A Radiator

for your Morgan

by GoMoG

Revisited in November 2023

Put simply, aluminum radiators dissipate

heat more efficiently

than traditional copper-brass radiators. Additionally, aluminum is

the way the performance radiator world went or at least until recently,

when plastic radiators with a variety of core types provided

massive savings in cost to manufacturers. Plastic radiators

should be, as you can imagine, a huge no-no for any car with a flexing

chassis. Morgan however, chose this route in 2008 . My strongest recommendation is to swap them out for something better on arrival. The newer Morgans, fit with a plastic radiator,

continue to report an ever growing rash of cooling issues (overheating) especially

when the bhp is over 200. Horsepower = heat and

yet they seem fit the same rad to 4/4s (100 bhp) that they fit to Roadster 3.7s

(280 bhp).

BRASS VS. ALUMINUM: RADIATOR THERMAL PROPERTIES

Around 25-30 years ago a big change happened across the auto and

cooling industry, most auto-manufacturers switched from copper/brass

radiators to aluminum radiators. Although some people speculate that

this was done for a cost benefit reason, the primary reason for changing

to aluminum radiator was simple; aluminum radiators are more efficient

in terms of their thermal properties. Aluminum radiators dissipate heat

better and more effectively than copper/brass radiators.

When comparing copper/brass radiators to aluminum radiators it’s

important to first think about the materials used and their advantages

and disadvantages. Although copper has better thermal conductivity than

aluminum, copper is too soft to build a radiator from. Since copper is

too soft for radiator construction, zinc is added to the copper to

create the alloy brass. Brass has a much stronger structure and is

suitable to build radiators. But there is a take away; the lost of

efficient thermal conductivity.The alloy brass only has about ½ the

thermal conductivity compared to aluminum (see the chart below).

| Copper |

406-430 |

Watts/Meters |

| Aluminum |

353-390 |

Watts/Meters |

| Brass (copper & zinc) |

109-125 |

Watts/Meters |

Aside from the differences in the thermal properties of the different

radiators, there are also some other important advantages gained when

switching to aluminum radiators. The two primary factors to consider

when evaluating why a aluminum radiator is more effective than older

copper/brass radiators in regards to overall vehicle performance and

cooling ability are:

Weight Reduction- Aluminum radiator are much lighter than brass

radiators. Weight reduction is the single most all encompassing upgrade

to any vehicle's performance. It improves acceleration, braking, and

fuel economy.

Material Stability and Ruggedness- Aluminum is a much stronger and

more durable material compared to brass. This allows aluminum radiator

cores to feature larger, “skinner” tubes which allow a greater volume of

coolant to enter the core and be cooled. The strength of an aluminum

core and tubes also allows for greater cooling system pressure which can

allow a smaller radiator to cool better.

In short, aluminum radiators mark a modern advancement in cooling.

Not only does the material dissipate heat at close to double the rate

compared to brass, but also reduced the overall weight of the vehicle

and provides a stronger and more durable core and tube design. All these

factors clearly lead to an overall increase in vehicle performance.

|

New Hope For Old and New Trad Morgans

I

have recently looked at this area again after a decade, and I am

saddened at what has transpired with the offerings. Once more, I am not likely to make

friends with this one, but observation is inarguable and I hope I can

encourage improve supply and discourage disappointment.

Morgan trad cooling is more much more than merely a swap to aluminum or a choice of more cores and fins. And

this is not a one size

fits all area. Each car must be diagnosed and individualized according

to its model and owner usage. But there are some basics that have been

discovered. The aftermarket does not follow them. They

design Morgan rads, for a very unusual car, as if it is merely

another no-name vehicle, something that even the Works began to realize

twenty years ago.

Experience, talent and an intimate knowledge of

traditional Morgans expresses itself in MUCH better designs.

My sadness referred to above is due to the fact that there has

been no progress in this all-important area for some time. In fact,

this area of the trads may have retrogressed.

TRAD MORGAN RE-DESIGN NEED

This

is an area where I have seen the creativity and expertise of Peter

Mulberry, the wind tunnel observations of Rob Wells and the hit-or-miss

experiences of the Factory combine. The area becomes vital as trad bhp

(bhp=heat) has been climbing and the world warms. Two salient factors

are observed making the classics unusual, different from other

vehicles, even those with the same engine.

