Please read the whole article. The internal links are for later convenience only.

IMPORTANT WATCHPOINT APRIL

23, 2018 - SINCE MALLORY WAS PURCHASED BY MSD/Holley, THIS WONDERFUL

PART HAS BEEN DISCONTINUED. All the best site and Auto suppliers list

it as

back ordered still. Holly will not sell it. They want to sell their own

stuff which is not IMHO, as good.

|

Updated OCTOBER 21, 2021. Holley never restarted production of the Uniite for this engine as they

promised 3 years ago. :( Used units under the part #s

below occasionally come up on ebay. I have been casting about for

a replacement as good. Sadly everyt4768901hing I have checked out, including

the programmable and touted 123 distributor, for which I have had mixed feedback. And it is costly!

I also believe in keeping Morgans as simple as possible and the Mallory

Unilite is tried and true in literally hundreds of installations I have

seen. However, I see that the Mallory Unilite pop-in unit is for sale

from Real Steel in their catalogue at page S7 and in the USA one can consult with Holley

HOWEVER, THIS SOLUTION CAN ONLY BE USED WITH A MALLORY POINTS

DISTRIBUTOR (I have tried many times with no luck)..the new control

point for these things for Holley. Please read the entire section on Mallory below nonetheless!! And do not forget the ballast resistor.

Best solution is to find a used unit ..either points or Unilite made

for the Land Rover or Buick 215. Numbers below. Otherwise, we can

live in hope waiting for Holley to servve the market as Mallory once

did.

THE GOOD

i. You will not need to remove the old distributor and switch the drive gear as you have to when using a full Mallory unit as the kit goes into the existing distributor.

ii. You get the historic reliablity, simplicity and precision of the

Mallory Unilite at a small fraction of its earlier full

distributor price as well as benefiting from decades of experience and

lore. A MALLORY UNILITE REALLY DOES MAKE A DIFFERENCE!!

iii. You can retain the original Rover/LRover distributor. (ugh!)

THE BAD

The kit does not support vacuum advance, which is really unnecessary

for a small hyper light sports car with such a large engine. |

1. Fitting a Mallory Unilite to a Plus 8

2. Recommended Wiring Setup

3. Which Mallory? DO NOT BUY A MALLORY DUAL POINT!!!

4. Ballast resistor

5. 1968 to 1977

6. 1977-2000 (or to 1998 Overseas models)

7. Removal of Old Distributor

8. Timing the Car

9. Major Watchpoint When Installing a MSD or Pertronix

A. Fix One

B. Fix Two

C. Fix Three

FITTING A MALLORY TO A PLUS 8 (without a MSD or Pertronix)

by Lorne Goldman & Win Muehling (updated July 23, 2017)

SEE ABOVE

The biggest weak point on all Rover/LR V8s until

GEMS

moved them to computer controlled distributorless ignition. (1968-2000

Plus 8s)

Rover tried one distributor design and amplifier

combo

after another. Some getting a little better and some getting a little

worse.

They were the Opus, the 35D8, the 35DE8, the 35DM8, the 35DML8. They

all

had a few vital characteristics in common,

1. the design degrades the spark from coil to plug

2. they are vulnerable to the elements and complex

to

maintain.

3. they are 2 to 3 times the price of other proper

options.

To address their issues, many solutions have been

tried.

Ignition modules like MSD, Lumenition, Micro Dynamics, or many others.

For the

distributor itself, many aftermarket

pop-in technologies

has been suggested. However, with all these solutions, the core problem

is unaddressed.

Ignition modules do not cure bad distributors and pop-in

technology does not cure bad mechanical designs.

Mallory

began in the early in the 20th century. They supplied Ford for many

years

until Ford moved to a cheaper supplier. They produce fine

simple-to-deal-with

product based on photo optics called the Unilite. The also make other

distributors

based on other technology. When the UK racers and tuners became

frustrated

a couple of decades ago, this is where they turned to for a solution.

Carson

City, Nevada. They are available in the UK from Real Steel, Rimmer

Brothers, and John Wolfe Racing. (Check the prices as they vary a lot!)

Mallory

began in the early in the 20th century. They supplied Ford for many

years

until Ford moved to a cheaper supplier. They produce fine

simple-to-deal-with

product based on photo optics called the Unilite. The also make other

distributors

based on other technology. When the UK racers and tuners became

frustrated

a couple of decades ago, this is where they turned to for a solution.

Carson

City, Nevada. They are available in the UK from Real Steel, Rimmer

Brothers, and John Wolfe Racing. (Check the prices as they vary a lot!)

The greatest distributor on the planet will not

give you

more power. One cannot make a bigger explosion by using a bigger match.

However, a substandard spark can be a @#%$! nightmare. One installs a

Mallory because you are tired of fighting an unreliable component and you are

searching for an instant start-up, a good idle and no hassles at any rev range.

