Roadster Anti-Tramp Bar Issue

At

the beginning of the Roadster Series II production (early 2008), the MMC

made some modifications to the rear suspension. They attempted to address

an axle

wind-up issue that was causing the prop-shaft to impact the car in

its most extreme expression. Their original solution was to fit a single

Mulberry

anti-tramp bar on the right hand side of the car. These anti-tramp

bars were already being used in paired sets on racing Roadsters.

At

the beginning of the Roadster Series II production (early 2008), the MMC

made some modifications to the rear suspension. They attempted to address

an axle

wind-up issue that was causing the prop-shaft to impact the car in

its most extreme expression. Their original solution was to fit a single

Mulberry

anti-tramp bar on the right hand side of the car. These anti-tramp

bars were already being used in paired sets on racing Roadsters.

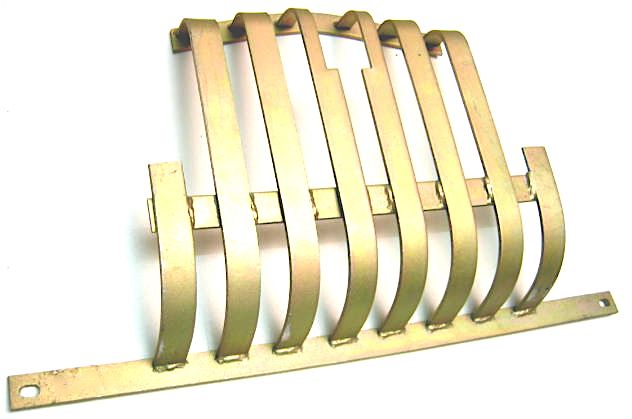

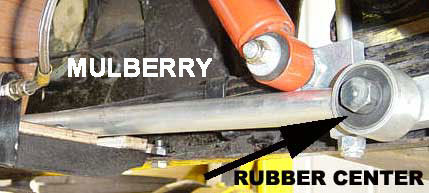

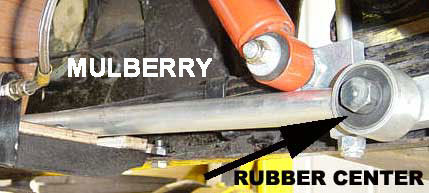

Traditionally,

anti-tramp bars are always fitted on both sides of a car. But it was felt

that a single bar would do the trick, cost less and the space on the right

is partially obstructed by the battery and its fittings. The first cars

with the Mulberry bars did well. Mulberry anti-tramp bars are designed

for Morgans. They are additionally unique as the end at the axle is fitted

with a compliant bush, press fit into the bar and through which a graded

metal attachment bolt is placed. This compliancy allows the suspension

to operate fully and freely, unlike many other anti-tramp solutions that

inhibit the up and down movement of the suspension.

Traditionally,

anti-tramp bars are always fitted on both sides of a car. But it was felt

that a single bar would do the trick, cost less and the space on the right

is partially obstructed by the battery and its fittings. The first cars

with the Mulberry bars did well. Mulberry anti-tramp bars are designed

for Morgans. They are additionally unique as the end at the axle is fitted

with a compliant bush, press fit into the bar and through which a graded

metal attachment bolt is placed. This compliancy allows the suspension

to operate fully and freely, unlike many other anti-tramp solutions that

inhibit the up and down movement of the suspension.

