GREASING MORGAN FRONT SUSPENSIONS

(cars from 2002 to 2006)

by Lorne Goldman

MAKE SURE YOU HAVE PICKED THE RIGHT GREASING ARTICLE

FOR YOUR MODEL YEAR ! YOUR CHOICES CAN BE FOUND HERE

UNDER "FRONT SUSPENSION GREASING".

| Please note that this configuration was only produced

for a short period and not long ago. Over time, the community will become

more familiar with them as experience grows. These pages will be updated

as warranted. |

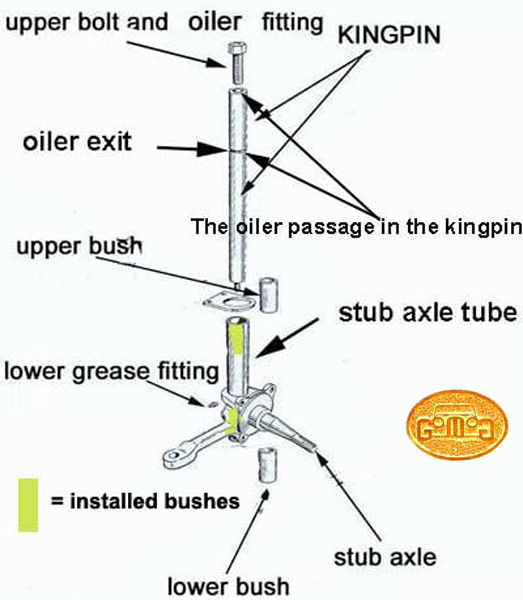

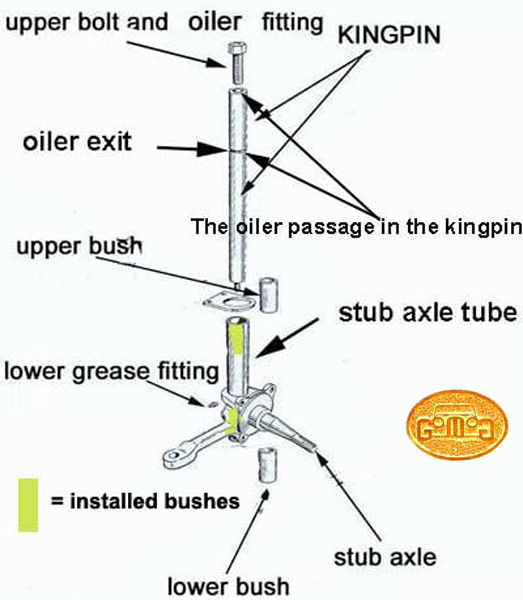

The

bushes fit in the stub axle tubes, one at the top and the other at the

bottom of the stub axle tube. As they do not fill the entire length of

the tube, a grease reservoir or "grease holding area" is formed between

the two bushes. As the stub axle slides up and down the kingpin, this reservoir

The

bushes fit in the stub axle tubes, one at the top and the other at the

bottom of the stub axle tube. As they do not fill the entire length of

the tube, a grease reservoir or "grease holding area" is formed between

the two bushes. As the stub axle slides up and down the kingpin, this reservoir  greases the kingpin (and therefore the bushes). The stub axle has a grease

nipple exactly adjacent to the middle of this reservoir to service and

fill this area periodically.

greases the kingpin (and therefore the bushes). The stub axle has a grease

nipple exactly adjacent to the middle of this reservoir to service and

fill this area periodically.

In 2002 and until sometime in 2006, the Works moved from

the earlier bronze bushes (1909-2002) to a new compound bush materiel called

Devol. If you have such a Morgan, you would be wise to read about them

in the Manual.