I have a great Mallory story involving Kevin

Vernon, the extremly talented owner of Tudor Motors up in Shropshire. Though Tudor is a century old,

Kevin has the same insatiable curiosity as our David Poole (GEMS). At the

time,he had the same set-up system on his Plus 8 as I have on mine. He had

just installed a Mallory I sent over and was wondering what all the fuss was

about. He pulled out his trusty oscilloscope and tested the spark

produced by his stock distributor side by side with the spark produced

by my Mallory. He was amazed. He had set his oscilloscope to the spark

range of his dizzy. The Mallory spark went right off the same chart!

I can recommend a Mallory Unilite for a Plus 8

with NO reservations. I have walked scores through the swap and all are happy.They are inexpensive, well made and

there is a ton of backup within the Morgan community and elsewhere.

MALLORY

DUAL POINT

N.B. I do NOT recommend the

Mallory Dual Point model for Plus 8s or Rover V8s and any car for that matter. For many reasons, they soon develop issues. However. I DO recommend that you modify it to make it into a Unilite. See my October 21, 2021 above! Inexpensive and effective.

|

| MALLORY

M.B.I. MAGNETIC BREAKERLESS OR ELECTRONIC

N.B. The external and

internal wiring of their magnetic

distributors (often called MBI for "Magnetic Breakerless" or

"Electronic" are the same as the Unilite. They are inherently less sensitive than the

Unilite..but they are also inherently less precise. They lose up to a

degree

in timing for

every 1000 rpm. Considering

that and our lack of familiarity

with them, they are not a good option. |

WHICH MALLORY DISTRIBUTOR?

There are some things you must know to order yours.

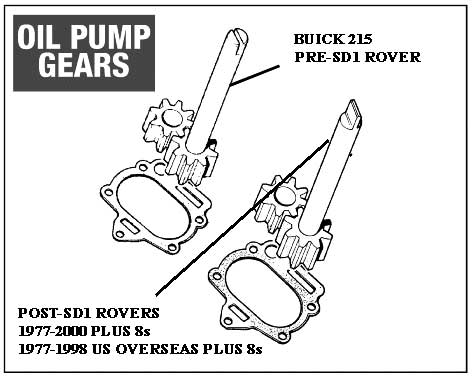

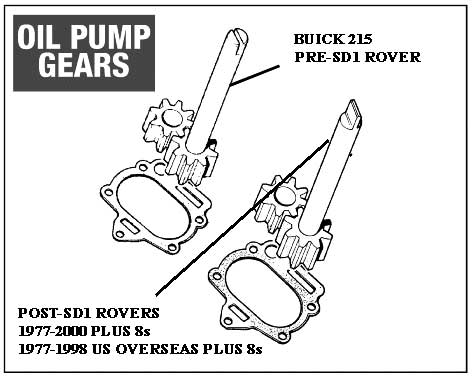

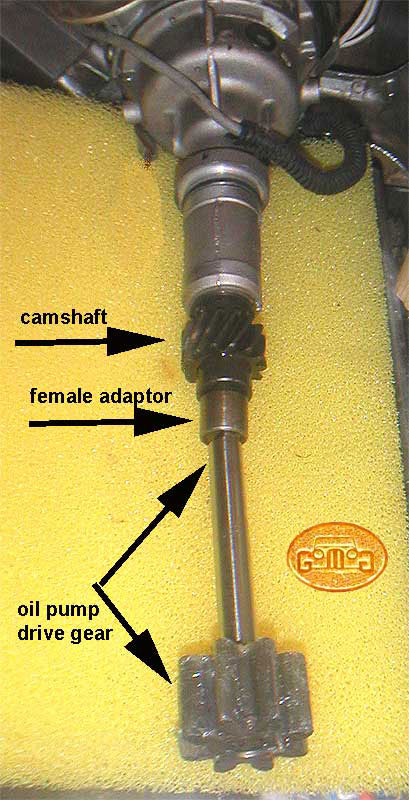

1. Distributored Rover V8s are divided into two

generations..by timing covers. The first decade of Rover production (1967-1977) used a

close copy of the Buick 215 timing cover.

This cover had an oil pump with a female drive gear driven by a male distributor

shaft. The second generation, (1977-GEMS cars), had a better oil pump

with a male drive gear driven by a female fitting on the distributor shaft.)

You must choose your Mallory model to match your generation.

cover.

This cover had an oil pump with a female drive gear driven by a male distributor

shaft. The second generation, (1977-GEMS cars), had a better oil pump

with a male drive gear driven by a female fitting on the distributor shaft.)

You must choose your Mallory model to match your generation.

2. Mallory, like most top-flight

earlier (and later) distributors must be ballast-resisted. (The earlier Rover

already has one.) This can be done by buying a distributor ballast resistor (they are made to

a standard) from Mallory or your local car part store or buying a

Mallory internally ballast resisted coil, a red top, (which normally

gets VERY hot!). This option simplifies the wiring but these coils don't last as long. I have had my

Mallory internally ballast resisted coil crack with the heat.