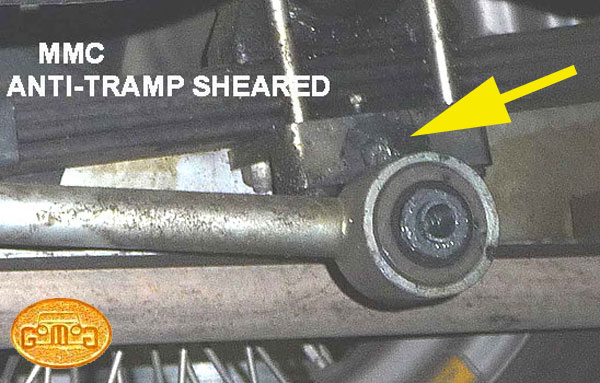

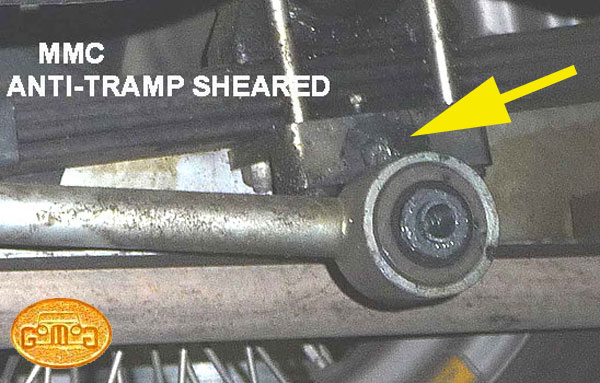

After the first few cars so fitted, the MMC decided to

copy the Mulberry design in hope of saving costs. In doing so, however,

they used different fittings and changed the all-important bush to something

less compliant. Anti-tramp bars on these Roadsters have a tendency to shear

their bolts at the axle saddle plate and bend or break their fitting bolts

at their front. The improper but most common solution is to greatly reinforce

the ends of the bars.

The MMC now makes the assembly with a more compliant bush

and higher graded fittings than these first copies. These are a better

idea for someone with this problem. The ideal fix would be to fit two quality

anti-tramp bars, one per side. assumijgn your lead fsprings are in order. (The

MMC had a forever run of iffy leaf springs.I changed those on my UK

Plus 8 four times in 6 years from 2005 to 2009).

I

have grave concerns on the long-term

affect of a single anti-tramp bar on what is a performance sports car.

If the massive tramp is sufficient to shear graded bolts that large, they

would have twisted the famous (and fragile) Morgan flexing chassis

before that. That will sadly change the handling and comportment of the

car, and most amateur drivers won't notice as it happens so

incrementally.

