THE POWER OF A MORGAN PLUS 8:

FACTS AND FICTION

by Lorne M. Goldman January 1997 though modified often.

Suggestions for More Power

History

By 1965, The Morgan Company was aware that the power output

of its four cylinder engine was too small for the demands of many customers.

The Company's waiting list had shrunk to two years.

The problem was to find just the right power plant. Triumph's

solution had been to fit a great straight-six into the TR-5 but this engine

was too high to fit into a Morgan. Lotus's twin-cam was too fragile and

the Ford V-6 was too heavy.

In 1966, as a by-product of an unsuccessful take-over

feeler from Rover, Peter Morgan was offered a crack at a new Rover purchase

from Buick, a lightweight aluminium V8 called the 215 or the Jetfire

which (in 1961-62) had been standard in the Buick Skylark and Oldsmobile

F-85 (though each had different heads, intakes and exhaust arrangements).

Maurice Owen, a race engineer, was engaged to experiment

with the engine's possibilities for Morgan and worked with drawings until

he found an old Buick engine to fiddle with. The engine was literally jammed

into a Plus 4 and was rolling in early 1967. After some Leyland/Rover problems,

the Plus 8 went into production in 1968 with 20 cars delivered. As a reference

point for power, an unmodified 4/4 of that time created about 75bhp. The

first Plus 8's (1968 to 1972) put out an unmodified 160.5bhp or 170hp on

the American standard, a significant boost of power.

N.B. BHP is a measurement of the actual usable power (not

calculated power) measured at the output shaft (usually the crankshaft)

rather than at the drive shaft or the wheels. Thus none of the auxiliaries

(gearbox, generator, alternator, differential, water pump, etc.) are attached.

It is called the brake horsepower because the shaft power is usually measured

by an absorption dynamometer or "brake." This is not the brake on the vehicle's

wheels but a testing device applied to the shaft. This instrument is applied

to stop or absorb the rotation of the output shaft and returns a value.

This standard is considered a far more reliable indication of effective

horsepower than the US HP.

In January of 1974, the compression was reduced in stages

to meet the first early European emissions requirements and the power dropped

to 143 bhp. At the end of 1976, the successor engine to first the Rover

V8 was introduced called the SD1 (Specialist Division 1) and power increased

again (12bhp) and reliability increased mightily.

In 1982 Stromberg carburettors replaced the SU's as Rover

again struggled to meet European emissions standards (calling for automatic

chokes controlled by water temperature) while still maintaining the power.

The Strombergs did the trick and horsepower held at 155bhp.

In 1984, Morgan offered a few new fuel-injected version

of the high performance "Vitesse" SD1 engine as an option. The Vitesse

engine, fitted with a new gearbox, was designed by Rover to be a

competition n motor. Power jumped dramatically on the first delivered

Morgan Vitesse EFI model produced without any compromise to the car saving

a cut away of the bonnet hinge to accommodate the plenum chamber of the

engine. This Plus 8, smaller and significantly lighter than today's version,

with the tubular manifolds and twin exhaust of the day (and Morgan's new

and first rack and pinion steering a standard), left the factory unmodified

with an amazing 205bhp and an estimated 248lbft. of torque at 4000 rpm..

It was capable of 0 to 60mph in 5.15 seconds. A limited number of

these optional Vitesse EFIs were produced in the period from September

1984 to early 1985 before the weight when up, the exhaust system became

a single pipe and engines were altered.

All Plus 8's were fuel- injected after January, 1987.

The power of the Plus 8's began to drop again in 1985

(190.4 bhp) and the torque tumbled to 198 lbft. with the introduction of

more emission safeguards embodied in the addition of catalytic converters,

the return to a single from dual exhaust. Structural changes gradually

increased the weight from 1884lbs to 2068lbs. Power fell slowly but continually

to 162bhp until the production in June of 1990 of a re-bored version of

the V8 increasing capacity from 3538cc to 3946cc. The horsepower climbed

back up to near 1985 standards and the torque was even better at lower

revolutions such that Autocar (May 1991) observed that the 1991 Plus 8

(0-60 in 6.1 sec.) showed its rump to a Porsche Turbo at any speed up to

80mph.

