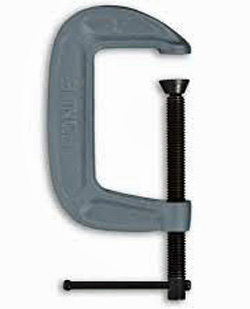

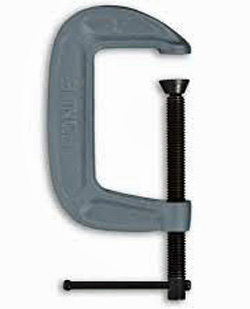

| WATCHPOINT: You may have to remove the floorboards under the seats to create access for the G Clamps. Remember, it easier and faster to have a clear space to work with than thinking you are saving time but not doing so. |

8. Clamp

the front of the leafspring to the chassis with several G clamps.

8. Clamp

the front of the leafspring to the chassis with several G clamps.  These thingies are a bit tricky, but easy enough after you know the watchpoints.

These thingies are a bit tricky, but easy enough after you know the watchpoints. | MMC Part Numbers | Description | |

| MRS0320 | 5 Leaf SALISBURY GKN Axle & 7 Leaf BTR Axle | 140mm |

| MRS0322 | 4 Leaf 4Str BTR Axle Long | 130mm |

| MRS0323 | 4 Leaf Short with Anti Tramp Bar 7/07 to 1/10 | 90mm |

| MRS0324 | 4 Leaf Long with Anti Tramp Bar 7/07 to 1/10 | 3/8 UNF |

| MRS0325 | 5 Leaf BTR Long | 140mm |

| MRS0326 | 4 Leaf Short without Anti Tramp Bar Short | 7/16unf |

| MRS0327 | 4 Leaf Long with Anti Tramp Bar | 7/16 unf |

| MRS0330 | 6 Leaf SALISBURY Axle Long | 150mm |

| MRS0335 | 6 Leaf Rear Spring BTR Axle Long | 150mm |

| MRS0340 | 7 Leaf Rear Spring SALISBURY Axle | |

| MRS0370 | Lugged 5 Leaf Springs | |

| MRS0380 | 6 Leaf Rear Spring SALISBURY Axle | 150mm |

| MRS0390 | Lugged 7 Leaf Rear Spring SALISBURY Axle |

| WATCHPOINT: After more than 25 years and 260,000 miles mogging different continents, provinces, States, ComtÚs, DÚpartments

and nations, I have come to conclusion that Morgans can be made to be

the most reliable vehicles I have ever encountered. It costs very

little to assure that..just wisdom and prudence. Owners should remember

the GoMoG RULE of BREAKAGE: Morgan

Breakage happens almost exclusively during your most precious Morgan

time, when you are using it! In other words, don't ruin the

best moments of your life (whether a weekend drive or a holiday) by

ignoring such stuff. In this case, it is nothing to swap in adequate

u-bolts or tell your service fellow to do so. As a rule, he is supposed to be checking/changing your u-bolts at every service anyway. P.S. If someone tells such stuff is a waste of time, they probably park their Morgan permanently on their coffee table with extremely limited usage, if any. Wisdom is free. |