The Morgan Classic Brake

System (A Complete Overview)

The Brake System

by Lorne Goldman

The brakes and tyres are the most important components on your car. If either fail, the result

can be disastrous. Brakes are actually energy conversion devices,

converting kinetic energy (momentum) of your vehicle into thermal

energy (heat).

When you step on the brakes, you command a stopping force ten times as

powerful

as the force that puts the car in motion. So the braking system exerts thousands

of pounds of pressure on each of the four brakes. Many electric cars now preserve that braking energy temporarily so as the release it immediately after for creating incredible start-off times!

| WATCHPOINT Since 1968 (Plus

8s) or 1978 (all cars) Morgans have been fitted with dual circuit master

cylinder systems, with each the front and the rear wheels braked by a separate

subsystem. That way, if one subsystem fails, the other can provide life-saving

braking power. These are infinitely safer than earlier braking systems. I

counsel you to ignore or caution anyone who suggests a single circuit system

be maintained rather than replaced. |

But the basic

process

of converting a vehicle's momentum into (wasted) heat energy has not

changed

since the days of the horse and buggy. To stop a horse drawn carriage,

the

driver would pull on a lever which would rub on the wheel. A good

braking system reflects the mass of the vehicle as the needed braking

energy is a function of of the size of that mass and balance.

EDITORIAL NOTE:

Outside of the simplicity and purity of their design, trad

Morgans set themselves apart from most automobiles by their very low

weight. HFS, a canny engineer of the Old School, knew that simplicity,

low weight and potent engine could beat all comers on the racing and

autocross competition. The early Morgan record in those fields is

remarkable. Even today, in their class, the 1968-70 Plus 8s are the

cars to beat in an all marque competition of that era!

But today's flock of moggers have lost their way on the braking side, as they have in other areas. :(

Very low mass means much less braking power is necessary. But that is

ignored by today's community. Even rear disk brakes are added when they

make no sense. They remind me of the true tale that Peter Morgan

prominently added front dampers only because they pleased the

sensibilities of the post-shock customers! (One day you should all remove the front dampers for a test ride. You will be surprised.) Morgans

don't need much braking. Front disks and rear drums are more than

sufficient for any road-going trad going Morgan and MOST racers I have

ever seen. The tedious expensive installation of rear disk brakes often

unbalances the braking again, making the comportment of the car harder

to control and often at the cost of a functional safety brake. We can

also theorize that the weight distribution of the unsprung weight

prejudices the perfect weight of the trad.

WATCHPOINT 1: The balance proportioning of the pre-1993 systems should be verified and corrected or click here as well. The

set up of the dual cylinder Girlings is incorrect for our cars. It was

correct when Bill Beck had the later AC power assisted system installed

in all the cars.

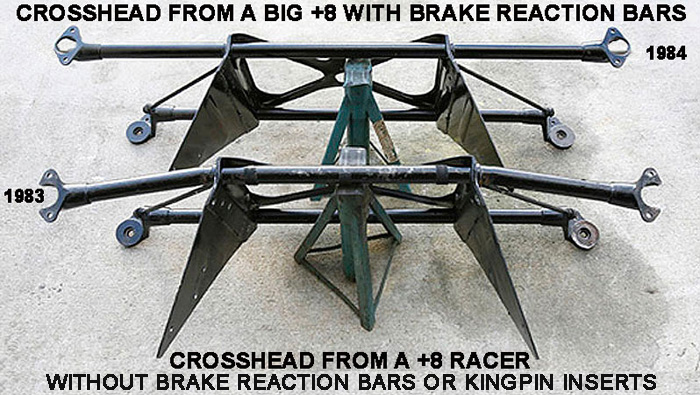

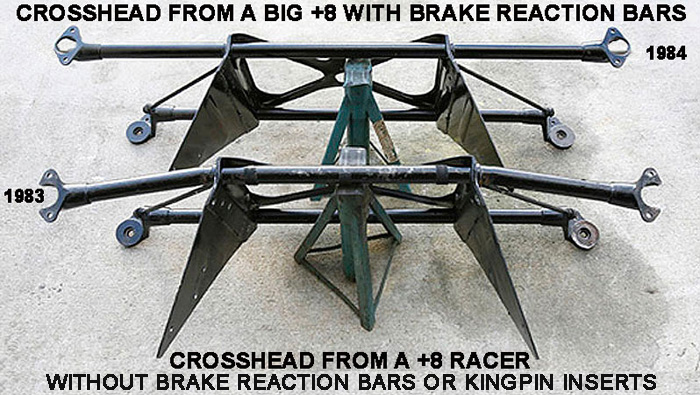

WATCHPOINT 2: The

design of the front end creates an unsteady hard-to-control factor on

hard braking. It so potent that eventually it bows the cross

member!! It can be easily/cheaply rectified in two ways..one goodThe

bad one is ingenious and simple! One bangs old kingpins down the lower

crossmember piece to stiffen it and prevent its bending. It also stops

the unsteadiness on hard braking. However, it add LOTS of weight at the

very periphery of the car, exactly where you DO NOT want it..like

putting a heavy case on the rear does.

WATCHPOINT 3:

I HAVE found a potent improvement in merely choosing better brake pad

and drum show improvement. Thpugh those chosen by some national

communities have a sad if any effect. Porterfields and one bad.

will change the effective braking of two pot braking (assuming the

rear shoes are done as well) to the effectiveness of the later 4 pot

calipers.

|

Why do so many new moggers adopt such stuff? In my humble

opinion, it certainly involves a blind copying of what OTHER marques

do. :( I believe it is also vastly encouraged by a very

fundamental, very charming human trait. Humans

can't love anything with expressing that. Just as we buy our loved

ones new silk ties and earrings, we find similar ways of

expressing our love for our Morgans! It is analogous to fondling. :D

Very satisfying emotionally but we too often betray the car and HFS'

wonderful earth bound common sense.

And

in my 25 year experience with our Community, involving many 1000s of

individual and public interactions, the greatest incentive to such

sadness is poor and/or absent maintenance. When it reaches a point

where even an amateur notices something amiss with the car, they are

now told by today's brethren to buy a completely new design from

the new predatory aftermarket!!! :(

| The GoMoG Law of Professional Servicing: Do

not report or repair any adjacent anomalies observed when doing this

task. It will unjustly give you a predatory reputation. Wait until the

area fails and the owner asks for a repair. Repair is far more

profitable than than prevention. You must create a clientele

with deep bond of trust of you(difficult in a hyper-suspicious world) before you can take care of their Morgan properly. |

Lastly, after 20 years of unsettled financial times from the Aero's development and today, and no in-depth in-house talent in control

of development, the MMC designs cars to please its current market

demographic rather the exigencies of logic. :( Accordingly,

today's fare is not susceptible to the home skills of owners and

is MUCH heavier. In a nutshell, Morgans changed because a

new owner demographic was sought out from 2000 on. Sadly, it

gave the company a negative value (aside from the equity of the last government grant), and forced the Family to sell for no more than the value of that grant

:( ending an over-100 year heritage and modern day miracle. We should

never allow our love of our Morgan prejudice them! Focus on add-ons

that do NOT add to the complexity of the car, its reliability, the ease

of understanding it, owner interaction, weight or handling. Tweaking, polished metal or chroming fits that bill for me! :D |

The brake system is

composed of the following basic components: The "master cylinder" which is

located under the hood, and is directly connected to the brake pedal, converts

your foot's mechanical pressure into hydraulic pressure. Steel "brake lines"

and flexible "brake hoses" connect the master cylinder to the "slave cylinders"

located at the wheel. Brake fluid, specially designed to work in extreme

conditions, fills the system. "Shoes" and "pads" are pushed by the slave

cylinders to contact the "drums" and/or "rotors" (discs) thus causing drag,

which (hopefully) slows the car.

