Background by Lorne Goldman

The braking system is the most important system in your car. If your brakes fail, the result can be disastrous. Brakes are actually energy conversion devices, which convert the kinetic energy (momentum) of your vehicle into thermal energy (heat). When you step on the brakes, you command a stopping force ten times as powerful as the force that puts the car in motion. The braking system can exert thousands of pounds of pressure on each of the four brakes. Since 1968 (Plus 8s) or 1978 (all cars) Morgans have been fitted with dual circuit master cylinder systems, with each the front and the rear wheels braked by a separate subsystem. They became mandatory in 1967 in the USA and by 1976 in Europe. If the front or rear brakes failed, a car still had braking from the other end. The tandem units are infinitely safer than earlier, single circuit braking systems. I counsel you to ignore or caution anyone who suggests a single circuit system be maintained rather than replaced.

But the basic process of converting a vehicle's momentum into (wasted) heat energy has not changed since the days of the horse and buggy. To stop a horse drawn carriage, the driver would pull on a lever which would rub on the wheel.

The brake system is composed of the following basic components: The "master cylinder" which is located under the hood, and is directly connected to the brake pedal, converts your foot's mechanical pressure into hydraulic pressure. Steel "brake lines" and flexible "brake hoses" connect the master cylinder to the "slave cylinders" located at the wheel. Brake fluid, specially designed to work in extreme conditions, fills the system. "Shoes" and "pads" are pushed by the slave cylinders to contact the "drums" and/or "rotors" (discs) thus causing drag, which (hopefully) slows the car.

Tandem (aka Dual) Versus Single Circuit Master Cylinders "Should I upgrade my brakes" is THE common question at most Morgan events or the GoMoG help Line for owners of older Morgans. Yet these cars had excellent brakes by the standard of their day and with their low weight, Morgans don't need much braking. However, there is a element that may point to a need for a SAFER brake system.

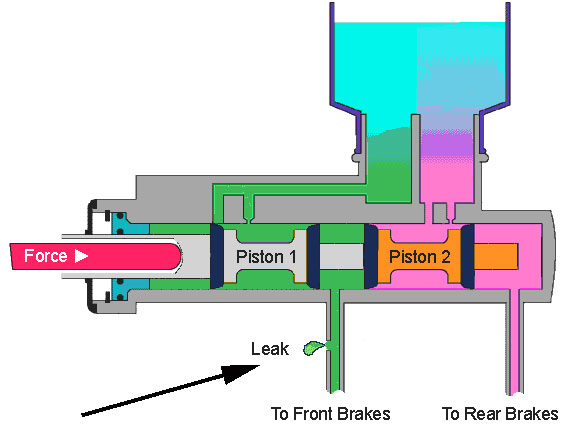

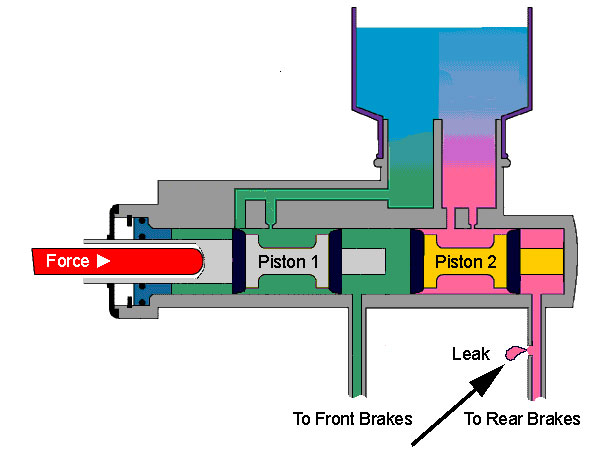

Most Morgans made before the 1970 will have single (piston) master cylinders (MC). A leak in that systems brake plumbing (not uncommon with any system), happening anywhere on the car, can render these brakes completely inoperable, leaving one to rely on the Morgan hand brake and luck. If you have one of these earlier cars, upgrading to a tandem master cylinder is very wise. You see a tandem master cylinder has TWO (not one) two pistons operating in tandem (one after another) in a common piston chmber and bore as shown in the diagrams.

N.B. In rear wheel drive cars (Morgans) the piston and its MC outlet that's located closer to the pedal (piston 1) activates the front brakes. The fluid pressured by this piston (1) also causes the movement of a second piston (piston 2). (Piston 2 applies the cars rear brakes).

A LEAK IN THE FRONT will not affect rear brakes and a leak at the rear will not affect front brakes. As can be seen from the first diagram, if a leak develops in the front brake system, piston 1 will move forward until it contacts Piston 2 (and its seal which isolates the hydraulic effect). Force from the brake pedal will be transmitted mechanically to piston 2 via piston 1. Braking performance will be compromised, but the rear brakes will still be functional. The pedal will need to travel further than normal to fully engage the rear brakes. Braking will be difficult iof only the rears are working but at least you HAVE brakes.