(Happily I carried another in the car). Go for a external ballast

resistor. It works with any coil.

| BALLAST

RESISTORS

N.B. If the ballast

resistor terminals touch (be careful of your bonnet stays!) or is poorly grounded, the wiring will deliver a

full 12 volts to the coil and then the distributor. That will overheat

the coil and/or destroy the photo-optic heart of the Mallory. Please look here as well. |

FOR

EARLIER PLUS 8s (1968-1976) (aka Pre-Sd1)

This is the same application as the early 1960s

Buick 215. Installation is straightforward. Click INSTALLATION. Click COIL

for coil choices and WIRING.

FOR LATER DISTRIBUTORED PLUS 8s (aka

post-Sd1) = Plus 8s 1977-1996 (in the US) and 1977-2000 (everywhere else)

APRIL

23, 2018 - SINCE MALLORY WAS PUCHASED BY MSD, THIS WONDERFUL PART HAS

BEEN DISCONTINUED. The told me they would start production in a year (7 years ago). BUT!!!

all service parts for the units are still available.

The part number you need is Mallory Unilite

4768901 with vacuum advance. This Mallory Unilites comes with 24 degrees of vacuum

advance (all Mallorys have an adjustable vacuum advance feature). There are

versions ending with a "2" rather than a "1" that come with 18 degrees of vacuum

advance). The model comes without the male ending you don't want but

you will be required to swap the distributor gear and its female connection

from your existing unit to the Mallory. This is not difficult and if

you are uncertain, have a local machine shop or garage do it for you.

| WATCHPOINT:

Do NOT follow Mallory's instruction

for the gear/female connector swap CLEARANCE. It is too large and can

create

a bit of oil seepage. Use a clearance of 5 to 8 thous |

REMOVAL

OF THE OLD DISTRIBUTOR

REMOVAL

OF THE OLD DISTRIBUTOR

Many prefer to set the engine at TDC before doing

this

work. This is not strictly necessary but it will mitigate problems if you get anything wrong..

1. Remove the coil-to-distributor wire.

2. Remove the vacuum advance hose.

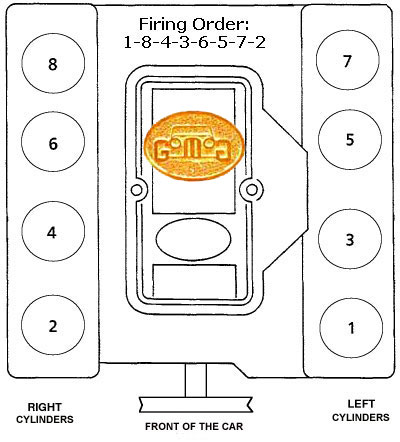

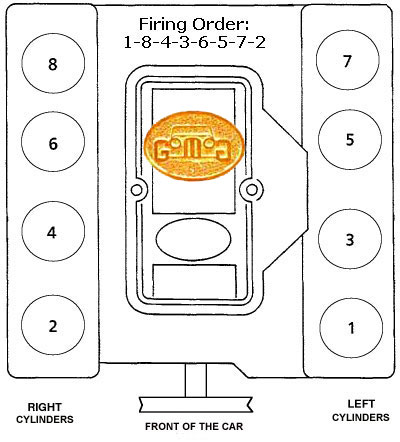

3. If you are unfamiliar with the order of the

ignition leads (the big wires from the distributor to the spark plugs) order,

mark the leads with something to identify them and take an image of the

leads still installed on the cap and the engine so that you can have the

right ignition wire on the right cap post going to the right cylinder.

Actually, you only need to know where the lead to cylinder one should be

(cylinder1 is the front right if you are standing in front of the car.). The

firing order, and therefore the order the cylinder leads are attached to the

cap is (clockwise).

4. Remove the ignition wires and the connections.

5. If there is a separate ignition module (most

Lucas

versions). remove it as well, you will not be needing it.

6. Remove

the cap and take an image of the rotor and the distributors relationship with the engine's .

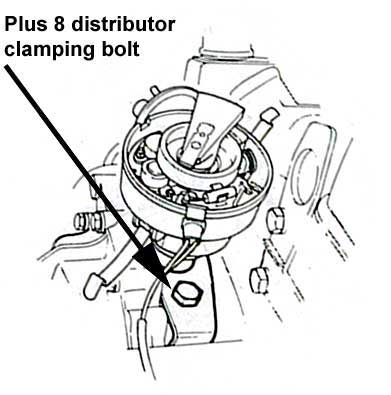

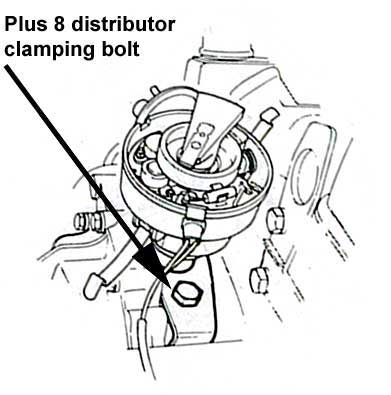

| 7. Undo the clamp holding

the distributor to the front

cover. |

|

8. Hold the

rotor and lift upwards to

slowly remove the distributor. The rotor will turn counter-clockwise

about

15-10 degrees as the distributor lifts and it disengages the camshaft

gear.