Presently, the Morgan website still lists its 3.9 litre

engine as producing 185bhp though this figure is dated and 190.3 bhp is

a more accurate figure. (The U.S 4.0 Plus 8 produces about 186.7bhp.) The

site also shows the 4.6 litre version but does not indicate performance

specifications or details but the Morgan dealers list the 4.6's power at

194.4bhp with 260ft/lb of torque. This too is probably inaccurate and an

appeal to Land Rover directly gives more plausible figures of 218bhp and

300 ft/lb.s of torque.

N.B. I have written a supplement

to this article including a power-to-weight analysis

in response to questions on this article.

N.B. Please note this article does not apply to

Plus 8's made for the U.S. market during the

period from 1976 to 1996. Please refer to an analysis

entitled Made

in the U.S.A (1971 to 1996).

J.E. Engineering, an advance British group specializing

in the Rover V8 performance engine has recently produced a 4.5 litre based

on the same engine block that reputably produces the better part of 300

horsepower and Rpi sells a 5.2 litre model that can be camshaft adjusted

to produce greater torque or horsepower according to your needs. The dyno

claims that the engine produces 334 bhp at 5500 rpm.

N.B. As a side note here, there has been much said about

the frightening mysteries of fuel injection. It is bunk. Fuel injection

systems were clouded with rumours by the manufacturers wishing you to service

at their dealers. The Plus 8 standard ECU (Electronic Control Unit) has

an inbuilt adjustment factor of 25%.

The Rover Vitesse / Buick Jetfire are amazing lumps. With

mild attention, they easily produce the magic one-for-one solution or one

horsepower per pound weight. For this reason, they are a popular

engine swap choice among hot rodders and kitcar builders. They collect

myths and fancy like few others. I will try to distinguish some from fact

from fiction.

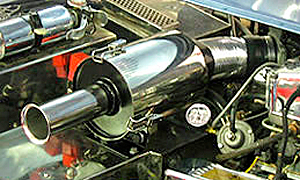

INSTALLING A BRANCH MANIFOLDS TWIN SYSTEM

There is no argument that an improved exhaust system is

good for the car. The engine will breathe better and engine temperatures

will drop. As the factory system installed is very restrictive, a free

flowing change is a fine adjunct to other major alterations to the engine.

A stainless or treated system is also prettier and maintenance

free.

However, exhaust is exhaust. It is not a prime ingredient

to combustion and happens after rather than before that fact. Aside from

mild adjustments to back pressure, the horsepower claims of exhaust system

sellers are simply ridiculous. You will be lucky to obtain an extra 2-3%

power from any exhaust system only but it will allow you to effect other

changes that will produce much more power than that. A twin big bore system

(2 diameter) is a start and will go well with flow-thru silencers (1976

style). The sound is simply incredible.

N.B. Remove your resonators. They are too far away

from the heat to properly clean themselves so they rust quickly, block

the airflow, reduce power and sound lousy. Please beware of the local emission

requirements if you choose to throw away your catalytic converters and

CHANGE THE RESISTOR (check out the Plus 8 page on "Cats").

Considering the price of a good full exhaust system from

manifolds to tailpipe, assume you will pay about $800.00 per horsepower

with the aesthetics unconsidered.

There is one codicil to this section that is the difference

between a single and dual exhaust system. For those of you unfortunate

to have a Morgan with a single exhaust system. Cars tested before and after

a switch from a small bore single system with manifolds to a dual large

bore system with tubular heddars have shown remarkable power increases

far beyond the minor percentages indicated above.

IMPROVING THE AIR FILTER

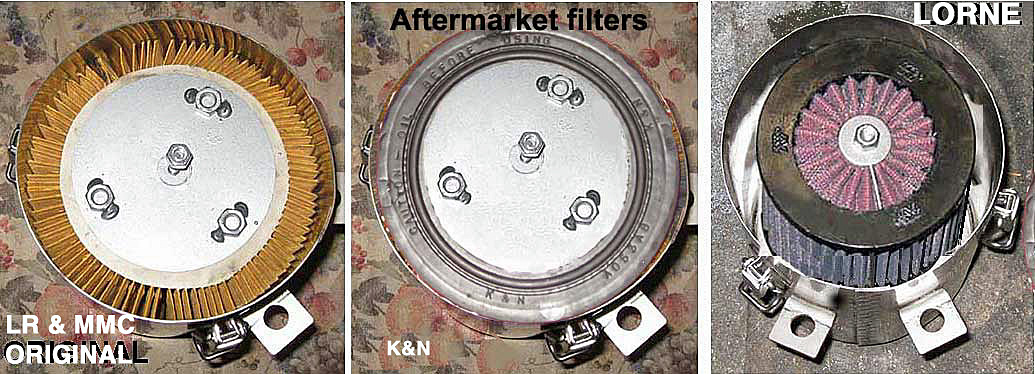

This is the best bargain for your horsepower dollar. The

standard paper filters, or even worse, foam filters restrict airflow

and thusly

the engine. Both dirty up over time causing further prejudice to your

power. K&Ns will clog over time as well, but that merely makes them

filter better until you clean and re-treat them with their oil again. I do mine once a year.

