The

Burman-Douglas Steering Box

The

Burman-Douglas Steering Box

| Some years ago, there was much agitation on a private Morgan forum (NBC) about a Burman-Douglas article originally contributed to GoMoG by the The Morgan Ear”, a wonderful Australian newsletter. The Ear and GoMoG have always exchanged info during a succession of Editors over the last 2 decades.Sadly, in 2006, the article's author, John Merton, sadly known for attacking other Morgan writers, added GoMoG to his hit-list as well. For the sake of community harmony, GoMoG's article was removed at the first complaint reported. However, John and two NBC mates, notably Tim Harris aka Hamwich, have remained inexplicably hostile at this Manual and spare no opportunity to pan it publicly. Neither John Merton nor any other person has ever contacted GoMoG on this steering box content. I am left with the conclusion that the goal is to have you consult their Manual. They call it "Morgantica". To my mind, the priority is always the health of your Morgan. Good luck! Feb 10, 2011 |

Diagrams (all diagrams expand into their own page if clicked)

1. The

Steering Gear

2. The

Steering Gear II

3. Component

Schematic (can also be used in conjunction with parts

sourcing)

Articles

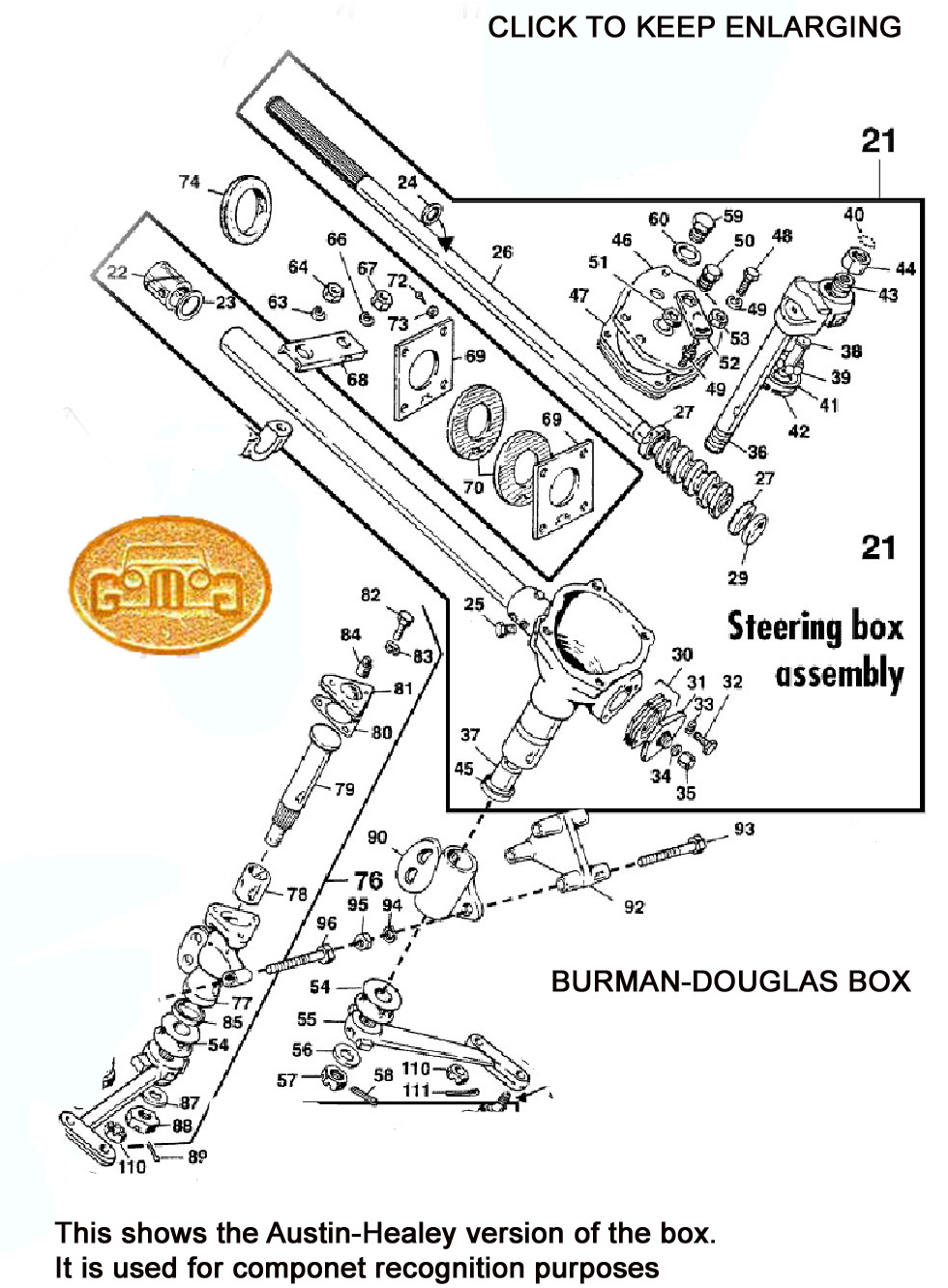

| N.B. Some links (Alpha) have been included to illustrate drop arm removal, oil seal replacement and ball bearing overhaul. In fact, the Morgan Burman box is a later box than the Alfa's. The main difference between the Morgan and the Alfa/Healey steering boxes is in the way the nut (a square block instead of the long Morgan nut) drives the rocker arm. The latter is made of a simple shaft and a plate screwed on it supporting a removable peg whilst the Morgan is an all- in-one piece. It can be presumed that the change was to simplify the machining and make it less expensive to produce. |

4. The

Burman Steering Box (from the History of Berkeley Sports Cars in the

US at coldplug.com)

5 Replace

the Burman Box Seal – in situ (thanks to our mates with Alfas!)

6. Replace

the Burman Box Seal II (thanks to our friends in Sweden at veloce.se!)

7. Tips

on steering box seal replacement, and type of seals found

8. Burman

steering box internals

9. Burman

steering box internals (with a possible source new casting)

Parts & Service

10. Anglo

Parts (UK)

11. Highwood

Alfa (US)

