Filling a BTR

Axled Morgan (4/4s, Plus

4s, Plus 8s, Roadsters from 1996)

by Lorne Goldman at the eMog Pub March

2001 (updated 28 March, 2022)

| N.B. Salisbury (until 1995) and BTR axles (from

1996) are very different. Do NOT confuse them as they MUST also be treated

differently. The BTR is a noticeably bulkier axle with two plugs, one at

the rear and another (the drain) at the bottom. The Salisbury Plus8s axles have three

square plugs (14mm). One at the top, one at the bottom and one at the rear.

The 4/4s/ and Plus 4s have two plugs. If you have doubts on which you have, contact the webmaster. |

IMPORTANT WATCHPOINT

for BTRS

Later BTR are technically spec'ed to last 40000-80,000

miles without a fluid change (I change mine every 25,000 miles). The level

should be checked at every service however (every 3000-5000 miles). If

"chattering" noises occur, it is time to refresh your friction modifier.

Read on.

FLUIDS FOR LSD BTRS

For the lubricant, the only supplier they recommended

was Castrol SAF-XJ. Sadly, this lubricant is easily sourced in the

UK and Europe but is not available in North America and some other countries

through Castrol. However, a BTR was used by BMW and it can be sourced under their part number 83 22 2 282 583 (see the label)

at any BMW dealer. This product already contains the necessary "Friction

Modifier" (aka STURACO, an Italian made product that goes by many names) so it is unecessary to add anything.

The Morgan Motor Company also uses and recommends this

lubricant rather than using their normal supplier of lubricants, Morris.

We have found that Morris, a very reputable firm, often has dated ideas of what should

be used in Morgan axles and gearboxes. They will also not give us a comprehensive

fluids' constituent list so there is no way of checking what is or isn't

in them. Considering the incidence of chattering BTRs filled at the Factory

(cured by the simple addition of 2-3 onzes of FM) and R380s gearboxes

filled with ATF (unwise) We prefer to pay it safe and go with what the

component manufacturers insist on.

In 2011. Use Castrol Syntrax Limited Slip 75w-140 (Formerly

SAF-XJ 75w-140) Castrol Syntrax Limited Slip 75W 140 (Formerly SAF-XJ 75w-140)

is a fully synthetic SAE 75W-140 hypoid gear oil formulated for use in

both conventional and limited slip differentials. Whilst being suitable

for all applications where a lubricant of this quality is specified it

is specially formulated for use with BTR differentials.

Here are "possible" alternatives for those of us in North

America. (I play it safe and buy at BMW.)

ALTERNATIVES

- Royal

Purple Max-Gear 85W-140 (friction modifier is already premixed)

-

Red Line 80W140 GL-5 Gear Oil with Redline

Limited Slip Friction Modifier

(for US owners only)

- Mobil

1 Synthetic Gear Lube 75W-140 to which one must add a Limited Slip

Friction Modifier (available at Ford)

FRICTION MODIFERS Please read this section below

GM Part No. 1052358

Ford Part No. F3TZ-19B546-MA

Chrysler Part No. 4318060

Isuzu Part No. 8-01052-358-0

Redline

Limited Slip Friction Modifier

(for US owners only)

| WATCHPOINT1: Should you read or hear of any advice of ANY other lubricant

for these axles, ignore it and sue the advisor. (sad smile) In all the

years of BTR use, the only failures heard of is from people who ignored

this rule. The first sign of failure will be a clicks or light clunk with

attitude changes. Damage will commence as soon as the wrong lubricant is

used and will continue spreading at a rate dependant on what was wrongly

chosen. |

FLUIDS FOR NON-LSD BTRS

The correct oil for a non-LSD BTR is Castrol SAF-XO. This

is also very hard to find. Castrol SAF-XJ will do or Redline 75-140 differential

oil is a good replacement as well.

However, Redline is a USA based concern and is over-priced

anywhere else. Using it outisde North America makes no sense as there

are so many alternatives. Additionally, non-LSD BTRS have no need of

the friction modifier.

FILLING A BTR AXLE

Take the car (if possible) on a short run to warm the

lubricant a bit.

1.

Place the car on a level surface.

1.

Place the car on a level surface.