A

LEAK IN THE REAR will cause piston 2 to move forward until it contacts

the closed end of the master cylinder housing at the very front. When this

make piston 2 immobile, all the pressure of fluid between the two pistons

will naturally be applied to the front brakes. Again, overall braking will

be compromised, but the front brakes will still be functional providing

the extra pedal travel is available. In other owrds, the pedal will need

to travel further than normal to fully engage the front brakes. Many inattentive

or inexperienced drivers will simply continue driving without rear brakes

functioning despite longer pedal travel and longer stopping distances.

It is for this reason that cars are fitted with the brake failure warning

light which detects a loss of brake fluid at the reservoir.

A

LEAK IN THE REAR will cause piston 2 to move forward until it contacts

the closed end of the master cylinder housing at the very front. When this

make piston 2 immobile, all the pressure of fluid between the two pistons

will naturally be applied to the front brakes. Again, overall braking will

be compromised, but the front brakes will still be functional providing

the extra pedal travel is available. In other owrds, the pedal will need

to travel further than normal to fully engage the front brakes. Many inattentive

or inexperienced drivers will simply continue driving without rear brakes

functioning despite longer pedal travel and longer stopping distances.

It is for this reason that cars are fitted with the brake failure warning

light which detects a loss of brake fluid at the reservoir.

UPDATING THE MC

To update from a single to tandem brake master cylinder, one can try to source the .75" bore Girling unit used from the 1970s to 1993. This will be very diffiuclt as the unit is obsolte now and no longer in prduction. When they WERE available before 2004, they were very dear, sold by the MMC for 335£ ($550 USD) each. However, there are alternatives. The .75 bore seems to be a happy compromise but it is bigger than the earlier single master. The larger diameter piston displaces more fluid per unit of travel so less pedal travel will be required to create the same effect at the wheels. Pedal effort will also be greater for the same effect. However, so far, no one doing a swap to .75" has been unhappy with the difference. If brake effort is a problem, owners can consider the present MMC master cylinder with its integrated booster.

See also: Morgan

Brake History (1978-2009)

Master Cylinder (pre-1993)

by Lorne Goldman

The master cylinder displaces hydraulic pressure to the rest of the brake system. It holds THE most important fluid in your car, the brake fluid. It actually controls two separate subsystems which are jointly activated by the brake pedal. This is done so that in case a major leak occurs in one system, the other will still function. N.B. We do NOT recommend the use of single circuit masters used on pre-1978 cars. Their lack of any redundancy or safety measures make them dangerous. The two sub-systems should be supplied by separate fluid reservoirs or they may be supplied by a common reservoir that is is split inside. The systems are divided front and rear. When you press the brake pedal, a push rod connected to the pedal moves the "primary piston" forward inside the master cylinder. The primary piston activates one of the two subsystems. The hydraulic pressure created, and the force of the primary piston spring, moves the secondary piston forward. When the forward movement of the pistons causes their primary cups to cover the bypass holes, hydraulic pressure builds up and is transmitted to the wheel cylinders. When the brake pedal retracts, the pistons allow fluid from the reservoir(s) to refill the chamber if needed. This is the system Morgan used from 1970s on.. a Girling unit from 1978-1993 and then a AP Racing system with an integrated booster.

On later models. if the brake light comes on, the fluid level in the reservoir(s) should be checked. If the level is low, more fluid should be added, and the leak should be found and repaired as soon as possible. Be sure to use the RIGHT BRAKE FLUID (see brake fluids and the note on Silicone fluid).. Switching to or from silicone brake fluid can contaminate the system. If this occurs, ALL of the seals in the brake system will need replacement, and that is usually a VERY expensive operation. The tandem master cylinder was devised to avoid the possibility of all the brakes of a vehicle being put out of action by a fracture in the pipe line leading to one brake cylinder. There are two pistons in the tandem master cylinder, in line with each other.

Difficulty in fitting brake lines to the master is due to the ends of the steel flares having been squashed by over tightening. Girling calls for a tightening torque of 15 inch lbs. The tube nuts should be able to be easily threaded all the way into the master cylinder ports by fingers alone.Replacement for the Morgan Dual Master Cylinder (pre-1993)

Many with single

master cylinders have switched, for safety reason, to the later Tandem Masters (.75 bore). Sadly,

the Girling unit used by Morgan from 1978 to 1993, is no longer available

and was very expensive when it was. One option that has been tried and tested

by many is the one used in the Subaru "BRAT" (aka the SHIFTER in the UK or

the BRUMBY in Australia). It will require adapters and a bit of curving of

the brake tubing and possibly relieving the entry hole into the car a bit

but it is a close match to the Girling and much cheaper new. It was used

on the following vehicles;