The relationship of the rotor angle and the distributor shaft end will

become very important at re-installation.

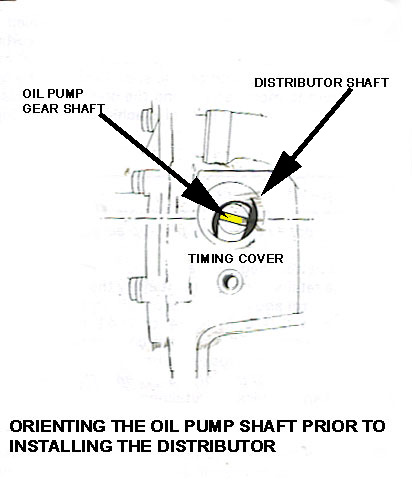

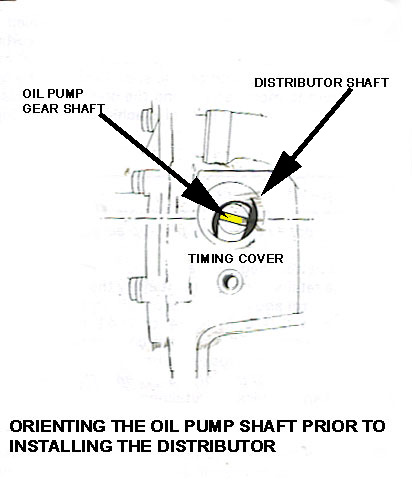

| 9.

Look down the distributor hole and

take a picture or the orientation of the oil pump drive gear. The oil

pump

drive gear must be turned on re-installation of the new distributor to

the angle that allows the rotor to arrive at the position you left it.

You will likely have to turn the oil drive gear to permit this to

happen.

This can be done with a clean screwdriver. |

|

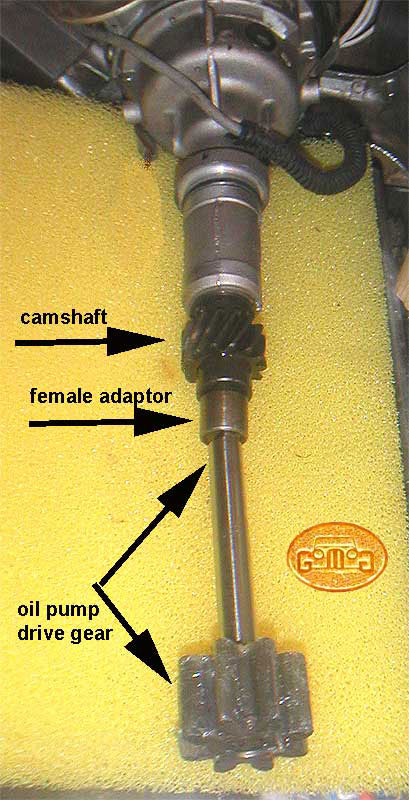

10. Now you must swap over the distributor drive

gear

and female interface fitting (along with that little washer that goes

on

the shaft between the camshaft gear and the bottom of the distributor

body.

Mallory sent a new one with the distributor.

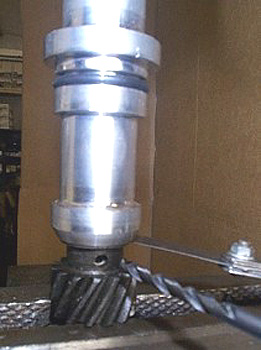

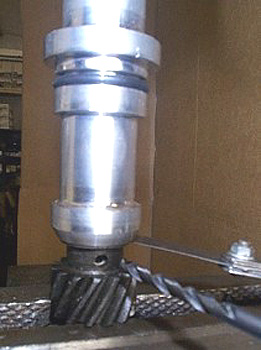

| 11. Tap out the pin the

holds the gear and female interface

to the old distributor's shaft. Slip the washer of the shaft of the

Mallory

and then slip on the gear and its attached female fitting. |

|

| 12. You must now drill the

shaft perfectly so that the

clearance between the gear/washer and the distributor is .005-.008

inches

(5 to 8 thous) measured by using a feeler gauge as shown at the left.

To

determine the correct bit, measure the removed pin.

This is the part that

scares most, with reason. If you

are concerned, go to a machine shop. They can do the job perfectly in a

few minutes.

|

|

13. Once the hole is drilled, use a pin,

preferably a

new one, to drive into the gear and shaft holes and firmly secure the

gear

to the shaft.