2. Jack up the rear and remove the level plug.

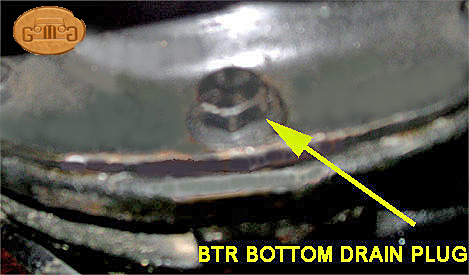

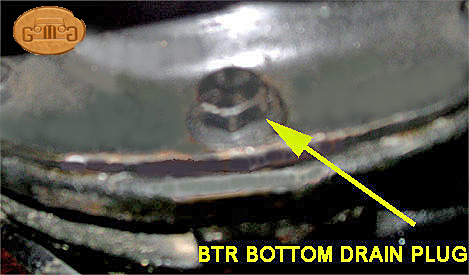

[A BTR has only two plugs, one is at the bottom rear and

often ignored by the uninitiated as they mistake it for a rear cover bolt).

It is used to drain the lubricant. The other is a threaded plug a bit offset

to the right in the middle of the rear cover. This one acts as a filler

and level indicator.]

3. Remove the drain plug. (As a precaution, you can strain

the lubricant to see if any debris is present.)

4. Replace the drain plug.

5. If you are adding Friction Modifier, pour it into the

differential first. (from the MMC)

6. Using a container or funnel/tube that allows access

to the rear filler hole, now fill the differential until the lubricant

runs out of the filler hole.

7. Replace the filler plug.

8. Clean the differential and check for leakage at both

plugs after your first run.

BMW and BTR recommend that the fluid level be confirmed

regularly but it need only be changed every 50,000 miles.

Greasing a BTR Axle

by Lorne Goldman

The BTR axles are closed end systems. There is no need

to grease them for normal maintenance as is required for the Salisburys.

Filling a SALISBURY Axle

(LSD)

by Lorne Goldman (updated May 2020

)

WATCHPOINT1: The

Morgan Salisburys are one-offs. Never used

on any vehicles save for Morgans. Parts from other Salisburys (which

went

the way of the dinosaur in 1996) are rarely interchangeable and

you would have to be a professional to recognise them.

The rumors of an old US Jeep relationship are untrue..though some

non-CW&P

items are similar to the one used in the old USA Studebaker. Salisbury

did not leave a supply of Morgan parts when it closed.

They had offered to produce a large supply of Morgan parts at 50%

before ending that line. However, Charles Morgan never replied, to

their letters and calls. So when Morgan woke

up to a sudden axle shortage, there was nothing similar to ship them.

That sert of circumstances seems to be the reason behind the

choice of the BTR axles, which are heavy items made for Australian

pickup trucks. As they were not modified for Morgans, it also explains

why the Morgan

rear ends suddenly ballooned in width in 1997 which

unfortunately vastly increases wind resistance and agility. I have one myself.

:(

A wiser choice would have been to choose one of the fanatastic units

made in the UK...Quaife for example. Charles Morgan's father Peter,

had fit a Quife differential into the Salisbury 7HA making the legenday

12HA in 1995/1996, easily the best axle a Morgan ever had! It

would have made the MMC

less vulnerable to exchange rates (which have been unkind to Morgans

since 1996) and the enormous shipping costs from Australia rather than

a supplier from England. But

there has not been an full automobile man at the MMC development since Bill Beck left in

2002.. :(

|

| WATCHPOINT2: Aside from both being members of the Dana-Spicer group,

the Morgan Salisburys have no similarity to the later (current) BTR. They

should NOT be treated the same and have different recommended oils. This

is very important. There are no Morgan Salisbury crown wheel and pinions,

(the weakest part of that axle) to be had any longer (N.B. November 2011 Billy

Bellinger has solved that now ). If perfect care is

not taken, or the axle is abused, the consequences are disasterous. |

The original Morgan Motor Company recommended fluids for a LSD Salisbury (Plus 8s &

7HA and 12HA) is a 80/90 Hypoy oil for limited slip differential (LSD)

axles:

1. Castrol Hypoy LS90

(No longer made by Castro, hard to find) (Actually an empty can has become collector's item)

2. Mobilube Mineral LSD 80/90

(still available but hard to find)

3. Royal Purple 80/90 LSD

4. Valvoline

(hard to find)

5. Mobil

75/90 or on Amazon UK

| A MODERN SUBSTITUTE: Castrol Syntrax 75W-90 easy to find everywhere |

ADDITIVE - FRICTION MODIFIER

They are all

the same product. Sturaco 7098 LO is an Italian-made friction modifier

to supplement sulfur-phosphorous gear oil additives for limited slip

performance. They alter the ineraction with the LSD lcutch plates.