Off hand, I cannot think of a stock Plus 8 air filter, for carb or EFI, that does much for these engines.

K&N

produce high-capacity, low restriction washable

filters that fit without any modification. (Buy the

full K&N kit with cleaner and oil spray..you will need them) However, their Part No E-2350,

wrongly recommended by dealers for ALL EFI Plus 8s, is a disaster for the 3.9s and GEMS though adequate for the fappers (1984-1990) The cost is about $65.00 and they

can be ordered through any auto supply specialist. You can assume a 4-6% power increase for three minutes

of work on the Flapper +8s. But they create a bad blockage

for the Hotwires and GEMS. If you DO get it right, (read on) the power

imporvements can be substantial..but this fiddling is more complicated

than it looks. I highly recommend..if it is merely a

filter swap you want to do with stock 3.9s/4.0s/4.6s, that you stick

with the original paper filters..or do what I did below. Please remember, I dyno test everything.

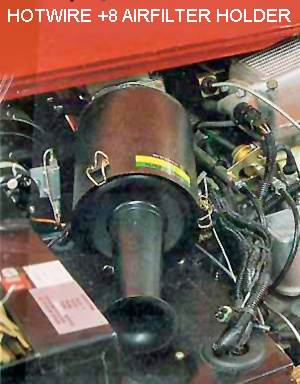

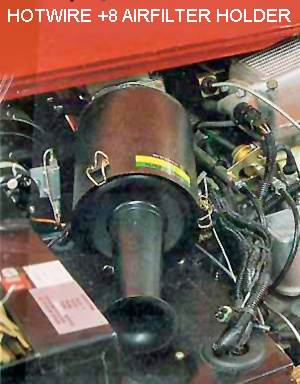

| WATCHPOINT I FOR HOTWIRE PLUS 8s: Please note that the Hotwire engine is very sensitive

to greater airflow. The stock fuel map was made too "lean" as is and more

air can make that worse. For that reason, any improvement with a Hotwire

must begin with better fueling. (new chip hopefully an Optimax or Tornado) |

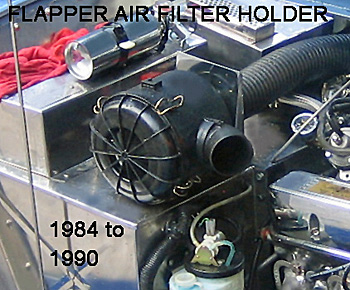

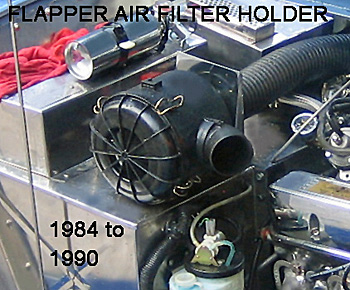

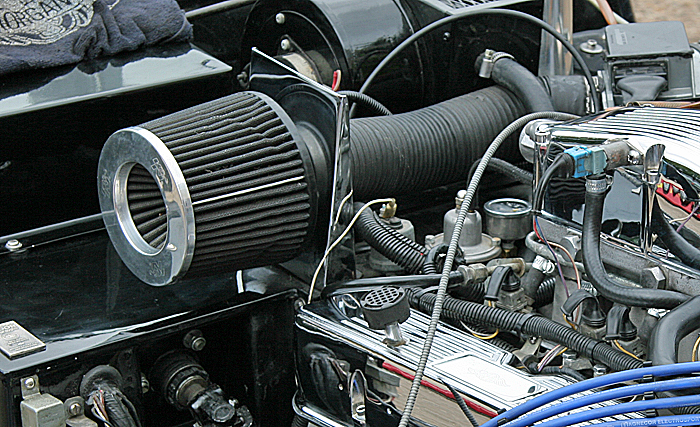

WATCHPOINT 2 FOR HOTWIRE PLUS 8s: The K&N commonly sold to fit the Hotwire trumpet air filter holder is a disaster. It works barely well enough for the earlier WATCHPOINT 2 FOR HOTWIRE PLUS 8s: The K&N commonly sold to fit the Hotwire trumpet air filter holder is a disaster. It works barely well enough for the earlier  American-football