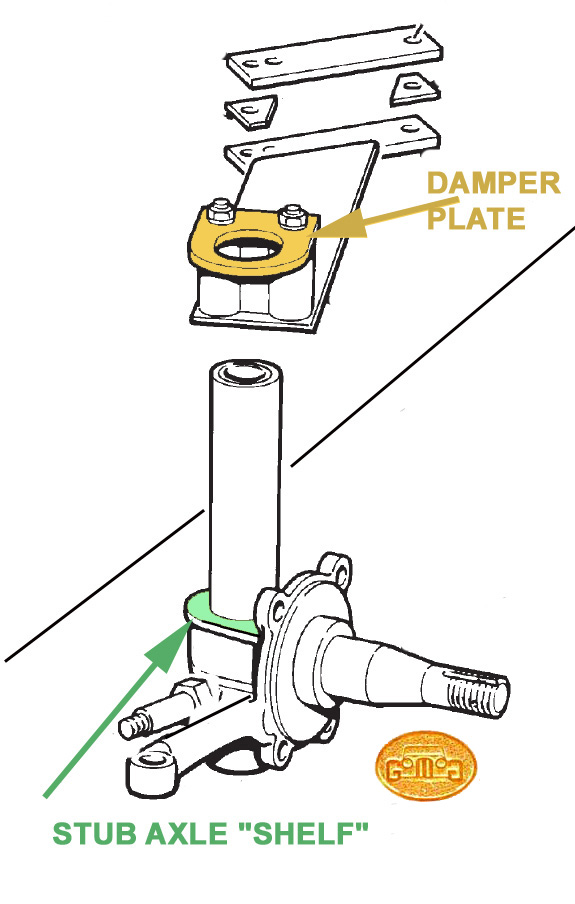

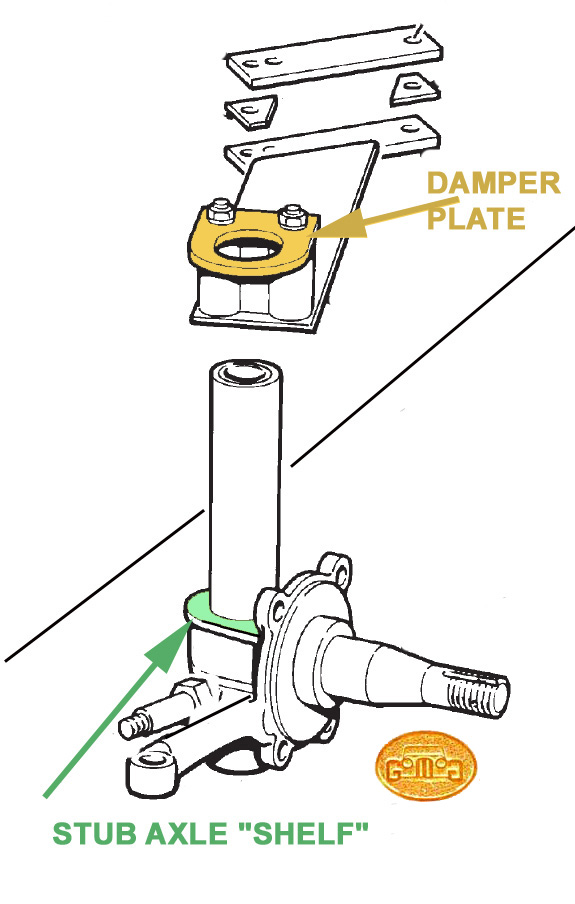

The annular

groove on the stub axle shelf, (created in 2000), was retained.

The main difference between greasing these cars and Morgans

from 2000-2002 is in the interval period between greasing. In this

case the Morgan Manual recommends 5000 miles and here they are almost right.

The Devol cars require less greasing than the bronze bushed cars. We recommend

intervals of 3000 miles. In any event, when the bushes require grease,

they announce that to you with squealing noises and groans. When you hear

that, you know you are not greasing enough or properly and the lack of

grease is starting to harm your bushes.

Greasing

can be done with the car on the ground or on jack stands. A one hand "pistol"

greaser can be used. (When I am home, I use a powerful electric grease

gun equipped with a flex hose. The device effectively creates an extra

hand which makes the job easier.) The grease nipple angle can make it hard

to properly center the grease gun but the angle of the grease nipple can

be changed to suit you. or alternatively, buy an angled nose for your grease

gun. A slight angle will do.