Sturaco 7098 LO has also been specially modified to have a low odor

content. It is used as a balanced additive formulated for use in

conjunction with various lubricants. LSD Additives" are friction

modifiers you can use to "tune" a clutch-type LSD. Non LSD-specific

oils often cause too much grab in a new LSD, so a dose of "friction

modifier" is added to relieve some of the chattering that might bother

you when going around slow corners.

Use with gear oil for units with limited slip units - Add 2% to 5%. The

recommended fluids for Morgan BTR LSD all recommend fluids with this

friction modifier after 1999, use it with the earlier LSD models as

well.

It is specifically made for Dana Spicer products (Morgan Salisbury and

BTR are made by Dana Australia) but has been adopted around the world

by the automotive industry. It is sold under different names, GM, Ford,

Suzuki, Redline and many, many others. Sadly, this has worked against

owners as I often find owners buying the same product form another

country at many times the price they can get it locally under the local

name used. For example, in the UK, Morgan owners are wisest to buy from Dana Spicer or HERE

or merely try a simple google search to save yourself 20£. No need to

order the same product under a different marketing name and have it

travel across the world twice merely to come back home. Morgan sourcing

and models often change from country to country as well as over time.

WATCHPOINT3:

Optionally and for nth degree fellas like me. Opinions vary on

what the differential breakwaway torque should be on our hyper light

Morgans. For

street cars, a breakaway value for the LSD clutch plates (yes LSDs have

internal clutch plates) between 20 and 30 lbs/ft is a good

point to start, depending on your Morgan usage and personal

preferrence. To fine tune this, merely add as much friction modifier as

you require to the same differential fluid but one WITHOUT a pre-added

friction modifier and add as much Sturaco as you want to your personal

taste. Alternatively, you can do the same thing by draining the fluid

you put in and adding a varying amount of a fluid withFM. N.B.

This last worries me. The general rule is never to mix differential

fluids and, these days, almost ALL synthetic differential fluids come

with FM pre-mixed.I opt for a varying amount of FM to the standard BTR fluid.

|

Can Friction Modifier be added to non-LSD differentials? It won't do anything. But it will cause no harm. Non-LSD differentials to not have clutch plates.

CAPACITY

| 4/4s |

Imperial Pints |

1.3 to 1.4 liters |

| Plus 4s |

2.5 Imperial Pints |

1.3 to 1.4 liters |

| Plus 8s |

2.5 Imperial Pints |

1.3 to 1.4 liters |

SALISBURY NON-LSDS

The recommended oil for a non-LSD Salisbury (4/4s

and Plus 4s) is now Castrol 75/90 or its equivalent. Salisbury axle

fluid should be ideally changed at 3000 miles intervals. One cannot exaggerate

the need to be careful. Never mix old and new oils.

Some of the newer dealers

suggest what they believe to be modern synthetic equivalents. However,

the Salisbury's are not noted for strength and parts are no longer

made. A chipped Crown Wheel and/or Pinion will and has sidelined many

Salisbury Morgans indefinitely, though they can be had with GREAT

DIFFICULTY. As Salisbury's original recommendation

has worked for 60 years, there is no logic in taking risks. A BTR

can be fit, but MMC waiting times run into many months for

a BTR and it is no longer known whether Classic Morgans will be

supplied since these models have been abandonned. The cost of the axle

and labor to remove the hubs, swap and weld

the brackets and install a new BTR will cost £4000...unless the

work is done by the owner and he is VERY lucky in their part

sourcing.

To replace, take the car (if possible) on a short run

to warm the lubricant a bit.

1. Place the car on a level surface.

2. Jack up the rear and remove the bottom plug of the

differential and allow the lubricant to drain. (As a precaution, you can

strain the fluid to see if any debris is present.)

3. Replace the bottom plug.

4. Remove the filler plug located at the rear right of

the differential.

5. Remove the plug at the top of the differential.

6. Fill from the top until the lubricant leaks from the

rear hole

7. Replace both plugs.

Greasing a SALISBURY Axle

by Lorne Goldman at the eMog Pub

The Morgan Salisbury axles have grease nipples

at both ends near the hubs. They can be accessed by removing the rear compartment

panel or from underneath. Often unseen (as it is traditionally covered

in years of hardened grud and owner neglect) and placed opposite of the

nipple on the axle shaft is a tiny excess grease hole. This is so often

encrusted with paint or dirt that many newbies refuse to believe it exists.

