (different design) and was probably tired of hearing stiff steering complaints from owners who never grease their Morgans. Though there was advice against, one does not

argue with the boss, especially a well-loved one. The oiler was removed

as soon as internal diplomacy allowed in 2002. Few, if any experts or dealers

had suggested its use for decades before. It was removed completely..though frankly, the MMC never got that area right.

| WATCHPOINT: Once you are removing the system, do it right.

Remove the oiler lines to the junction on the bulkhead. The pre-1998 cars

feed the pressure gauge from the oiler junction at the bulkhead. You can

replace the gauge with its electrical version. Both VDO and Smiths oil

gauges come in an identical-looking electrical gauge that functions by

electrical signal rather than an oil feed. That removes all risk. Or,

if you wish to keeping the mechanical oil pressure gauge, plug the feeds

to the oiler system at that junction with bronze threaded plugs. Even

so, you would be to change the feed to the junction to an Aeroquip line.

There are many reported incidents of that nylon oil line breaking or melting

with sad result. Happened to me as well! |

In 2007 the MMC replaced the damper plate and blades with

steering races (bearings) copied from the systems of designed by John Sheally, Peter

Mulberry and popularized by eMog in 2001/3. However, the MMC stub axle design proved to inadequately replenish

bearing assembly with grease. To assist in this task, they once again drilled passages

down their kingpins to feed the bearing housing, a wider one that would

specifically feed their bearing system with a large grease nipple atop

the kingpin. Meanwhile, the aftermarket systems noted work well without this passage. Just

grease the lower grease nipple normally and wait for the grease to appear

at the edge of the bearing cup.

See FRONT SUSPENSION LUBRICATION

Steering components

The only remaining part of the front suspension that can

contribute to the vibrations is the steering box and the tie rods.

Borrowing a section from Fred Sisson's book (Notes

from a Morgan Garage), he discusses a problem with the tie rods:

"I found a source of play on my +4 steering.

It is a simple adjustment to eliminate it. The Pitman arm (on the steering

gear box) transfers it's motion to the tie rod (the rod between the front

wheels transverse rod) via the drag link. The ball end on the drag link

fits into a clamp-on fitting on the tie rod.

I noticed that the first motion of the transfer

rod would twist the tie rod about 1/8 of a turn before it actually moved

the tie rod. The ball tie rod ends allow this rod to twist that much.

By loosening the clamp and rotating it on the tie

rod slightly, the twisting motion was eliminated, thus tightening the steering

action some.

I've checked a friend's +4 and found the same problem.

You might want to check your car too. Just have a friend move the steering

wheel while you watch the action of the tie rod. With a little experimenting

you will find a position for the clamp that will not twist the tie rod.

Fred Sisson 1992"

Morgan Classics have had 4 different steering assemblies (at the time of this writing).

The first 4/4s were similar to that on the Trikes. They simply had a reduction

gear mounted on the steering column. This was quickly change and a Cam Gear then a Burman

worm and nut box was installed. This was used up until the later 1980s

when the steering box was changed to a Gemmer box.

The Burman box has an adjustment for loading the worm.

Also check that the bolts on the top of the steering box have not vibrated

loose. To check the worm loading, jack up the car and disconnect the Pittman

arm (the big heavy steel arm coming from the bottom of the box) from the

drag link (cross bar that connects to the tie rod). Carefully turn the

steering wheel from lock to lock. There should be just a slight (ever so

slight - about 12 in. pounds) increase in the force required to move the

steering wheel through center. If not, loosen the locking nut on the screw

adjuster located on the top of the steering box. Turn the adjusting screw

slightly, tighten the locking nut and re-test. Once there is some resistance

felt, no further adjustment is required.

Mating New Bushings to

the Kingpins (updated 2014)

by Lorne Goldman

Morgan stub axles are not made to a dimensionally consistent standard. In welding the kingpin tubes to the axles,

the Factory warps the kingpin tube and they do not correct the anomalies they create. Ergo, except for Devol-bushed cars made between late 2001 and 2006, each tube is can be different. Instead of correcting the tubes to a standard (which would

require a one time honing or reaming of the tubes themselves

to a common ID and matched alignment of both ends). Without a common ID

and alignment, resultant fit bushes cannot be used and we are forced to

align the bushes each time we replace them a sad waste of time fraught

with the possibility or making an error.

