BRAKE

REACTION BARS

by Gerry Willburn and Lorne Goldman

(Lorne) Smart trad owners all use them, the Factory install them on request....but why?

Too many owners, don't understand them. They put them on because someone tells them to. As I an amateur, myself, I dislike that. One

of the great gifts of Morgan ownership is that they can lead to

mechanical and electrical understanding that can massively benefit your

life and not merely your Morgan (s).

Trad

Morgans are not perfect..though they CAN very close to be so with a bit

of common sense and this Manual. Auto mechanics is not magic...and the

experience of long mileage can reveal ALL. My Morgans have become the

most reliable vehicles I have ever known

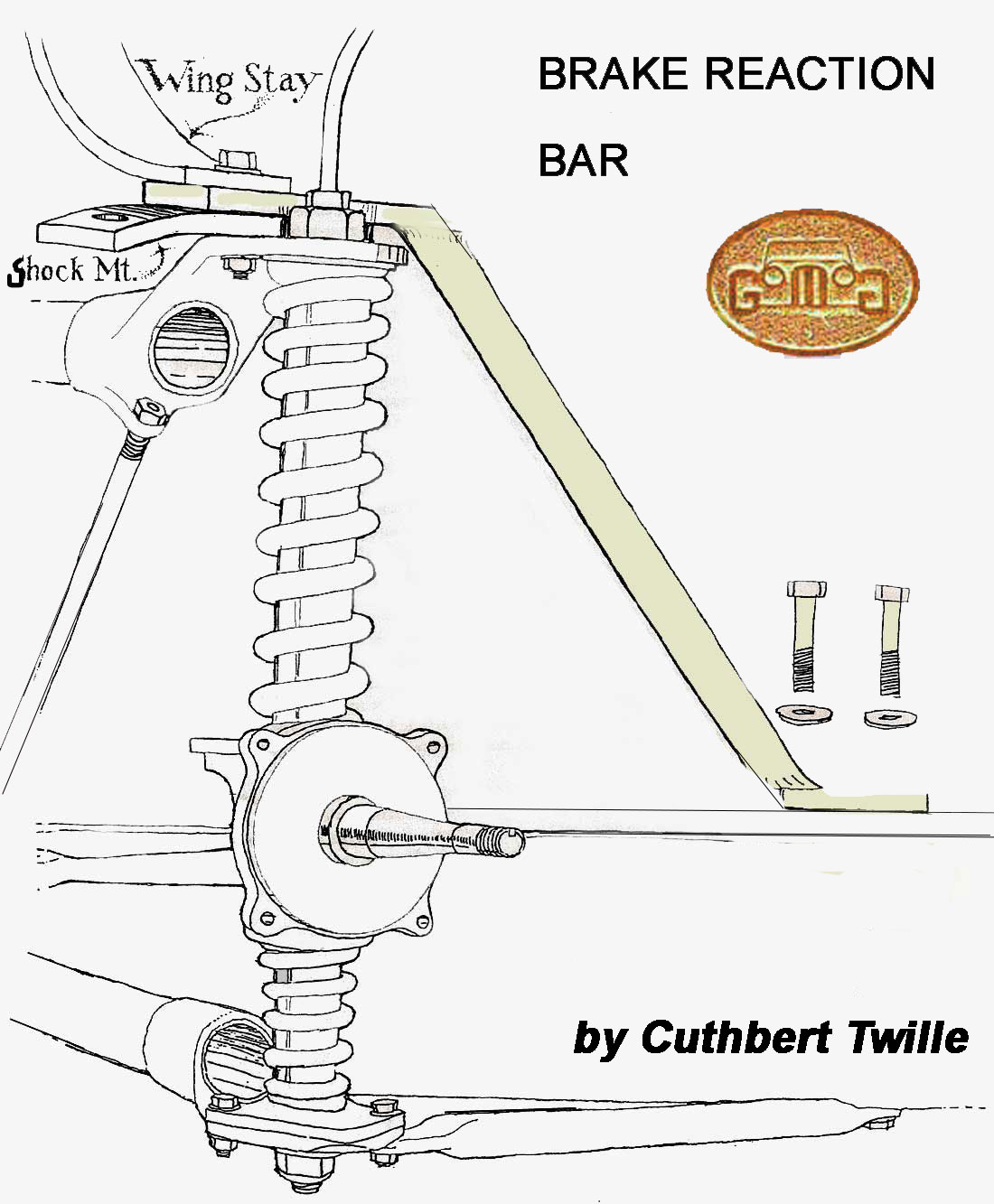

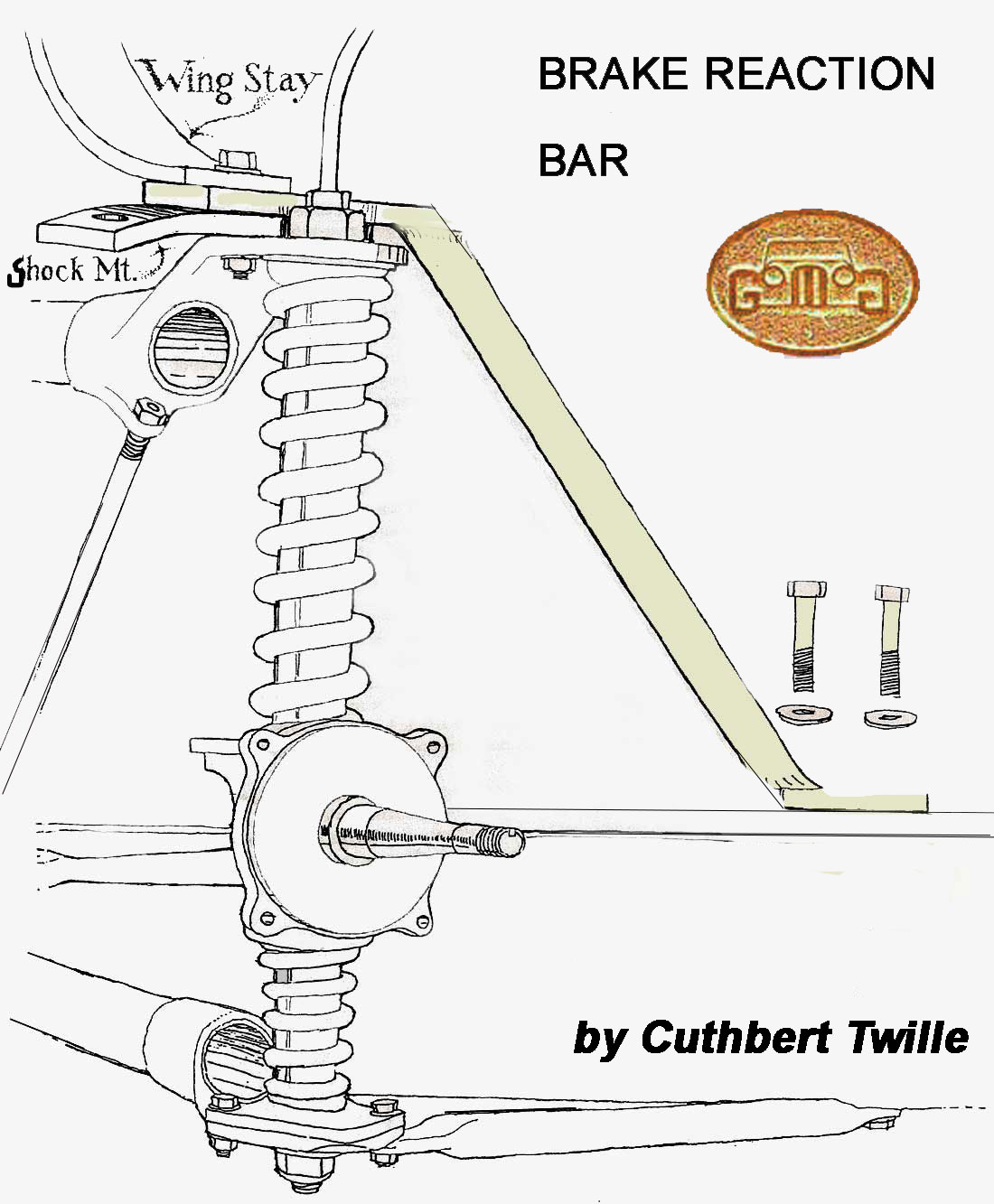

Brake reaction bars (or Upper Cross Axle Braces, as

they were once known) address the movement of the top of the suspension

pillar and locates it with respect to the chassis. There is already

a brace from the bottom of the pillar back to the chassis to locate that

end. However, under hard braking, the top of the kingpin assembly moves

under that force to ill effect, being that wobble of the front end you feel..which also reaches the steering wheel. Hard braking is urgent enough that you do NOT want to be controlling the steering wheel at the same time! There are two basic sources of this movement;

(a.) the action of the suspension itself, particularly on washboard surfaces

and (b.) rotational reaction from braking stresses.

(Gerry Willburn) I