Some History and Notes

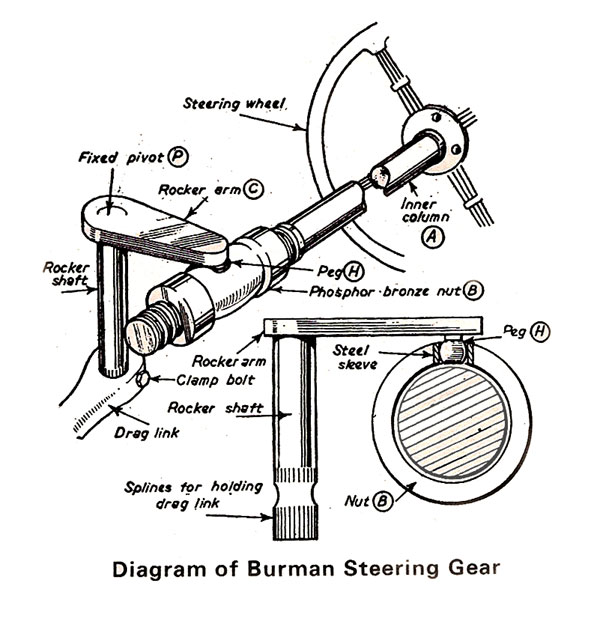

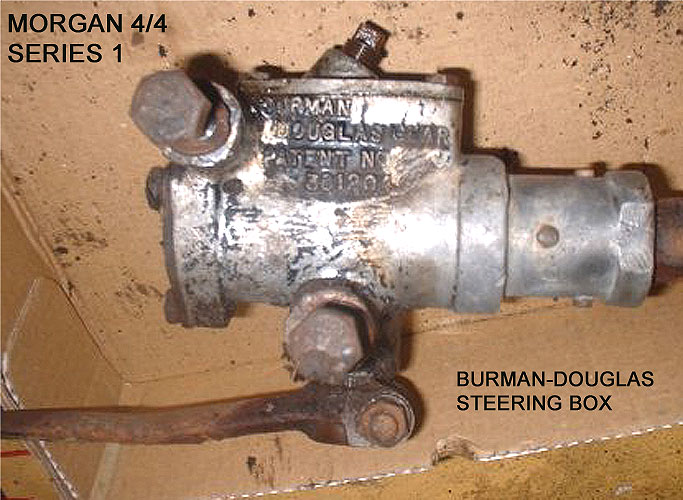

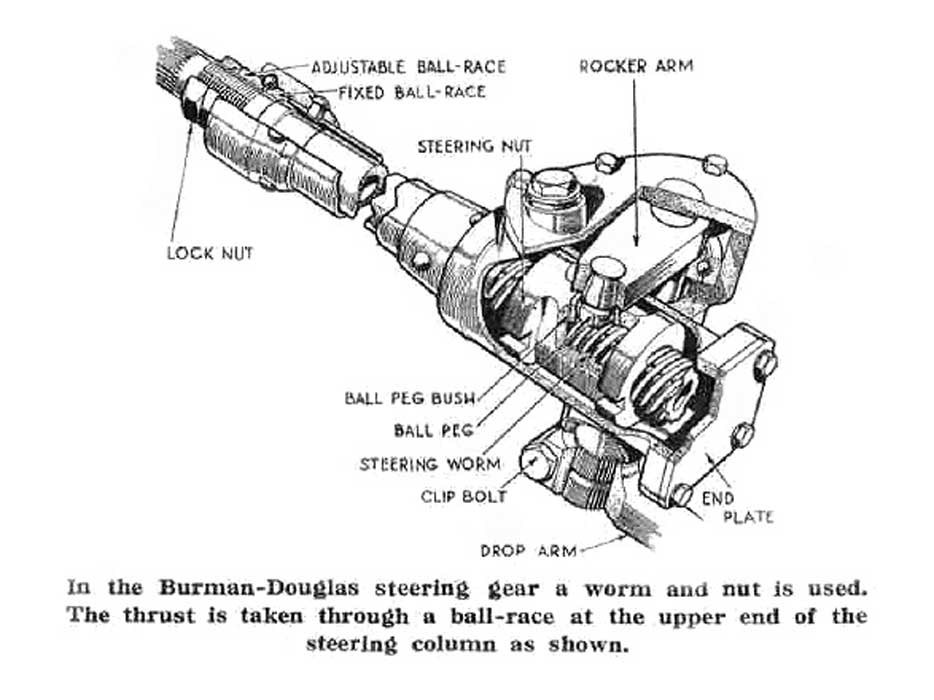

The Burman-Douglas steering box was used by many marques. Though there are fitting and other differences, the principles are the same and the components identical in most cases. It was manufactured by Burman and Sons Ltd, of Ryland Road, Birmingham, England, not far from Malvern.

It has a recirculating worm and nut design, the precursor

of the recirculating ball. It was fitted to pre- and post-war vehicles,

Armstrong Siddeley, the Ford Eight, the Ford Prefect, the Bedford CA, Alfas,

Volkswagons, Austin Healey Daimler, Ford, Lanchester, Hillman, Humber,

Lea Francis, Rovers, Singers, the S.S., Standard, Talbot, Triumph, Vauxhall

and, of course, Morgans. In its day, the Burman Douglas box was considered

a  quality

part in a model specification (but that was not saying much!). The Morgan

variant is unusual in that it is one of the few cast from aluminum rather

than iron.

quality

part in a model specification (but that was not saying much!). The Morgan

variant is unusual in that it is one of the few cast from aluminum rather

than iron.

Its major competition in the UK at the time was Bishop Cam and Marles (who later called themselves Marles-Weller). All three were bad. The least sophisticated and oldest of the three was the Bishop cam designed in the early 1920s. However, the Bishop Cam had a provision to adjust it for wear. The