If course it would be much safer, easier and less

costly to simply press bushes

in and expect, automatically, a correct clearance and/or alignment of

top and bottom. But, as Morgan has planned it, you can have one bush

askew one way and the other end askew another way along with varying

clearances after the bushes are force-pressed into the lopsided tube,

inconsistent ID tubes, making the kingpins bind and seize. So properly sizing and aligning new bushings to

the kingpins is absolutely key to

the success of the job. So once the old bushings have been removed and

the new ones forced in, they will have to be

mated (aligning the bushes with each other and the kingpins and also

machined so that the interior diameter of the

bushes has the right clearance for the kingpins). This will require

either that you purchase some special tools aka

a line reamer) or find a machine shop that will do the work with more

sophisticated equipment, (computerized laser guided honer.)

These

are the two methods of obtaining a correct bush fit. One is to use a

line reamer, the other is to have them computer guided honed.

The consensus of opinion is that the honing is preferred as a better

and a computer-consistent precision fit

can be attained every time. I have tried both ways, a few times, and never noticed a difference. As well, honing allows for improved lubrication

of the bushes on the same principle that encourages the honing of engine cylinder walls. Knowledgeable owners simply

use hardchromed kingpins and forget such esoteric niceties. I

once had mine done at our nearby a machine shop with a laser-guided

Sunnen honer. $20 per axle. However, I admit to using a line reamer

whenever I am faced with bronze bushes....much more convenient.

THE TEST OF A PROPERLY DONE JOB IS THAT THE KINGPIN, PLACED IN THE STUB AXLE AT THE TOP, WILL DROP SMOOTHLY RIGHT THROUGH THE STUB AXLE TUBE. More owners and machine shops make the clearancetoo little rather than too much.

Hard Chromed Versus Stainless

Kingpins (1998, updated 2014)

by Lorne Goldman

FRONT END LIFE

The

variance in front end lifetimes depends the kingpin material and the

frequency and quality of owner care. I recommend the front end be

cleaned and PROPERLY be greased (properly) every 1500 miles. These

figures come from feedback in my archives, gleaned from

personal and forum correspondence. Be very careful on who you choose to

redo your front end installation and the source of the

hardchromes.

Metal bar stock comes in a variety of grades and features. It is not

only the hardchroming that produces the legendary longevity, it is the

quality of the metal under the plating. If it is too soft, the plating

wears quickly, like the factory's stainless pins.

|

Negligent or sporadic care & without little leather booties and coupled with ANY bush material

|

Proper Care |

| MILD STEEL (MMC) |

3000 to 10,000 miles |

25,000 to 30,000 miles |

| STAINLESS STEEL (ORIGINAL MMC) |

10000 to 15,000 miles |

30,000 to 40,000 miles * |

| HARDCHROME |

40,000 to 50,000 miles |

100,000 + miles

|

| WATCHPOINT: Sadly, the

later Factory stainless kingpins will wear before the bush material

no matter what you use for the latter. Additionally, from the longevity point

of view, it does not matter what bush material you favor, though

different types have garnered the fanatical devotion of religious

zealots. As long as you use the proper hardchrome bar stock, within a

proper installation, the longevity of your front end will satisfy the

most prolific driver. So

you can ignore all the web advice to use only the sacred secret product

found in Lost Inca cities with an installation involving ritual

chanting and the sacrificial blood of innocent virgins. This stuff is

not magic nor rocket science..it is merely misunderstood for a very

long time and that continues to this day. BTW. whatever you do, avoid Suplex...a

$2000 method to cure a $5 problem. I have not been without a fellow

owner that cannot get his car back on the road after a bad

installation since the idea appeared. It DOES have two good

elements to it, namely shortening the overlong rebound spring...a

mistake the Factory mistakenly adhered to from some time in the 1950s

The second is that forces owners or their installers to do routine

maintenance that has been neglected for ages and created the need for a

fix in the first place. :( Frankly the latter makes me happy with it.

ANYTHING that forces maintenance is a good thing. |

HISTORY

For

years, it was mistakenly thought that road grit caused the premature

wear..always in the lower bush. The theory was that water and the grit

formed an abrasive paste that entered the area between the kingpin and

bushes and destroyed one or both. This may well be a contributing

factor, but there has never been any empirical proof. In 2003, with the

advent of Devol bushes, the causes for  bush

wear became crystal clear. The lower part of the mild steel kingpins

quickly rusts at the bottom, where water accumulates in idle periods.