This

is an area where I have seen the creativity and expertise of Peter

Mulberry, the wind tunnel observations of Rob Wells and the hit-or-miss

experiences of the Factory combine. The area becomes vital as trad bhp

(bhp=heat) has been climbing and the world warms. Two salient factors

are observed making the classics unusual, different from other

vehicles, even those with the same engine.

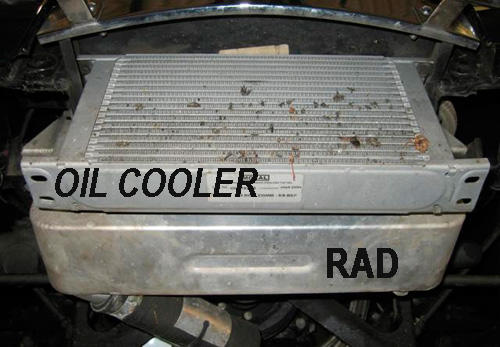

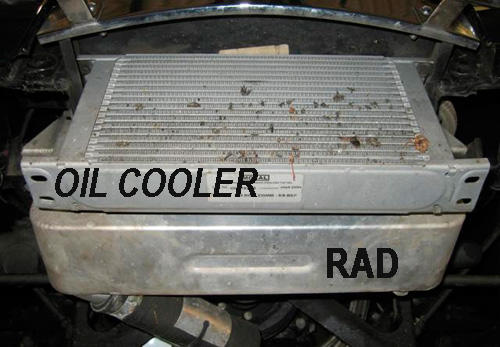

1. The first factor is that old trad rads are designed to be canted at the top rearwards.

They welded on bracketry won't permit anything else without

modifications. Yet Rob Wells observed that the same rads allow a

substantial amount of the airflow, (entering the small entry

in the cowl) to go over the rad rather than through it! Rob's diagram

is found to the right. The MMC has confirmed this by example. Morgan

Rads, trad or others, are installed at 90 degrees or near since

2008.

2. The rads are designed with stock fins and cores. If the subject car

has more power, they keep adding cores. This makes the likelihood of

the rad acting as a dam rather than a cooling device even greater.

3. The earlier rads (for Triumph Plus 4s) do not provide for sufficient space for a adequate rad fan at the rear! Placing a fan in front of a radiator is a big cooling no-no. By using a more upright radiator with a tinner more modern core will allow for a proper rear mounted fan.

Review of the Trad Aluminium Radiator Market 2023

RON DAVIS

If you restrict you purchasing to the USA, this

is a better option than Griffin. It goes by the

name of Ron Davis Racing Products. RDR knows Morgan rads

a bit better than any in the USA and has done many since the dear Bill Fink began using them. The joints on the rad

are welded very well. I found the

cooling ability of my Ron Davis rad better than my Griffin (tests

back-to-back

on the same day, roads and ambient

If you restrict you purchasing to the USA, this

is a better option than Griffin. It goes by the

name of Ron Davis Racing Products. RDR knows Morgan rads

a bit better than any in the USA and has done many since the dear Bill Fink began using them. The joints on the rad

are welded very well. I found the

cooling ability of my Ron Davis rad better than my Griffin (tests

back-to-back

on the same day, roads and ambient  temperatures). They can also flush mount

a high powered SPAL fan if you so choose and I very much recommend that for

the pre-2000 cars that can fit one. Many of cooling issues are

caused by woefully inadequate fans the MMC used to use. SPAL became the MMC favorite in the late 1990s.

temperatures). They can also flush mount

a high powered SPAL fan if you so choose and I very much recommend that for

the pre-2000 cars that can fit one. Many of cooling issues are

caused by woefully inadequate fans the MMC used to use. SPAL became the MMC favorite in the late 1990s.

But see the RDR Rad to the left and right. Note the thicknesses!

RDR

service is very good. Expect to save 10-20% on a Griffin package after

everything is factored in. They also weld the joints rather than epoxy

them like Griffin. Like RDR and all current after market suppliers, RDR will

not use a plug-in Otter switch but they can offer you a range of rad

fan

switches or make the threaded bung you wish. (Big engines see the

BMWs

above). Most US dealers use them..likely the typical knee-jerk reaction for a home-grown products.

Two important codicils.

1. Like most aftermarket rads, RDRs, especially those made for the bigger-engined Morgans, (Roadsters, and Plus 8s) are unwisely designed. I will explain further on. And Roadsters, aside from the very early ones already fit with aluminum rads at the Factory,

come with inadequate cooling directly from Malvern..much as the Plus 8s

did. If driven as they should be (why on earth buy a sports car and drive

it as tamely as possible?!!!) they boil over with stock MMC cooling.