| N.B. There are ways to correct a Morgan chassis, in some

countries, there are professionals with equipment made for this purpose

that can do this perfectly (lazer-guided) and not cost an arm and

leg. |

SUSPENSION NOTE (EARLY

2009 TRADS)

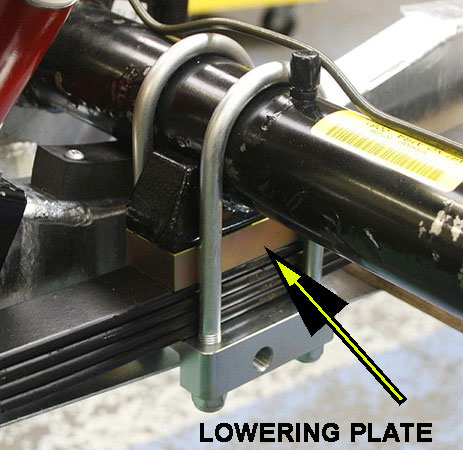

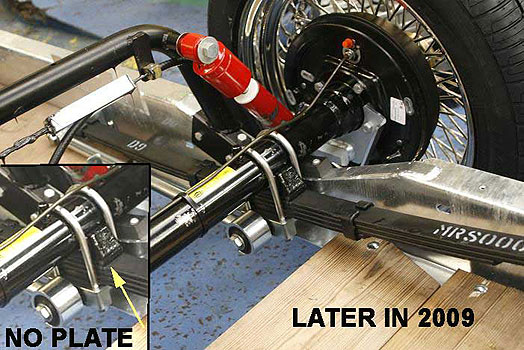

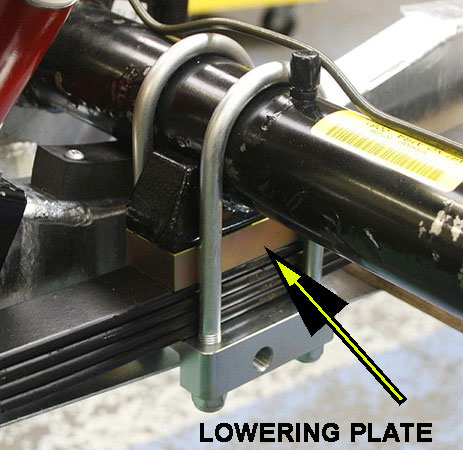

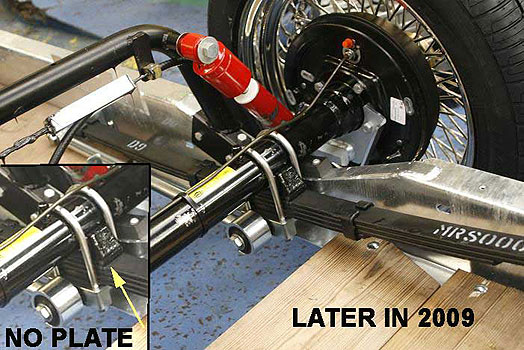

Sometime

in 2008, the MMC realized that their new 4 leaf rear springs were losing

their ride height, allowing the rear ends to prematurely sag to an unacceptable

degree. There seems to have been an attempt to address this first with

a higher arc specification but ultimately this did not provide the desired

result. At some point, the company turned to a new, higher quality

spring supplier with an excellent reputation. (And the cost of Morgan leaf

springs since doubled.) Apparently, on fitting the first batch of

these springs, it was immediately apparent that the arc specification given

the supplier was now too high. So as to use these springs, the company

fitted "lowering" plates between the leaf springs and the saddle plate.

These are used by racers to give a car a racing profile (see racing Roadsters).

In this case, they lower the ride to a more normal height.

Sometime

in 2008, the MMC realized that their new 4 leaf rear springs were losing

their ride height, allowing the rear ends to prematurely sag to an unacceptable

degree. There seems to have been an attempt to address this first with

a higher arc specification but ultimately this did not provide the desired

result. At some point, the company turned to a new, higher quality

spring supplier with an excellent reputation. (And the cost of Morgan leaf

springs since doubled.) Apparently, on fitting the first batch of

these springs, it was immediately apparent that the arc specification given

the supplier was now too high. So as to use these springs, the company

fitted "lowering" plates between the leaf springs and the saddle plate.

These are used by racers to give a car a racing profile (see racing Roadsters).

In this case, they lower the ride to a more normal height.

However,

in fitting these plates it is necessary to use longer u-bolts. Morgan rear

u-bolt length is very important. If they are too long, they will bend and

crack the thin horizontal flange at the ladder frame of the chassis.

If the thin flange is broken, a crack in the perpendicular "strength) section

of the frame soon follows. A SPECIAL NOTE must be attended to by these

owners. The newest leaf springs have the correct arc and ride height WITHOUT

this plate. When leaf spring replacement becomes necessary, the plate should

be discarded and NEW shorter u-bolts used rather than the originals with

these "transition" cars.

ROADSTER SUMPS

It is very easy to damage the Roadster sumps and much

more through a DDE (Deadly Domino Effect). The Roadster clearance at the

sump is only 3.35" on the right hand side and the sumps are made of cast

aluminum. Cast aluminum sumps can crack like egg-shells. The Plus 8s had

the same clearance and were frequently bottomed at the sumps as well. However,

they were made of steel (the Company did not long switch to aluminum sumps

as Land Rover did). Steel dents rather than cracks. It was/is a simple

matter to remove them and bang them out.

It is very easy to damage the Roadster sumps and much

more through a DDE (Deadly Domino Effect). The Roadster clearance at the

sump is only 3.35" on the right hand side and the sumps are made of cast

aluminum. Cast aluminum sumps can crack like egg-shells. The Plus 8s had

the same clearance and were frequently bottomed at the sumps as well. However,

they were made of steel (the Company did not long switch to aluminum sumps

as Land Rover did). Steel dents rather than cracks. It was/is a simple

matter to remove them and bang them out.

So

far, we have seen damage ranging from a cracked sump and a slow leak

(which

must be caught before severe internal engine damage occurs from oil

starvation)

all the way through a crack sufficiently large to instantly void the

engine

of oil and a domino impact that damages the gearbox, prop shaft and

differential. There is no steel sump available at the time of this

writing. So the best fix is that

of Peter Mulberry at Mulfab. Mulberry

increases the clearance at the right side by cutting down the sump. The

cost is very reasonable, and there is no waiting time as Peter inventories

pre-made replacements. Your old sump, in damaged or undamaged condition

will need to be traded.

