Your system

has failed if you get a reading above 50mV (0.05 volts) The source (s) of

the current leakage should be found, as they can destroy a radiator or

other components in a short period of time, depending on the level of voltage.

Your system

has failed if you get a reading above 50mV (0.05 volts) The source (s) of

the current leakage should be found, as they can destroy a radiator or

other components in a short period of time, depending on the level of voltage.

All coolant fluids have corrosion inhibitors. Problem is they fade away with time and people don't change their coolant often enough (if ever). When the corrosion inhibitors are used up and the pH of the coolant drops to 7 or below, aluminum becomes a sacrificial anode and the cooling system is eaten away.

Testing for Stray Current in the Cooling System

Another BIG factor in corrosion is stray voltage in the coolant. This causes corrosion even when the coolant is in good condition. If the engine does not have a good ground connection, voltage from the charging system will flow through the coolant to ground, creating and speeding electrolytic corrosion.

One needs a voltmeter (multimeter) with a scale capable of reading in millivolts. (I use those with digital read outs.)

1. Empty the vehicle of coolant and flush with clean water.

2. Fill the cooling system with distilled or demineralized water. (A coolant filled system gives inaccurate readings.)

3. Connect the voltmeter to the battery ground and the positive terminal into the coolant making sure not to touch the metal core or filler neck).

4: With the ignition on and again with the engine running, turn on every component. While you are monitoring the presence of stray voltage in the cooling system, have a fellow worker operate the brake lights, parking, head and high beam lights and everything you can't turn on while you're monitoring your voltmeter.

5. Note any voltage and any increases in voltage and what component increased it.

Your system

has failed if you get a reading above 50mV (0.05 volts) The source (s) of

the current leakage should be found, as they can destroy a radiator or

other components in a short period of time, depending on the level of voltage.

Your system

has failed if you get a reading above 50mV (0.05 volts) The source (s) of

the current leakage should be found, as they can destroy a radiator or

other components in a short period of time, depending on the level of voltage.

The system is fine if your voltmeter reads below 50mV (0.05 volts) so refill your cooling system with coolant.

The New Plastic Radiators (October 2008)

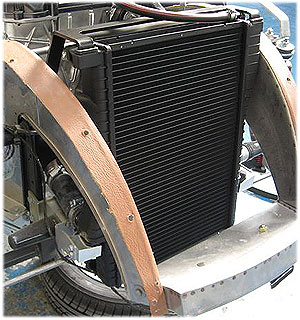

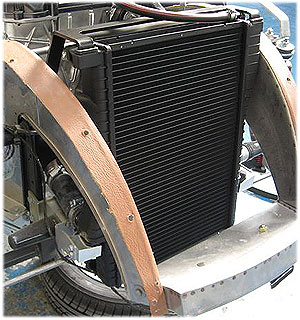

In early 2008, the

Morgan Motor Company began to switch the traditional copper rads in their 100 bhp 4/4 classic cars from

to plastic cross flow radiators like many mass-produced modern cars today. This was an immense saving for

the company of hundreds of pounds per car, though it has not been reflected in the pricing.

Additionally, the odd hoses necessary to reach the inconveniently placed

out/inlets suggests it is a mass-produced generic model but I have done

no research as to their source and Morgan will not reveal it.

Though effective

for cooling, plastic is rigid and not ideal for the famous Morgan

chassis flexing. A quick Google reveals that even modern car owners, with modern suspensions,

despair about the trend to this plastic rads. And OUR cars are famous for their vibration

and chassis movement. As such, these rads have a tendency

to have the plastic crack at the corners where the brackets or any tension

occurs, or even at the tank. Additionally, plastic radiators, are (according to Morgan) impossible

to fix, even if they crack at easily an accessible areas. Accordingly, it is recommended

that these rads be very regularly checked. Anyone with one of the earlier installations should

consider fitting softer interface reels/bumpers to absorb the forces that are causing the damage.

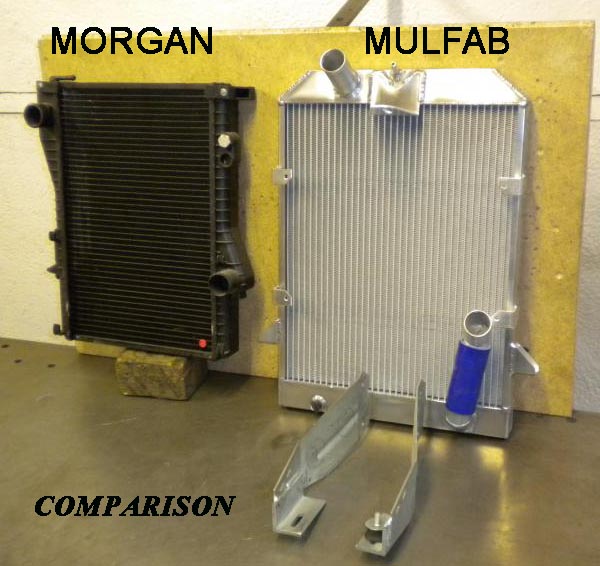

Ideally, one should

consider replacement with an aluminum radiator offered by the aftermarket

alloy rad or an earlier Morgan copper rad. Click HERE

REVISITED: (April 2014)