must admit that when I first put them on our DHC back in 1959, I had never

even heard of brake torque reaction. I was addressing the movement

on uneven surfaces which (in addition to making the steering a bit vague)

caused cracking of the front wings just inboard of the wing lamps due to

movement of the wing stay attached to the top of the pillar. These cracks

began to appear within weeks after we bought the car!

I asked Chuck Talbott (then Tech Editor of the Morgan

Plus 4 Club) and he told me that all of the racers had installed a brace

from the top of the pillar to the chassis where the damper blade is attached.

I built them myself (as well as for all of the Morgans I have had through

the years). All were made from aluminum and I used thin wall electrical

conduit tubing.

After

cutting approximately to length (a little long),

one end is flattened with a hammer on an anvil (or the end of a vice)

and

drilled to take the oiler bolt at the top of the king-pin. This is then

bent to the angle required, the other end measured and flattened. It is

bent to shape and trimmed as necessary, then drilled to take the

forward damper blade bolt.

It is a very simple installation. The only trick is

the avoid accidentally nudging the kingpin assembly after you remove

the top bolt. Take it out and then immediately put the bar and bolt

back on and thread the bolt, to secure it but not to tighten it

completely at this stage. I am

concerned that you lose the exact alignment of the top bolt into the

kingpin threads and or the kingpin and the main spring dislodge. (That is dangerous!!) Then let it find its proper spot on the frame, drill that hole and tighten the two bolts. I have never seen

any indication of damage to the frame through their use.

One precaution

is to use bolts weak enough to shear in an impact.

WATCHPOINT:

(Lorne) Brake Reaction Bars are made of a number from a number different metals

and formats and levels of sophistication these days. They can also be purchased

from Mulfab or almost everyone. See PARTS page. There is also a write-up on making and fitting them

in Cuthbert Twillie's famous A Yank in Malvern and that is the source of the diagram above. They can even be as effective when made from a flat metal strap you can find as scrap. WATCHPOINT:

(Lorne) Brake Reaction Bars are made of a number from a number different metals

and formats and levels of sophistication these days. They can also be purchased

from Mulfab or almost everyone. See PARTS page. There is also a write-up on making and fitting them

in Cuthbert Twillie's famous A Yank in Malvern and that is the source of the diagram above. They can even be as effective when made from a flat metal strap you can find as scrap.

Update July 2012: I have noticed that the Factory

has copied the Mulberry design

and is now selling them in stainless through their dealership network. I have no reports as yet on the strength

of their retaining bolts.

Please note: The pictures

here, all different versions, show different attachment point as well.

Each has been successfully used by Morgan experts.

