| PLEASE NOTE That

my Morgan accident experiences, both minor and very severe, along with

my examinations of scores of others, I am of the opinion that the

Morgan traditional sports cars are uncannily safe..a lucky result of it

impact absorbing wooden frame and pleating metal chassis. Stiff

chassis may be good for manufacturers as they allow for cookie cutter

cars, but they transfer impact force to occupants, something profession

racers know all about. However, trads have a few danger point s that

can be easily and inexpensively sorted. |

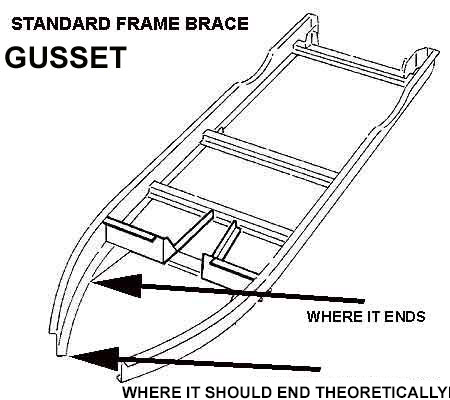

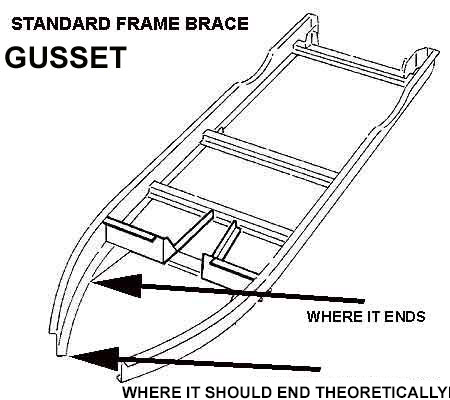

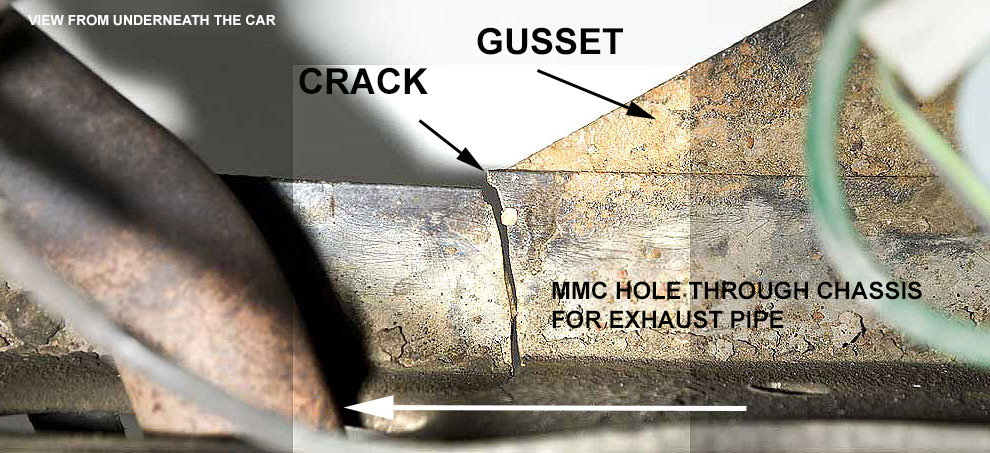

plague of

cracked chassis at a different place. I think of such things the Deadly Domino Effect. Read on.

plague of

cracked chassis at a different place. I think of such things the Deadly Domino Effect. Read on. along the frame under the hole. So now we have

a flexing chassis that cannot flex equally in that area, and

accordingly, develops frame cracks at either end. :) These have

the same effect as a patch..so the later cars are "pre-patched".

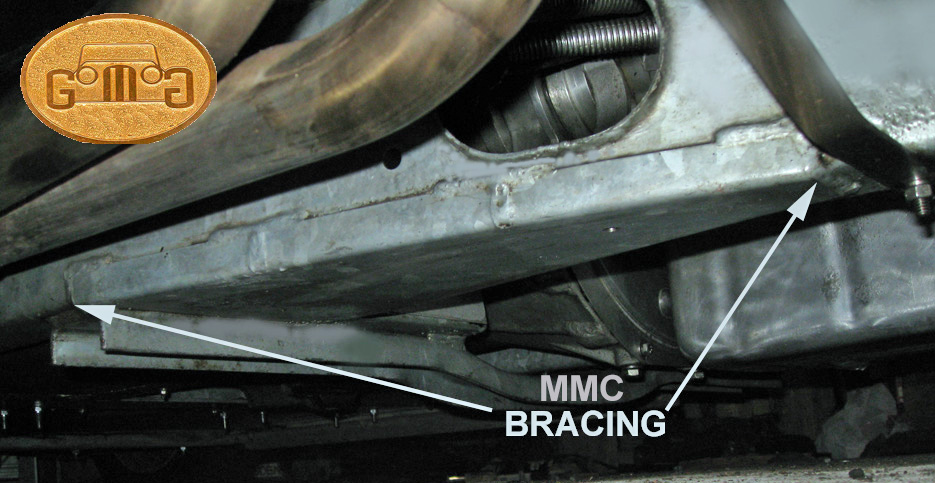

along the frame under the hole. So now we have

a flexing chassis that cannot flex equally in that area, and

accordingly, develops frame cracks at either end. :) These have

the same effect as a patch..so the later cars are "pre-patched".  FRAME STIFFENING AT THE REAR (now being written)

FRAME STIFFENING AT THE REAR (now being written)