Play

anywhere in the drive line will create "clunks" as the orientation of the

car or drive train changes..i.e. taking off rapidly at a certain angle,

reversing, going forward after reversing, etc.

Play

anywhere in the drive line will create "clunks" as the orientation of the

car or drive train changes..i.e. taking off rapidly at a certain angle,

reversing, going forward after reversing, etc.

I have often been approached (more often but not exclusively from newbies) with worried queries about a clunking sound from the rear...soon discovered to be rear axle related. This seems to happen more often with Plus 8s and of these, more often with Salisbury Plus 8s. Read on.

Play

anywhere in the drive line will create "clunks" as the orientation of the

car or drive train changes..i.e. taking off rapidly at a certain angle,

reversing, going forward after reversing, etc.

Play

anywhere in the drive line will create "clunks" as the orientation of the

car or drive train changes..i.e. taking off rapidly at a certain angle,

reversing, going forward after reversing, etc.

When it first happens, you have no choice but to check

it out. Here are some areas to examine..in no special order.

1. THE AXLE U-BOLTS

Over time, they stretch. Then the resultant bit of looseness

will cause a sound when they are under a bit of stress from movement in

one direction or another. This is very common with all Morgans Classics.

The U-Bolts must be regularly checked and tightened at every service and

replaced every 1-2 years.

As well, because of the lack of clearance with the thin

chassis flange, the MMC uses nylon-lined nuts(rather than axle u-bolt nuts

made for this purpose) with them and these cannot be properly torqued.

I use stover nuts. These are ovalized nuts that are short and made to

"jam" on without movement and without resorting to a nylon coating on the

thread top. As well, Morgan uses nylon lined nuts with them and these

cannot be properly torqued.

THE WHEEL SPINNERS OR NUTS

If insufficently tightened on the hubs, both bolt on and

(especially) knock-off wheels can make a clunk in the same manner as loose

axle u-bolts will. In both cases, this can lead to serious  damage. Some

professionals will tell you that splined hubs and wheels are self-tightening.

Do not believe them. Ferrari used to recommend 300 lbft of torque for their

spinners and they were much closer to correct. If there is any looseness,

the splines on both wheel and hub destroy each other to your immense cost. Click Here

damage. Some

professionals will tell you that splined hubs and wheels are self-tightening.

Do not believe them. Ferrari used to recommend 300 lbft of torque for their

spinners and they were much closer to correct. If there is any looseness,

the splines on both wheel and hub destroy each other to your immense cost. Click Here

WHEN TO GREASE YOUR U-BOLTS and CROSS-PIN CARDAN JOINTS

The recommended interval is every 5000 miles. A dry joint of this trype runs a dire risk of shearing.

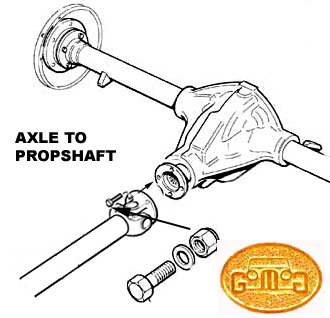

THE PROPSHAFT NUTS & BOLTS

The bolts holding the axle to the propellor shaft should be examined for tightness.

After all this is said and done, the limited slip Salsibury (used on Plus 8s from 1968 to 1996), makes a characteristic clunk..often on reversing or reversing

and going forward. It is a function of the clearance of the internal components

and is harmless. Once you have assured yourself that nothing else is amiss,

learn and remember this sound so that you can distinguish when something

else may be at fault.

reversing

and going forward. It is a function of the clearance of the internal components

and is harmless. Once you have assured yourself that nothing else is amiss,

learn and remember this sound so that you can distinguish when something

else may be at fault.

The BTR, especially later versions, can make an unpleasant chattering sound. We corresponded extrensively with both the Australian manufacturers of the axle and the Morgan/BTR specialists in the UK and were told that this sound occurs when the wrong lubricant is used and/or that lubricant does not have a special friction modifier added.

For the lubricant, the only supplier they recommended

was Castrol SAF-XJ. Sadly, this lubricant is easily sourced in the

UK and Europe but is not available in North America and some other countries

throigh Castrol. However, a BTR was used by BMW and it can be sourced under their part number 83 22 2 282 583 (see the label)

at any BMW dealer. This product already contains the necessary "Friction

Modifier" (aka Sturaco) so it is unecessary to add anything.

The Morgan Motor Company also uses and recommends this

lubricant rather than using their normal supplier of lubricants, Morris.

However, we have found that Morris has often dated ideas of what should

be used in Morgan axles and gearboxes. They will also not give us a comprehensive

fluids' constituent list so their is no way of checking what is or isn't

in them. Considering the incidence of chattering BTRs filled at the Factory

(cured by the simple addition of 2-3 onzes of FM) and R380s gearboxes

filled with ATF (unwise) We prefer to pay it safe and go with what the

component manufacturers insist on.

In 2011. Use Castrol Syntrax Limited Slip 75w-140 (Formerly SAF-XJ 75w-140) Castrol Syntrax Limited Slip 75W 140 (Formerly SAF-XJ 75w-140) is a fully synthetic SAE 75W-140 hypoid gear oil formulated for use in both conventional and limited slip differentials. Whilst being suitable for all applications where a lubricant of this quality is specified it is specially formulated for use with BTR differentials.

Here are "possible" alternatives for those of us in North America. (I play it safe and buy at BMW.)

GEAR FLUIDS

- Royal

Purple Max-Gear 85W-140 (friction modifier is already premixed)

-

Red Line 80W140 GL-5 Gear Oil with Redline

Limited Slip Friction Modifier

- Mobil

1 Synthetic Gear Lube 75W-140 to which one must add a Limited Slip

Friction Modifier (available at Ford)

| WATCHPOINT: Should you read or hear of any advice of ANY other lubricant

for these axles, ignore it and sue the advisor. (sad smile) In all the

years of BTR use, the only failures heard of is from people who ignored

this rule. The first sign of failure will be a clicks or light clunk with

attitude changes. Damage will commence as soon as the wrong lubricant is

used and will continue spreading at a rate dependant on what was wrongly

chosen. |

LEAKING DRAIN PLUGS

by Lorne Goldman

Nothing is perfect or can remain so for long. Drain plugs, when cross-threaded, over-tightened or simply having a speck of something on them, leak...and that tendency increases as the fluid they are holding thins with heat and/or pressure. Let us examine on the drain plugs on the differential, the gearbox and the oil pan/sump.

Most of these plugs use crush washers in copper, plastic or neoprene to insure a leakless fit. If so, use one and change it every time you change the fluid. However, even these may not do the trick.

Not to worry. Carefully wrap some teflon "plumber's" tape (P.T.F.E.) around the threads of the plug. That will do the trick. If you can find it, use the yellow colored tape rather than the other colors (white or pink). Yellow is the best for petroleum products, though I survived for a decade on the white.

REMOVING THE SALISBURY AXLE

by Peter Mulberry and Lorne Goldman