Disc brakes have been

used for years for front wheel applications, (and on many older cars are

fast replacing drum brakes on the rear wheels). This is generally due to

their simpler design, lighter weight and better braking performance. The

greatest advantage of disc brakes is that they provide significantly better

resistance to "brake fade" compared to drum type braking systems. Brake fade

is a temporary condition caused by high temperatures generated by repeated

hard braking. It occurs when the pads or shoes "glaze" due to the great pressure

and heat of hard use. Once they cool, the condition subsides. Disc brakes

allow greater air ventilation (cooling) compared to drum brakes. Drum brakes

are not internally ventilated because if they were, water could accumulate

in them. Disc brakes can rapidly fling off any water that they are exposed

to, and so they can be well ventilated. Morgan rotor (discs) are quite thick

which requires higher temperatures to heat but are also difficult to cool

for the same reason. High performance disc brakes have drilled or slotted

holes through the face of the rotor, which helps to prevent the pads from

"glazing" (becoming hardened due to heat). Many suppliers sell ventilated

discs for racing applications.

Disc

Brakes

by Lorne Goldman

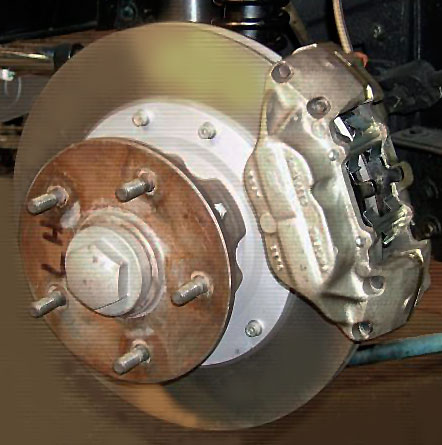

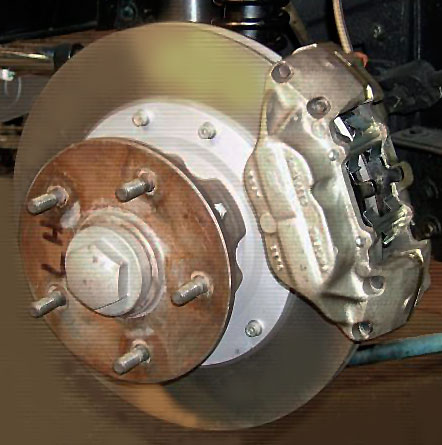

Disc brakes use a

clamping action to produce friction between the "rotor" and the "pads" mounted

in the "caliper" attached to the suspension members. Inside the calipers,

pistons press against the pads due to pressure generated in the master cylinder.

The pads then rub against the rotor, slowing the vehicle. Disc brakes work

using much the same basic principle as the brakes on a bicycle; as the caliper

pinches the wheel with pads on both sides, it slows the bicycle. Disc brakes

offer higher performance braking simpler design, lighter weight, and better

resistance to water interference than drum brakes.

Disc brakes, like

many automotive innovations, were originally developed for auto racing, but

are now standard equipment on the front wheels of all Morgans and the rear

brakes are of the "drum" type. Drum brakes use two semi-circular shoes to

press outward against the inner surfaces of a steel drum. The older cars

have drum brakes on all four wheels and their are suppliers who sell

a rear disc brake conversion kit.

Because disc brakes

can fling off water more easily than drum brakes, they work much better in

wet conditions. This is not to say that water does not affect them, it definitely

does. If you splash through a puddle and then try to apply the brakes, your

brakes may not work at all for a few seconds! Disc brakes also allow better

airflow cooling, which also increases their effectiveness.

Rotors

(Discs)

by Lorne Goldman

The rotor (also

called the disc) is clamped by the brake pads in order to slow the vehicle. The rotor is a

heavy circular steel plate attached to the wheel providing a two sided braking surface.

Pressurized fluid in the brake lines flows into

one or more "slave" cylinders in each caliper. The fluid pressure is

exerted against the slave pistons, which force the brake pads against the

surface of the disc. As the pads clamp onto the rotor, intense heat is

generated, which can in extreme conditions actually cause the rotor to glow red

hot, affect the nearby ignition coil and the ENGINE!

!

The surfaces of the

rotor are "turned" (re-machined) whenever the brake pads are replaced in

order to remove the "glazed" surface which forms on the rotors. The turning

process also "trues" the disc (makes it perfectly flat) which eliminates

the pulsations which are experienced when the rotor is warped. Warped rotors

give a slight tugging when the brakes are applied, and send a pulsing sensation

back through the brake pedal. Rotors have "minimum thickness" and if it is

"turned" to resurface, it may become too thin to withstand heat as it warms,

requiring replacement. In fact, the ability of the discs to resist heat is prejudiced

before they ever reach the minimums. In my book, that makes skimming Morgan discs like

one does with other cars, a losing game..especially as the odd Morgan discs are not easily available at every brake

shop. Maximum run-out on the rotor faces is only .002 inches (.0508 mm). The maximum

permissible finish of the disc machining is 15-30

micro inches circumferentially and 50 micro inches measured laterally, merely one very

thin cut (if that) that might last a very short while unless your usage is negible. When you get

near these limits, a skimming of

the disks won't help you for long. I DO NOT skim my Morgan disks. I replace them. Why ruin a vacation

of a outing because you wanted to save a few pennies? That being said, aside from trying to skim the used

disks of my first Morgan at 30k, I have never had to replace from disks. It is all in the matter

of how you drive your Morgans. I do not use my brakes much. 95% rural driving. I haven't used my backup new

disks on three Morgan Plus 8s over the last 30 years and 250,000 miles.

Pre-1992 4/4 and Plus 4s arrive new at .375, later models and Plus 8 start at .500". Please

note that Morgan Discs/Rotors are specially ordered by the Company, if you find

a suitable replacement please email

me.

(Semi metallic brake

pads give better performance, longer replacement intervals and reduced "fade",

but they also wear down the rotor more quickly than organic [non-metallic]

pads.) Recently, I decided to try Carbon Kevlar pads and and rear shoes and

I am very pleased with the difference. The braking has more "feel" and is

far more effective in all conditions.... no squeaking either! I use Porterfield R4-S

THE

TEN COMMANDMENTS OF DISC BRAKES

1. A brake disc is

one of a vehicle's active safety components. Competence and constant technical

updating is therefore essential for anyone dealing with it.

2. It is appropriate

to regularly check the disc thickness and appearance. A change must be made

before the disc thickness reaches its minimum value (thickness) [.450 inch

on a Plus 8 or post-1992 4/4 or Plus 4], or whenever anomalies are noted

on the disc surface. The thickness of the rotor indicates how resistant it

will be to the high heat of its use. Below a certain point, it will not be

able to stay true for any period.

3. The disc assembly

instructions must be read and scrupulously followed at all times.

4. Discs on the same

axle must always be changed together.

5. Brake pads must

be changed together with the discs. The correct choice of pads is essential

for braking efficiency and comfort.

6. The discs and pads

being replaced are an important source of information. Always carefully inspect

the disc condition (condition of the braking surfaces, colors, appearance,

etc.). This may show anomalies in one or more components (calipers,

pads, bearings), and before changing the discs any such problems

should be identified

and solved.

7. Clean the disc

and most important the hub surface, and remove any traces of corrosion.

8. Properly tighten

the bearing nut and replace the pin with a new one. Properly tighten the

fastening bolts in a cross-wise order using a torque wrench to check to applied

torque. The same instruction goes for installing the wheel.

9. Check the run-out

of the brake disc, by using a run-out gauge attached to a fixed part of the

suspension.

10. In order to allow

a perfect fit of the materials and guarantee top performance, observe

a short running-in period (180-300 miles), using only regular and smooth

braking action.

DRILLED, SLOTTED & SMOOTH ROTORS (BRAKE DISCS) by Lorne Goldman

Without question, brakes are the most powerful system on your vehicle. No matter how much horsepower

you have, none of it’s of any use if you can’t brake off enough speed to keep from rear-ending the car in front of you. On the other hand,

traditional Morgans are so light that braking is never a large task,

with the

codicil that the front becomes unsteady on hard braking and brake reaction bars become an inexpensive and smart idea. The factory brakes

provide ample stopping power for regular road driving.