black helmet used for the Flappers (pictured on the left) but is insane for the

Hotwires (to the left). The same filter creates an air block/dam and gratly reduces bhp. I discovered this

when I swapped out MY ugly football helmet for a pretty chromed trumpet

from the Factory. The Flapper air filter holder has its inflow access from its

side and, aside from cleaning or merely turning the filter so that the

air enters a still clean part of the filter, it is a partial improvement over stock. But using the same filter in the

Hotwire trumpet is nutty, but most owners and dealers do it without a thought. Pictures tell the story. American-football

black helmet used for the Flappers (pictured on the left) but is insane for the

Hotwires (to the left). The same filter creates an air block/dam and gratly reduces bhp. I discovered this

when I swapped out MY ugly football helmet for a pretty chromed trumpet

from the Factory. The Flapper air filter holder has its inflow access from its

side and, aside from cleaning or merely turning the filter so that the

air enters a still clean part of the filter, it is a partial improvement over stock. But using the same filter in the

Hotwire trumpet is nutty, but most owners and dealers do it without a thought. Pictures tell the story.

The internal

holding plate of the trumpet blocks the airflow, forcing it to try to

find a path in the tiny space between the circumference of the filter

and the filter holder. In the main, the air comes rushing down the horn

of the trumpet and slams into the filter holding plate...and the E-2350 K&N

makes this worse. It also comes from the Factory improperly angled, as can be seen from the picture. and influences the resultant idle's steadiness aside from thinning the mixture which is sad as the stock air/fuel mixture already produces high heat. Even

on my Flapper system, I noted a significant dyno difference (I tune my Plus 8 on a dyno). On the other hand, the football helmet is super ugly! Lastly, Hotwire air/fuel mixtures cannot be easily adjusted to compensate as can Flappers (with an adjustable fuel pressure gauge and/or the flapper tension spring inside its AFM.

WATCHPOINT 3: When

I got very into experimenting with my Plus 8s, I called the UK and

struck up a friendship with their technical design team for this area. I also spoke

with other air induction experts. They all told me that a differenty

sysdtem was not always a blessing. Seems the quantity of air must

be properly complimented by shaping the air correctly or that power and

more importantly, torque, can be prejudiced unless the conduit can be

"shaped" to enhance same and its steadiness. I confirmed their advice a

number of times on a dyno. For example, attaching a large free flowing

K&N type filter directly to the MAS/AFM can increase power while

making its delivery unsteady and, in the case, of the 3.9 (which

arrives with a too lean mixture) WAY TOO LEAN. (Plus 8s have been saved

from the ravages of these over lean mixtures and other problems by the

fact that their load is so light.) Additionally, suspended cone filters

produce an unsteady flow as well.

|

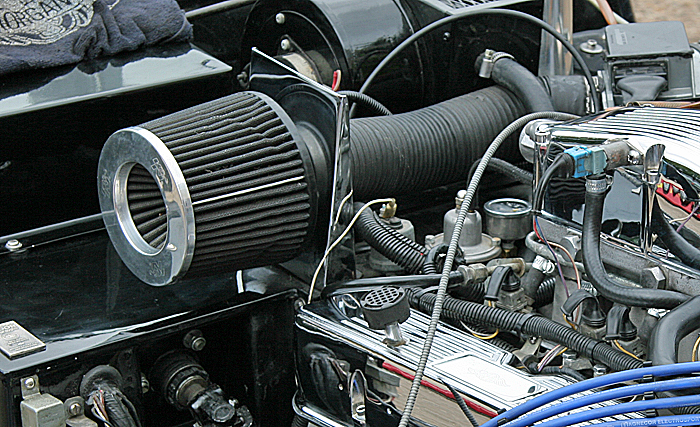

CONE FILTERS:

