WING

STAY ISSUES

by Lorne Goldman at

the eMOG Pub June 2005 (Updated July 2012)

|

Properly shaped and fitted

wing stays are vital. Without the wing stays, the wings would be cantilevered

off the thin inner wings, held along most of its length merely by the tiny

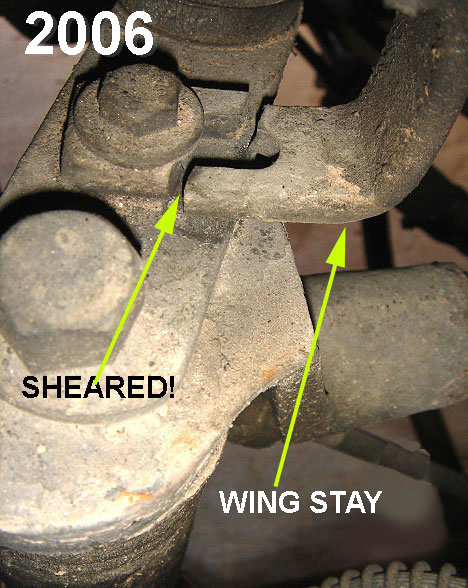

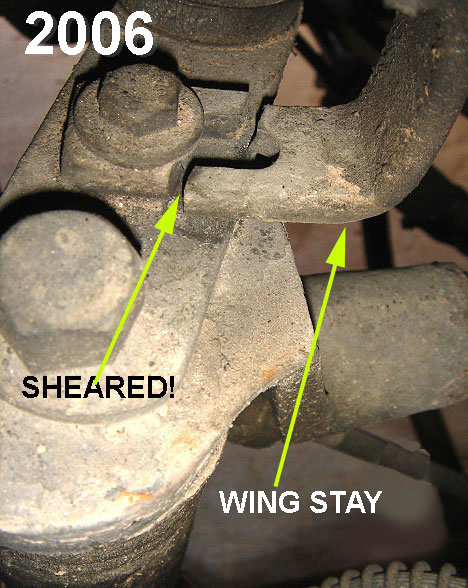

screws at the valence. Considering how many of these stays break since

the new era at the Factory began, the forces on them are anything but negligible.

You don't want your Morgan wings to flap. :)

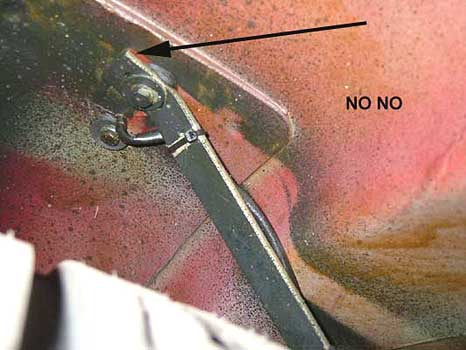

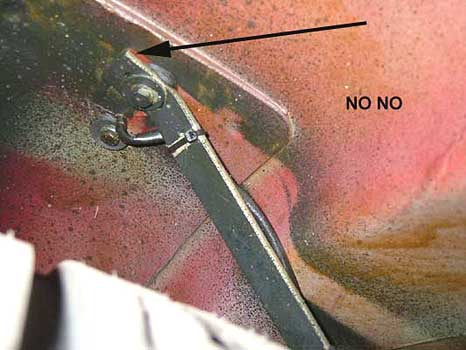

Poorly shaped or fitted wing

stays can cause much damage, metal rubbing, cracking or worse..

There are two watchpoints.

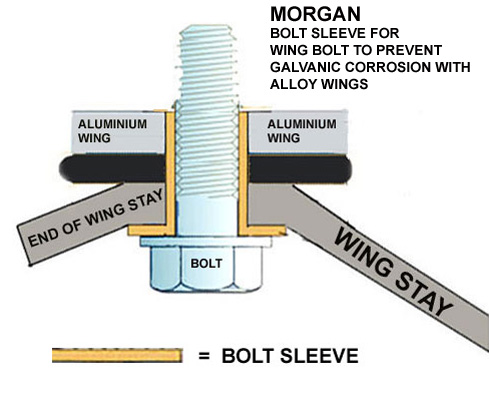

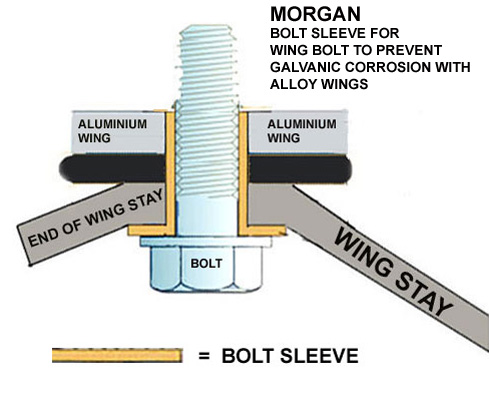

The first is to isolate the steel of the stay and the steel of its holding

bolt from the alloy wing. The rubbing and the common grounding of the side

light through the holding bolt to the wing is a recipe for an electrolytic

reaction between the steel and the aluminum that will rot the wing.

|

|

Sadly, since Peter's passing (2003), every effort at the

Factory has become based on cost in order to cut down production time and the need for expertise.

In this area, the Factory production department began, in the early 2000s,

to slot the stay's bolt holes to save time fitting them to each car as

no two Morgans are exactly alike. However, the slotting allows the

stays to shift, and wing/stay damage became epidemic since then. With my

first Morgan,

Sadly, since Peter's passing (2003), every effort at the

Factory has become based on cost in order to cut down production time and the need for expertise.