INSTALLATION OF THE NEW

DISTRIBUTOR

14. (Also see "TIMING THE CAR" below.) There are

two important

things to understand for reinstallation of the distributor.

A. You want to start off with the rotor facing

very close

to the same way as it was when you took the old distributor out. This

will

only be possible if the oil pump gear the distributor shaft interfaces

with is angled to permit this. If you are too far out, the

car will

not start or back fire as your spark will be out of sync with the

engine.

When you swapped over female interface gear, it is

very

unlikely its orientation in relationship with the rotor stayed the same

as the same relationship with the old distributor. Ergo, the oil pump

gear

will often only cooperate to permit the correct final orientation of

the

rotor if you turn the oil pump gear to allow to arrive at the right

place.

Firstly, take a look at the images

you

took to see where you want;

i. the distributor aligned (using the

cap clips

or the vacuum unit as references with points in the engine).

ii. the rotor aligned, from the image you

took with the

cap off but 15-20 degrees more counterclockwise.

Click here

for why.

iii. At your workbench, hold your lightly

distributor

in your table and align the rotor and distributor to approximate the

same

relationship in the image.

iv. Now look under the distributor to see

how the slot

is angled in the female interface fitting. Compare that with how the

oil

pump gear is angled..either by looking down the distributor hole on the

engine or the image you took.

v. NOW using a long screwdriver,

turn the oil pump

gear in the engine to match the angle of the female interface on the

distributor

vi. Reinstall holding the rotor and

turning it the same

amount clockwise seen in #ii. as it engages the oil pump to seat

ENTIRELY.

| WATCHPOINT:

You are now close to starting OR

180 degrees out. If it doesn't start (with a friend turning it overhigh compression and

you fiddling at the dizzy. Remove and turn the rotor 180 and reinstall.

see

below. |

15. Reinstall the wires as indicated below.

16. Put the vacuum advance hose back on.

TIMING

THE CAR

There is some understanding necessary to timing a

4 stroke

engine. The crankshaft pushes the piston up twice for every one spark.

That has consequences.

Here are the strokes and what is happening

during each.

1. COMPRESSION stroke where the fresh air/fuel air

mixture

is compressed (all valves shut)

2. POWER stroke, starting with the spark

and resultant

combustion that pushes the piston down.

3. EXHAUST stroke, where the piston comes

back up but

with the exhaust valve open to allow the spent gases to escape.

4. INTAKE stroke when the piston goes down

sucking in

a fresh air/fuel mixture with the intake valve open.

In other words the piston is at the top, pointing

to the

same scribe, in two of the four strokes, COMPRESSION and EXHAUST. Set

the

rotor to the COMPRESSION stroke and you're fine. Set the rotor to the

EXHAUST

stroke and you are exactly 180 degrees off. Without other measures, you

have a 50-50 chance you got it right.

Frankly, for most people, that is the best way of

discovering

WHETHER they got it right. Try to start the car. If they are Piston 1

COMPRESSION

stroke's top, the car will at least attempt to start (sometimes with a

bit of adjustment. If they have it on the EXHAUST stroke, the car will

not start or may even backfire. If that happens, I simply tell them to

lift the distributor enough to disengage it and turn the rotor 180 and

re-engage it.

Of course, there are WAYS of determining the real

TDC.

But for most people I help, it is a bit beyond their skill level and

too

invasive. One way is to use your thumb to block the number 1 spark plug

hole while someone hand cranks the engine. When it is on the

COMPRESSION

stroke, you will feel compression against your thumb. (When it is on

the

EXHAUST stroke, there is no compression as the exhaust valve in that

cylinder

will be open.) When you know you are on the right stroke, you simply

have

your friend turn the crank until scribe marks say it is TDC.

The other way, surer, is to remove the valve

cover, have

a friend turn the crank until it is approaching the TDC scribe make

with

both piston 1 valves closed. (BTW, never trust Rover or LR scribe

marks.

They are inaccurate 50% of the time.)

I have found it useful to use a bit of white paint

to

mark timing points I need after I have found them. For example, one for

TDC and another for where my car likes to run on the fuel I normally

use.

This is especially important for high

compression

variants of the engine. With these engines, I have one mark for TDC,

another

mark for normal running and a last mark for running when I am traveling

and the quality of the petrol drops.

| WATCHPOINT:

