JACKING

POINTS (Point de levage)

JACKING

POINTS (Point de levage)

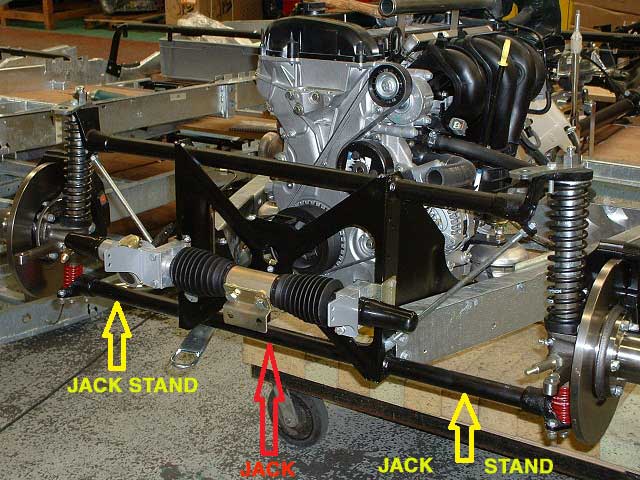

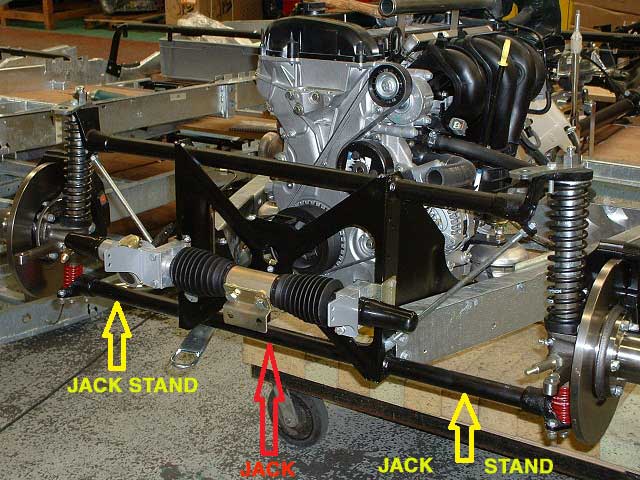

Lift the front wheels by placing the jack in the middle of the lower tube of the crossframe. Place the the two stands under the tube between the chassis and the wheel (see image). Slowly lower the car onto the stands. As a precaution, unless you need that area, always leave the jack in position as an extra safety measure.

On lève les deux roues avant en plaçant le cric au milieu du tube inferieur du croisillon. et les chandelles sous le tube entre le châssis et la roue.

At the rear, the jack is placed in the middle of the rear cross member and the stands are placed under the frame rails just forward of the transom. Again unless you need that area, always leave the jack in position as an extra safety measure.

Pour l'arrière, on place le cric au milieu de la

traverse arrière et les chandelles sous les longerons de châssis

juste en avant de la traverse.

| WATCHPOINT: It is unsafe to trust your health or that of your Morgan to a jack only. If you are required to jack the car roadside, remove a wheel and place it under the frame where you are working. If the jack fails or slips, the car will fall on the wheel/tyre. |

Jacking Roadside

by Lorne Goldman

On occasion, the Auto Gods may require you to jack your car roadside. This requires special precautions because of the uncertainty of the road surface and the lack of jack stands and the inadequacy of the normal car jack. We recommend you first remove your spare and place it under the car at the jacking point. This trick has often been a life and car saver. If your jack slips the car will settle onto the tyre rather the ground or you.

We also suggest that you wedge rocks under the front and rear of the tyres to prevent the car moving while you work. VIDEO

Morgan Bracketry Warning

by Lorne Goldman

The following might sound like apostasy to some but this comes from a fellow enthusiast with 400,000+ kms of mogging experience with three Morgans made from 1984 through to 2002. I have had horrendous experiences that would have turned of others, but my wife and I have stood up after each and continued mogging. That is how much fun we have had in them!!!

MORGAN BRACKETS BREAK. THAT HAS BECOME WORSE OVER THE YEARS TO THE PRESENT, though news of the newer cars comes second hand off forums and from repair people. Profit problems and constant change always put much pressure on part sourcing and their quality. The MMC has been in that scenario since 2000. :( To confirm, cut through the niceities by using the filed Company House figures and subtract the current hard assets from the current value of the 2000 hard assets and reduce further by the grants given by the British government since that time.