In this area, the Factory production department began, in the early 2000s,

to slot the stay's bolt holes to save time fitting them to each car as

no two Morgans are exactly alike. However, the slotting allows the

stays to shift, and wing/stay damage became epidemic since then. With my

first Morgan, I went years with no stay problems and then, when my car

returned from the Factory in 2003, my new stays cracked five times in two

years before I diagnosed the issue with the slots. The Factory sells the

newer problem causing stays only. I switched them for unslotted stays, old ones I had from the 1980s before Steve Morris' shortcuts began and

I haven't had an issue since...in 18 years.

I went years with no stay problems and then, when my car

returned from the Factory in 2003, my new stays cracked five times in two

years before I diagnosed the issue with the slots. The Factory sells the

newer problem causing stays only. I switched them for unslotted stays, old ones I had from the 1980s before Steve Morris' shortcuts began and

I haven't had an issue since...in 18 years.

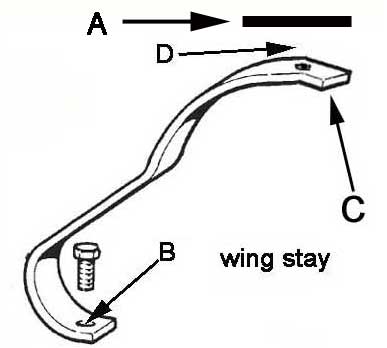

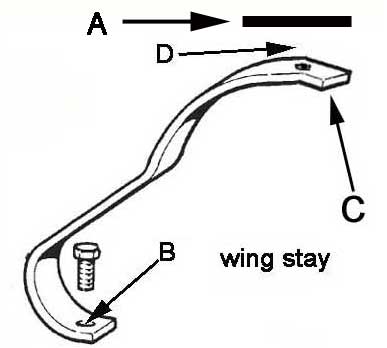

With a strong arm, a big

hammer, a drill and a table vice, these stays are not difficult to make

and/or shape perfectly by any owner. And those with the newer slotted stays

would be wise to switch to made-to-measure stays, like they had in the

earlier Morgan eras and everyone would be prudent to make sure their stays

are shaped like the diagram below. 1. The stay must be flat where the lower

bolt is fitted. 2. The stay must rise up to the upper bolt and touch only

the wing only at D after which it stay must immediately curve down (C).

(3). Place a 1/4" thick rubber washer between the stay and the wing (A).

4. Coat the bolt with silicone to prevent steel and alloy contact. (One

can also use a plastic sleeve over the bolt.)

WATCHPOINT Beware.

For those of us with later Morgans (post-2000ish) and who do not tend them themselves, any Morgan dealer who does any

servicing at all has seen this problem over and over. Yet some will sell and

send you the same slotted stay/support when yours breaks. Waste of

money and a recipe for another frustrating experience, Additionally,

only an experienced Morgan dealer will know how shape and install them

though the right way takes no extra time. Before purchasing, ask whether

they are sending you another slotted stay.

|

BRIGHTER WING LAMPS

by Lorne Goldman and André Koopmann

|

If you wish to keep your original look, but also have brighter lights for your torpedo side lamps.The mounting plate is

galvanized steel, with a 21w amber capless bulb and 5w clear capless

bulb. They can supply the 21w capless in clear if required!

Look into this conversion kit from Stafford Vehicle Components of Malvern, England.

|

BETTER PLINTHS

by GoMoG

Plinths (say that 5 times

quickly without tripping on your tongue!) is the name for the bases Morgan

uses for the indicator and brake lights places on the

rear wing and the two smaller version in front for the indicator lights.

Sadly they are made of a cheap plastic that are either chromed or painted

at the rear and left black in front. They are delicate and can break.

The constant expansion and contraction of the plastic with temperature eventually causes the chrome or paint to bubble and/or crack.

However,

better quality products

are available. For example, for two decades, John Worrall at Heart of

England Morgans offered these plinths (for both front and back) in

high quality mirror

polished stainless. He also offered spot/fog lamp bases for those of us

who wish to have them fixed to the wing rather than hanging on bumpers

or badge bars. Melvyn Rutter also offers chrome-plated bronze plinths for

the rear for many years. But the chromed softer metal is much more delicate and less long wearing but

they are very pretty as well. I have used them both.

Sadly, since Peter's passing (2003), every effort at the

Factory has become based on cost in order to cut down production time and the need for expertise.

In this area, the Factory production department began, in the early 2000s,

to slot the stay's bolt holes to save time fitting them to each car as

no two Morgans are exactly alike. However, the slotting allows the

stays to shift, and wing/stay damage became epidemic since then. With my

first Morgan,

Sadly, since Peter's passing (2003), every effort at the

Factory has become based on cost in order to cut down production time and the need for expertise.

In this area, the Factory production department began, in the early 2000s,

to slot the stay's bolt holes to save time fitting them to each car as

no two Morgans are exactly alike. However, the slotting allows the

stays to shift, and wing/stay damage became epidemic since then. With my

first Morgan, I went years with no stay problems and then, when my car

returned from the Factory in 2003, my new stays cracked five times in two

years before I diagnosed the issue with the slots. The Factory sells the

newer problem causing stays only. I switched them for unslotted stays,

I went years with no stay problems and then, when my car

returned from the Factory in 2003, my new stays cracked five times in two

years before I diagnosed the issue with the slots. The Factory sells the

newer problem causing stays only. I switched them for unslotted stays,