Without question, brakes are the most powerful system on your vehicle. No matter how much horsepower

you have, none of it’s of any use if you can’t brake off enough speed to keep from rear-ending the car in front of you. On the other hand,

traditional Morgans are so light that braking is never a large task,

with the

codicil that the front becomes unsteady on hard braking and brake reaction bars become an inexpensive and smart idea. The factory brakes

provide ample stopping power for regular road driving.

Here is the analysis.

Smooth Brake Rotors

Smooth Brake Rotors

A premium set of smooth

rotors provides more than enough stopping power under normal driving

conditions. They provide the most surface area where drilled

and slotted rotors reduce it. They also are very effective at acting as

a heat-sink, which is exactly what a brake rotor was designed to do.

They’re also not as

prone to cracking under extreme use unlike drilled rotors can be. The absence of slots or

drill holes allows smooth rotors to maintain maximum structural

stability and integrity, making them suitable for moderate track use

when paired with performance brake pads and high-boiling point brake

fluid.

Slotted Brake Rotors

Slotted Brake Rotors

Slotted

rotors, as the name implies, have grooves cut along the face of the

rotor where the pad makes contact. This is because under repeated heavy

braking, as the temperature of your brake system increases, a layer of

gas and dust forms between the pad and rotor from the material transfer

caused by friction. The slots in the rotor allow an escape route for the

built-up gases. This allows more of the brake pad’s surface area to

contact the rotor, resulting in better pad bite and more consistent

stops. Also, this increased surface contact results in a higher

coefficient of friction, so you’re actually using less energy to slow

your vehicle the same amount. The venting provided by slotted rotors is

one of the main ways to combat brake fade and maintain consistent

stopping power, lap after lap. Slotted

and drilled brake rotors help evacuate those gases and dust, shed

heat, and keep the pad from "glazing" by keeping the brake pad surface

clean. And on wet surfaces and/or raining conditions, slots and cross-drilled holes can help push water off the braking surface for better stopping power.

| WATCHPOINT: Some dedicated

slotted “racing” rotors employ a sharp edge on the slots to cut

into the brake pad a small amount for better bite, but this can greatly

accelerate brake wear. |

Cross Drilled Brake Rotors

Cross Drilled Brake Rotors

Cross-drilled

brake rotors look undeniably cool peeking out from behind a set of

wire wheels and they keep your brakes the same way – cool. In the

early days of racing, drilled rotors were an effective way of venting

the layer of gas and dust that inevitably builds up between asbestos

brake pads and the rotor under repeated, hard braking. However, as technology and brake pad materials have progressed (see brake pads) venting gas has

become less of an issue. These days, while they still look

great and perform well, the drill holes are more for aesthetic reasons

than anything else. For performance driving, slotted rotors have become

the preferred choice because cross drilled rotors are more prone to

stress cracking under extreme use.

Just take a look through the spokes on the wheel of any modern race car

– there won’t be a drilled rotor in sight. And, for street

driving, the temperatures your brakes encounter never even come

close to the levels they do on the track. So, the venting properties of

drilled rotors offer the added benefits of keeping temperatures down

under normal driving for prolonged pad life, as well as improved

wet-weather performance by allowing water to escape the rotor’s

surface, increasing initial pad bite.

Drilled & Slotted Brake Rotors

Drilled & Slotted Brake Rotors

Drilled and

slotted rotors provide the looks and functionality of both cross-drilled

rotors and slotted rotors combined. However, they are still not ideal for the abuse

they would suffer on vigorous breaking (i.e. the drill holes being prone to

stress-cracking). See Drilled rotors above.

CONCLUSION: Choosing the Right Brake Rotor

There are a few things to keep

in mind when choosing cross drilled or slotted brake rotors. For

street-driven vehicles, both perform equally well and don’t suffer any

detrimental side effects aside from those mentioned. Slotted or cross drilled rotors will not decrease your vehicle’s original stopping distance.

Their purpose is to dissipate heat and gases to combat brake fade and

provide consistent stops after prolonged abuse. In order to take a

sizeable chunk out of your stopping distances, a set of sticky tires

and dedicated high performance brake pads are the recommended

upgrades. For eye-catching, high-end style, drilled or drilled &

slotted rotors are sure to turn heads. For daily driving, any of the

above provide more than enough stopping power, especially on the MUCH

lighter traditional Morgans. All the being said, the steadier feeling

slots offer in the rain and wet surfaces is an improvement for Morgans,

which are very sensitive to road conditions.

Brake

Pedal by Lorne Goldman

The brake pedal, (in

case you're one of those people who don't use it), is located between the

accelerator pedal and the clutch. The brake pedal is connected to the master

cylinder via a push rod which has a "slack" adjuster fitting to properly

adjust the brake pedal relationship to the push rod.

The brake pedal is

solidly mounted to the firewall, and works as a force multiplying lever.

Stepping on the brake pedal pushes a piston within the master cylinder, thereby

pressurizing the hydraulic brake lines. The hydraulic pressure pushes the

brake shoes and pads against the brake drums and rotors, thus slowing the

wheels.

The brake pedal gives

feedback to the driver which can be beneficial to good maintenance, and therefore

potentially save your life. If the pedal pulses when pressed, the usual culprit

is a warped rotor, which is potentially destructive to the caliper. If the

pedal squishes down when pressure is applied, a dangerous leak is likely

present (even if fluid does not drip out anywhere). Your brake pedal should

not move more than a small amount when you press it, no matter how hard it

is pressed. It should not feel sponge like: a spongy pedal spells trouble

in the braking system. With the car parked, press the brake pedal firmly

and hold the pressure. If the pedal sinks slowly, a leak is present.

A good rule of thumb

is this: ANY changes in the "feel" of your brake pedal should be a cause

for serious concern. Remember, with brakes, there is NO excuse for poor maintenance.

Brake

Drums (generally)

The brake drum is

a heavy flat-topped cylinder, which is sandwiched between the wheel rim and

the wheel hub. The inside surface of the drum is acted upon by the linings

of the brake shoes. When the brakes are applied, the brake shoes are forced

into contact with the inside surface of the brake drums to slow the rotation

of the wheels.

They are not cooled

internally, because water could enter through the air vent cooling holes

and braking would then be greatly impaired.

One advantage of drum

brakes is that they can easily be set up to be mechanically activated by

a pull cable (for use as parking brakes). Drum brakes are usually quite sufficient

for rear brakes because most of the car's weight transfers to the front wheels

during hard braking. The reduced weight on the rear wheels makes the higher

performance of disc brakes somewhat unnecessary except in racing.

The working parts

of a drum brake are contained inside the brake drum. The drum is attached

to the hub of the wheel and revolves with it. Inside the drum are a pair

of curved brake shoes that are held close to the drum by retractor springs.

The shoes and actuator linkages are mounted to the backing plate behind the

drum. When the brake pedal is pressed, fluid is pressurized in the wheel

cylinders. Pistons in the wheel cylinders then push outwards against both

shoes, overcoming the retractor spring tension and pressing the shoes against

the drum. The friction of the shoes against the drum slows the wheel. When

pressure is released from the brake pedal, the retractor springs force the

shoes back to their normal (released) position. The springs force the brake

shoes slightly back (inward) away from the drum when the brake is released.

These springs, along with the other brake hardware, should be replaced every

other time the brake shoes are replaced.

As the linings of

the shoes wear down and become thinner, an adjustment screw must be used

to keep the shoes close to the drum but without touching until applied.

Back

Plate by Lorne

Goldman

The backing plate

is a round, stamped steel disc, used to keep water out of the drum/rotor,

and in drum brakes as a mount for the wheel cylinder. It is bolted to the

end of the rear axle housing. The backing plate is the foundation for the

wheel cylinder and brake shoe assembly. By the way, the racers prefer they

older adjustable rear brakes (pre-7/1993) to the later self-adjusting brakes

used after.

Anchor Pins and Shoe Retainers

The anchor pin is

a strong metal pin mounted to the backing plate, which prevents the shoes

from turning along with the wheel when the brakes are applied. Shoe retainers

are small spring clips of various designs used to hold the brake shoes against

the backing plate. These pins insure shoe alignment and prevent them from

rattling.