I use the ones just above in this box. I obtained them polished stainless

from John Worrall. They are fit in the Mulberry fashion pictured above.

|

(Gerry) The first thing I noticed after installation was how much

better the steering felt in rough corners. The cracking of the

(Gerry) The first thing I noticed after installation was how much

better the steering felt in rough corners. The cracking of the  wing

ceased (and was covered up by installation of wing mirrors over the top

of the existing cracks and bolted through the wing stay). I have since

installed them on every Morgan that Barbara and I have owned and several others for friends. I think they are beneficial to all Morgans. I

have always installed them "to fit" and never made any attempt to adjust

caster through them. I am the most surprised that they only recently

(in the last several years) re-surfaced as a "new" innovation in England.

wing

ceased (and was covered up by installation of wing mirrors over the top

of the existing cracks and bolted through the wing stay). I have since

installed them on every Morgan that Barbara and I have owned and several others for friends. I think they are beneficial to all Morgans. I

have always installed them "to fit" and never made any attempt to adjust

caster through them. I am the most surprised that they only recently

(in the last several years) re-surfaced as a "new" innovation in England. (

wryly)

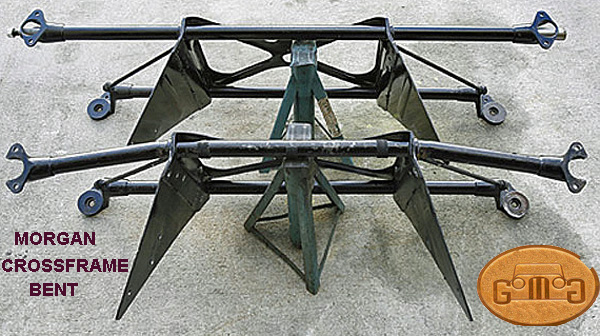

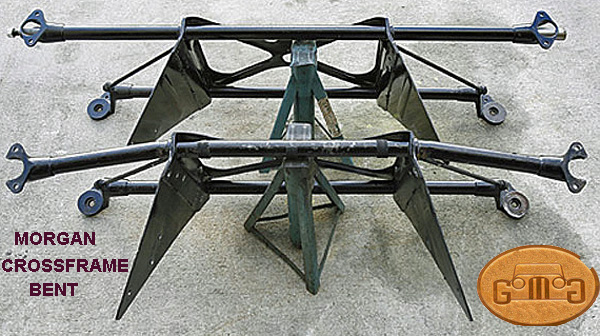

(Lorne)

The second thing they prevent, especially for those of us, like

racers, who brake hard and often. They prevent the deadly bending of the

cross-frame. See the famous John Sheally II's old cross frame

to the right. Even a bending of the cross-frame subtlety is enough to sadly alter your front end dynamics

without you knowing it.

Please NOTE: The Cuthbert Twillie diagram to the left attaches the bar to the wing stay foward of the old one-shot oiler hole which eMog and logic convinced the Factory to get rid of. This attachment point should have no prejudicial effect and is less invasive and risky for one-shot oiler cars..

As well. one shot oiler bolts (a unhelpful system) are not graded and

can shear. THE MOST IMPORTANT WATCHPOINT in this process is the

one alluded to above. Where Morgans are at their unintentional best is

the amazing crumple zone effect they have....many years before Formula

One and the then regulatory authorities realized that

safety feature. It saved the lives of my wife and I in

2002. My wife and I survived as the Morgan flexing ladder frame,

eliminated in 2020, combined with the wooden tub also eliminated at the

same time, absorbed impacts before they reach the cockpit.

In the front part of the car, Morgan bend at the bulkhead, allowing the

entire front suspension and the engine to resist the impact force's

egress before they too reach the cockpit. (I have seen the Aeros react

the same way). Though unplanned, this crumple feature is fantastic.

Morgans do have unsafe areas, but with a negligible amount of money and

good sense, they can be cured.

