RESTORING A MORGAN - page

two

by Lorne Goldman

STAGE TWO

The full extent of a restoration project cannot be fully

determined until the car is disassembled. If there is any signs of metal

rot..add paint and coating stripping to this disassembly to get to the

same point of decision as there is no way of ascertaining the extent of

damage with still painted or coated metal.

N.B. On the other hand, if the metal skin and wings

are solid, there is no advantage to stripping paint. It will not prejudice

the quality of a respray unless there is some inherent problem with the

original paint and prep. If you have a Superform winged car ..special care

should be taken and the wings examined by an expert. There is an incidence

of a chemical reaction between the paint and the adhesive at the wing molding

which can produce a bubbling.)

DISASSEMBLING THE CAR

1. We began by removing the seats, the carpets, the wheels,

the quarter panels, the door panels and the exterior fittings.

2. The parts are sorted and, if necessary, labeled as

they are removed. Each is subject to an examination and a decision. For

example, the instruments are analyzed for damage and/or corrosion and choices

made to refurbish them inhouse, re-bezel them, re-face them, or even replace

them.

In this case, the faces are fine and all the gauges function

well and suit the chosen color scheme. However, there is corrosion

on some of their rims. The instruments (VDOs) will be cleaned and re-bezeled

in chrome by Belmog through John Worrall (Heart

of England Morgans).

The

dash is beyond anything but visible patching. There are cracks throughout

and the surfacing around the switch cluster has cracked off. Rarther than

seeking out another stock dash, I had called on the services of the

Morgan community's master dash maker, Matthias

Kaufelt, before the project began in hope of getting a sublime MK masterpiece

in the intervening weeks until it is needed. A black crackle boss

will be polished back to alloy, the plastic column surround will be changed

polished stainless.

The

dash is beyond anything but visible patching. There are cracks throughout

and the surfacing around the switch cluster has cracked off. Rarther than

seeking out another stock dash, I had called on the services of the

Morgan community's master dash maker, Matthias

Kaufelt, before the project began in hope of getting a sublime MK masterpiece

in the intervening weeks until it is needed. A black crackle boss

will be polished back to alloy, the plastic column surround will be changed

polished stainless.

New rubber bobbins are needed for rad and exhaust, new

Lucas reflectors, new wing treads, new threshold plates, new light plinths

in polished stainless, new turn buckles, press studs, sidescreen knobs,

wing beading, mirror bases, filler hoses, rad hoses, gaskets...and then

more gaskets. The logistics must come together before the car does. The

owner can and should be key in helping with the logistics.

3. More parts are removed and scrutinized. As each comes

off, new vistas appear (wry smile), some indicating more work to be done

than first imagined and some indicating less.

The inner wings show minimal surface corrosion but dirt

cakes everything. It will be removed..and all parts brought back to "shiny

metal" (which is actually a trade term).

4. The wings have been sent off for stripping so we can

fully ascertain their condition (normally a 2 week job). They are Morgan

alloys from the pre-Superform days and are a big question mark. A better

look and a more informed decision can be taken on their return.The dismantling

process continues. The bulkhead is off next and the car is getting considerably

more difficult to recognize as such.

5. The bumpers and bright work are off for polishing.

The wheels, Morgan Plus 8 alloys, are pitted and show corrosion is some

spots. They are sent off for sand blasting and re-coating. I have chosen

a special color and we have plans to bring it out by polishing the metal

and brightening the glow on the alloy wheels. (more of this later!).

N.B. I had immediately tossed the stock tyres

that came with the car. I have switched to a remarkable new Michelin offering

called Primacy Sports in a "W" speed rating. Quite a remarkable increase

in fun and safety!

6. As the car becomes denuded..more is revealed and 15

years of neglect sees light. The bracketry is grouped, inspected and most

heads to the shot blaster tomorrow. Other items will be be dealt with inhouse.

STAGE 3

COMPONENT PREPARATION

1. The tub's skin will also have to be stripped but this

area must be done by hand in shop. It is done partly with the application

of a chemical paint remover and partly by sanding. A plastic envelope enhances

the effect of the chemicals.

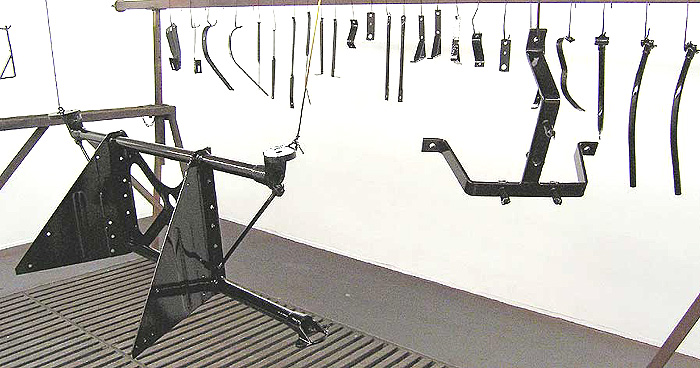

2. Progress is made with other items. The list of bracketry

and components has been finished, decisions on whether to replace or refinish

each item have been made and the parts sorted accordingly to the work required

on them. Those for refinishing are sent to a shot blaster for cleaning

down to the metal.

Here are some laid out before before the leave the shop.

(See if you can recognize them!)

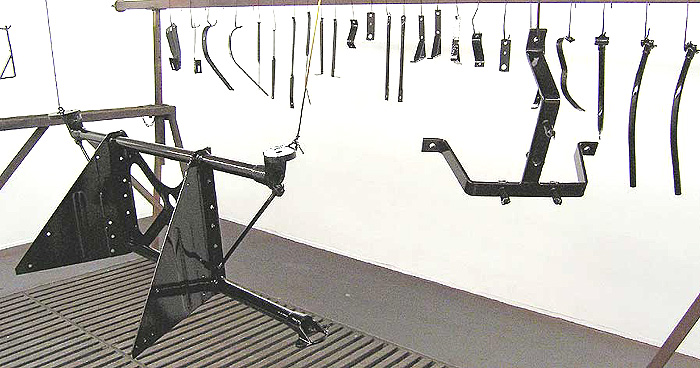

3. They return three days later stripped clean. They are

now strung for preparation and paint. Here they are with the rust primer.

4. The pieces are now sprayed with high gloss black paint

mixed with special hardeners. This

gives a very deep high gloss surface that is extremely

reflective (almost mirror-like) and resistant, leaving the items looking

and protected far better than they did when new (over 15 years ago).

PAGE 3

The

dash is beyond anything but visible patching. There are cracks throughout

and the surfacing around the switch cluster has cracked off. Rarther than

seeking out another stock dash, I had called on the services of the

Morgan community's master dash maker, Matthias

Kaufelt, before the project began in hope of getting a sublime MK masterpiece

in the intervening weeks until it is needed. A black crackle boss

will be polished back to alloy, the plastic column surround will be changed

polished stainless.

The

dash is beyond anything but visible patching. There are cracks throughout

and the surfacing around the switch cluster has cracked off. Rarther than

seeking out another stock dash, I had called on the services of the

Morgan community's master dash maker, Matthias

Kaufelt, before the project began in hope of getting a sublime MK masterpiece

in the intervening weeks until it is needed. A black crackle boss

will be polished back to alloy, the plastic column surround will be changed

polished stainless.