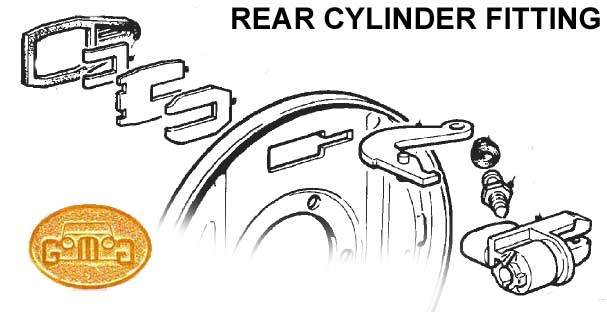

Wheel (Slave) Cylinders

Wheel cylinders, also

called the "slave" cylinders, are cylinders in which movable piston(s) convert

hydraulic brake fluid pressure into mechanical force. Hydraulic pressure

against the piston(s) within the wheel cylinder forces the brake shoes or

pads against the machined surfaces of the drum or rotor. There is one cylinder

for each wheel. Drum brake wheel cylinders are made up of a cylindrical casting,

an internal compression spring, two pistons and rubber cups or seals. This

type of wheel cylinder is fitted with push rods that extend from the outer

side of each piston through a rubber boot, where they bear against the brake

shoes. Only one of the Morgan rear wheel cylinders has a bleeder screw

(right hand side) (or bleeder valves) to allow the system to be purged

of air bubbles.

As the brake pedal

is depressed, it moves pistons within the master cylinder, pressurizing the

brake fluid in the brake lines and slave cylinders at each wheel. The fluid

pressure causes the wheel cylinders' pistons to move, which forces the shoes

against the brake drums. Drum brakes use return springs to pull the shoes

back away from the drum when the pressure is released.

N.B.

See the note on master cylinders

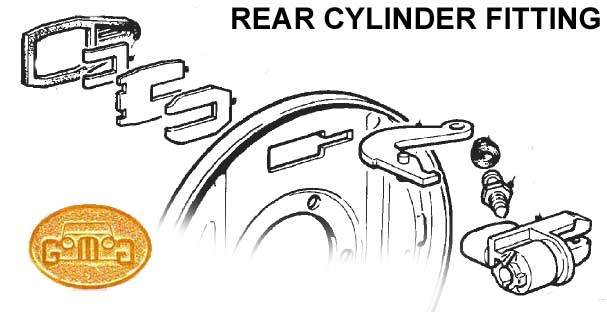

Removing Rear Slave Cylinders (pre-1993) by Lorne

Goldman

Removing the Morgan

wheel cylinders can be a trick at first. The little shims/clips and doodads

are great fun. There are three of them holding the rear cylinder in its slot

(but allowing it to move in the slot). The two bigger ones nearer to the

back plate are U-shaped and (they come in from different ends) lock together

at one end with two locking tabs holding them together. This is extremely

hard to see the first time without 15 year old eyesight and an electron microscope.

First remove the third one which is the obvious outer one applying the pressure.

You may have to remove the parking brake lever to do this. After removing

this pressure shim, use a good light, and possibly a magnifying glass to

see the two locking pieces and the tabs..lifting the two apart at the locking

tabs with a very small screwdriver or even an exacto knife and then sliding

one (the lower?) back to disengage them.

Special Note on Wheel Cylinders!

by Lorne Goldman December 21, 2005

The Works has announced

that the Girling rear brake cylinders are no longer available and has sent

this information to their Agents. This crucial parts was/is used on the following

Morgans

+4s 1958 to 7/1993

4/4s from 1960

to 7/1993

+8s from 1968

to 7/1993

In fact, there is

a readily available OEM match sourced by an eMOG member at a retailer. Here

are the details.

Pattern Rear Brake

Cylinders manufactured by Past Parts,

part no. 25-0146

They take Visa

and are willing to ship worldwide.

Cost is GBP 15.08.

Special Note on

Wheel Cylinders! (post-1993s)

by Lorne

Goldman June 2012

The wheel cylinders

are Caparo AP Braking CW 15953 which are matched by Delphi Lockheed LW 15953.

Notes

on Removing Morgan Brake Drums (Series V 4/4)

from Paul Helman

Those large screws

on the drum alone are not what you are looking for. All they do is

retain the drum to the hub. You should also be looking at those quarter inch

27/inch threaded hex bolts.

Try backing off all

the way on your adjuster screws then gentle tapping around the rim of the

drum (using a piece of wood between hammer and drum rim) should get it off.

I assume your basic configuration is similar to mine (Series V 4/4) which

I am currently redoing.

N.B. I suggest new

retaining bolts to avoid shearing off the bolt when retightening the drum.

(I did this twice recently necessitating removal of the hub and a bit of

careful drilling to extract the body of the bolt with a stud extractor without

damaging the thread of the mounting holes in the rim of the hub. These are

hardened bolts so it did present a challenge. I am getting somewhat

adept at it just through repetition..

Removal of the the

hub is easy once the drum is off by using a large gear puller. Hopefully

your cotter pin has been installed in such a manor that straightening it

will be no problem . Once the cotter pin is removed, the removal of

the castellated nut is no problem. This is what made  removal of the sheared

bolt relatively easy with the hub in hand and the careful use of a drill

press. This is not something to be tried with the hub still mounted.

removal of the sheared

bolt relatively easy with the hub in hand and the careful use of a drill

press. This is not something to be tried with the hub still mounted.

BRAKE DRUMS REMOVAL (pre-1993)

by George Dow at the eMog Pub

Most old cars that

I have worked on have a securing screw that is usually done up too tight.

These screws are there to stop the drum coming off with the wheel when it

is changed, therefore do not need to be done up tight "too" tight at all.

If you have a suitably sized screwdriver that can take a hit on the handle,

put the driver in the screw head and give the screw a hit before you try

to loosen it (if you have such screws fitted) If that don't work.....an

impact driver might do the job. (Please remember to NOT use it to put them

back on! Some anti-seize on the threads can help next time you decide to

remove them.

First back off the adjuster (at the rear of the back plate) on these pre-1993 (Triumph rear brakes).

You can also borrow a brake drum puller. See method at the right

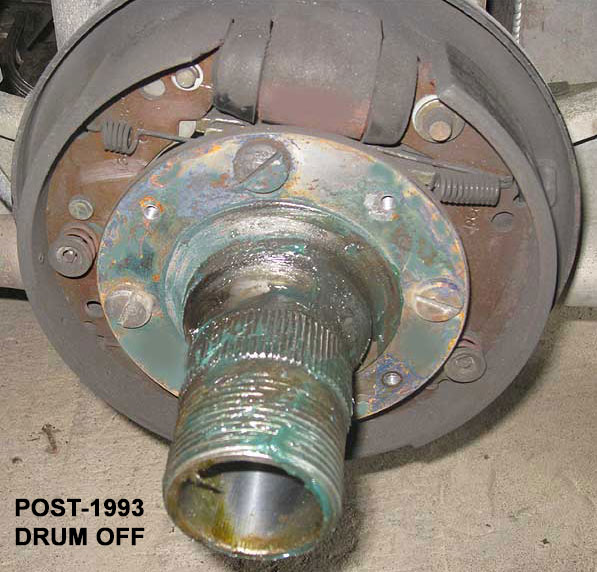

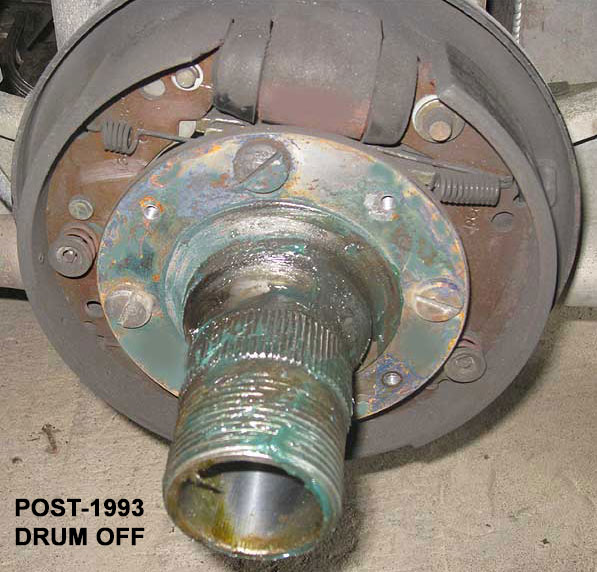

BRAKE DRUMS REMOVAL (post-1993)

by Lorne Goldman years later

George's instructions above

will pretty much do the trick. However, the post-1993 reardrums do NOT

have a post adjuster at the rear of the back plate. (for this reason

many racers move back to the earlier pre-1993 versions (if they are

lucky enough to find a back plate!). At one point, Librands was looking into having a better rear drum system made. Check with them.