So the trick is to use these reaction bars to steady the front end,

providing the great benefits discussed above but WITHOUT eliminating

the natural safety elements and having these bars transfer impact

forces in an accident to the cockpit. To achieve this is merely a

matter of using weak bolts that will shear in an impact but are strong

enough to do the job intended. As Gerry noted above, we are not sure

the what bolts the Factory uses with THEIR kit. I use the pretty polished bars shown

above..and they will shear not only at the bolts but at their bend

pleats as well.

THE CROSSFRAME (aka crosshead) Morgan

is the ultimate governor of steering and front suspension dynamics.

Sadly, they can bend , either in an accident or, especially in cases of

the more powerful Plus 8s, by braking forces over time. Many old timers

use their old kingpins rammed down the lower tube to prevent this, but

GoMoG /eMog popularized the brake reaction bars, which have multiple

beneficial effects, among which is the prevention of this sad effect

forever. It also cures the problem without adding much weight, unlike

the kingpins.

| WATCHPOINT: Please NOTE that cross frame must

be properly adjusted to each car. That is the reason for the adjusters

at each end. One carefully measures the distance between points at the

the rear of the chassis and using a leveler to confirm the straightness

of the crossframe and adjusts accordingly. Brake reaction bars will also help with this issue over time. |

The Goal: To insure that the crosshead is perpendicular to the longitudinal axis of the chassis.

METHOD

by Jean Frédéric Frôt

1. Position the crosshead roughly in position with the wings resting on

the lower chassis all along and clamp the two parts together.

2. Measure the distance between the kingpin hole in the top lug and the

rear hole of the rear suspension spring bolt on the opposite side. The

two diagonals should be the same within approx 3 to 5 mm. Shuffle the

crosshead and re-clamp until this is achieved. The bottom tubes should

be kept

as close as possible to the chassis ends without actually touching them.

3. Then adjust your chassis so that it is horizontal using a spirit

level and shims between the chassis and the resting pads of the axle

stands. Ideally

do this both longitudinally and transversely.

4. Using a suitable straight rod (wood, metal ) passing through the top

and bottom lug and a spirit level, check that you have a castor angle of about 2 degrees. A smart phone with Carpenter app will be very useful for this

operation by avoiding having to trace projection lines on the floor and

use Pythagorus'

formula. Giggle the crosshead to get the right angle and clamp firmly, check your diagonals again until you are happy that you are square

and that the castor angle is right at the same time. Clamp firmly and

drill the holes. Bolt with good quality high tensile bolts (do not use

stainless which is too malleable) Do not transfer dimensions from an old chassis or old crosshead. This is prudent as the MMC was never very precise with welding jig of the

crosshead and even less so when fitting it to the chassis.

This all will ensure that the car will not crab (4 wheels parallel) and

that the steering keeps the car in a straight line when letting go of

the wheel on a

straight flat road (castor) but will be easy to turn (providing that the

toe in angle is correct). Not enough castor and the car wanders like a

supermarket

trolley, too much and the car does not want to change direction. Remember that the camber angle is not adjustable on most Morgans, though the

MMC sold adjustable camber plates for a short period a decade ago.

WATCHPOINT: The Adjusters

Pre 1996 used 3/8 BSF, 20 tpi

Post 1996 used 3/8 UNF 24 tpi |

WATCHPOINT:

(Lorne) Brake Reaction Bars are made of a number from a number different metals

and formats and levels of sophistication these days. They can also be purchased

from Mulfab or almost everyone. See PARTS page. There is also a write-up on making and fitting them

in Cuthbert Twillie's famous A Yank in Malvern and that is the source of the diagram above. They can even be as effective when made from a flat metal strap you can find as scrap.

WATCHPOINT:

(Lorne) Brake Reaction Bars are made of a number from a number different metals

and formats and levels of sophistication these days. They can also be purchased

from Mulfab or almost everyone. See PARTS page. There is also a write-up on making and fitting them

in Cuthbert Twillie's famous A Yank in Malvern and that is the source of the diagram above. They can even be as effective when made from a flat metal strap you can find as scrap.