Outside of great quality

workmanship on the mechanicals and its billet rather than cast body,

Mallory

Unilite magic is based solely on its optical trigger unit which is

common

to ALL Unilites for all cars and easily found. This device can be

tested

in situ in seconds roadside and replaced in minutes. If I can do it,

anyone

can do it. Outside of the USA (where the modules are available at every

auto store on every corner, carry an extra module with you. REMEMBER do not jump

start your car with the ignition

hooked up as this can kill the Unilite's ignition module. Disconnect

battery

and charge IT! or disconnect the distributor. |

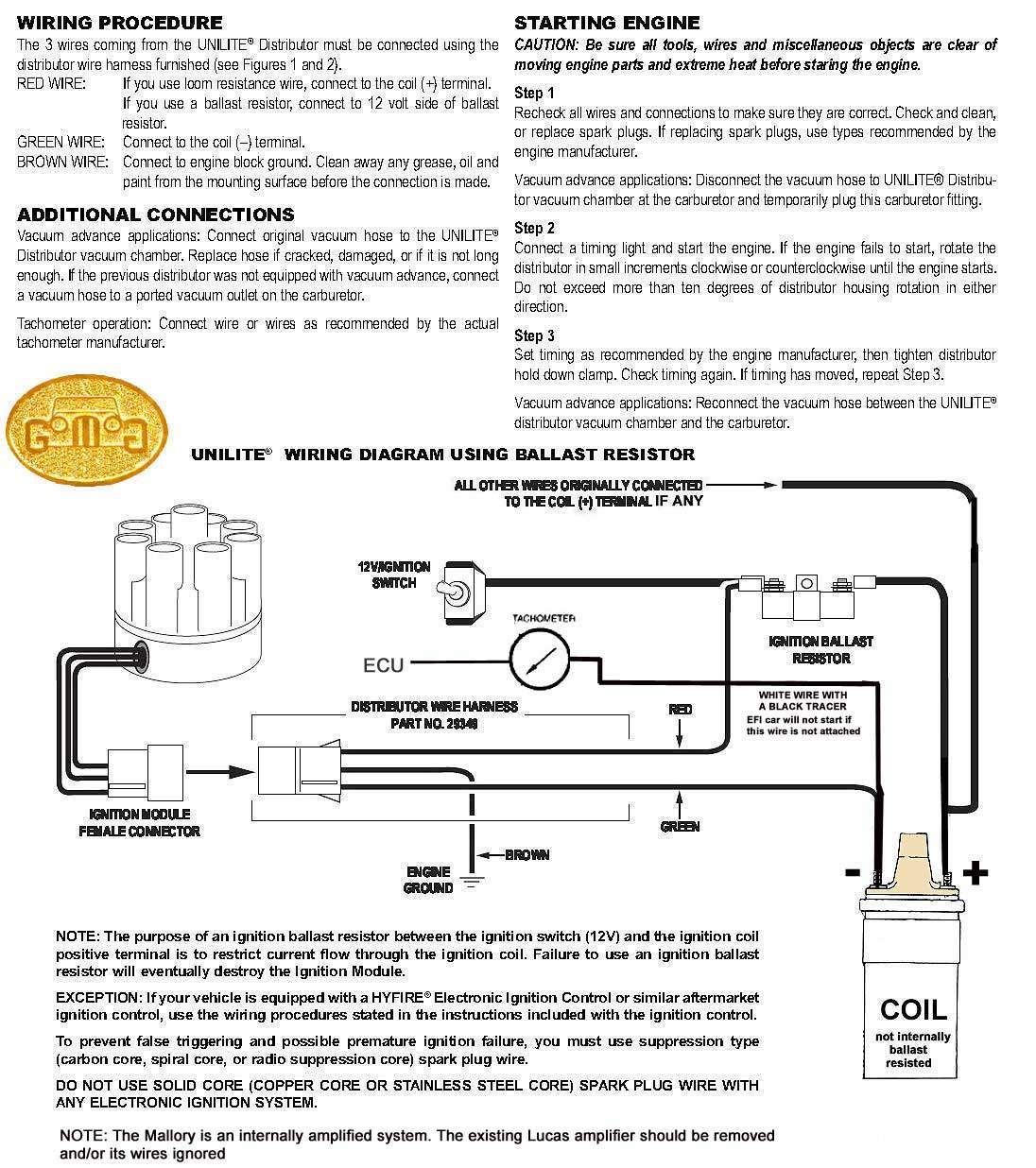

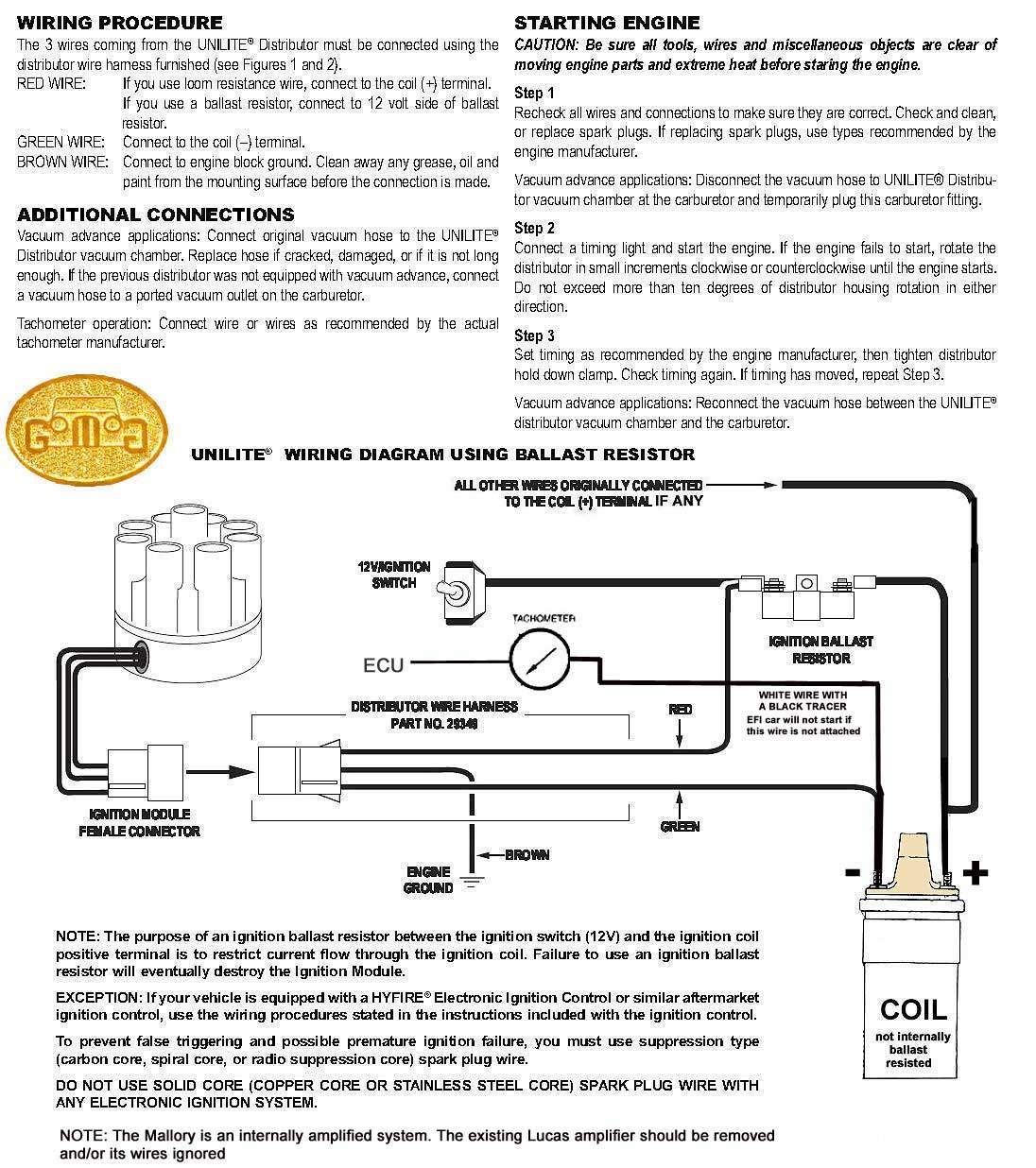

WIRING

A MALLORY UNILITE FOR

A LR/ROVER V8

by Lorne Goldman

If Using an

Internally Ballast

Resisted Coil

OR

If

Using a Ballast Resistor and

Standard Coil (recommended)

If using a ballast

resister

and standard coil.

If using a internally

ballast

resisted coil (not recommended)

Major Watchpoint When Installing a MSD or Pertronix

by Lorne Goldman & Win Muehling

Like

so many other little fixes I take for granted now, I kept forgetting to

post this important watchpoint..though I have so often come across it

in the last twenty-five years and saved so many hands-on people

from despair

with it. In a nutshell, for most mid- to later Morgans (and other

British cars)... British cars)...

In a nutshell, the British signal from the distributor to the

tach and, if you have EFI, on to the computer is of a

different format that

your car. Otherwise you would not be reading this.

So

if you fit a Morgan or other British car with either of the

titled devices, the tach won't work properly..or with EFI cars,

the car won't run.