George's instructions above

will pretty much do the trick. However, the post-1993 reardrums do NOT

have a post adjuster at the rear of the back plate. (for this reason

many racers move back to the earlier pre-1993 versions (if they are

lucky enough to find a back plate!). At one point, Librands was looking into having a better rear drum system made. Check with them.

Aside from terminal furstration occasioned by amateurs fitting a new

rear cylinder or shoes into this very fiddly system, many

mistakenly remove the hub fittings. These are the huge slotted fittings

that clear the drum and are visible from the outside. One would think

that even a first time cursory examation would show that these things

do not have anything to do with the drum at all, but this has not been

obvious to everyone. LEAVE THEM ALONE unless you wish to remove the hub

and drums off the axle, a very tough job needing a slide hammer.

To remove the drum, merely remove the little bolts and then bang the

drum outward (from their interior edge) with a rubber hammer .

Brake Calipers

The caliper works

like a C-clamp to pinch the pads onto the rotor. It straddles the rotor and

contains the hydraulic "slave cylinder" or "wheel cylinder" piston(s). One

caliper is mounted to the suspension members on each wheel. Brake hoses connect

the caliper to the brake lines leading to the master cylinder. A "bleeder

valve" is located on each caliper to allow air bubbles to be purged from

the system.

Morgan calipers contain

two (and recently four) separate pistons. These calipers are fixed in place;

i.e., there is no lateral movement like the newer floating caliper, the pistons

take up the slack on each side of the rotor. These are called "dual cylinder"

or "dual piston" calipers, and are standard equipment on many performance

cars.

Brake Pads and Brake Shoes

Brake pads and brake

shoes are composed of a friction lining material mounted onto metal backing

plates. Brake linings are designed to have a specific coefficient of friction.

The linings contact the drums and discs, create drag, and thereby retard

the speed of the vehicle. The lining material is designed to wear down faster

than the rotors and drums they rub against, so that they are the only part

that usually has to be replaced. When worn out pads and shoes are replaced,

the drums and rotors are re-machined or "turned" (a small amount of metal

is removed from their surfaces) so that the brake shoes and pads will "break

in" properly.

Because of intense

friction and heat produced in braking, brake linings were first composed

of heat resistant asbestos compound. When it was discovered that breathing

dust containing asbestos fibers cause serious bodily harm, asbestos pads

were replaced with other types. There are now three basic types of materials

used in brake linings: (1) non asbestos organic, which is usually made from

filler materials and high temperature resins; (2) metallic; and (3) semi

metallic, which are composed of finely powdered iron or copper, graphite,

and small amounts of inorganic filler and friction modifiers. The first and

third types of brake lining are used for conventional brake service. Under

extreme braking conditions (sports cars, ambulances, police cars), the metallic

type of linings are used, because they provide more constant frictional characteristics

(reduced brake fade) than the other two. Organic pads and shoes wear down

the rotors and drums less than semi metallic or metallic pads, but also wear

down quicker themselves, requiring more frequent replacement.

Most pads and shoes

have "wear indicators" built into them, or into the hardware which holds

them in place. The wear indicators cause a squealing noise when the linings

wear down to the level of the indicator. Mechanical wear indicators (small

metal tabs) allow the driver to know when their brakes are needing replacement

before serious damage occurs. When the pads or shoes wear out completely

(past the wear indicators) and the backing plates contact the drums or discs

for extended periods of time, the damage which results can require replacement

of the rotor or drum, which is MUCH more expensive than the shoes and/or

pads! (Some advanced braking systems have electronic wear indicators built

into the linings, which allow the driver to be warned by a light on the dash.)

Better

Pads and Shoe Compound

As noted above, I

decided to try carbon kevlar pads and and rear shoes and after search about

a bit. I am very pleased with the difference. I have experience with five

compounds used on Morgans.

MMC

STOCK PADS Caparo Brakes (post June 1993)

These have the braking

compound that will be provided by the MMC as original stock. They are the

bottom of the list for feel and effectiveness but are serviceable. The have

an infamous  tendency to squeal. They also do not fit properly requiring, on the advice of the supplier, remedial measures at your first service. Available from your Morgan dealer or off

ebay.co.uk.

tendency to squeal. They also do not fit properly requiring, on the advice of the supplier, remedial measures at your first service. Available from your Morgan dealer or off

ebay.co.uk.

GREEN STUFF

PADS

The UK community favors

EBC Green Stuff Pads. I tried them on our UK Plus 8. IMHO they are better

than the stock pad as they act normally when cold. But other than that they seem to be nowhere near as performant

as something made specifically for road going sports cars. On that point, I have never read anything noteworthy

about them in performance applications and I removed them after a single season.

However, they seem to wear well and make less noise than the stock pads. British Company

PORTERFIELD PADS

I first bought these

24 years ago at the suggestion of John Sheally II, the racer. I started with their Brake

pads and then their shoes in the same compound 20 years ago (their R4-S

compound). I now swear by them. The braking has more "feel" and is far

more effective in all conditions.... no squealing either. To give you an

example, I found the 2 pots calipers had the same braking power as 4 pots

when the Porterfields were put on! US Company. And they seem to last forever!

I first bought these

24 years ago at the suggestion of John Sheally II, the racer. I started with their Brake

pads and then their shoes in the same compound 20 years ago (their R4-S

compound). I now swear by them. The braking has more "feel" and is far

more effective in all conditions.... no squealing either. To give you an

example, I found the 2 pots calipers had the same braking power as 4 pots

when the Porterfields were put on! US Company. And they seem to last forever!

Master

Cylinder (pre-1993) by Lorne

Goldman

The master cylinder

displaces hydraulic pressure to the rest of the brake system. It holds THE

most important fluid in your car, the brake fluid. It actually controls two

separate subsystems which are jointly activated by the brake pedal. This

is done so that in case a major leak occurs in one system, the other will

still function. N.B. We do NOT recommend the use of single circuit

masters used on pre-1978 cars. Their lack of any redundancy or safety measures

make them dangerous. The two sub-systems

should be supplied by separate fluid reservoirs or they may be supplied by

a common reservoir that is is split inside. The systems are divided front

and rear. When you press the brake pedal, a push rod connected to the pedal

moves the "primary piston" forward inside the master cylinder. The primary

piston activates one of the two subsystems. The hydraulic pressure created,

and the force of the primary piston spring, moves the secondary piston forward.

When the forward movement of the pistons causes their primary cups to cover

the bypass holes, hydraulic pressure builds up and is transmitted to the

wheel cylinders. When the brake pedal retracts, the pistons allow fluid from

the reservoir(s) to refill the chamber if needed. This is the system Morgan

used from 1970s on.. a Girling unit from 1978-1993 and then a AP Racing system

with an integrated booster.

On later models. if

the brake light comes on, the fluid level in the reservoir(s) should be checked.

If the level is low, more fluid should be added, and the leak should be found

and repaired as soon as possible. BE SURE TO USE THE RIGHT BRAKE FLUID (see brake fluids

and the note on Silicone fluid) FOR YOUR VEHICLE.

Switching to or from silicone brake fluid can contaminate the system. If

this occurs, ALL of the seals in the brake system will need replacement,

and that is usually a VERY expensive operation. The tandem master cylinder was devised to avoid the possibility of all

the brakes of a vehicle being put out of action by a fracture in the

pipe line leading to one brake cylinder. . There are two pistons in the

master cylinder, in line with each other.