I like them. But they do not shape the air flow as well as the right

air filter holder and conduit. And, on an enhanced Plus 8, after a

certain point of  tuning

and capacity, they make (at least for me) an unacceptable induction

howl. Admittedly, this occured on my Canadian Plus 8, a lightened

Factory one-off designed by yours truly with the Works and many Morgan celebrati and powered by a tuned 4.8 LR V8 (increased

capacity from Omega pistons) and increased air flow due to Super Flares

trumpets and a larger Bosch L-Jetronic AFM from Jaguar. I found

the induction noise embarrassing..though tuning

and capacity, they make (at least for me) an unacceptable induction

howl. Admittedly, this occured on my Canadian Plus 8, a lightened

Factory one-off designed by yours truly with the Works and many Morgan celebrati and powered by a tuned 4.8 LR V8 (increased

capacity from Omega pistons) and increased air flow due to Super Flares

trumpets and a larger Bosch L-Jetronic AFM from Jaguar. I found

the induction noise embarrassing..though  the power & torque did go

up while both became unsteady. I do like engine rumble and exhaust

tone..but those, on my car, are controllable by my throttle foot. the power & torque did go

up while both became unsteady. I do like engine rumble and exhaust

tone..but those, on my car, are controllable by my throttle foot.

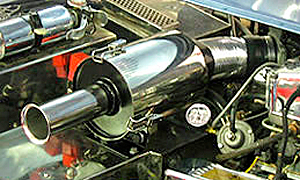

Interestingly, I tried the cone filter on my UK Plus

8..which is set up a bit differently. It is a lower (8.5) compression

4.6, but also with greater airflow and on a fast road cam and Jag AFM that

puts out significantly more power than stock but 42 bhp less than the

CDN car. The induction noise disappeared on this car. Image to the right. For

the holding bracket, I had one made in polished stainless steel at the local machine shop.

The image was posted to eMog in 2005 and there have been many who

copied successfully the idea since.

SOLUTION:

I

finally found a filter for CDN car that touched all the right bases and that the dynometer saluted at. :) I

have to thank the Factory Parts department in Malvern, who tempted me

with a chromed 3.9 trumpet they had!!!! Land Rover changed to the

trumpet when the discovered the back helmet restricted airflow. With the right inverted K&N cone filter, my problems with Canadian car were resolved

1. It produces as much power as the cone filter

2. It has a shaped flow and a much steadier power/torque

3. It fits into the original 3.9 Trumpet filter holder and looks like it belongs on a Morgan.

4. It allows for both indirect

AND direct airflow and eliminates the air dam, not creating the problems that a huge filter

directly on the conduit (without a filter box).

| LOW AIR INTAKES:

Avoid

forced air systems that pick up debris and force feed it to your

engine. This might make sense for racers who retrict their Morgan usage

to carefully prepared and cleaned race tracks, but make NO sense for a

road-going Morgan. I have seen or opened up a fair number of Morgan

engines and you would be appalled at their innards after a some time

with a low intake. A racer's priority is to win. However, a mogger's priority is

to have a car capable of meeting all conditions WITHOUT A RACER'S SUPPORT

INFRASTRUCTURE A COUPLE OF HUNDRED METERS AWAY and surviving these

conditions with aplomb. |

|

ADVANCING THE IGNITION TIMING (for all Plus 8s save for GEMs)

Another goodie! But you have to be careful. Dyno tests

have shown a 12-16 bhp boost is possible by advancing the engine timing up

to 4/5 degrees from the stock 6 BTC.

The care comes in for three reasons.

A) You might have trouble with this timing with consistently

hot weather ie. 95F+. So time will tell you the best advance.

B) You have to use premium gas (octane 93+ [aka 97/8 in Europe]) or better still octane

boosted premium petrol;

C) Your emissions may increase which may cause a problem

in annual testing jurisdictions.

The best way to try this is to increase the timing one

point at a time and test drive the machine up a familiar mild long slope

in a higher gear (i.e.4th) after each adjustment. When the car starts to

"ping" reduce one point and there you are!

Costs per horsepower are 0...only time and optionally

the ongoing factor of premium gas and/or octane boosters.

PERFORMANCE CHIP (for Hotwire and GEMs Plus 8s)

Your ECU can be reprogrammed with a performance chip,

a new fluel map. We have had great success with Mark Adams Tornado chips for the 3.9 and his chips for the GEMS plus 8s are a life

saver. These specialist chips deal with the mid-range power slump of the

hotwire Plus 8s and improve gas mileage. For the GEMs, they solve a slew

of issues. Power gains here are from 20-30 horsepower and costs of

the performance chip are approximately $600.00 or $20-$30 per horsepower.

