Meanwhile,

with the car stripped, we can examine other areas. The brakes receive special

attention. A number of serious

Meanwhile,

with the car stripped, we can examine other areas. The brakes receive special

attention. A number of serious  problems

are discovered.

problems

are discovered.

9.  Meanwhile,

with the car stripped, we can examine other areas. The brakes receive special

attention. A number of serious

Meanwhile,

with the car stripped, we can examine other areas. The brakes receive special

attention. A number of serious  problems

are discovered.

problems

are discovered.

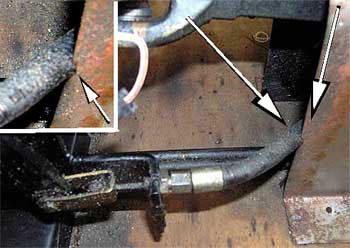

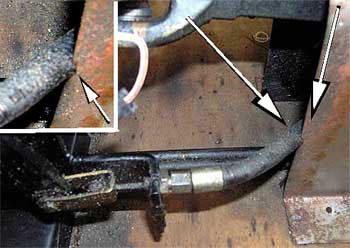

The rear lines have corroded to a point where they have begun to leak at the junctions and the line itself is about to crack. For a mogtraveler like myself this is the worst type of issue. It is not a part you would think to carry, it takes days to arrange sourcing, it is dangerous and it can spoil a holiday. Happily Tudor makes their own lines in house and the new brake pipe they use is Kunifer tubing. It will last at least another 16 years...far longer than MMC stock.

I was concerned about the rear cylinders and indeed, they both prove to be bad. The shoes are shot. The lot is replaced from Tudor's inventory.

The safety brake cable shoes the result of a Morgan design problem. The passage of the cable abuts the propshaft cover and the cover's thin edge has cut into the cable sheathing. Each time the cable was used, the situation deteriorated further. The cable is replaced and its passage rationalized.

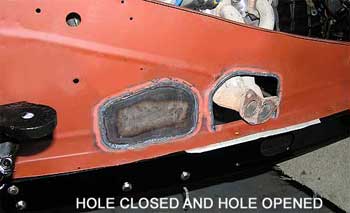

N.B. Any part that requires alteration cannot be surface finished until those alterations are done. The mild steel must be rust primed but not finally painted until the holes are cut and the welding is over. Ditto with the metalizing of the manifolds. This cannot be done until the possibility of surface damaging has passed. It is this dance between priming, repairing, modifying, refitting, re-priming (or sometimes polishing) and then repainting/topcoating that creates a ongoing dance of parts going on and off the car, with many of items this happens 3-4 times.

Don't get confused, the dance becomes a Grand Ballet "Restoration" by the time your car is finished!