The rusted exterior surface of the kingpin then acts as a rasp,

grinding away at the bush. Stop the kingpin from rusting and the

lifetime of the bush, of whatever material, is multiplied enormously.

That is why the popularity of hard chromed kingpins has soared in the

last decade, spread by eMog forum testing and there universal success.

bush

wear became crystal clear. The lower part of the mild steel kingpins

quickly rusts at the bottom, where water accumulates in idle periods.

The rusted exterior surface of the kingpin then acts as a rasp,

grinding away at the bush. Stop the kingpin from rusting and the

lifetime of the bush, of whatever material, is multiplied enormously.

That is why the popularity of hard chromed kingpins has soared in the

last decade, spread by eMog forum testing and there universal success.

Actually,

hardchromed kingpins

have a very long history in the

community. They were installed by enthusiasts as far back as the

1950s. I have been using them since 1997.

By chance, in 2004 I discovered a fine fellow in Birmingham (the UK

one) and spent a lovely afternoon with him. He was an 85 year

old Morgan enthusiast and retired master machinist. He had bought a

Morgan directly

from Peter in 1958. After developing the Morgan wobble after 13,000

miles, he examined the wear and then made

himself some hardchrome kingpins from centerless ground (to make the

surface perfect) 1 inch bar stock. He slipped them in and never needed

to redo his front end in his whole tenure with the car and he sold

it..in 1991 with 95,000 miles!

Hardchrome,

also known as industrial chrome or engineered chrome, is used to reduce

friction, increase wear time and provide a corrosion barrier. Unlike

Decorative or Show chrome it is very hard, measuring between 66 to 70

HRC. Hard chroming also tends to be thicker than a decorative

treatment, typically ranging from 0.075 to 0.25 millimeter (0.0030 to

0.0098 in), but can range up to 0.005 to 0.01 mil (0.00013 to 0.00025

mm). Buying 1 inch hardchrome bar stock means that there is no need to

ream or hone more of the bushes than you have to. Like all metals used

in precision hydraulic applications, hard chromium plating is subject

to different types of quality requirements depending on the

application, for instance, the plating on hydraulic piston rods are

tested for corrosion resistance with a salt spray test. As well, the

metal plating varies according to the task you wish to put it to. Steel

offers an immense range of possibilities. Hardchromes have hundreds of

years of history and tested experience. If you go to any hydraulic

application, (such as a earth moving machinery), you will see that the

actuating levers are hardchromed. The immense feedback level and

choices of bar quality make it an ideal kingpin. The eMog group spread

its advantages. I have had three Morgans, with an aggregate of 225,000

miles on them (and counting!). I have used the HC kingpins on them

since 1997 and never needed to do the front end again after

installing them on each car. In a nutshell, they eliminate the need to

ever do a front end job twice, at least in your lifetime. I have run

these hardchromes with bronze, DEVOL and Vesconite bushes.

PM

and the Factory tried chroming pins in the 50's but simply plated them

with Show chrome. But this was an error. Show chrome is very soft and

if the pins are not centerless ground and this type of chroming

actually makes the surface anomalies worse. The soft surface didn't

last more than a couple of weeks of driving. So sadly, the chroming

idea was shelved, but even worse, it became a given to them that all

types of chroming would not work. In 2003, I was consulted by the

Factory when they ran into trouble with mild steel pins and DEVOL

bushes. We went back and forth for a couple of weeks and I tried to

steer them to hardchromes, but I was unsuccessful. They went with

their current stainless steel. Stainless steel also comes in different

grades, though there is a much more limited grade range and a shorter

history for all of them. eMog found that their stainless kingpin grade

wore faster than the DEVOL bushes!