Difficulty in fitting

brake lines to the master is due to the ends of the steel flares having been

squashed by over tightening. Girling calls for a tightening torque

of 15 inch lbs. The tube nuts should be able to be easily threaded

all the way into the master cylinder ports by fingers alone.

Replacement for the Morgan Dual Master Cylinder

(pre-1993)

WATCHPOINT: We are looking for other alternatives. Suggestions welcome! April 14, 2022

|

Many with

single

master cylinders have switched, for safety reason, to Dual Masters.

Sadly,

the Girling unit used by Morgan from 1978 to 1993, is no longer

available

and was very expensive when it was. One option that has been tried and

tested

by many is the one used in the Subaru "BRAT" (aka the SHIFTER in the UK

or

the BRUMBY in Australia)..but other marques also adopted it and it is

VERY hard to find now. If one is found It will require adapters and a

bit of curving of

the brake tubing and possibly relieving the entry hole into the car a

bit

but it is a close match to the Girling and much cheaper new.

Many with

single

master cylinders have switched, for safety reason, to Dual Masters.

Sadly,

the Girling unit used by Morgan from 1978 to 1993, is no longer

available

and was very expensive when it was. One option that has been tried and

tested

by many is the one used in the Subaru "BRAT" (aka the SHIFTER in the UK

or

the BRUMBY in Australia)..but other marques also adopted it and it is

VERY hard to find now. If one is found It will require adapters and a

bit of curving of

the brake tubing and possibly relieving the entry hole into the car a

bit

but it is a close match to the Girling and much cheaper new.

If anyone finds another suitable replacement, please advise me.

SUBURU BRAT MASTER

CYLINDER

by Lorne

Goldman

By the way, this SUBARU MC was used on the following cars. (12) 1978-1981

1600 (2) 1978-1979

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

1600 DL (2)

1978-1979

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

1600 FE

(1) 1979-1979

1979 H4-1595cc 1.6L

2 BBL Vin EA71

1600 GF

(2) 1978-1979

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

BRAT (5) 1978-1981

1981 H4-1781cc

1.8L 2 BBL Vin EA81

1980 H4-1595cc

1.6L 2 BBL Vin EA71

1980 H4-1781cc

1.8L 2 BBL Vin EA81

1979 H4-1595cc

1.6L 2 BBL Vin EA71

1978 H4-1595cc

1.6L 2 BBL Vin EA71

CROSS REFERENCE

PART NUMBERS

REPCO P8970

ACDELCO US 18M112

AIMCO M900304

RAYBESTOS MC39170

| PROPORTIONING WATCHPOINT

(1978-1993) : Savvy owners have discovered that the original Girling MC (1978-1993)

provides a 50-50 division of hydraulic force to front and rear brakes. This

is very unusual for a front disk/rear drum set up. We know of three cures.

A. One can use

a proportioning valve, (fitting it at one of the rear junctions seems easiest)

and adjust the proportion until the car is under complete control (57-60

% bias in favor of the front) or, if you are the mathematical sort,

you can use a brake bias

calculator.

B. One can use

the later AP Caparo (originally Lockheed) 1993-on Master Cylinders which

are proportioned correctly. However, these come with a booster which can

make fitting difficult as the reservoir can abut the exhaust too closely

requiring a remote reservoir.

C. Fit the Subaru

MC above which comes with proper proportioning.

The result is

a happy one. The rear brakes stop locking first making the rear end of the

car more controllable under braking. Take note, brakes are not an area

for mistakes. If you have ANY concerns, use the services of a competent professional.

That being said, even a Morgan pro not be aware of the proportioning

issue.

|

Master Cylinder Bore Size

by Lorne Goldman

The question of MC bore size has become more important as other Tandem master cylinders have being replacing the earlier (and dangerous) single cylinder brake systems Morgan used.

Decreasing MC

bore size will decrease your pedal effort and increase your pedal

travel. Conversely, a larger bore in your master cylinder will,

all other components being the same, increase your pedal effort and

decrease your pedal travel. As with some other brake parts purchases,

this comes down to your preference for how the brakes "feel" under foot

when you are driving...but Morgan owners want to retain the original

feel all while significantly increasing their safety. The magic number

is a bore size of .75" (3/4 inch)

Attaching the Brake Lines to the Master Cylinder

The ends of the NUTS

that push the flares up against the sealing surfaces in the wheel and master

cylinders are what get mushroomed out and that prevents the threads on the

nut from getting in far enough to engage the threads in the cylinders.

If you look at the nuts, the ends closest to the flared end of the brake

pipe have no threads. That portion of the nut is supposed to be smooth and

straight. That is the area that normally gets mushroomed out from over tightening.

That is the area that needs to be filed down so that its diameter is smaller

than the inside diameter of the threads. DO NOT FILE THE ACTUAL

FLARED END OF THE BRAKE LINE ITSELF. If the end of the nut is the proper

diameter and the threads on the nut and in the cylinder are in good shape,

and the nut is carefully started STRAIGHT into the threaded hole of the cylinder,

then it should screw right in with your fingers until it bottoms against the

flared end of the brake pipe. Then just snug it down with a 7/16 line wrench

and

check for leakage

with pressure applied to the brake pedal.

Flaring

Brake Lines

I do not recommend

single flares for brake lines. These will work acceptably for fuel lines

but are a no-no for brake lines. The safest ends for brake lines use either

a double flare or bubble flare. The problem with bubble flares are that they

are considerably harder to make perfectly for the home garagiste and for

this reason I am loathe to suggest that they be made by any other than a

professional.

I do not recommend

single flares for brake lines. These will work acceptably for fuel lines

but are a no-no for brake lines. The safest ends for brake lines use either

a double flare or bubble flare. The problem with bubble flares are that they

are considerably harder to make perfectly for the home garagiste and for

this reason I am loathe to suggest that they be made by any other than a

professional.

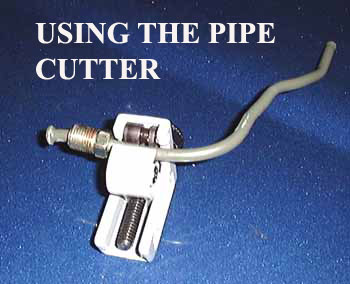

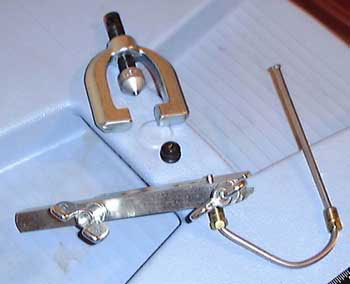

MAKING A DOUBLE FLARE

by Robert Robinette

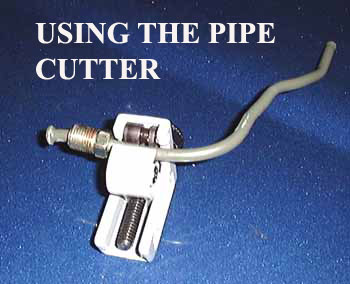

Tools: I use a

pipe cutter ($10) and a double-flare tool ($40-50) a table vice and a file.

Tools: I use a

pipe cutter ($10) and a double-flare tool ($40-50) a table vice and a file.

Put the pipe cutter

on the brake line where you want to cut it. Gently tighten the knob on the

cutter and then spin the cutter around the pipe about three times and then

tighten the knob a little more and repeat then repeat until the line breaks

in two. Now immediately slide on the flare nut. REMEMBER TO PUT THE FLARE

NUT ON THE PIPE BEFORE YOU FLARE IT OR YOU WILL HAVE TO CUT OFF YOUR NICE

NEW FLARE AND START OVER! Once you can slide the flare nut on the tube enough

to get a clamp on you're fine.

Now smooth out the

outer edge of the pipe with a file and use a deburring tool (or hand use

a large drill bit) to smooth out the inside edge of the pipe.