OTHER POSSIBILITIES

There

are scores of other improvements to performance

that are possible with this marvellous engine. There is, however, a Law

of Diminishing Returns. Each extra horsepower costs more and

presupposes

other modifications or compromises. One should assume the maximum hp

one

can coax from and injected 3.5 or 3.9, while still being able to

smoothly

drive it to the pharmacy, is in the neighborhood of 265 hp. A carb

version can go as high 215 hp without sacrifice of a smooth idle.

There are three facts to consider. Firstly, full performance

engines run well at mid and high revolutions and poorly at low. That type

of power will not help you unless you are a racer. Secondly, most power

adjustments are concurrent applications not cumulative. In other words,

many power increasing modifications presume others will also be done so

that you can assume a power gain from each but only in concert. Lastly,

each improvement puts a strain on the whole system and a previously unnoticed

weak area can "pop" up to give you headaches.

A quick overview of other changes;

1. UPGRADE THE DISTRIBUTOR,

COIL, IGNITION AMPLIFIER AND LEADS

(all models except for GEMS)

Options here include a Mallory Unilite (NOT a Mallory

Dual Point) with Vacuum Advance. See other parts of this Manual for full

instructions. ALL Rover distributors deliver a degraded, inferior spark.

A Mallory cures that.

DISTRIBUTOR ISSUE

(for all Plus 8s except GEMs)

The Lucas Distributors/Ignition set up are all

lousy..according to any osciliscope testconfiguration of the Morgan

front end and the

placement of the distributor make for water access into the

distributor.

Inevitably, this leads to rust within the distributor, a poorer spark,

poorer combustion and trouble during damp conditions. All this leads

people

to believe that the Lucas distributor is the culprit. The solution is

quite

simple. Clean your distributor thoroughly and regularly. Be careful, as

more than one RR owner has found the rotor arm stuck fast to the

distributor

shaft when trying to replace it during routine maintenance. Pulling up

too hard on the rotor can break the plastic C-clip that holds the upper

and lower parts of the distributor drive shaft together. If it is

stuck,

try tapping DOWN with a screwdriver or chisel and break it into pieces

to get it off the shaft.

IGNITION LEADS

The stock leads are not great. Changing them to Magnecor

"Blues", Reds or "Blacks" will serve the power goal well. There is no bhp difference between the colors. I have tried them all and now use blacks.

IGNITION AMPLIFIER

(for all Plus 8s except GEMs)

On all distributors from 1976 to 1982 and from 1986 on,

the ignition amplifier module (on the outside of the distributor) can give

trouble. This item converts the magnetic impulses from the distributor

into a larger signal to fire the primary circuit in the ignition coil.

Often, the heat build-up under the hood will eventually cause this amplifier

module to fail intermittently, stalling the engine. The faulty unit can

become so sensitive to temperature that even a minute or two of cooler

air provided by opening the hood can get it working again.

2. INSTALL AN ADJUSTABLE RISING

RATE FUEL REGULATOR

(for all Plus 8s except GEMs)

This cute little item increases your fuel pressure when

you are accelerating at a faster curve than stock and is adjustable as

well..thereby effectively "reprogramming" the fueling on Flapper engines.

With Hotwire Sytsems , one still gets the acceleration boost and one can

trim the pressure to correct parameters. As well, Hotfire systems are only

closed loop until 3000 rpm. That means that after this point, the lambdas

will not null out increased fueling. Set the pressure to 40-41lbs and see

the difference.

3. INSTALL A WEBER CARBURETTOR

(for carb'ed Plus 8s only)

For carb'ed models, try the Weber/Edelbrock 4 barrelled

500 CFM. This carb will fit into a Morgan using an Offenhauser "low rider"

intake manifold. Some Plus 8s can fit the Edelbrock Performer intake. The

Weber is easy to set up and easy to maintain, rejet and rebalance unlike

the commonly used 4 barrelled Holly 390 CFM.

| (The Holly venturi size is too small for a heavy breathing

engine resulting in additional vacuum, which in turn confuses the vac secondary.

Its design also forces you to spend too much time assembling and disassembling

the thing to get it right. All to no end or a sacrifice in power in comparison

to the better designed Weber.) |

4. INSTALL PERFORMANCE INLET MANIFOLD (for carb'ed Plus 8s only)

see the Offenhauser from Edelbrock above. All intake

manifolds can also have the ports widened and polished for better airflow.

See manual for that.

