The Plus 8 engine relies on oil volume rather than than oil pressure as do other engines. So the oil doesn't have to have extreme

temperature or pressure capabilities. The use of synthetic or semi-synthetic

oils for pre-GEMS is not necessary and a waste of money considering how often it is advisable

to change it with the engines made from 1968 to 1996 (USA) or fit until 2000 (UK). Frequent

(2500-3000 mile) oil changes will have a much better effect on your engine than

using expensive oils.

| WATCHPOINT: And with a volume system, engine oil heat becomes moot. I have a 4.8 version of this engine on a cam (aka high revving) and a oil temperature gauge. All of which has proven to me, inarguably, that the system does NOT produce temeratures sufficient to require the added cost and risks of an oil cooler, (extra connections, a decrease in front clearance etc). In fact, on a road-going Plus 8, all oil coolers seem to do is unforgiveably raise coolant temperatures when they are installed usually under right under the radiator! Makes me wince when I espy one with. |

A somewhat thicker standard oil doesn't hurt so 10W40 or 20W50 is a good option. The lifters, Detroit made for the 215 version, were made for 20W50. Make sure that you use an engine oil with good detergent qualities, particularly for the V-8's as they tend to be very sensitive to oil sludge. (Avoid Quaker State like the plague). Castrol Longlife is good..subject to the ZDDP codicil.

Standard synthetic Mobil 1 is rated at 5/30. If you want to use synthetic anyway (TVR is recommending synthetic in their Rover V8's) then preferably use the thicker Motorsport 4T grade which is rated at 10/40 or Mobil 10/50. This will reduce oil consumption and premature wear of the bearings.

In the manuals for older models, it states that oil changes should take place every 5000 miles. For later models it was set at every 12,000 miles, but this figure tends to be very inadequate and wildly optimistic if you want the engine to last as long as you do. As a rule of thumb, I use an interval of 3000 miles or every year (whichever comes first) should be used. When I open up my engines, they are pristine.

Change the oil filter at the same time you are changing oil. Some people only change the filter after every second oil change. Normally it won't hurt but then it's easy to forget it the second time also! and the cost of a filter isn't that big. Another reason is that the amount of flow pumped out by the oil pump reduces when the filter is becoming clogged. As noted, this V8 needs copious amounts of oil to keep it well lubricated so it is better not to count beans on this point and just change the filter together with the oil.

If your engine is used for short distances, or you expect a lot of sludge and such inside the engine, you can try the following trick. Before changing the oil. Drain some engine oil (about 1 litre) and top up the oil level with 1 litre of ATF oil (Automatic Transmission Fluid). ATF oil has very good cleaning properties and does a good job of internally cleaning the engine. Leave it in for about 100 miles in the engine. Then drain all the oil and refill with normal engine oil. It will certainly help a lot.

Sadly, the oil pressure relief valve can create much sadness. It would be wise to read that codicil below.

V8 Oil pressuresFor pre-GEMS models

Warm 27-35 psi at 2600 rpm.

Warm 12-20 psi when idling.

When cold, your oil pressure can be much higher. I have seen as much as 50-60 psi. Let your engine warm up. High pressure is can even be dangerous for pre-GEMS cars.

| WATCHPOINT: If your oil pressure, when the engine is warm, is much higher than these figures, be very wary. Your oil high pressure relief valve may be sticking or otherwise faulty. |

For post-GEM models (2000 on except for post-1998 overseas cars)

For pre-GEMS models

Warm 27-35 psi at 2600 rpm.

Warm 12-20 psi when idling.

When cold, your oil pressure can be much higher. I have seen as much as 50-60 psi. Let your engine warm up. High pressure is can even be dangerous for pre-GEMS cars.

| WATCHPOINT: If your oil pressure, when the engine is warm, is much higher than these figures, be very wary. You oil high pressure valave may be sticking or otherwise faulty. |

For post-GEM models

(2000 -2004 or the end of the PLus 8 line) except for post-1998 overseas cars)

These cars use an entirely different oil pump and pressure system driven off the crankshaft. Their pressure will run higher. If the pressure gauge shows nothing and the oil pressure light doesn't show up you've still got around 7 psi left of pressure. Stop the engine immediately and check for the reason the gauge shows so little pressure. If the engine starts to rattle then stop the engine instantly because the oil pressure is so low it isn't enough to keep the hydraulic lifters pressurized and you are about to cause great damage. With the GEMS variant you have to start thinking about a rebuilt when the pressure drops to around 20 psi when running at 2400 rpm with a warm engine. Oh! and remember the bi-metal oil pressure gauge on the dash isn't the most accurate instrument there is. So before rebuilding take a reading with a proper oil pressure gauge! (I switched to a electric sensor pressure gauge. Looks the same, is more accurate and less prone to messy failure.)

