The

unfortunate use of the one-shot oiler began a decades long (and silly)

debate on greasing from the top of the kingpin, using the oil or grease passages

the MMC drilled down the shaft. from time to time. (sad sigh)

The

unfortunate use of the one-shot oiler began a decades long (and silly)

debate on greasing from the top of the kingpin, using the oil or grease passages

the MMC drilled down the shaft. from time to time. (sad sigh)  The

unfortunate use of the one-shot oiler began a decades long (and silly)

debate on greasing from the top of the kingpin, using the oil or grease passages

the MMC drilled down the shaft. from time to time. (sad sigh)

The

unfortunate use of the one-shot oiler began a decades long (and silly)

debate on greasing from the top of the kingpin, using the oil or grease passages

the MMC drilled down the shaft. from time to time. (sad sigh)

Perhaps the issue with understanding how the original one-shot oiler CANNOT function as a lubrication system arises out of the fact that most of us never see or study the kingpins carefully before they are installed, and then, after they are installed they are covered by their main springs, their dust covers and most often filth preventing an easy visual analysis. However, even installed, a tape measure can tell you all you need to confirm the elements you need know. (Or just a glance will do it if you understand where everything is.)

Even if the passage was extended it did work, it is dangerous as it offers no visual confirmation that one should stop greasing! The inevitable result, with either oiling greasing remotely is that an excess hits the adjacent discs and makes the car a deadly danger to drive!!

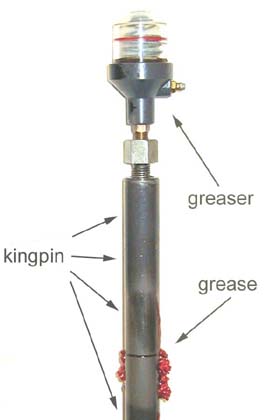

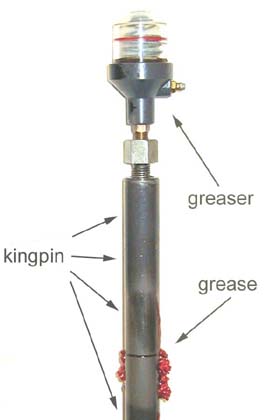

HFS's system for greasing the kingpins was by filling

the grease reservoir formed in the stub axle tube (the passage the kingpin

is installed) in the space between the upper and lower bushes. The lower

grease nipple is placed exactly at the reservoir and allows us to fill

the reservoir with grease. When suspension goes up and down, the reservoir of grease

travels up and down the kingpin.. greasing it and the bushes continually.

This effect is enhanced with the addition of steering races aka bearing systems. The

upper bush is never greased by this method but it doesn't seem to mind.

In fact, I cannot think of a single alternate method that greases the

upper bushes

in a fashion simpler and wiser than HFS' original design. Proof is that they rarely

wear much. It is the bottom bush that requires replacement.

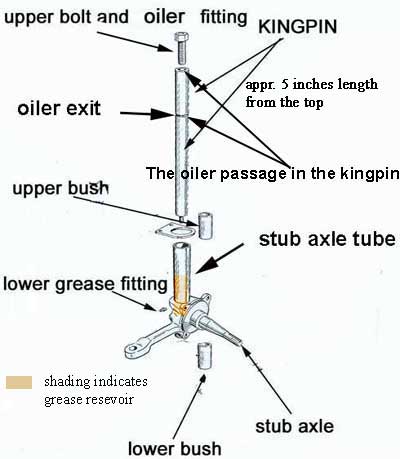

Look at the diagram on the right. As you can see,

the one shot oiler passage exits the kingpin (used up to 2002) above the stub axle

and higher than the all-important reservoir when at rest.To confirm this, measure

down from the top of the kingpin 5 inches and then ask yourself what grease

up there can do that could possibly replenish the reservoir. So if

you hope to use the old oil passage for grease instead of oil, it cannot help in any

way unless you drill it further.

So, what was it made to be used for? In their wisdom, the PM felt that the area (the shelf) the spring and damper plate rests on had to be greased or rather oiled. This was a decidedly odd decision considering they had advertised the damper blade as a "friction damper" two decades before, but there you have it! At least, the one-shot oiler inundated the area in oil which had some lubricating consequence for the damper plate (and sadly your brake rotors eventually! I get one frightened contact a year with that problem..)

Some say that a remote system extends the life of

the front end. IT CANNOT unless the owner NEVER greases, which has became more and more common every year trads were made.

At that point, owners sadly become prey for expensive and unnecessary

gimmicks and addons and fads. These all seem great because, in the

process of installing them, standard maintenance must finally be done by the installer.

Additionally, if it is imagined remote greasing is a replacement

for filling the stub axle grease reservoir, considering where it  exits, you will only shorten the front

end life for lack of grease in the reservoir.

exits, you will only shorten the front

end life for lack of grease in the reservoir.

HOWEVER, there is some logic in modifying the kingpins and extending the one-shot oiler passage all the way to a point where it can reach the bushes and the grease reservoir. But then, how would you know whether you had filled or over-filled the reservoir or whether your brakes had been greased as well by sad chance? This happens often.

What about those who have steering bearing cars...either

from a retrofit or later stock Factory fare (in 2008 the new MMC copied

the steering races adopted by the eMog community).

What about those who have steering bearing cars...either

from a retrofit or later stock Factory fare (in 2008 the new MMC copied

the steering races adopted by the eMog community).

When it comes to the retrofit cars (left), the old kingpin configuration installation assures that the bearing assembly is fed by the lower grease nipple that also fills the bearing assemblies. In the case of the newer kingpins, a hole was drilled inside and angular grovw which happily serves to bearing assembly! However, the kingpin must be mildly modified. As long as you assure yourself that the steering race or bearing assembly is grease fed from the bottom, all will be well. Please post on the GoMoG Garage.

Some have maintained that the newer bushes, with their spiral grooves cut down in their inboard surfaces, will pick up grease from the top and it will eventually worm it way around to the grease rsservoir. Please step back and think about this conceit for a moment. They are suggesting that you use a hard-to-reach upper grease nipple to force grease down a passage in the long kingpin, squeeze into a spiral groove and have it wind its way down the kingpin into the grease space, which is already filled directly by another grease nipple specific to the reservoir! The same logic could be used to pour petrol over the entire car in hope it would suck in some place useful. (giggle) Lastly, remote greasing is a blind job. The words "remote" and blind" are interchangeable in this usage. The user of these methods has no idea whether the greasing has been over or underdone. Whether some will been thrown off onto the adjacent brake discs and create a disaster while driving..and the user never gets a look at adjacent areas, even unrelated ones, that may be seriously wanting some attention...like a shock that kas lost its nut, a main or rebound spring that has cracked, a leaking radiator or hose..the list is endless and I have heard them ALL!!!

| WATCHPOINT: In 2002, the MMC removed the one-shot oiler system and the oil passage down the kingpin. However, in 2009, they adopted a steering race (bearing system) made popular by eMog. Rather than using one of the systems tested by the Community, used for many years, they tried their own. The bearing systems previously in use all use the existing greasing structure to feed the bearing assembly. However, this was apparently not understood by the Factory. Instead, they redesigned the HFS' kingpin once again and drilled a grease passage down the kingpin to a point adjacent their little bearing assembly (steering race) and have three exit holes in that area that will hopefully fill the assembly. This grease does not fill the aforementioned reservoir. Much more on this here |