away.

away.

Many times the heat transferred to the lubrication system from combustion, and the kinetic components of an engine, are overlooked until a problem arises during dynamometer or track testing. A study was undertaken to develop a heat flow and heat transfer model of an engine's lubrication system to predict primarily sump oil temperatures, and secondarily, coolant temperatures. The temperature relationships between the oil and coolant were found to be most interesting. This technical brief is a summary of the referenced paper. A model was developed to account for numerous items in the engine /lubrication system:

1. Engine Speed and Load,

2. Head and Block Geometry

3. Bearing Clearances

4. Piston Design

5. Coolant and Ambient Temperatures

6. Material Properties.

(If the engine had an oil squirter system, this was included as well.)

Energy balance equations and heat input sources were incorporated into the model, with heat sources and heat sinks within the engine accounted for. In each test, a measured quantity of oil was used.

To verify the model, the model was plotted against full-up V8 engine data from a dynamometer. The model correlated quite well with the dynamometer data, with a slight under-estimation of oil sump temperature at high rpm. It was found that the piston undercrown contributed about 70 to 80% of the heat into the oil with bearings contributing 10 to 20% of the heat energy to the oil. Here is a breakdown of heat sources for engine oil 2,000 RPM:

Energy to Oil from Piston

Undercrown - 76%

Main and Big End Bearings

- 13%

Camshaft Bearings - 1%

Energy to oil from Cylinder

Wall - 0%

Oil Deck in Head - 2%

Oil Pump Energy - 8%

At 4,000 RPM, the only increase in heat energy came from the Main and Big End bearings at 19%, a 6% increase from 2,000 RPM. The Piston Undercrown's energy contribution to oil temp was 4% less at 72% for the 4,000 RPM case.

The predicted sump (bulk) oil temperature versus the coolant temperature was shown to be about 18 to 20 degrees C higher for the oil than for the coolant at 2,000 RPM. At 4,000 RPM WOT, the oil sump temperature was about 50 degrees C higher than the coolant temperature. The slope for both RPM ranges was about 0.7 C/C, which means that on the average, the Oil Sump temperature is always 1.2 to 1.43 times higher than the coolant temp. Engine oil temperatures varied with engine output and coolant temperatures varied with engine output, airflow and radiator capacity.

An interesting side-bars of the study was that the bulk oil temperature increased "only" 0.3 C for every 1.0 C increase in ambient (outside) temperatures.

The Sad Myths

About Morgan Oil Coolers and Plus 8s (revisited 2020)

by Lorne Goldman

Many believe that the racing

world shows the way for technological discoveries that can guide the non-racing

owner. Though there are exceptions, generally speaking nothing can be further

from the truth. The goal of a racer is to win. Nothing else matters. His

racer performs in a limited supwer controlled environment, without stop signs, red lights,

speed limits or bumper to bumper traffic. And the pilot has an elaborate support network meters  away.

away.

On the other hand, the goal of a road-driver is to have a car that causes him the fewest problems and provides the greatest comfort in the widest set of conditions without any support network immediately at hand.

For example, a racer deals

only with perfect roads surfaces, so his suspension is an afterthought.

He has no bumper-to-bumper traffic to contend with  so

cooling is approached differently as his racer is normally at speed, revving

very high with a substantial speed-created airflow. So a most striking

example of the difference between a racing car and a road car is the racer's

use of a oil cooler and its dangers when used in normal driving.

so

cooling is approached differently as his racer is normally at speed, revving

very high with a substantial speed-created airflow. So a most striking

example of the difference between a racing car and a road car is the racer's

use of a oil cooler and its dangers when used in normal driving.

Let's look at this oil engineer's data above in ordinary Morgan layman's terms. Morgans do not have oil temperature gauges fitted. (though I do in my Morgan..merely to confirm my thoughts when running.). This lack of a gauge is a good thing as few understand what oil is supposed to do. They have no idea what the temperature of the oil is supposed to be, imagining it should be the same as the coolant!! My on-road observations match Bob the Oil Guy's empirical testing. My oil temp goes up with high engine rpm and rapid gear changes. After all, oil is there to reduce friction from the internal movement of the engine's components. The faster the engine turns, the more friction and therefore the more the oil will be heated. But the coolant has the radiator and its airflow to balance that and more. The faster the car goes, the more airflow. Ergo the greater the cooling to compensate for race track heat. Bob and his team is right as the truth is that oil temperature and coolant temperature are not overly related. Especially with pre-GEMS Plus 8s (1968-1996 in the US and 1968-2000 in Europe) which use a volume rather than a pressure oil system.