Invariably,

the hardchromes lengthens the lifetime of the front end by many

multiples. Two aftermarket sources sprung up early on, one being Greg

Solow of the Santa Cruz, CA "The Engine Room" who hardchromes Morgan

kingpins (thickening them by approximately .012") and the other being

Machiel Kalf from the Netherlands who uses pre-made 25mm hardchrome bar

stock. As both are not exactly 1", the diameter of a Morgan kingpin,

both must be installed WITH the bushes to ream/hone them to a proper

fit. The  advantage

of 1 inch hardchromed bar stock is that the kingpins can be installed

at any time, simply replacing the ones that are there without redoing

the bushes etc. This will extend the remaining lifetime of the existing

front end without further ado. Though the ideal is to change the bushes

as well at the same time, there is no harm in adding many years onto

what you have with limited work.

advantage

of 1 inch hardchromed bar stock is that the kingpins can be installed

at any time, simply replacing the ones that are there without redoing

the bushes etc. This will extend the remaining lifetime of the existing

front end without further ado. Though the ideal is to change the bushes

as well at the same time, there is no harm in adding many years onto

what you have with limited work.

The reluctance

of the MMC to move to hardcrhomes is explained above. But the

reluctance of the community stemmed from the prices at the time. In

Greg Solow's case, the hardchroming of used pins was very expensive. In

the case, of Europe and the UK, the pins sold by Kalf and which he

supplied to Melvyn Rutter were priced (350£) so much above cost that it

discouraged the larger community on that side of the Atlantic from

considering them. However, in 2001, with eMog encouragement, John

Worrall of Heart of England Morgans began offering them at a normal

markup and the price went down to 40£.One can now purchase hardchrome

from many sources.

It is not a complicated procedure. I make my own out of C1045 or C4140

bar stock at my local machine shop. Anyone with a lathe can do the job.

It was MUCH harder (PUN!) to convince owners to try them!

The reason hardchromes save the bushes is that the stock mild steel

kingpins rust quickly at the bottom, especially if the car is not used

daily. The rusted kingpin surface acts like a rasp and eats away at any bushing

material, whether bronze or (much faster) plastic. The hardchromes keep

a slick, effectively self-lubricating, rustless surface. Unpolished

stainless pins are not as helpful and the grade the MMC sells wears quickly regardless of bush type.

|

The reason hardchromes save the bushes is that the stock

mild steel kingpins rust quickly at the bottom, especially if the car

is not used daily. The rusted kingpin surface acts like a rasp and eats

away at any bushing material, whether bronze or (much faster) plastic.

The hardchromes keep a slick, effectively self-lubricating, rustless

surface. (Unpolished stainless pins are not as helpful.)

However, because of the experience with soft chrome 50 years earlier,

(see above) the Factory moved to stainless steel pins in 2004. This is

a non-typical use of stainless bars and, unlike the hardchrome bars,

they have no track record in this type of usage. To date (2008), there

are many verified reported cases of premature KINGPIN wear with the

Factory stainless kingpins, indicating they may have chosen too poor a

grade of metal. The curious thing is that this wear occurs even with

the plastic Devol bushes when the bushes show no wear!! It is

hoped that the MMC will switch to hardchromes or upgrade the stainless

bar stock they are buying

Hard chromed or stainless kingpins can be fitted to ALL classic Morgans.

N.B. Extensive experience

with the hardchromes has shown that the life of the front end is

extended significantly regardless of what type of bush material is used

or whether they have annular grooves, or lips to prevent grit entry, or

gaiters (booties) or garlic cloves or ritual chanting. Do not

waste your time and money.

|

The DEVOL MORGANS (2001-2006)

by Lorne Goldman (5 updates since 2001)

At

the end of 2001, after a transition period of a few variations on the

theme, the Works removed the one-shot oiler system first installed in

the early 1950s and began using a new kingpin bush material rather than

the traditional phosphor bronze bushes used for almost a century. Many

have refer to them as plastic" or "neoprene" or "nylon" but, in fact,

they are not. They are Factory machined from a polyethylene plastic

called DEVOL S made in Scotland by a company called Devol. They were

brought in to extend the notoriously short Morgan bush life AND to make

the task of bush installation easy rather than the involved task it is

now. Sadly, a number of factors and teething problems intervened,

giving these bushes an undeserved bad reputation. After approximately

2500 "Devol Morgans", the MMC abandoned the idea and returned to bronze

bushes. Subsequently, the MMC stopped supplying Devols and the Devol

cars must use oversize non-resultant fit bronze bushes, or make their

own out of Devol material.

|

WATCHPOINTS:

1.The

primary cause of premature bush wear was never caused the bushes or the

material used for them..it was the use of mild steel kingpins. These

quickly rust at the bottom bush when the car is stored for anything but

a very short time. The exterior surface of the kingpins quickly becomes

as rough with surface rust and acts like a rasp to grind through any

material, especially the new space-age materials. Many moggers, myself

included, have avoided this result for decades by using hardchromed

graded steel kingpins, a item made for this application for the last

two centuries. 100,000+ mile front ends were achieved by our group

since the 1980s.