Burman-Douglas did not. The first boxes to Series I were the Burman worm and nut type. It is not adjustable for wear and is giving grief to owners as spares are inexistent. The Series 1 Morgans can quickly develop many inches of play to sad effect. Some reports have the post-war Burmans being worse than the pre-war ones.

But there is one advantage to the Burman-Douglas box, it is a bit better than the very crude Cam Gears box that the Works adopted in 1953/4. Yet many of the Burman boxes were removed and Cam Gears boxes retro-fitted. I think that there is a lot of confusion between the Bishop, Burman and the Cam gears. The later being the better design as it remains adjustable and has the lowest friction. The worm and nut system does not allow any adjustment and has a high wear. The Cam gears got rid of that. This was encouraged by the Factory who made up a kit for the conversion and promoted it as a big step forward. Ironically, many of these cars were retrofit once again over their following decades with a Gemmer!

There are easy ways to distinguish

between the Burman-Doulgas and the Cam Gears steering boxes if you are

unsure of which you have. The steering wheel on the Burman-Douglas is on

a tapered shaft and fit with a woodruff key. The Cam Gears has a splined

shaft. The Burman has two large narrow hex nuts, placed under the steering

wheel to adjust the end float in the inner column. As noted, there is no

adjuster on the top plate on the Burman box, just the raised filler plug.