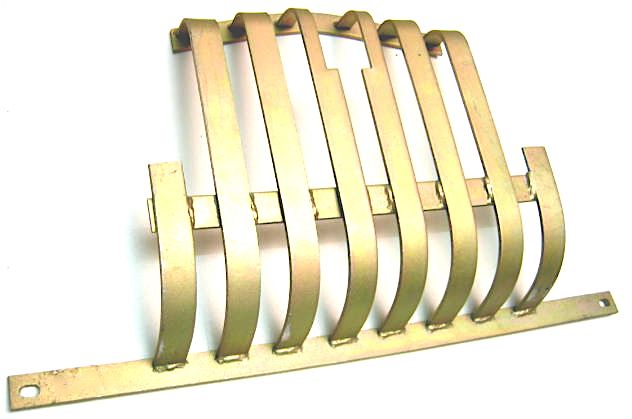

WATCHPOINT: Another of the more dangerous aspects of this issue

is some of the solutions recommended publicly! Invariably, these aggravate

the problem by spreading the impact area and making other areas vulnerable to other types of damage that can be even more costly.

The worst of these (though there are many) I have seen thus far is that favored

by the Factory. They sell a "sump guard" which consists

of a very thick aluminum plate which straddles the bottom

front of the engine compartment and is attached to the car

frame at it weakest area, the thin

Morgan frame flange rather than attached at the thick

vertical section of the frame.

areas vulnerable to other types of damage that can be even more costly.

The worst of these (though there are many) I have seen thus far is that favored

by the Factory. They sell a "sump guard" which consists

of a very thick aluminum plate which straddles the bottom

front of the engine compartment and is attached to the car

frame at it weakest area, the thin

Morgan frame flange rather than attached at the thick

vertical section of the frame.

Like

the aluminum sump itself, the aluminum plate will crack on impact and

if it doesn't it can split and surely bend the all-important frame

flange. When a Morgan frame flange

splits, it always leads soon to a frame crack in the vertical section

which should, properly, require an entire frame replacement. (ugh!) Additionally, equally silly, the plate stops before

the sump. As

the stock sump is closer to the ground than the flange, the protection

afforded the sump is illusory. To top this nonsense off, unlike

other sump guards used for the same engine in other vehicles, it blocks

the airflow from engine and engine bay, something all Morgans,

especially the Roadsters with their inadequate radiators, need very

badly. Here is an Alfa Romeo 105 sump guard available from many

sources, protecting the same sump in for THEIR Ford 3.0. Until

something better

comes along, I would recommend a combination of the Mulberry solution

with an Alfa Romeo guard. You will note that they warn against using the MMC/TalkMorgan solution? There is much at stake here. The guards

sell online, or through Alfa Romeo dealers for 35 to

50£. If it were me, I would have the long horizontal piece bent to be

bolted onto the vertical

sections of the frame on both sides as well as the flange (for

positioning) and use the rear bolts into the engine block or the

bell housing.

Like

the aluminum sump itself, the aluminum plate will crack on impact and

if it doesn't it can split and surely bend the all-important frame

flange. When a Morgan frame flange

splits, it always leads soon to a frame crack in the vertical section

which should, properly, require an entire frame replacement. (ugh!) Additionally, equally silly, the plate stops before

the sump. As

the stock sump is closer to the ground than the flange, the protection

afforded the sump is illusory. To top this nonsense off, unlike

other sump guards used for the same engine in other vehicles, it blocks

the airflow from engine and engine bay, something all Morgans,

especially the Roadsters with their inadequate radiators, need very

badly. Here is an Alfa Romeo 105 sump guard available from many

sources, protecting the same sump in for THEIR Ford 3.0. Until

something better

comes along, I would recommend a combination of the Mulberry solution

with an Alfa Romeo guard. You will note that they warn against using the MMC/TalkMorgan solution? There is much at stake here. The guards

sell online, or through Alfa Romeo dealers for 35 to

50£. If it were me, I would have the long horizontal piece bent to be

bolted onto the vertical

sections of the frame on both sides as well as the flange (for

positioning) and use the rear bolts into the engine block or the

bell housing.

SOURCING

To source a new sump, pre-2006 (aka Roadster I) sumps

are the same as those from either a Mondeo ST220 or a Jaguar S-Type (99).

They should be very easy to find at any break-up yard in the UK. Post-2006

(Roadster II) are a mildly different matter. The post-2006 Roadsters use

the engine from made-for-USA Ford entry level 4x4 called the Escape. From

memory, I think Morgan is the only company using them on the east side

of the Atlantic..so exact version used sumps will be an impossibility locally

for these. However, you will find both sumps easily enough in the US and

at reasonable prices. In all cases, a professional can adapt the earlier

version to a later Roadster.

Front Belt & Pulley

The Roadsters use a different belt and pulley than its

Ford Escape brethren.