However,

in a dire situation, the MMC and the aftermarket, like anyone in trade

under pressure, will go for any quick fix. (who can blame them?!) The

MMC switched to a low grade unpolished stainless steel pins and then

changed to bronze bushes when the cheap stainless pins themselves wore

quickly. So did the aftermarket when called on by owners for a quick

solution. THEY came up with mildly oversized bronze bushes so the DEVOL

owners could fit them to their oversized stub axles rather than the

DEVOLS. The Bill Beck common sense dream of resultant fit bushes

forever died aside from a small club.

I have

used DEVOLS for 110000 kms and 21 years. No problem except in the

beginning..when I received my car from the Factory in 2003, mild steer

kingpins and DEVOL bushes. With many other things to do to sort upon

arrival, I left the Factory kingpins in for 3000 miles before

disassembling and putting locally made graded hardchromes in. By that

time, the mild steel kingpins had already rusted and damaged the

original DEVOLS. I swapped in a new set, something that can be done

with resultant fit DEVOLS with the stub axles still on the car,

substituted my hardchrome kingpins and over 100,000 kms on since.

Sadly,

the true story never spread, especially after I ended eMog. (It was too

exhausting for me! It ended with the highest traffic ever enjoyed by a

Morgan forum. to this day) People became fixated with "bush" material

like Vesconite or wrongly assumed the British made DEVOL bushes must be

swapped out..even if not worn. I saw a younger mechanic and retailer,

infamous for advertising his wares on an owners' forum recently

recommend that, whether necessary or not!!! The installation of

press fit oversized bronze requires MUCH more work, as explained above.

It is not totally his fault for the advice..he never knew the story and

was merely hired and trained to make oversize bushes. His knowledge

goes no farther than that. Few without the eMog experience do. I

respect the people who have used Vesconite but when it was put on my UK

Plus 8 (regular, not high lube Vesconite) my front end seized within 100 miles. The installation was done by one of the most respected Morgan mechanics in the UK.

|

In

2002, right after the first cars were fit with Devol, Bill Beck, a fine

fellow and (the last) full mechanical designer at the Factory left the

MMC employ after 25+ years.. By the 2003, reports were coming in from

everywhere that the bushes were lasting as little 3000 miles! A quick

examination showed the cause. They looked for a solution.

I was

contacted by the Factory by the director then in charge, Mark Aston. He

wanted input on hardchromes. They too had reasoned out that any surface

that does not rust should solve the problem. We went back and forth for

a month or so. Sadly, for reasons explained here, in early 2004, the

Company moved from mild steel to stainless steel kingpins. This

is an unusual material to use in this application and there was no

track record for it. By 2006, some owners were discovering that the

kingpins (insufficient quality) were wearing faster than the Devol! But

by then Mark Aston had ceased working for the company as well.

DEVIL's RESULTANT FIT

One super

feature of these bushes is that were made to be a "resultant fit"

meaning that the bushes will automatically have the correct ID once

pressed into the stub axles without the need for reaming or honing.

They also can be removed and inserted with the need for a multi-ton

hydraulic press. To makes this possible, the Factory reamed the stub

axle tube to a standard ID. This was not done and the ID varied

from stub axle to stub axle as their tubes distort when they are welded

to the cast stub axle. We shall call these specially aligned axles the

Devol cars. They were a massively smart move, multiplying Morgan front

end longevity and making the dreaded front end job something any owner

could perform on his driveway. However, Morgan Morgan had problems as

the bushes were not as simple to produce bushes made from the older

bronze stock. The older bushes had no need for precision as they were

individually fitted to each and every kingpin ON THE CAR. And, at the

time the company did not own a modern honer to make the job easy and

perfect. The front end of some cars would seize. Sadly, in 2006, after

approximately 2500 cars they abandoned DEVOL and the entire concept of

a resultant fit in any material. They now do not make or supply Devol

bushes, forcing the DEVOL cars to move to specially made over-sized

bronze bushes which must be specified on order, then reamed and mated

on installation. The 10 minute job at home is now hours with

specialized equipment mentioned for other Morgans.Regular bronze bushes

cannot be fit to DEVOL cars...they create a too-loose fit into the stub

axle. However, since the lack of knowledge of DEVOL caused it to be

eliminated (a tragedy as they work perfectly if hardchromes are

correct) N.B. We found that the cheap stainless the MMC used would wear

much faster than the DEVOLs!!!!