The end plate on the Burman box is a conical shape held in place by three,

rather than the square plate held by 4 bolts one finds on the Cam Gears

box.

| N.B. Morgan steering took a BIG step forward when the company was able to mandate an excellent French manufacturer to adapt one of its steering system for Morgans. We call it Gemmer Box. This was followed by the Jack Knight Morgan Rack & Pinion. With both, Morgan steering and front suspension entered a new era. The Gemmer swap for Burman-Douglas or Cam Gears Steering boxes has become THE common upgrade for earlier Morgan owners. Prudent maintenance may get the best out of your Burman-Douglas but the simplest fix is to fit the Gemmer. Sadly, Gemmer supply has become spotty and uncertain, both of the box (RHD and LHD) and the drop arms. |

ALPHA ROMEO |

|

BISHOP GEARS BOX

(aka Cam Gears Ltd.)

by Jean-Frederic Frot at the eMog Pub February

10, 2011

The

drag ling clamp to the tie rod is set once and for all and should not be

adjusted unless the ball joints have been disturbed or replaced. Its correct

position allows to have the steering box on the high spot (dead center)

when the wheels are pointing straight ahead. It should be clamped tight

and should not slide or rotate.

The

drag ling clamp to the tie rod is set once and for all and should not be

adjusted unless the ball joints have been disturbed or replaced. Its correct

position allows to have the steering box on the high spot (dead center)

when the wheels are pointing straight ahead. It should be clamped tight

and should not slide or rotate.

The high spot is created by machining the cam with the groove slightly narrower (0.001 to 0.002") than is normal width in the area where the steering wheel is in the center. The high spot is there to stiffen the steering slightly when the wheels are pointing straight ahead so that it is easier to maintain the car in a straight line without having to correct constantly.

If the parts are in good condition and the peg is set correctly, there should be no detectable play in the steering, especially on dead center where the high spot is making it even tighter. The myth of the play being a normal occurence is due ONLY to lack of maintenance. If one drives the car for a long time without adjusting the peg, the cam wears unevenly and it becomes difficult, even impossible, to adjust the peg correctly.

This groove in the cam is trapezoidal and the peg is machined conically. As the peg wears, adjustment allows the peg to sink deeper into the groove, catching up any existing play and rubbing on a fresh unworn surface. All the play will therefore be recovered.

In extreme cases, the peg could eventually bottom into the groove, making it impossible to adjust any further but I have never seen it happen.

There is a kit offered by British Vintage Car Factors. The idea behind these kits is to replace the adjusting screw by a spring loaded finger that presses constantly on the peg to push it down into the cam groove so that adjustment is no longer required. However, I have strong reservations. This system will make the steering stiffer but most of all will wear the cam and peg much faster. In the original design, adjusting the peg means that there is no downwards pressure whilst this system does. I would rather spend ten minutes every 5,000 miles and keep my cam and peg forever than having to replace them. I am not even sure that you can get the parts these days.

There is a lot of confusion between the Burman Box and the Cam Gears Box (aka the Bishop Gears box). The later is the better design as it is adjustable and has the lower friction of the two. The Burman worm and nut system does not allow any adjustment and has very high wear. Happily, Cam Gears box solved this issue. The shims in the end plate of the Cam Gears are there to adjust the ball bearings end float of the steering column, as this is minimal in most cases, it has only a small effect on the steering play. To test it, just pull and push on the steering column, if a visible play can be detected, they need adjusting by removing some of the shims. I have seen a few cases where some of the balls had broken. Needless to say the steering becomes pretty stiff and makes a horrible grinding noise. Remarkably, it did not jam! As the bronze ball races were damaged, a full replacement of the steering column was a cheaper option.

Of course, the ultimate steering system for these Morgans is the Gemmer with the recirculating balls with low friction and wear. (N.B. Sadly, they are no longer available.)

| WEBMASTER NOTE: It is interesting to know that Cam Gears received a patent for a Rack & Pinion Steering system one year before Morgan began installing their cam gear system. The patent was granted in October of 1953 by the German Patent Office, and in 1957 by the British Patent Office and in 1964 by the USA Patent Office. Cam gears continued filing new steering designs with various patent offices into the 1980s. |

Morgan Cam Gears Overhaul (Bishop Gears)