These cars use an entirely different oil pump and pressure system driven off the crankshaft. Their pressure will run higher. If the pressure gauge shows nothing and the oil pressure light doesn't show up you've still got around 7 psi left of pressure. Stop the engine immediately and check for the reason the gauge shows so little pressure. If the engine starts to rattle then stop the engine instantly because the oil pressure is so low it isn't enough to keep the hydraulic lifters pressurized and you are about to cause great damage. With the GEMS variant you have to start thinking about a rebuilt when the pressure drops to around 20 psi when running at 2400 rpm with a warm engine. Oh! and remember the bi-metal oil pressure gauge on the dash isn't the most accurate instrument there is. So before rebuilding take a reading with a proper oil pressure gauge! (I switched to a electric sensor pressure gauge. Looks the same, is more accurate and less prone to messy failure.)Plus 8 Oil Pressure Relief Valves

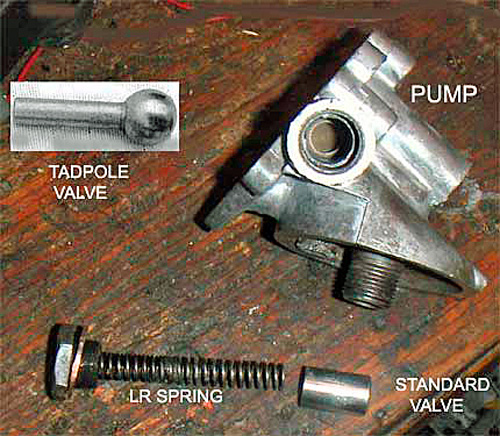

The oil pump has, a relief valve. They are installed in the oil pumps as a emergency measure to:HOWEVER, there are weak points that CAN be easily addressed.

A. First of all, ignore most of the "cures" offered. Most merely cause more problems.B. Maintain your pump. I have found that the pumps are scored over time, and pressure falls. I keep my base pressure high merely by refurbished my Plus 8 pump(s) in top form. This can be done with a wooden block and a sheet of metal sandpaper while watching TV or a movie.

C. There are two types of pressure to contemplate. (i) Pressure at idle and (ii) pressure at speed. Pressure at idle can be very low (see above) But low pressure at idle is less important and less potentially damaging than pressure at speed.

D. The pressure relief valve piston installed by the manufacturers (Rover, LandRover & GM) can be a disaster waiting to happen, especially with cars that are used sporadically and stored for LONG periods.

E. The modern Rover/LR suppliers to the engine offer only invasivesuper expensive solutions if any. Happily, the performance suppliers to the Buick 215 world have had a longer time to test and solve such things. Since the demise of the production of the LR engines, they are a must-see.

SOLUTIONS

I have owned (much of the time simultaneously) and have 5+ engines for them. I have rebuilt a few from a bare block. AND I am an amateur, which makes me easier to understand and I have no connection to ANY supplier. I have over 250,000 miles on my Morgans clocks. I have tried, installed and rejected many things, regardless of their cost or the time involved. THIS is where this all is coming from. It frightens me what is being advised by Morgan forums today. We have fallen a LONG way since eMog. :( experience,

these warnings are absurd, likely an effort to sell more parts.

Humanity, especially the West, has been driven to lose the simplest

skills and only replace everything, often will lower quality stuff. Fixing components is not only cheaper, it is far more convenient and leaves one with a higher quality car. We have past the stage where we can trust new parts even if we can find them!

experience,

these warnings are absurd, likely an effort to sell more parts.