You COULD HAVE obtained adequate cooling from the MMC (when Peter Mulberry was still around to supply ) but only if

you asked for a "performance upgrade" and then the right Peter Mulberry product would have been fit for a price. (sigh)

REASON 2 RDR decided to address that by installing a thicker core. I had the first of these on a Morgan. They had had success with that with other big motor cars. But

trad Morgans have always had a problem with airflow through the

rad..and  most of the, prior to the plastic rads were canted at 30

degrees encouraging air to sadly go over the rads rather than through

them. The thickness of the core

determines the resistance the radiator puts up fighting airflow

through

it. The best race preparers in England have correctly noted to me

(they have the results from professional airflow chambers) that this

forces much of the air around and over the radiator..not helping in the

cooling process at all. There are methods to address this (which I will explain in another article when I find the time) but

the punchline is that RDR's super thick core for bigger engined

Morgans, combined with Morgan dynamics creates a very poor result

as well as making installation of both the rad and a better fan super

difficult. I doubt RDR or the Morgan dealers selling them are aware of this, but there you have it. You can also obtain RDRs through Morgan Spares (aka Morgans of New England) and this will eliminate any fitting risk.

most of the, prior to the plastic rads were canted at 30

degrees encouraging air to sadly go over the rads rather than through

them. The thickness of the core

determines the resistance the radiator puts up fighting airflow

through

it. The best race preparers in England have correctly noted to me

(they have the results from professional airflow chambers) that this

forces much of the air around and over the radiator..not helping in the

cooling process at all. There are methods to address this (which I will explain in another article when I find the time) but

the punchline is that RDR's super thick core for bigger engined

Morgans, combined with Morgan dynamics creates a very poor result

as well as making installation of both the rad and a better fan super

difficult. I doubt RDR or the Morgan dealers selling them are aware of this, but there you have it. You can also obtain RDRs through Morgan Spares (aka Morgans of New England) and this will eliminate any fitting risk.

Mulfab

increases the cooling by making their rads thinner..allowing more

airflow THROUGH

the rad and adding more capacity by lengthening it

at the bottom. My guess is that if their thinner rads are made to

Morgan size, they will cool much better than the originals, can be

canted upright and allow the fitament of a rear fan (VERY DESIRABLE) on

TR Plus 4s. Merely copying older radiators in aluminum is, IMHO,

treading water.

SUMMARY

Using my original Morgan

Plus 8 (copper) rad as a starting point, my big Morgan engine was 5C degrees cooler under

normal driving conditions and 9C cooler under stress conditions with the

Griffin. The time it takes to cool from 108C (fan on temperature) to 88C (thermostat closure) was approximately 7

minutes at 60 mph. However, the Ron Davis Racing rad was 2C cooler than the Griffin under

all conditions (tested on the same day, same car, same coolant on the same

road). BUT the Mulberry beat the RDR by an additional 3C degrees in all

conditions and cooled from 108 to 88 faster. To this one must add the effect of the better SPAL rad fan when NOT moving. However, the RDR did 2C better than the  originally

used on my first Morgan. (It is now on my former UK Plus 8.) All Morgan

rads are a better option in this regard than Griffin. They are made

with welded joints rather than epoxy ones (which

eventually crack). It is has the same height and width of the original

Morgan radiator by has a thicker core for more powerful Morgans (Plus

8s and Roadsters). Both Griffins and RDRs are generally more expensive

than the more competitive UK market. (I exclude the current plastic

radiators from the Morgan Motor Company which I cannot recommend,

for reason given) though there are elements that can be learned

from them.

originally

used on my first Morgan. (It is now on my former UK Plus 8.) All Morgan

rads are a better option in this regard than Griffin. They are made

with welded joints rather than epoxy ones (which

eventually crack). It is has the same height and width of the original

Morgan radiator by has a thicker core for more powerful Morgans (Plus

8s and Roadsters). Both Griffins and RDRs are generally more expensive

than the more competitive UK market. (I exclude the current plastic

radiators from the Morgan Motor Company which I cannot recommend,

for reason given) though there are elements that can be learned

from them.

| WATCHPOINT: The late Bill Fink told me that

the cooling ability of an aluminum radiator can be increased by

painting it black and this could be an excellent idea for those of us in hotter

climates. It would also make the radiator virtually indistinguishable

from a Morgan trad original from the pre-plastic rad days. I have kept mine unpainted and polished to a chrome

finish. (vanity, vanity!) I have seen some people paint them..which

makes them look like the old style MMC rads. |

THE NEWER GENERATION OF TRAD ALUMINUM RADIATORS (November 2023)

Good new and bad news. :)

COST: The price of trad radiators has dropped a lot with the appearance

of Made in China rads. There are a few of Chinese brands selling on ebay everywhere.