5. INSTALL A PERFORMANCE

CAMSHAFT

There are many made for this engine and each have advantages

and disadvantages depending what you expect from your motor. Check out

the lines of Oselli, Kent, Piper, Crane, J.E. Motors and Crower. (The writer

prefers the Piper 270-272). Calculate 0-25 bhp depending on which of the

"reasonable" camshafts you choose.

It is wise to be very careful with the choice you make

here. It is not simply of decision of how much power you want but "where"

you want it. A cam developing large amounts of power at high rev's are

good for those of us who specialize in Autobahn racing in a straight

line with hands clutching the wheel and a crazed grin frozen on one's face

for hours. On small country roads this same camshaft will perform poorly.

6. UPGRADE THE TIMING CHAIN

Install a duplex venier timing chain. (This is an eventual

must anyway as the standard Rover chain stretches very badly over time.)

7. STROKE THE ENGINE

This can be done with seasoned 3.5 or the 3.9 all the

way up 5.2 litres. However, if you are going this far.. why not buy

a new lower engine block at a much cheaper price? New 4.6 blocks, with

their structural improvements and better oilways, can be had for 1500 USD

making stroking a less than ideal solution. The parts of the engines remain

interchangeable. The 4.6 can itself be modified to a capacity of 5.5L

This can be done with seasoned 3.5 or the 3.9 all the

way up 5.2 litres. However, if you are going this far.. why not buy

a new lower engine block at a much cheaper price? New 4.6 blocks, with

their structural improvements and better oilways, can be had for 1500 USD

making stroking a less than ideal solution. The parts of the engines remain

interchangeable. The 4.6 can itself be modified to a capacity of 5.5L

8. INTAKE TRUMPETS

(EFIs only)

The intake can be modified to take larger trumpets or

one can use carbon fiber Super Flares trumpets.

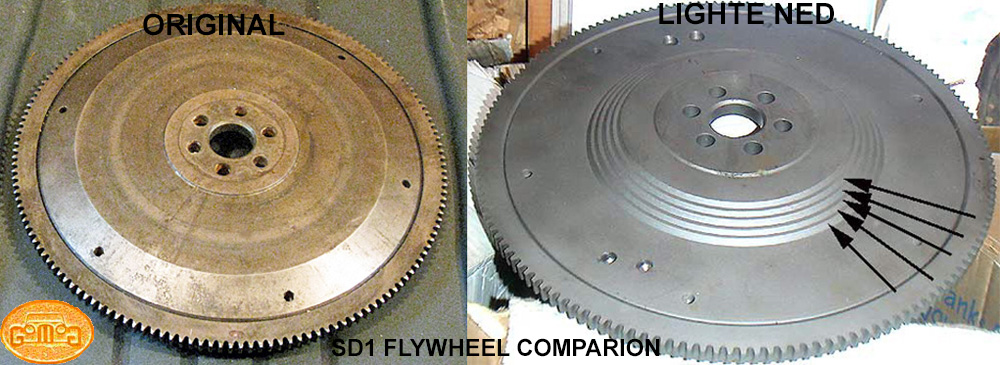

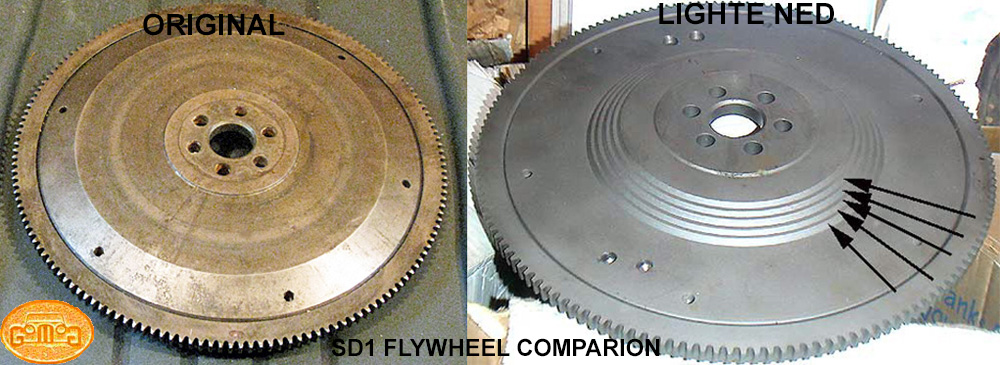

9. LIGHTENING THE FLYWHEEL

There are many other possibilities. For those of you with

a fascination for power or a yen for the "fastest" Morgan, I strongly suggest

that you adopt a "buyer beware" attitude. A good automobile is a

well harmonized compromise of many parts. Also, never believe the claims

of your "expert". No one knows the true performance of an engine without

a proper dyno testing. If you have not done this, your claims to

horsepower are most likely wishful thinking.

