RESTORING A MORGAN - page

three

by Lorne Goldman

5. The refurbishing of the retained componentry continues

(front suspension next!), replacements are sourced for items too worn,

unrefurbishable and simply unwanted.

6. December 19th, 2006. It's a good day! Something I had

been very concerned about, a full chassis examination, happened early this

morning in Market Drayton.

The

flexing Morgan chassis (aka frames) are wear parts. Though they will normally

last 20+ years, this is not a rule, and they CAN last less. Our UK Mog

comes from an era which is post-cuprinol, so I did not worry on the wood,

but it is from the era of pre-galvanizing frames and had never been heavily

undercoated (one of the reasons I bought it).

The

flexing Morgan chassis (aka frames) are wear parts. Though they will normally

last 20+ years, this is not a rule, and they CAN last less. Our UK Mog

comes from an era which is post-cuprinol, so I did not worry on the wood,

but it is from the era of pre-galvanizing frames and had never been heavily

undercoated (one of the reasons I bought it).

It has been gone over with a fine tooth-comb and it is

solid as Gibraltar!

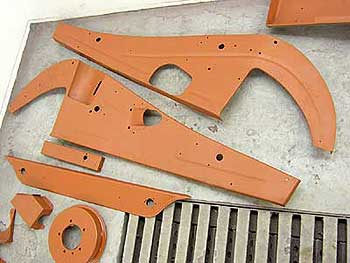

The frame is shot-blasted, sanded smoth and flat,

primed, sealed and painted.

N.B. Sheet steel panels are sand blasted only

if they are very rusty, BUT you have to have find somebody who is really

good and have a lot of faith in them, as the heat generated during blasting

can easily destroy the panels. DO NOT DO IT UNLESS YOU REALLY TRUST THE

OPERATOR!!

6. All mild steel parts are inspected as they are stripped

and then immediately primed. The priming is necessary even if they are

to be modified or repaired as air quickly rusts absolutely bare steel within

hours ...especially in England.

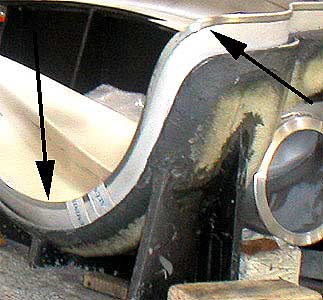

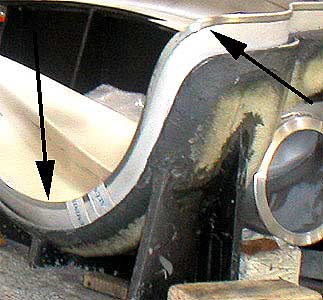

8. The wings,

cowl and bonnet have returned from the stripper. The closeup look at the

stripped parts show a sad story. There are far from perfect. There are holes

at the wing lamps. Not uncommonly, the stress at this point has been too

much for the wing. However, a real expert can fix this as good as new by

welding in fresh metal aluminum. See picture. A section is cut out

and replaced, then ground and sanded to leave the repair imperceptible.

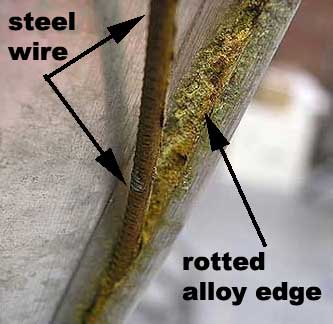

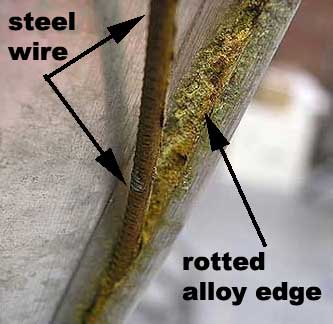

The damage goes further though. The pre-Superform alloy

wings (1960s to 1998) were/are made by a company called Vintage Wing and

Radiator. These are made by metal beating and use an alloy soft enough

to be susceptible to this. To stiffen the edge of the wings, a steel wire

was used and the edge rolled around it. Over time, there is a hostile electrolytic

reaction between the two metals and edge of wings rot. If it is caught

in time, the edge can be "unrolled", the wire removed, the cavity cleaned

out thoroughly and the wire replaced with non-reactive compounds that will

prevent the two metals from reacting with each other.

This is where only the best of experts can advise you.

Kevin considers the wings for a day or two and regretfully reports that

he cannot absolutely guarantee that a repair will last more than 2-5 years

in British weather. That counsel, from that source, is enough for me. I

am looking for a "forever" car and though a future wing replacement is

nowhere as onerous a task as restoration. I make a decision to consider

other options.