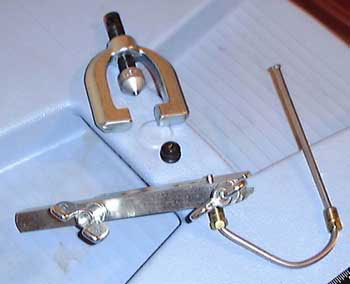

Double-flare tool

with pipe clamped, ready to flare (note both flare nuts are in place on pipe)

Put the flare

tool's pipe clamp on using the appropriate sized hole that matches your brake

line. Expose the required amount of pipe, clamp it down, attach the correct

adapter for the pipe you are using, screw it down on the pipe while watching

the pipe to make sure it doesn't slide out of the clamp. Now back out the

clamp and remove the adapter, then finish the double-flare by screwing down

the flare tool into the pipe. It's easier than it sounds, just follow the

directions that come with the tool. Repeat for the other brake line end.

.

Blow some WD-40 or

other solvent through your short line and then blow compressed air through

the line to dry it out. Push the brake pedal a little to flush some brake

fluid through the line coming from the master cylinder-this must be done

to remove any debris that got into the line during cutting, sanding and flaring.

Here is an explanatory

Video (If the video does not appear, please advise me)

| WATCHPOINT You must

torque the brake line nuts to 113-190 inch pounds! (about 10-15 foot pounds)

If you don't, you run the risk of having a nut coming loose and dumping brake

fluid with a loss of brake pressure and braking ability. |

Brake Lines

Brake lines are small

steel tubes often with special internal coatings to prevent rust and corrosion.

These tubes connect to the master cylinder, and then run under or at the sides of the chassis to

each of the wheels. At the wheel, a "brake hose" connects the brake line

to the caliper or wheel cylinder. As the brake pedal is pressed, the master

cylinder forces the brake fluid throughout the brake lines and into the wheel

(or brake) cylinders. This pressure causes the slave cylinder pistons to

move, forcing the shoes and pads against the drums and rotors to slow the

vehicle.

People use different

materials for brake lines. One is excellent and most others are unwise for one reasons or another.

For flexible

lines,

into the calipers and from the rigid line to the rear brake system,

I use Aeroquip, a stainless steel braded "forever" solution, the best

there is for this usage. They are available from Morgan specialists like Brands Hatch Morgans.

WATCHPOINT For the rigid lines, there is another forever product, copper/nickel product called Cunifer or Kunifer.

It is a UK invention that has swiftly gathered universal acceptance in the US and Australiaas

well.

It has all the advantages of copper but is much stronger and enduring.

GoMoG does not recommend ANYTHING else and it was recommended to

me by people a trust completely. I use it myself. Sadly, as I have

mentioned before many countries, US, Australia, the UK, often

myopically use only products and lore found locally. I

am Canadian and merely buy from any country that has the most suitable

product for the task. However, I understand we are all shaped by our

various cultures. After 30 years of dealing with Morgans all over the world, I have learned a lot.

|

Two closely fitted

pistons are located inside the dual circuit master cylinder. The inner part

of the piston is pressed against a rubber primary cup that prevents fluid

from leaking past the piston. The outer end of the piston is pressed against

a rubber secondary cup. This prevents the fluid from getting out of the master

cylinder. The inner piston also has several little bleeder ports; these pass

through the head to the base of the primary cup. Both of the piston assemblies

are in the cylinder, and are kept there by a stop plate (or snap ring) in

the end of the cylinder. A push rod, connected to the brake linkage, applies

pressure to the pistons.

Two closely fitted

pistons are located inside the dual circuit master cylinder. The inner part

of the piston is pressed against a rubber primary cup that prevents fluid

from leaking past the piston. The outer end of the piston is pressed against

a rubber secondary cup. This prevents the fluid from getting out of the master

cylinder. The inner piston also has several little bleeder ports; these pass

through the head to the base of the primary cup. Both of the piston assemblies

are in the cylinder, and are kept there by a stop plate (or snap ring) in

the end of the cylinder. A push rod, connected to the brake linkage, applies

pressure to the pistons.

Though master cylinder

kits are sold to repair leaking cylinders and replace all the rubber components,

it is commonly accepted that the master cylinder is better completely rebuilt

with the cylinders re-shaped or replaced as new when there is a problem.

A Morgan master cylinder is normally good for 40,000 miles before a rebuild.

have the MC sleeved with stainless steel and it will become a "forever" component

requiring only rubber part replacement at long intervals.

Please note that when

replaced the Master Cylinder itself MUST be "bled" of air bubbles. This is

done with hoses attached to the cylinders brake lines and looped back into

the reservoir. By pumping the brakes, the hoses will expel bubbles into the

fluid in which the other hose ends are submerged.

Caliper Piston Seals

The caliper piston

seals are designed to keep the fluid pressure behind the pistons, and to

retract the pistons enough to allow the brake pads to just barely clear the

rotor, thus reducing rolling resistance. The seals should NEVER leak. If

a leak is detected, it must be repaired immediately, because the fluid which

escapes can defeat braking power by getting on the disc, and the pressure

loss can affect brake safety.

Brake

Hoses

The master cylinder

is connected to each wheel by brake lines and hoses. Brake hoses are specially

constructed flexible tubes with metal ends for transmitting fluid under extreme

pressure. These hoses are used to connect the calipers to the metal brake

lines, allowing the caliper to move when the wheel turns or goes up and down.

The entire hydraulic system is filled with brake fluid, which is pressurized

by the movement of the master cylinder's pistons. This fluid is very important.

Always use only the recommended fluid.

When you remove a

wheel, these hoses are easily visible. If the hoses appear cracked or brittle,

they should be replaced immediately. Close inspection of the brake hoses

is a good way to prevent catastrophe!

Brake

Fluid

Brake fluid is a special

liquid for use in hydraulic brake systems, which must meet highly exact performance

specifications. It is designed to be impervious to wide temperature changes

and to not suffer any significant changes in important physical characteristics

such as compressibility over the operating temperature range. The fluid is

designed to not boil, even when exposed to the extreme temperatures of the

brakes.

Different types of

brake fluid are used in different systems, and should NEVER be mixed. Most

cars use "DOT 3" or "DOT 4" brake fluid. Some newer cars use silicone brake

fluids. Though Dot 3 and 4 are compatible, Dot 5 should NEVER be mixed together

with either, because the seals in each car are designed to work with only

their specific fluid types. For example, the mixing of "Silicone" brake fluid

and conventional glycol based DOT 3 or DOT 4 fluids should be avoided at

all costs, as the two fluid types are not miscible (they will not mix together).

DOT 3 brake fluid and DOT 4 brake fluid CAN be mixed.

SPECIAL

NOTE ON SILICONE BASED BRAKE FLUIDS

Girling has advised

that silicone based brake fluids DO CAUSE SEAL EXPANSION.OR THE CREATION

OF A GOOEY SUBSTANCE THAT COLLECTS AROUNDS THE SEALS; In most cases, in street

driven cars this is not a problem because the hydraulic cylinder seal fits

into a groove in the piston. The groove is very deep, and the piston and

the seal slide back and forth in the bore of the cylinder in which they are

a close fit. The 10% expansion of the seal, (this is the figure used

by Girling), only makes for a tighter seal. But in some older

Girling master cylinders, the seal fits into a groove in the body of the

cylinder and the piston, which is smooth, slides back and forth through the

seal. And experience has shown that in these cylinders, the expansion

of the seal causes the seal to lose contact with the piston and the cylinder

stops working. In fact ALL pressure is lost and the pedal goes right

to the floor! The type of cylinder where this has occurred is used

in all Morgans up to about 1955. All the sealing setup

in most disc brake calipers is the same as this, therefore the use

of silicone should be restricted to clutch hydraulics and drum brake systems

that use the later design master cylinder and where the cars are driven infrequently

and are really "garage queens."

IT IS NOT

RECOMMEND TO USE SILICONE FLUID FOR ANY DISC BRAKE CAR THAT IS EVER

DRIVEN HARD. As the temp of the fluid rises, the fluid becomes more

and more compressible, and it becomes more susceptible to contributing to

a sudden, total, and unpredictable lack of any pedal pressure and consequent

brake failure. It is just not worth the risk.

If you are not

racing your car or you are a Concours competitor then silicone brake fluid

can be used. But for the reasons mentioned, it is wiser to stay away!