The

Works reported that their original DEVOL test car reached and passed

50,000 miles without discernible bush wear. The earlier bronze could be

expected to last 10,000 to 25,000 miles depending on the quality of

maintenance and kingpin type. In my case, my present DEVOLs (now fitted

with hardchromes kingpins I made locally, have no discernible wear in

110,000 kilometers and counting. However, my first set of DEVOLs,

delivered with mild steel kingpins, were shredding after 3000 miles!

The difference was usage. The Factory test cars are used constantly,

which left no time for kingpin rust to occurs at the lower bush in over

the times the vehicle is dormant for more than a few days.

|

These bushes have a tiny ridge on the ends. This ridge acts as a

barrier to grit, and draws grease into the area between it and the

grease reservoir in the tube (the space between the bushes and the

kingpins). When reamed, this useful ridge is removed. However, after

Bill Beck left, some of the cars began appearing with the bushes

pressed in backwards with the little ridge inside the tube. This acts

in the opposite way, allowing grit to accumulate between the bushes and

the kingpins.

|

|

SWELLING & SEIZING

Most

importantly, the Factory had an inconsistent experience with the DEVOL

bushes in the UK. This was self-caused but they did not understand that

at the time. And by that time, Bill Beck, the former chief designer had

also left the company. The reaming of the stub axle tube, and the

bushes, made by the Factory from material supplied to them, were not

made to a consistent size, ID or OD. As well, after Bill Beck quit in

2002, the production department changed the amount they were reaming

the stub axle tubes and that changed the resultant clearance. Some

DEVOL cars began seizing the kingpins. ALL reports of seizures are from

the UK. Elsewhere the bushes performed superbly if the kingpins were

changed to hardchromes. The ease of DEVOL installation is a pleasure

taking only minutes to swap bushes rather than hours of precise

machining and specialized equipment.

Devols were

used for 5 years or approximately 2400 Morgans, or more than 1/2 the

trads made in the first decade of the millennium. Because of their

larger tube ID they must continue to use Devol or use oversize bronze

bushes. The company will no longer supply Devols but DEVOL,

a large Scottish company, has distributors all over the planet.

Oversize bronze bushes can be made at a local machine shop. You merely

call the company or a local seller and get a sufficient amount.

For all these reasons, I recommend the following to the DEVOL car Owners whose front ends needs attention;

IF YOU ARE IN THE UK: Use hardchrome kingpins and the oversized bronze bushes for DEVOL stub axles.

IF YOU ARE

OUTSIDE THE UK: Use hardchrome kingpins and DEVOL bushes made for DEVOL

Axles or Hi-Lube Vesconite. They are all easily machinable.

There are 3 unique items to the Morgan suspension: the

bushings, the damper blades and the one-shot oiler. Replacing the bushings

will require the rebuilding of the front end. (See the article by John

T. Blair - Rebuilding the Front End) However, the

damper blades can replaced without totally disassembling the front suspension and a rebuild for DEVOL cars is very easy.

There are 3 unique items to the Morgan suspension: the

bushings, the damper blades and the one-shot oiler. Replacing the bushings

will require the rebuilding of the front end. (See the article by John

T. Blair - Rebuilding the Front End) However, the

damper blades can replaced without totally disassembling the front suspension and a rebuild for DEVOL cars is very easy.

The

The

advantage

of 1 inch hardchromed bar stock is that the kingpins can be installed

at any time, simply replacing the ones that are there without redoing

the bushes etc. This will extend the remaining lifetime of the existing

front end without further ado. Though the ideal is to change the bushes

as well at the same time, there is no harm in adding many years onto

what you have with limited work.

advantage

of 1 inch hardchromed bar stock is that the kingpins can be installed

at any time, simply replacing the ones that are there without redoing

the bushes etc. This will extend the remaining lifetime of the existing

front end without further ado. Though the ideal is to change the bushes

as well at the same time, there is no harm in adding many years onto

what you have with limited work.