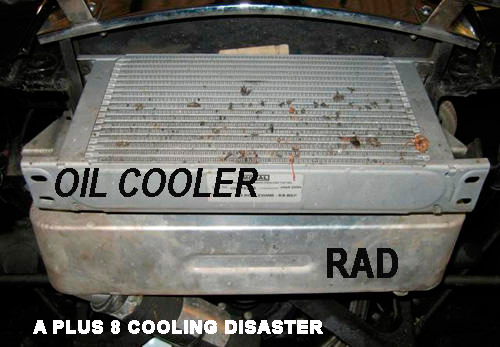

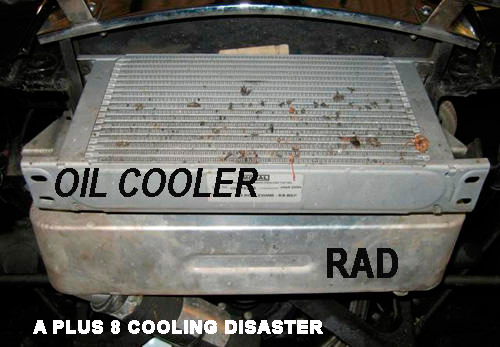

Coolant and the coolant system cool the engine, while oil is used to lubricates it and reduce friction. Yet some people don't understand that. They fit expensive oil coolers that are unnecessary and unsightly..offering themselves more areas for a disaster from road debris under the car and more oil connections that can leak or rupture. Most importantly, Morgan oil coolers. lacking a good place to install them, concentrate the much higher heat of oil in the worst possible place! (As Bob points out, the oil is normally 10C+ hotter than coolant!) Yet on a Morgan, the oil coolers are inevitably placed UNDER OR IN FRONT THE RAD! The image to left was taken from a new Morgan Plus 8 owner, who had a super thick RDR installed..which already reduces airflow through it and therefore cooling, then proceeded to install a oil cooler adjacent to and in from of the rad!!!...effectively blocking the airflow even more.

Additionally, the lower part of a radiator is normally the most effective part. It gets more and colder airflow. As well, the hot coolant enters at the top of the rad and exits at the bottom. With a Morgan oil cooler, it is placed so as to heat the bottom of the rad..and it is not hard to imagine what happens when the car is not moving. So they make their situation worse, and then they leave it in that sad place no matter what they flee to next! In traffic, without any air flow to remove that oil cooler heat rising upward, their cars are a disaster waiting to happen, especially as stock cooling systems on Morgans are marginal..and often worse than that with their bigger engined models.

With a road

driven Plus 8, whose (pre-GEMS) oil system is one based on volume

rather than high pressure, the oil cooler fetish is downright

ridiculous. I run Plus 8s with highly tuned and cammed 4.8s and my dash

contains an oil temperature gauge. If you feel your oil is

over-heating look elsewhere for the problem.

| WATCHPOINT: Bob's oil engineer

group makes a VERY important point. Most people have no clue what their

oil temperature should be. It is blessing that cars are not fitted with

oil temperature gauges. (Indeed, I often wonder at the presence of an

oil pressure gauge. By the time one notices there is none, it is too low,

it is too late.)

However, they do not stress the greater concern. Knowing about oil temperatures is when they are TOO LOW. "Too high" is not as relevant as oil is there to lubricate, not cool the engine. Too low is probably the most important thing to know, specifically for those of us who are pushing our cars hard. Free revving (or worse – racing) an engine that has not fully reached its minimum oil operating temperature is extremely dangerous. And most cars have nothing that will tell you this. As a general rule of thumb, after the car is warmed up, oil tends to be at least a few degrees warmer than the coolant. The engineers above state it will be 1.2 to 1.43 times the temperature of the coolant after the car is FULLY at running temps. In my experience, I find it the same at low revs on a wet day and as much as 30C more on a hot track day with an average of 10C more normally. However, it takes much longer for oil to come up to temperature than coolant. When you start your car in the morning, most of us are wise enough to not push the car until the coolant gauge is up to operating temperature. This is certainly better than pushing it cold, but it's still not quite ideal. You see, the oil, especially in colder ambient temperatures, takes longer than coolant to come up to temperature. Oil will not get to its minimum happy operating temperature easily by simply idling or revving at a standstill. It requires driving around and putting some LOAD on the engine. I see people in the pits at races all the time revving their motors to "warm the engine up". It won't do any good and is only putting premature wear on the car. The best way to get a car's oil temperature up is to simply drive it around. Use your oil pressure gauge to extrapolate its temperature. Cold oil produces higher pressure than those recommended for your car. So what's the danger of running an engine cold? Partial or total engine failure. In layman's language, you making it more likely to break something or prematurely wear the engine innards. In all engines, the clearances are significantly tighter, creating extreme amounts of stress on the engine's internals and the piston rings will not have properly sealed with oil temps too low. In short, it's really bad for your engine to run it hard until it's OIL is completely warmed up. Coolant temperature are a false indicator here. Do not worry so much about high oil temps, the opposite should be your concern. |