Humanity, especially the West, has been driven to lose the simplest

skills and only replace everything, often will lower quality stuff. Fixing components is not only cheaper, it is far more convenient and leaves one with a higher quality car. We have past the stage where we can trust new parts even if we can find them! | WATCHPOINT FOR GEMS PLUS 8S: Nobody is going to like me for this one but I do not follow the modern "fact" template of trying to win a "market" by restricting my advice to fake facts that please. I dispense advice based on my experience, quality of the product and ease of sourcing now and for the future. So far, no one is rushing to supply GEMS Plus 8s/Land Rovers and parts have run out. A limited number of those were made. But the mainstream Rover V8 (1968-1996) are still amply supplied either the Rover/LandRover/Buick215 communities. If I had a GEMS Plus 8, I would considered either swapping to or stockpiling componets for a switch back to the older front end, with their over 2,000,000 units made. |

PLUS 8 OIL PANS AND MORGAN SUMPS IN GENERAL (revisited 2020)

by Lorne Goldman

I do not write this for racers. Should advice be needed for such usage please contact me personally.

Many Morgans are infamous for insufficient ground clearance. Nowhere is this more dangerous that at the oil pan or sump. However, for most of the classics' history this was not a problem as steel sumps were the general automobile industry rule. Steel sumps can be repaired with a 2x4 and a hammer by anyone. They very rarely are pierced, they merely dent. However, in the lst 2-3 decades, the industry has been looking everywhere for any cost saving they can find (aka "hidden inflation"). With the start of the Steve Morris regime at the MMC, this modern trend has been embraced. Like most automobiles, quality has been debased.

In the sump department, modern cars now use cheaper cast aluminum sumps. Sadly, these crack like egg shells when impacted and that can cause a world of damage and frustration. The Roadsters, among other models, have been beset with that plague. Sadly most efforts at a remedy make the situation worse. The proper fix is a steel sump. However, Morgan no longer will spend money for such things. Gone are the days when even the careful Peter Morgan will spend on bespoke headers for the Plus 8. The wisest thing for owners is to group together and mandate a specialist, and buy in bulk. eMog was famous for such things. However, today's Morgan owners and forums are less mechanically savvy.

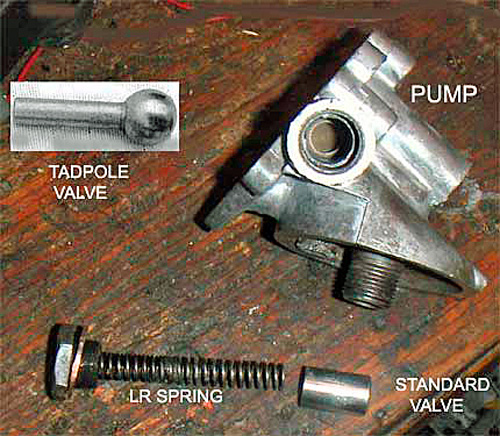

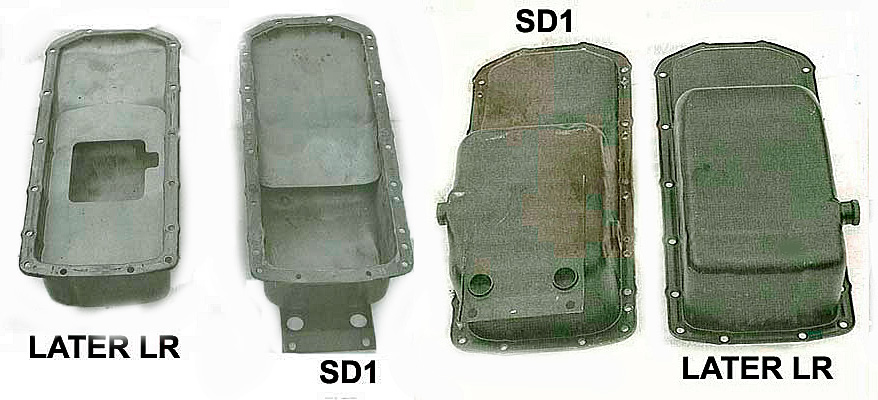

There are many LR/Rover Plus 8 sump variations out there..all used at one time as standard. However, we can eliminate the earlier Buick 215 sumps as they don't fit and the later cast aluminum sumps are as problematic as the Roadster mentioned. I have used the early Sd1 sumps and the later steel LR sumps..used between the demise of the early sumps and the advent of the aluminium sumps that GEMS land Rovers use. (Morgan, after sadness with the aluminum sumps, rushed back to the steel sumps. However this was before the modern era decisions.) There are only two Plus 8 stock sumps since 1976 that should be addressed, Both are pictured below. There is the smaller looking sd1 sump, often with a flange that is attached to the bottom of the bellhousing and the other is the later LR sump, without a flange. They are both steel..and that is the main thing.