Replacement parts are:

Pulley: Gates GNAT38008

Belt: Gates K060747

At

the beginning of the Roadster Series II production (early 2008), the MMC

made some modifications to the rear suspension. They attempted to address

an axle

wind-up issue that was causing the prop-shaft to impact the car in

its most extreme expression. Their original solution was to fit a single

Mulberry

anti-tramp bar on the right hand side of the car. These anti-tramp

bars were already being used in paired sets on racing Roadsters.

At

the beginning of the Roadster Series II production (early 2008), the MMC

made some modifications to the rear suspension. They attempted to address

an axle

wind-up issue that was causing the prop-shaft to impact the car in

its most extreme expression. Their original solution was to fit a single

Mulberry

anti-tramp bar on the right hand side of the car. These anti-tramp

bars were already being used in paired sets on racing Roadsters.

Traditionally,

anti-tramp bars are always fitted on both sides of a car. But it was felt

that a single bar would do the trick, cost less and the space on the right

is partially obstructed by the battery and its fittings. The first cars

with the Mulberry bars did well. Mulberry anti-tramp bars are designed

for Morgans. They are additionally unique as the end at the axle is fitted

with a compliant bush, press fit into the bar and through which a graded

metal attachment bolt is placed. This compliancy allows the suspension

to operate fully and freely, unlike many other anti-tramp solutions that

inhibit the up and down movement of the suspension.

Traditionally,

anti-tramp bars are always fitted on both sides of a car. But it was felt

that a single bar would do the trick, cost less and the space on the right

is partially obstructed by the battery and its fittings. The first cars

with the Mulberry bars did well. Mulberry anti-tramp bars are designed

for Morgans. They are additionally unique as the end at the axle is fitted

with a compliant bush, press fit into the bar and through which a graded

metal attachment bolt is placed. This compliancy allows the suspension

to operate fully and freely, unlike many other anti-tramp solutions that

inhibit the up and down movement of the suspension.

Sometime

in 2008, the MMC realized that their new 4 leaf rear springs were losing

their ride height, allowing the rear ends to prematurely sag to an unacceptable

degree. There seems to have been an attempt to address this first with

a higher arc specification but ultimately this did not provide the desired

result. At some point, the company turned to a new, higher quality

spring supplier with an excellent reputation. (And the cost of Morgan leaf

springs since doubled.) Apparently, on fitting the first batch of

these springs, it was immediately apparent that the arc specification given

the supplier was now too high. So as to use these springs, the company

fitted "lowering" plates between the leaf springs and the saddle plate.

These are used by racers to give a car a racing profile (see racing Roadsters).

In this case, they lower the ride to a more normal height.

Sometime

in 2008, the MMC realized that their new 4 leaf rear springs were losing

their ride height, allowing the rear ends to prematurely sag to an unacceptable

degree. There seems to have been an attempt to address this first with

a higher arc specification but ultimately this did not provide the desired

result. At some point, the company turned to a new, higher quality

spring supplier with an excellent reputation. (And the cost of Morgan leaf

springs since doubled.) Apparently, on fitting the first batch of

these springs, it was immediately apparent that the arc specification given

the supplier was now too high. So as to use these springs, the company

fitted "lowering" plates between the leaf springs and the saddle plate.

These are used by racers to give a car a racing profile (see racing Roadsters).

In this case, they lower the ride to a more normal height.

It is very easy to damage the Roadster sumps and much

more through a DDE (Deadly Domino Effect). The Roadster clearance at the

sump is only 3.35" on the right hand side and the sumps are made of cast

aluminum. Cast aluminum sumps can crack like egg-shells. The Plus 8s had

the same clearance and were frequently bottomed at the sumps as well. However,

they were made of steel (the Company did not long switch to aluminum sumps

as Land Rover did). Steel dents rather than cracks. It was/is a simple

matter to remove them and bang them out.

It is very easy to damage the Roadster sumps and much

more through a DDE (Deadly Domino Effect). The Roadster clearance at the

sump is only 3.35" on the right hand side and the sumps are made of cast

aluminum. Cast aluminum sumps can crack like egg-shells. The Plus 8s had

the same clearance and were frequently bottomed at the sumps as well. However,

they were made of steel (the Company did not long switch to aluminum sumps

as Land Rover did). Steel dents rather than cracks. It was/is a simple

matter to remove them and bang them out.