Many with single

master cylinders have switched, for safety reason, to the later Tandem Masters (.75 bore). Sadly,

the Girling unit used by Morgan from 1978 to 1993, is no longer available

and was very expensive when it was. One option that has been tried and tested

by many is the one used in the Subaru "BRAT" (aka the SHIFTER in the UK or

the BRUMBY in Australia). It will require adapters and a bit of curving of

the brake tubing and possibly relieving the entry hole into the car a bit

but it is a close match to the Girling and much cheaper new. It was used

on the following vehicles;

SUBURU BRAT MASTER

CYLINDER

by Lorne

Goldman

SUBARU (12) 1978-1981

1600 (2) 1978-1979

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

1600 DL (2)

1978-1979

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

1600 FE

(1) 1979-1979

1979 H4-1595cc 1.6L

2 BBL Vin EA71

1600 GF

(2) 1978-1979

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

BRAT (5) 1978-1981

1981 H4-1781cc

1.8L 2 BBL Vin EA81

1980 H4-1595cc

1.6L 2 BBL Vin EA71

1980 H4-1781cc

1.8L 2 BBL Vin EA81

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

CROSS REFERENCE PART NUMBERS

REPCO P8970

ACDELCO US 18M112

AIMCO M900304

RAYBESTOS MC39170

| SUBARU UPDATE!!! |

| PROPORTIONING WATCHPOINT

(1978-1993) : Savvy owners have discovered that the original Girling MC (1978-1993)

provides a 50-50 division of hydraulic force to front and rear brakes. This

is very unusual for a front disk/rear drum set up. We know of three cures.

A. One can use a proportioning valve, (fitting it at one of the rear junctions seems easiest) and adjust the proportion until the car is under complete control (57-60 % bias in favor of the front) or, if you are the mathematical sort, you can use a brake bias calculator. B. One can use the later AP Caparo (originally Lockheed) June 1993-on Master Cylinders which are proportioned correctly. However, these come with a booster which can make fitting difficult as the reservoir can abut the exhaust too closely requiring a remote reservoir. C. Fit the Subaru MC above which comes with proper proportioning. The result is a happy one. The rear brakes stop locking first making the rear end of the car more controllable under braking. Take note, brakes are not an area for mistakes. If you have ANY concerns, use the services of a competent professional. That being said, even a Morgan pro not be aware of the proportioning issue. |

Master Cylinder Bore Size

by Lorne Goldman

The question of MC bore size has become more important as other Tandem master cylinders have being replacing the earlier (and dangerous) single cylinder brake systems Morgan used. The bore size for pre-July 1993 brakes is .75 (The power assist system used after is 20.6mm [.8125"])

Decreasing MC bore size will decrease your pedal effort and increase your pedal travel. Conversely, a larger bore in your master cylinder will, all other components being the same, increase your pedal effort and decrease your pedal travel. As with some other brake parts purchases, this comes down to your preference for how the brakes "feel" under foot when you are driving...but Morgan owners want to retain the original feel all while significantly increasing their safety.

Two closely fitted pistons are located inside the dual circuit master cylinder. The inner part of the piston is pressed against a rubber primary cup that prevents fluid from leaking past the piston. The outer end of the piston is pressed against a rubber secondary cup. This prevents the fluid from getting out of the master cylinder. The inner piston also has several little bleeder ports; these pass through the head to the base of the primary cup. Both of the piston assemblies are in the cylinder, and are kept there by a stop plate (or snap ring) in the end of the cylinder. A push rod, connected to the brake linkage, applies pressure to the pistons.

Though master cylinder kits are sold to repair leaking cylinders and replace all the rubber components, it is commonly accepted that the master cylinder is better completely rebuilt with the cylinders re-shaped or replaced as new when there is a problem. A Morgan master cylinder is normally good for 40,000 miles before a rebuild. have the MC sleeved with stainless steel and it will become a "forever" component requiring only rubber part replacement at long intervals.

Please note that when

replaced the Master Cylinder itself MUST be "bled" of air bubbles. This is

done with hoses attached to the cylinders brake lines and looped back into

the reservoir. By pumping the brakes, the hoses will expel bubbles into the

fluid in which the other hose ends are submerged.

Attaching the Brake Lines to the Master Cylinder

The ends of the NUTS that push the flares up against the sealing surfaces in the wheel and master cylinders are what get mushroomed out and that prevents the threads on the nut from getting in far enough to engage the threads in the cylinders. If you look at the nuts, the ends closest to the flared end of the brake pipe have no threads. That portion of the nut is supposed to be smooth and straight. That is the area that normally gets mushroomed out from over tightening. That is the area that needs to be filed down so that its diameter is smaller than the inside diameter of the threads. DO NOT FILE THE ACTUAL FLARED END OF THE BRAKE LINE ITSELF. If the end of the nut is the proper diameter and the threads on the nut and in the cylinder are in good shape, and the nut is carefully started STRAIGHT into the threaded hole of the cylinder, then it should screw right in with your fingers until it bottoms against the flared end of the brake pipe. Then just snug it down with a 7/16 line wrench and check for leakage with pressure applied to the brake pedal.