Vintage Wing & Radiator still supply the older Morgan wings through

the MCC and to the market directly in both alloy and steel. (Steel wings

may rust

Vintage Wing & Radiator still supply the older Morgan wings through

the MCC and to the market directly in both alloy and steel. (Steel wings

may rust but there are always repairable as they will not rot in the same

way the Vintage alloy wings will.). The wait is three weeks. However,

the Vintage wings are made as they always were. As they are beaten to shape.

This means that much filler and preparation time will be necessary to make

them smooth and consistent. As well, they still use the steel stiffening

wire on a roll edge and will not change even on request. A few years will

create the same problem unless we open up the edge and treat the wire in

hope of slowing the inevitable process. Lastly, the soft Vintage

alloy wings are susceptible to road damage and star fractures.

but there are always repairable as they will not rot in the same

way the Vintage alloy wings will.). The wait is three weeks. However,

the Vintage wings are made as they always were. As they are beaten to shape.

This means that much filler and preparation time will be necessary to make

them smooth and consistent. As well, they still use the steel stiffening

wire on a roll edge and will not change even on request. A few years will

create the same problem unless we open up the edge and treat the wire in

hope of slowing the inevitable process. Lastly, the soft Vintage

alloy wings are susceptible to road damage and star fractures.

Superform

wings are formed by suctioning heat-softened alloy sheets onto a Morgan

wing mold. This makes their consistency and surface finish near perfect.

As it is heat not hammering that forms the wing, the alloy used is far

harder than that used by Vintage Wing & Rad and the Superforms are

far more damage and stone resistant than the earlier wings. The edge is

not rolled but rather formed by a molding which is epoxied on. (In the

earlier Superform days, this epoxy and MMC paint process could cause a

reaction appearing as bubbling around the edge.)

The

MMC charged far more for Superform wings Vintage Wing &

Radiator wings

but that difference is made up in a saving on restorer preparation

time and cost. They are better, bit lighter product. However,

though Superform

were wings regularly supplied to the Factory, (they no use a

different process as Superform is much less in business than it once

was) but Plus 8 wings (front) have

gone the way of the Plus 8 and are stocked now only when ordered. I

recommend the new VW&R.

N.B. It was noted by many that the rot

with many of the older Vintage Wing & Rad wings can likely be cured by cutting

out the rolled edge and steel wire and using a Superform wing moulding

to refinish the edge. This would save 100s of Morgan wings. However, we

were informed by the MMC that they will not supply them (or

anyone else) this molding by itself. New wings must be purchased.

In sum, I no longer believe that earlier alloy winged

Morgans should merit a premium in the buying price over steel. Steel wings

last longer, are considerably more impact resistant and can always be repaired

if they rust. Early alloy wings come with their rot pre-determined and

impossible to repair, are very suceptible to impact leading to paint stars

and cracks.

Page four

The

flexing Morgan chassis (aka frames) are wear parts. Though they will normally

last 20+ years, this is not a rule, and they CAN last less. Our UK Mog

comes from an era which is post-cuprinol, so I did not worry on the wood,

but it is from the era of pre-galvanizing frames and had never been heavily

undercoated (one of the reasons I bought it).

The

flexing Morgan chassis (aka frames) are wear parts. Though they will normally

last 20+ years, this is not a rule, and they CAN last less. Our UK Mog

comes from an era which is post-cuprinol, so I did not worry on the wood,

but it is from the era of pre-galvanizing frames and had never been heavily

undercoated (one of the reasons I bought it).

Vintage Wing & Radiator still supply the older Morgan wings through

the MCC and to the market directly in both alloy and steel. (Steel wings

may rust

Vintage Wing & Radiator still supply the older Morgan wings through

the MCC and to the market directly in both alloy and steel. (Steel wings

may rust but there are always repairable as they will not rot in the same

way the Vintage alloy wings will.). The wait is three weeks. However,

the Vintage wings are made as they always were. As they are beaten to shape.

This means that much filler and preparation time will be necessary to make

them smooth and consistent. As well, they still use the steel stiffening

wire on a roll edge and will not change even on request. A few years will

create the same problem unless we open up the edge and treat the wire in

hope of slowing the inevitable process. Lastly, the soft Vintage

alloy wings are susceptible to road damage and star fractures.

but there are always repairable as they will not rot in the same

way the Vintage alloy wings will.). The wait is three weeks. However,

the Vintage wings are made as they always were. As they are beaten to shape.

This means that much filler and preparation time will be necessary to make

them smooth and consistent. As well, they still use the steel stiffening

wire on a roll edge and will not change even on request. A few years will

create the same problem unless we open up the edge and treat the wire in

hope of slowing the inevitable process. Lastly, the soft Vintage

alloy wings are susceptible to road damage and star fractures.