However, there is also a new UK player who is selling trad radiators at

double the earlier rad prices. The new Mulfab, is holding

steady at the prices we saw under its old ownership, (in the 500 quid

range) but rads

for models with air conditioning require a bit more. The "heavy duty"

radiator for Plus 8s is now approximately 800£. Sadly, I can no longer recommend Mulfab as I once did. These prices do not include the radiator fan, the type of which is as important as the radiator itself.

The new UK player is a company called  . Their product looks very good and is reported as such. It is priced at £1,135.77.

I am unaware of the core size. However, it is merely a copy of the same

old technology. Those ideas were/are dated. We can do better.

. Their product looks very good and is reported as such. It is priced at £1,135.77.

I am unaware of the core size. However, it is merely a copy of the same

old technology. Those ideas were/are dated. We can do better.

The New CHINESE RADIATORS FOR MORGAN (very new)

I now

have enough reports on these to recommended them, if only for their

amazing price. Yes, they blindly follow the same old, same old designs.

So far, scores have been installed with no more problems than we

have seen with any other made-for-Morgan supplier. However, they are selling at less than 1/3 the price we have seen before them. They too are merely a copy of the same old technology. Those ideas

were/are dated. We can do better. I am working on that as I write this.

March 7, 2024.

BACK

If you restrict you purchasing to the USA, this

is a better option than Griffin. It goes by the

name of Ron Davis Racing Products. RDR knows Morgan rads

a bit better than any in the USA and has done many since the dear Bill Fink began using them. The joints on the rad

are welded very well. I found the

cooling ability of my Ron Davis rad better than my Griffin (tests

back-to-back

on the same day, roads and ambient

If you restrict you purchasing to the USA, this

is a better option than Griffin. It goes by the

name of Ron Davis Racing Products. RDR knows Morgan rads

a bit better than any in the USA and has done many since the dear Bill Fink began using them. The joints on the rad

are welded very well. I found the

cooling ability of my Ron Davis rad better than my Griffin (tests

back-to-back

on the same day, roads and ambient  temperatures). They can also flush mount

a high powered SPAL fan if you so choose and I very much recommend that for

the pre-2000 cars that can fit one. Many of cooling issues are

caused by woefully inadequate fans the MMC used to use. SPAL became the MMC favorite in the late 1990s.

temperatures). They can also flush mount

a high powered SPAL fan if you so choose and I very much recommend that for

the pre-2000 cars that can fit one. Many of cooling issues are

caused by woefully inadequate fans the MMC used to use. SPAL became the MMC favorite in the late 1990s. This

is an area where I have seen the creativity and expertise of Peter

Mulberry, the wind tunnel observations of Rob Wells and the hit-or-miss

experiences of the Factory combine. The area becomes vital as trad bhp

(bhp=heat) has been climbing and the world warms. Two salient factors

are observed making the classics unusual, different from other

vehicles, even those with the same engine.

This

is an area where I have seen the creativity and expertise of Peter

Mulberry, the wind tunnel observations of Rob Wells and the hit-or-miss

experiences of the Factory combine. The area becomes vital as trad bhp

(bhp=heat) has been climbing and the world warms. Two salient factors

are observed making the classics unusual, different from other

vehicles, even those with the same engine.  most of the, prior to the plastic rads were canted at 30

degrees encouraging air to sadly go over the rads rather than through

them. The thickness of the core

determines the resistance the radiator puts up fighting airflow

through

it. The best race preparers in England have correctly noted to me

(they have the results from professional airflow chambers) that this

forces much of the air around and over the radiator..not helping in the

cooling process at all. There are methods to address this

most of the, prior to the plastic rads were canted at 30

degrees encouraging air to sadly go over the rads rather than through

them. The thickness of the core

determines the resistance the radiator puts up fighting airflow

through

it. The best race preparers in England have correctly noted to me

(they have the results from professional airflow chambers) that this

forces much of the air around and over the radiator..not helping in the

cooling process at all. There are methods to address this

. Their product looks very good and is reported as such. It is priced at

. Their product looks very good and is reported as such. It is priced at