But manufacture was more precise and reliable then than it is now. They

ALL

have these holes. Scrub and clean the area with a solvent if you

have not used it before. This will not make it visible but it will hopefully

loosen/soften the crust enough to make it pop open and usable again. It

is the only way to determine when you have greased enough (and the the

two axle sections take a LOT of grease!) If this excess grease hole is

too solidly blocked, you greasing can force out the seal on that

side.

Assuming the hole is unblocked, the greasing is simple.

Simply pump until you see a thin "worm" of grease coming out from this

hole opposite the nipple. Repeat for the other end of the axle. Grease

the axles and chnage the fluid at 3000 mile intervals.

Greasing a Morgan PROPSHAFT(4/4s,

Plus 4s, Plus 8s and Roadsters)

by Lorne Goldman at the eMog Pub

The Morgan propshaft has not changed much in 50 years...at

some point the splined end of the longer section changed from metal to

neoprene but little else of note was altered. From time to time, if it

is out for a period for another reason, it is could be wise to have it

tested for balance, as an unbalanced propshaft will  cause

vibration.

cause

vibration.

Sadly, though it requires very little care, it often doesn't

get ANY! It needs to be greased and have come across many they haven't

been seen a grease gun a decade and more after they left the Factory.

The propshaft has three grease points. One within the

rear u-joint that it is bolted to the axle, a second at the front on the

body of the propshaft that fills the propshaft itself and a third on the

second u-joint at the front of the propshaft that is bolt to the output

shaft of the gearbox.

The rear grease point is accessible from underneath or

above the axle compartment. Raise the rear of the car and turn the

rear wheels until you see the grease nipple and you have a good line on

it for your greaser. The front two grease points are accessible from underneath

the car or from an access panel at the right or left at the rear of the

gearbox cover. The access panel will vary in placement or sometimes not

exist at all!

Propshaft to Differential Flange Torque

by Lorne Goldman

Morgan does not give torque settings for this VERY important area...but both Salisbury and BTR do!

| SALISBURY - ALL |

35 ftlbs or 47 nm |

| BTR - ALL |

37 ftlbs or 50 nm |

However, some pointers from my experience. Firstly..use grade 8 bolts (& nuts!) or better. The bolts I received with my Morgans were ungraded!

Secondly, I frown on the use of nylon rimmed nuts (aka nylocs), that

the Factory has used...both here and in other key areas. They cannot be

reliably torqued and create disasters waiting to happen. Instead, I use

stover nuts, which take less space and will never loosen, despite being a pain to put on or take off. Lastly, I torque to the bolt's limit.

SALISBURY RATIOS

| WATCHPOINT: Though

Salisbury axles were very popular with many cars for many years, those

used on Morgans were specifically made for Morgans. That being said Morgan Spares, the famous US dealer, has adapted the Salisbury from a Studebaker (IIRC) for Morgans. Excellent product from all accounts! Both can now can supply the once impossible-to-find final ratios as well as adding a wider choice for Morgan Plus 8 owners 4.1, 3.9, 3.7, 3.5, 3.3 and 3.08. |

Original Ratios

Plus 8s: (SALISBURY LSDs) (work in progress)

| NAME |

WHEN

|

FINAL RATIO

|

COMMENTS |

| 7HA |

1968-1972 |

3:58 |

|

| 7HA |

1972-1994 (?) |

3.31 |

|

| 12HA |

1994-1995(?) |

3.31 |

SALISBURY WITH A QUAIFE DIFFERENTIAL

Inarguably the best stock axle ever used with a Morgan 4 wheeler |

BTR (work in progress)

| NAME |

WHEN

|

FINAL RATIO

|

COMMENTS |

| BTR |

|

3:06 |

|

| BTR |

|

3.23 |

|

| BTR |

|

3.45 |

|

| BTR |

|

3.78 |

|

Greasing Universal Joints

1. Clean area around U-Joint and Grease Nipple, removing any dirt or extra grease.

2. Apply grease gun end to Grease Nipple.

3. Begin pumping grease into U-Joint.

4. Watch for any liquid and debris to be purged from the caps of the joint.

5. Stop when new grease begins to be purged from the joint.

6. Wipe excess grease off U-Joint.

https://www.youtube.com/watch?v=8EzhKPM7e4o

1.

Place the car on a level surface.

1.

Place the car on a level surface.

cause

vibration.

cause

vibration.