But I am not concerned about the state of the Company as I am about my fellow moggers safety. My experience is not unusual for Morgans, they merely happen earlier to me because of my mogging distance. As well, we use our Morgans primarily for long distance travel in North America and Europe. Ruining regular two month holidays 5000 miles from home is no fun. You will not find a Morgan bracket in Brindisi or Appalachilcola. And how much confidence can you have replacing a bracket that broke with the same thing?!! I stopped doing that 25 years ago, when, (guess what) the replacements broke as well!

I have learned to have the brackets re-designed to be stronger and made out of much higher grade materials. (duh!) The difference in price between a single Morgan part made in cheap pot metals or ungraded steel and much better stuff is negligible. Often, it is a saving!! However, in some countries, do not tell the machinist what he is making and what it is for! Luckily, I live in two countries (Quebec and Ecuador) where liability laws are mitigated by the fact that repair rather than replacement/ improvement is still the rule.

In no special order, in the Morgan bracket areas, I have had the follow break.

2. The lower brackets holding the rear shocks on. (MMC)

3. The lower brackets holding the front shocks on. (MMC)

4. The metal straps (wing stays) steading the front kingpin assembly. (3 times) (MMC)

5. The many screws, bolts and nuts that loosen. (yes! you can stop that using different methods!) (MMC)

6. The exhaust system brackets (MMC)

7. The radiator brackets and radiators. (MMC)

8. The brackets (both types) holding the front bumper on. (MMC)

9. The brackets and screws holding the fuel tank to the wood planks. (MMC)

10. The steering column collapsible feature. (MMC)

11. Exhaust system brackets (MMC)

12. Axle U-Bolts (MMC)

13. The large upright bracket on his copy of David Rutherford's shock conversion. (Melvyn Rutter)

14. Silencer brackets (Melvyn Rutter)

15. The tensioning cup holding the LT77/R380 shift lever. (Rover)SPECIAL NOTE ON TOWING A LT77 OR R380 MORGAN (Land Rover Gearbox Plus 4s and Plus 8s 1977-2004)

There has been some very bad advice recently posted to TalkMorgan and again on The Morgan Experience. Please take the advice from these sources with much caution. In this case, it has been suggested that one must remove the propshaft before towing any of the noted models!!! This type of error is a function of not understanding why. I have occasionally found the same advice in silly Manuals! Generic advice does not cover the issues of the Plus 8 and Plus 4 LT77 and R380 gearboxes.

The Problem

These gearboxes have internal oil pumps for lubrication of their gears and bearings. The pump is run off the tail of the layshaft and oils various bearings by means of passages in the mainshaft. It's to assist the splash lubrication, and not really replace it.

WATCHPOINT: All the

Sherpa Haynes manual (Likely the source of this nonsense) say is that LT77 equipped models  should have the

propshaft removed for towing, as the oil pump will not operate without

the engine running. This non-operation occurs because the turning of the rear wheels,

even with the engine off or in neutral

(which detaches the OTHER side

of the engine/gearbox relationship) turns the gearbox innards and

eventually (I lasted 6 miles) The lack of lubrication does NOT happen

instantly, but it DOES happen within a short period of travel. Obviously, removing the propshaft is a ridiculous and super tedious roadside job, totally impractical for a Morgan owner. should have the

propshaft removed for towing, as the oil pump will not operate without

the engine running. This non-operation occurs because the turning of the rear wheels,

even with the engine off or in neutral

(which detaches the OTHER side

of the engine/gearbox relationship) turns the gearbox innards and

eventually (I lasted 6 miles) The lack of lubrication does NOT happen

instantly, but it DOES happen within a short period of travel. Obviously, removing the propshaft is a ridiculous and super tedious roadside job, totally impractical for a Morgan owner. |

So what is the PRACTICAL solution? Only tow these Morgan with their rear wheels not moving. (duh!) That can be done in two ways.

1. Tow from the rear with the steering wheel locked in place. (Tedious but tons easier than removing the propshaft.)

2. This type of towing vehicle #1 cause damage. Due to this, in the last 40 years, smarter tow trucks have been designed. They lift the entire car onto a platform on the tow truck. Merely make sure that the towers you use send you one of those. They are commonly found. I recommend you use these tow truck for any vehicle, not only Plus 8s.