There is no contest as to which is the more desirable. The later steel sump adds 20mm (an immense amount) to ground clearance and also carries an extra liter of oil!!! Additionally, there is a bit more clearance for the crankshaft inside, which makes a swap to a 4.6 easier. (I use the later sumps with the earlier cork gasket made for the earlier sd1 sumps. This alone allows my 4.6 rank to clear without the necessity of "relieving" the front of the sump. The extra liter in capacity keeps my engine and oil running cooler. I also add oil until 1/2 liter above the fill line. The pre-GEMS versions of the engine use a volume rather than a pressure system and the additional oil does no harm whatsoever. I know racers who add a full extra liter.

I bought 2 of these sumps when their prices were in the 5-10£ range. When I get a dent, I swap one in for the other and bang out the dent on the wounded one with a 2x2 and a small sledge at my leisure. Sadly, their popularity and the sad experience of the crowd with the later cast aluminum sumps has pushed their prices as high as 200£ and they have become unobtainium. I recommend UK breakup yards and/or patience. But if you see one, BUY IT.

| WATCHPOINT: The very worst sump for Plus 8s is the latter cast aluminum sumps usually installed as origunaks with the adoption of the GEMS line. Happily, the Morgan Company became savvy and swapped them out for the earlier steel sumps. Like all aluminium sumps, these do not dent when struck but rather crack like eggshells, much like the sumps on Roadsters. Cracked aluminum sumps happen constantly with the low Morgan clearance). The company should have spent a little extra money for a proper bespoke sump for the poor Roadsters. They would have recouped merely selling them to other sports marques using the same engines. Too late now. However, I keep looking for a steel solution from the aftermarket. Watch this space. |  |

PROPER SUMP INSTALLATION (The need for a gasket in ALL cases) 1999 (Revisited June 2020)

I explained the basics of this area 20 years ago. But recent

questions in my inbox suggest it needs repeatng with a more expansive

more explanation. These sumps notoriously leak...like the valve gaskets

above. I

cannot tolerate either and the dribbling can be eliminated with proper

parts and a savvy installation.

Firstly, the steel sumps above are different in the area that creates the leaks..namely the flange. The earlier flanges were outdented (yes that is a real word!)..made for the cork gaskets. The later post 1991 sumps that I recommend now were indented, to allow for quicker and cheaper installation using silicone. Sadly, the latter is a more tricky process that has not stood the test of time. Happily, I found the earlier cork gaskets can work with them as well.

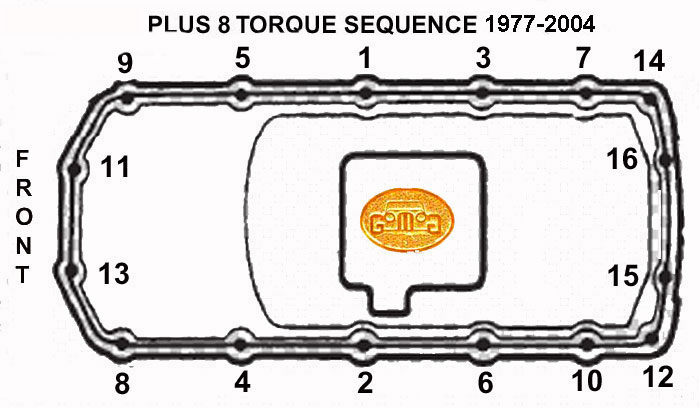

The key to non-leaking has two installation watchpoints.

1. Regardless of whether called for or not, use a cork gasket and only tiny dabs of silicone in a few spots to keep it in place while your carefully torque in the sequence below.