Since 2008, Morgan

began fitting these 4/4 rads noted above, to their more powerful cars...Plus

4s and Roadsters. Some recall the first public appearance of the Plus

4S  model

(250 bhp) where their demo spectacularly overheated and overflowed

on the track with a non-Morgan crowd at hand. With the 285 bhp 3.7

Roadster these radiators are at the worse, creating a tragedy in would

could be only a mildly poor specification. Worth these the experience

is

chronic if

the car is driven as a sports car or used on a hot day (30C +). After

one of the first 3.7 Roadsters spilled its coolant at Silverstone, the

Factory offered customers the a Mulfab Rad as a "performance upgrade"

to make the car

fit-for-purpose. I strongly advise ANY Morgan buyer to install a proper

radiator if they intend to use their Morgan purchase as a sports car

rather than, admittedly, a very pretty touring car. Otherwise, they

will quickly,

instinctively and unknowingly, adapt to the radiator short comings and

drive in a pedestrian fashion. This is most important for Roadsters but

applies to all Morgans still orginally fitted with plastic. Having

a grandmotherly streak, I feel bad for the owners every time I see a

plastic rad. Unlike so many, I do not write any article here with the

hope of pleasing people. Mechanics is too serious a subject.

model

(250 bhp) where their demo spectacularly overheated and overflowed

on the track with a non-Morgan crowd at hand. With the 285 bhp 3.7

Roadster these radiators are at the worse, creating a tragedy in would

could be only a mildly poor specification. Worth these the experience

is

chronic if

the car is driven as a sports car or used on a hot day (30C +). After

one of the first 3.7 Roadsters spilled its coolant at Silverstone, the

Factory offered customers the a Mulfab Rad as a "performance upgrade"

to make the car

fit-for-purpose. I strongly advise ANY Morgan buyer to install a proper

radiator if they intend to use their Morgan purchase as a sports car

rather than, admittedly, a very pretty touring car. Otherwise, they

will quickly,

instinctively and unknowingly, adapt to the radiator short comings and

drive in a pedestrian fashion. This is most important for Roadsters but

applies to all Morgans still orginally fitted with plastic. Having

a grandmotherly streak, I feel bad for the owners every time I see a

plastic rad. Unlike so many, I do not write any article here with the

hope of pleasing people. Mechanics is too serious a subject.

The urgency of this advice will vary with the power of the specific

Morgan and the heat of the day.. But regardless of where you are or how

you use your car, why risk ruining a Morgan outing? Worse still,

drivers adapt automatically to the inadequacies of their car. Why limit

your driving because of an ill-chosen component?

RECENTLY, there are some generic sellers offering plastic radiator

repair solutions. The feedback on these is poor for the Morgan rads.

Plastic radiators have special issues of pressure and heat that make

them difficult to repair successfully..but technology keeps marching

on. (hopefully) I cannot see how such a repair would address the Morgan

chassis flexing forces. The repaired rads crack even more readily. But

at the cost, it is worth a try. (shrug)

Sadly, these plastic replacements offered by Morgan

are, for some reason, priced far beyond the level of other plastic rads

from other marques or generic models. Their prices are the same as a

bespoke all metal rad. So the decision to upgrade your rad when it

cracks is not a cost factor.

| USA | http://www.urethanesupply.com/radiator.php |

| UK |

http://www.ehow.co.uk/how_6801320_repair-holes-plastic-radiator-tanks.html |

REVISITED AGAIN: (January 2019) Our fears about them, expressed above in 2008, have sadly proved prescient. :( Not only are these radiators inadequate for any bhp beyond 200, but they crack and shear over time, often ruining your anticipated Morgan outing or your long-awaited annual mogging trip. Buy yourself an aluminum present, or even an used (re-cored) older Morgan radiator (they appear on ebay from time to time..and.or a Morgan dealer might have one out back). I now recommend that if ANYTHING becomes amiss with one of these, do not bother repairing it. Think of the cost of a repair as a discount on something better. These rads merely degrade the product to the short-term benefit of MMC profit. Times have changed. The MMC is a modern company now. Happily, the plastic rad era ended when the company abndonned traditional Morgans in 2019 though we are told the CX radiators generation have been recalled for other reasons.