Come to think of it though, there is nothing wrong with

wishful thinking. Costs are nothing, installation time is negligible

and horsepower gains are unlimited.

Should you wish further information, I would suggest you email

me. There

are many other possibilities. For those of you with

a fascination for power or a yen for the "fastest" Morgan, I strongly

suggest

that you adopt a "buyer beware" attitude. A good automobile is a

well harmonized compromise of many parts. Also, never believe the

claims

of your "expert". No one knows the true performance of your engine

without

a proper dyno testing and a dyno is merely the best tuning device, not

an absolute comparison for all other engines except tested on the same

dyno.

Come

to think of it though, there is nothing wrong with wishful

thinking. Costs are nothing, installation time is negligible

and imagined horsepower gains are unlimited.

WATCHPOINT 2 FOR HOTWIRE PLUS 8s: The K&N commonly sold to fit the Hotwire trumpet air filter holder is a disaster. It works barely well enough for the earlier

WATCHPOINT 2 FOR HOTWIRE PLUS 8s: The K&N commonly sold to fit the Hotwire trumpet air filter holder is a disaster. It works barely well enough for the earlier  American-football

black helmet used for the Flappers (pictured on the left) but is insane for the

Hotwires (to the left). The same filter creates an air block/dam and gratly reduces bhp. I discovered this

when I swapped out MY ugly football helmet for a pretty chromed trumpet

from the Factory. The Flapper air filter holder has its inflow access from its

side and, aside from cleaning or merely turning the filter so that the

air enters a still clean part of the filter, it is a partial improvement over stock. But using the same filter in the

Hotwire trumpet is nutty, but most owners and dealers do it without a thought. Pictures tell the story.

American-football

black helmet used for the Flappers (pictured on the left) but is insane for the

Hotwires (to the left). The same filter creates an air block/dam and gratly reduces bhp. I discovered this

when I swapped out MY ugly football helmet for a pretty chromed trumpet

from the Factory. The Flapper air filter holder has its inflow access from its

side and, aside from cleaning or merely turning the filter so that the

air enters a still clean part of the filter, it is a partial improvement over stock. But using the same filter in the

Hotwire trumpet is nutty, but most owners and dealers do it without a thought. Pictures tell the story.  tuning

and capacity, they make (at least for me) an unacceptable induction

howl. Admittedly, this occured on my Canadian Plus 8, a lightened

Factory one-off designed by yours truly with the Works and many Morgan celebrati and powered by a tuned 4.8 LR V8 (increased

capacity from Omega pistons) and increased air flow due to Super Flares

trumpets and a larger Bosch L-Jetronic AFM from Jaguar. I found

the induction noise embarrassing..though

tuning

and capacity, they make (at least for me) an unacceptable induction

howl. Admittedly, this occured on my Canadian Plus 8, a lightened

Factory one-off designed by yours truly with the Works and many Morgan celebrati and powered by a tuned 4.8 LR V8 (increased

capacity from Omega pistons) and increased air flow due to Super Flares

trumpets and a larger Bosch L-Jetronic AFM from Jaguar. I found

the induction noise embarrassing..though  the power & torque did go

up while both became unsteady. I do like engine rumble and exhaust

tone..but those, on my car, are controllable by my throttle foot.

the power & torque did go

up while both became unsteady. I do like engine rumble and exhaust

tone..but those, on my car, are controllable by my throttle foot.

This can be done with seasoned 3.5 or the 3.9 all the

way up 5.2 litres. However, if you are going this far.. why not buy

a new lower engine block at a much cheaper price? New 4.6 blocks, with

their structural improvements and better oilways, can be had for 1500 USD

making stroking a less than ideal solution. The parts of the engines remain

interchangeable. The 4.6 can itself be modified to a capacity of 5.5L

This can be done with seasoned 3.5 or the 3.9 all the

way up 5.2 litres. However, if you are going this far.. why not buy

a new lower engine block at a much cheaper price? New 4.6 blocks, with

their structural improvements and better oilways, can be had for 1500 USD

making stroking a less than ideal solution. The parts of the engines remain

interchangeable. The 4.6 can itself be modified to a capacity of 5.5L