Correct Centering Position |

Can Use for Dayton Manufactured After 1990 |

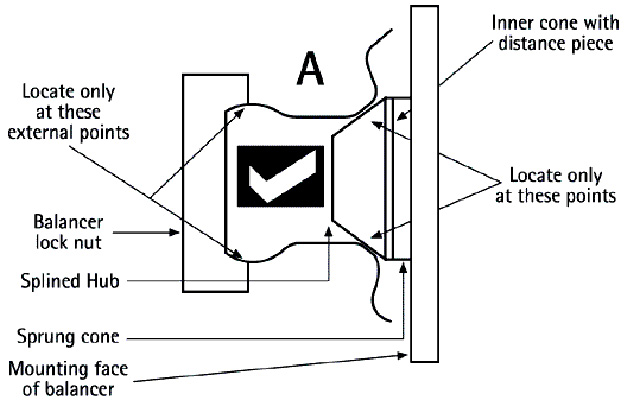

Special attention is required when balancing spline-drive

(sometimes referred to as "center-lock" or "Dunlop style") wire wheels.

To properly balance this style of wheel, it must be centered on the

balance apparatus in exactly the same manner that it is centered on the

car. The two seating surfaces that center the wheel can be seen in Figure

#1. These two bevels are typically "machined" surfaces as opposed to less

exact "rough-cast" surfaces. Note that the splines are used to drive the

wheel, not center the wheel. Balancing spline-drive wheels by using a computer

spin balancer is only effective if the wheel is centered as shown in Figure

#1.

Correct Centering Position |

Can Use for Dayton Manufactured After 1990 |

Some spin balancers have a cone set designed specifically for spline-drive wheels but these are very rare. Dayton Wheel Products spline-drive wire wheels manufactured since 1990 have a fully machined hub that allow most cones to accurately center the wheel.

Another simple but very efficient method for balancing is the bubble balancer. This method was used when the cars were new. Spin balancing on the car is another alternative. This is especially effective if the suspension system is worn or brake drums are out of balance.

A properly balanced wheel will almost always require weights on both the front and rear sides of the rim.

To test a wheel for "trueness," mount it on the cars rear spline (without a tire). Tighten the knock-off cap and spin the wheel slowly using a dial indicator pointer on the inside bead of the rim (where the tire seats). Do not check for trueness on the outer edge of the rim. When measuring a movement of 1/16" or less is acceptable. Worn threads on the cap or hub or a worn bevel on the hub or cap can make the wheel appear out of true. If the wheel appears to have excessive runout, mark on the wheel the location of the highest reading. Remove the wheel and rotate it 180 degrees and place the wheel on the same hub. Recheck for runout. If the highest reading changes position from that marked a worn part or parts are indicated. (Figure # 3)

New

Spline

Slightly

Worn

Worn

Dangerous

Spun Wheel

Repair of worn splines is not feasible or recommended. It is quicker,

easier and less expensive to replace the wheel or wheels with new spline

drive wheels.

Balancing II (from Motor Wheel Services)

The following instructions are intended as a guide to assist in solving problems that are commonly encountered when balancing centre-lock wire wheels on a electronic balancer.

CORRECT

Fitting & Balancing - Centre-lock Wire Wheels

The above diagram shows the centre shell of a wire wheel

attached to a balancer and is the correct method of locating the wheel.

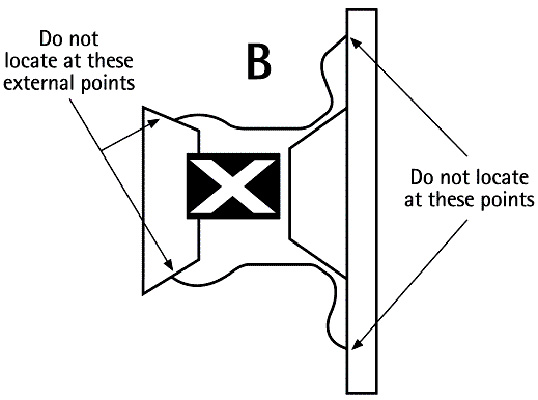

INCORRECT

Fitting & Balancing - Centre-lock Wire Wheels

The above diagram shows the centre shell of a wire wheel attached to a balancer and is the incorrect method of locating the wheel. This method will give false readings and the appearance of untrue wheel or wheels where large amounts of weight would be required to balance.