Sequence torquing is a key to keeping the gasket flat.

| WATCHPOINT 1: Silicone can often be a leak producer here. Coating a cork gasket on both sides not only prejudices the cork's natural sealing properties, it also makes it too easy for the gasket to slip while torquing, either imperceptibly or opulently with the result being a wasted gasket, a mess on the floor and much frustration. Beware. Cork and pressed paper and such things are excellent leak stoppers. They are merely more expensive for manufacturers than silicone and involve more labour time. |

| WATCHPOINT 2: One can also upgrade the Rover cork gasket to the rubber/cork offered for Buick 215s in the USA. VERY GOOD as is there gaskets for the rocker/valve covers (assuming the little dowels in the newer LR valve covers give you the creeps [yes they can fall into the engines to sad effect]). Beware of the super early sump configuration which are different and will not fit. |

Silicone makes the gasket slip out while tightening and imperceptibly (or opulently) makes the cork slip out. Silicone also prejudices the absorbtion and sealing value of cork. For very early

2. Torque in the correct

sequence and in 2 or 3 rounds of torquing. Over torquing is also a recipe for a disaster. Figure 7-8 ftlbs. Overtightening

A few years ago, motor oil companies began reducing the amounts of ZDDP. ZDDP or zinc dialkyldithiophosphate, was the most common anti-wear agent used in all motor oils for decades.

A few years ago, the US government decided that it would require auto manufacturers to guarantee a 150,000 mile lifespan for catalytic converters by 2009 (100,000 for 2004 and 120,000 for 2006). The EPA offered vehicle manufacturers "credits" for early implementation as well as penalties for violation of these standards. Over a long period of time (100,000 miles), ZDDP can coat the cats and reduce their effectiveness. Automotive manufacturers have pressured their oil suppliers to remove substances from motor oils that would shorten the service life, including the proven EP (extreme pressure) additive ZDDP. The oil companies responded by lowering or removing ZDDP without informing the public.

Sadly, ZDDP is necessary to flat tappet engines...i.e Triumphs and Rover V8s 1968-2004. The Rover V8 was one of the few flat tappet engines left on the road. So far, it has been irrefutably determined that the absence of ZDDP can cause tappet and camshaft damage when breaking in a new engine, flat tappets or flat tappet cams. Camshaft suppliers to these engines now recommend a special lubricant for the breaking in period that contains sufficient amounts of ZDDP.

Long term damage without

ZDDP has not be determined. Nonetheless, it is better to be safe than sorry.

Maintain a minimum level of .13% ZDDP in your oil. That can be done by adding

GM's Engine Oil Supplement or ZDDPlus, the amount of which will vary

with the motor oil you choose.

http://www.zddplus.com/

There is a sad characteristic of the Buick/Rover oil pumps. They can lose their prime, thus leaving the engine without a lubricating oil supply, which leads to a major engine failure in a minute or so. That being said, in the many many times I have dealt with these oil pumps I have seen one lose its prime once and that after the pump was out and in pieces for weeks. However, it is better to be safe than sorry.

When there is air in the oil pump it will be compressed and the pump will not pump out oil and no oil pressure will be indicated. Don't run the engine when this happens! The pump has to be primed.

There are three ways to do it:

1. Packing the Pump With Vaseline (aka Petroleum Jelly)

Drain the oil and unscrew

the oil filter

Unscrew the six

bolts from the pump cover.

Fill the cavities

between the gears with vaseline

Fit a new gasket

and refit the bolts (torque down to 10-15 lb/ft)

Replace the pre-filled

oil filter and top up the oil

Start the engine

and check for oil pressure and leaks.

2. Turning the Oil Pump Drive Gear

Remove the distributor.

Make an adapter to fit the oil pump drive gear

and using an

electrical drill, turn the the drive gear until the pump primes.

3. Packing the

Pump with Vaseline Using a Grease Gun

by John Sheally II for the eMog Pub

Fill a cleaned out

standard grease gun with one half pint of Petroleum Jelly

Leave the standard

grease connector tip on the gun. (for zerks or grease nipples)

Remove the Oil

Pressure Relief Valve Plug

Extract the Spring

from the relief valve.

Insert the grease

gun in the housing fill with the half pint of Jelly.

Replace spring

and plug and you have a direct well packed oil pump gear housing. with no

mess.

Oil additives

Aside from the codicil above about ZDDP, please forget them oil additives!! For example Slick 50 isn't paying back millions of dollars back to customers for nothing. The firm isn't even allowed to advertise that it's products reduce wear!!...this should say enough. Teflon additives tend to block the small oilways and clog up the oil filter doing more damage to the engine then you imagined.

Oil Change Standard ProcedureNo oil change method is foolproof here but if you change oil and use this procedure there is less chance of having to prime the pump. However old and new oil will be mixed a tiny bit.