The other problem

(not usually mentioned) with silicone fluid is that it is much more difficult

to bleed the brakes. Pumping the pedal vigorously as one does with

glycol will cause air to dissolve into the silicone fluid and defeat the

process. One must be very gentle with the pedal action when bleeding

or use a power bleeder.

MORE

ON SILICONE FROM A GREG SOLOW EMAIL

Because we do a lot

of restoration work, I thought it would be a good idea to try silicone fluid.

We started using it for the first time about 15 years ago. What we

have found is that glycol based fluid does NOT cause Girling or Lockheed

seals to expand, silicone based fluid DO CAUSE SEAL EXPANSION.

This has been confirmed by a press release that I have from Girling that

they put out about ten years ago. In most cases, in street driven cars this

is not a problem because in most hydraulic cylinders the seal fits into a

groove in the piston, The groove is very deep, and the piston and the

seal slide back and forth in the bore of the cylinder in which they are a

close fit. The 10% expansion of the seal, (this is the figure used

by Girling), only makes for a tighter seal. But in some older Girling master

cylinders, the seal fits into a groove in the body of the cylinder

and the piston, which is smooth, slides back and forth through the seal.

In our experience, in these cylinders, the expansion of the seal causes the

seal to lose contact with the piston and the cylinder stops working. In fact

you completely lose ALL pressure and the pedal goes right to the floor!

The type of cylinder where this has occurred is used in all Morgans up to

about 1955. All the sealing setup in most disc brake calipers is the same

as this, we have decided to restrict the use of silicone fluids to

clutch hydraulics and drum brake systems that use the later design master

cylinder and where the cars are driven infrequently and are really "garage

queens."

The other cars we

use these fluids on are cars like MG T series and Morris Minors where the

master cylinder is mounted under the floor boards and are therefore exposed

to a lot of moisture as well as having the later design of cylinder.

WE DO NOT RECOMMEND

THE USE OF SILICONE FLUID FOR ANY DISC BRAKE CAR THAT IS EVER DRIVEN HARD.

As the temp of the

fluid rises, the fluid becomes more and more compressible, and it becomes

more susceptible to contributing to a sudden, total, and unpredictable lack

of any pedal pressure and consequent brake failure. It is just not worth

the risk. Regards,

Greg Solow of the ENGINE ROOMWATHCPOINT

One of the WORST things

that can happen to your car is if the brake fluid becomes contaminated, because

the seals are designed to work with only pure brake fluid. "System contamination"

means that all of the piston seals and hoses are deteriorating, and therefore

must be replaced, a MAJOR expense. So, be VERY careful what you put in the

master cylinder reservoir!

It should be noted

that brake fluid is highly corrosive to paint, and care should be used not

to get it on your car's finish.

Brake fluid will become

oxygenated over time and should be changed at intervals which are a function

of time as well as mileage.

Without question, brakes are the most powerful system on your vehicle. No matter how much horsepower

you have, none of it’s of any use if you can’t brake off enough speed to keep from rear-ending the car in front of you. On the other hand,

traditional Morgans are so light that braking is never a large task,

with the

codicil that the front becomes unsteady on hard braking and

Without question, brakes are the most powerful system on your vehicle. No matter how much horsepower

you have, none of it’s of any use if you can’t brake off enough speed to keep from rear-ending the car in front of you. On the other hand,

traditional Morgans are so light that braking is never a large task,

with the

codicil that the front becomes unsteady on hard braking and

Cross Drilled Brake Rotors

Cross Drilled Brake Rotors

removal of the sheared

bolt relatively easy with the hub in hand and the careful use of a drill

press. This is not something to be tried with the hub still mounted.

removal of the sheared

bolt relatively easy with the hub in hand and the careful use of a drill

press. This is not something to be tried with the hub still mounted.

George's instructions above

will pretty much do the trick. However, the post-1993 reardrums do NOT

have a post adjuster at the rear of the back plate. (for this reason

many racers move back to the earlier pre-1993 versions (if they are

lucky enough to find a back plate!).

George's instructions above

will pretty much do the trick. However, the post-1993 reardrums do NOT

have a post adjuster at the rear of the back plate. (for this reason

many racers move back to the earlier pre-1993 versions (if they are

lucky enough to find a back plate!).  tendency to squeal. They also do not fit properly requiring, on the advice of the supplier,

tendency to squeal. They also do not fit properly requiring, on the advice of the supplier,  I first bought these

24 years ago at the suggestion of John Sheally II, the racer. I started with their Brake

pads and then their shoes in the same compound 20 years ago (their R4-S

compound). I now swear by them. The braking has more "feel" and is far

more effective in all conditions.... no squealing either. To give you an

example, I found the 2 pots calipers had the same braking power as 4 pots

when the Porterfields were put on!

I first bought these

24 years ago at the suggestion of John Sheally II, the racer. I started with their Brake

pads and then their shoes in the same compound 20 years ago (their R4-S

compound). I now swear by them. The braking has more "feel" and is far

more effective in all conditions.... no squealing either. To give you an

example, I found the 2 pots calipers had the same braking power as 4 pots

when the Porterfields were put on!  Many with

single

master cylinders have switched, for safety reason, to Dual Masters.

Sadly,

the Girling unit used by Morgan from 1978 to 1993, is no longer

available

and was very expensive when it was. One option that has been tried and

tested

by many is the one used in the Subaru "BRAT" (aka the SHIFTER in the UK

or

the BRUMBY in Australia)..but other marques also adopted it and it is

VERY hard to find now. If one is found It will require adapters and a

bit of curving of

the brake tubing and possibly relieving the entry hole into the car a

bit

but it is a close match to the Girling and much cheaper new.

Many with

single

master cylinders have switched, for safety reason, to Dual Masters.

Sadly,

the Girling unit used by Morgan from 1978 to 1993, is no longer

available

and was very expensive when it was. One option that has been tried and

tested

by many is the one used in the Subaru "BRAT" (aka the SHIFTER in the UK

or

the BRUMBY in Australia)..but other marques also adopted it and it is

VERY hard to find now. If one is found It will require adapters and a

bit of curving of

the brake tubing and possibly relieving the entry hole into the car a

bit

but it is a close match to the Girling and much cheaper new.  I do not recommend

single flares for brake lines. These will work acceptably for fuel lines

but are a no-no for brake lines. The safest ends for brake lines use either

a double flare or bubble flare. The problem with bubble flares are that they

are considerably harder to make perfectly for the home garagiste and for

this reason I am loathe to suggest that they be made by any other than a

professional.

I do not recommend

single flares for brake lines. These will work acceptably for fuel lines

but are a no-no for brake lines. The safest ends for brake lines use either

a double flare or bubble flare. The problem with bubble flares are that they

are considerably harder to make perfectly for the home garagiste and for

this reason I am loathe to suggest that they be made by any other than a

professional.  Tools: I use a

pipe cutter ($10) and a double-flare tool ($40-50) a table vice and a file.

Tools: I use a

pipe cutter ($10) and a double-flare tool ($40-50) a table vice and a file.

Two closely fitted

pistons are located inside the dual circuit master cylinder. The inner part

of the piston is pressed against a rubber primary cup that prevents fluid

from leaking past the piston. The outer end of the piston is pressed against

a rubber secondary cup. This prevents the fluid from getting out of the master

cylinder. The inner piston also has several little bleeder ports; these pass

through the head to the base of the primary cup. Both of the piston assemblies

are in the cylinder, and are kept there by a stop plate (or snap ring) in

the end of the cylinder. A push rod, connected to the brake linkage, applies

pressure to the pistons.

Two closely fitted

pistons are located inside the dual circuit master cylinder. The inner part

of the piston is pressed against a rubber primary cup that prevents fluid

from leaking past the piston. The outer end of the piston is pressed against

a rubber secondary cup. This prevents the fluid from getting out of the master

cylinder. The inner piston also has several little bleeder ports; these pass

through the head to the base of the primary cup. Both of the piston assemblies

are in the cylinder, and are kept there by a stop plate (or snap ring) in

the end of the cylinder. A push rod, connected to the brake linkage, applies

pressure to the pistons.