Greasing

can be done with the car on the ground or on jack stands. A one hand "pistol"

greaser can be used. (When I am home, I use a powerful electric grease

gun equipped with a flex hose. The device effectively creates an extra

hand which makes the job easier.) The grease nipple angle can make it hard

to properly center the grease gun but the angle of the grease nipple can

be changed to suit you. or alternatively, buy an angled nose for your grease

gun. A slight angle will do.

1. Turn the steering wheel until you have the best angle

at the nipple,

2. Pump until the grease flows out under the damper plate

(which sits on the stub axle shelf.). (That takes a lot of pumps!)

| N.B. If the grease flows out the bottom of the assembly,

it is a sign that your car is due for a front end bush and kingpin renewal.

The reasoning for this is unassailable. As noted, Morgan stub axles are

made with a drilled passage to the shelf damper plate and it is this the

main spring sits upon (or with or without an intervening steering race).

However, the bottom bushes wear faster then the tops especially if you

are still using mild

steel kingpins. When these bushes become too worn, the grease will

flow downward around them and out rather than forced up through the grease

passage as planned. That much wear in the bottom bushes heralds the need

for bush replacement. |

| N.B. You no longer need to lift the damper plate as

you did with earlier cars (1936-2002) If

you see the grease exiting from the lower rungs of the Main Spring above

the axle, the likelihood is that you have not greased the underside of

the damper plate, a task as important as filling the reservoir. You have

either not bothered to lift the damper plate or have not done it sufficiently. |

4. Turn the steering wheel and do the other side.

5. Clean away any excess with a rag and, if necessary,

brake cleaning spray. If any grease gets on your adjacent brake rotors,

the effect on braking and steering is dangerous.

| PLEASE NOTE: I have received many

notes lately on the difficulties owners are having pumping grease into

the stub axles in front. At first I thought it was the grease gun they

chose, but I soon found the problem was even more basic. Many owners change

the stub axle grease nipple (zirk) for angled ones which allow an easier

time fitting their grease gun onto it. Sadly, they do not notice that the

threaded portion of the Morgan grease nipple is short..shorter than most

available. When they fit the new nipples they often thread them until they

are forced into the kingpin. This blocks the flow of grease despite the

use of eye-popping pressure. The front gets little of its needed grease

feed and the kingpin can be damaged. |

The

bushes fit in the stub axle tubes, one at the top and the other at the

bottom of the stub axle tube. As they do not fill the entire length of

the tube, a grease reservoir or "grease holding area" is formed between

the two bushes. As the stub axle slides up and down the kingpin, this reservoir

The

bushes fit in the stub axle tubes, one at the top and the other at the

bottom of the stub axle tube. As they do not fill the entire length of

the tube, a grease reservoir or "grease holding area" is formed between

the two bushes. As the stub axle slides up and down the kingpin, this reservoir  greases the kingpin (and therefore the bushes). The stub axle has a grease

nipple exactly adjacent to the middle of this reservoir to service and

fill this area periodically.

greases the kingpin (and therefore the bushes). The stub axle has a grease

nipple exactly adjacent to the middle of this reservoir to service and

fill this area periodically.

Greasing

can be done with the car on the ground or on jack stands. A one hand "pistol"

greaser can be used. (When I am home, I use a powerful electric grease

gun equipped with a flex hose. The device effectively creates an extra

hand which makes the job easier.) The grease nipple angle can make it hard

to properly center the grease gun but the angle of the grease nipple can

be changed to suit you. or alternatively, buy an angled nose for your grease

gun. A slight angle will do.

Greasing

can be done with the car on the ground or on jack stands. A one hand "pistol"

greaser can be used. (When I am home, I use a powerful electric grease

gun equipped with a flex hose. The device effectively creates an extra

hand which makes the job easier.) The grease nipple angle can make it hard

to properly center the grease gun but the angle of the grease nipple can

be changed to suit you. or alternatively, buy an angled nose for your grease

gun. A slight angle will do.