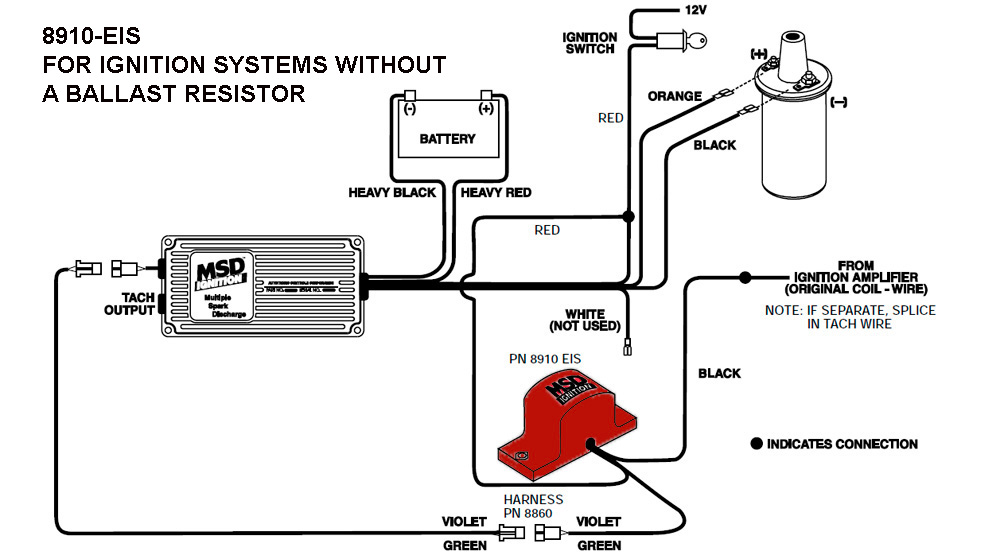

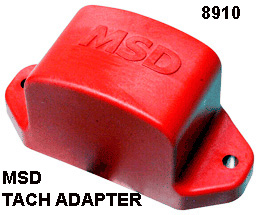

One way the problem can be solved by fitting a small device, made by MSD,

that translates the signal from the dizzy to something the British tach

and computer can understand. It is called an Tach/Fuel Injector

Adapter PN 8910 and here is the MSD documentation.

Essentially, you have to re-convert the signal (called TCV) to your newly added MSD or Pertronix to match the UK tach (and computer) again. That signal is called RVI. Read this article for more info. It is from the British side. It shows how the tach can be converted.

That

being said I have seen the necessaitity of this adapter with pre-EFI

(1984) Plus 8s. I have a 1984 L-Jetronic systems and do not need

add tach adapter.

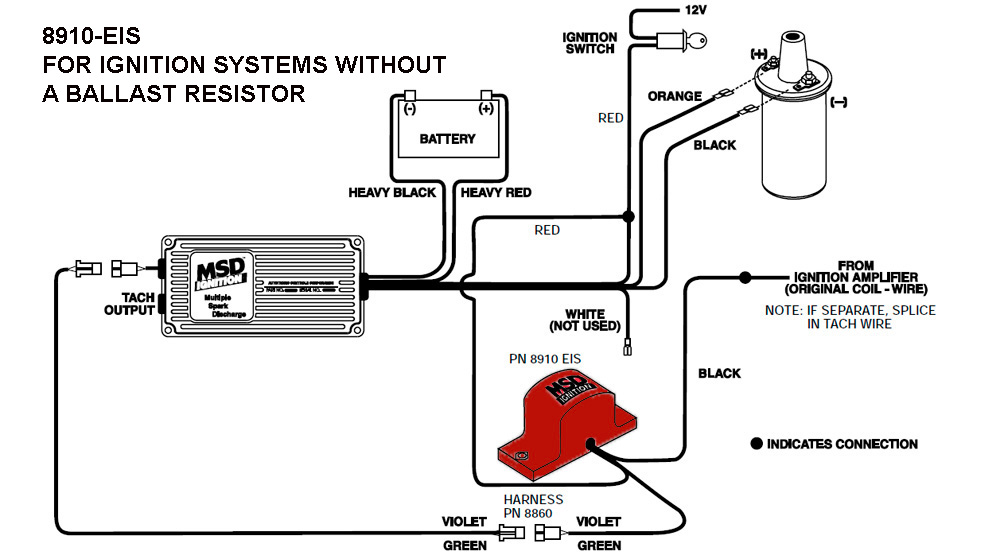

Tach/Fuel Injection Adapter PN 8910 by MSD

The PN 8910 (Electronic Ignition System) will interpret

the trigger signal into a signal the factory fuel injection and tachometer will recognizewhen

an MSD Ignition is installed. This adapter is designed for current limiting ignition systems

(no ballast resistor). Please

note that the adapter comes in two formats..one for ignitions with a

ballast resistor and a second for ignitions without a ballast resistor. BUY THE RIGHT ONE.

(8910-EIS).

INSTALLATION

1. Mount the Tach Adapter in a location away from direct

engine heat making sure the wires reach the MSD unit and the coil. The PN 8860 Magnectic

Pickup extension harness may be used 1. Mount the Tach Adapter in a location away from direct

engine heat making sure the wires reach the MSD unit and the coil. The PN 8860 Magnectic

Pickup extension harness may be used

2. Locate the WHITE wire coming from the MSD and disconnect

it from the factory wire that it was connected to (this should be the points or ignition

amplifier wire). Seal the WHITE wire as it will not be used anymore. Leave the other MSD

wires connected.

3. Connect the BLACK wire of the PN 8910-EIS to the wire

coming from the points or ignition amplifier. (This is the same wire that the WHITE

wire of the MSD was connected to.)

4. Splice the RED wire of the PN 8910-EIS to the small RED

wire of MSD Ignition.

5. Connect the magnetic pickup connector, the GREEN AND

VIOLET wires, to the corresponding connector of the MSD.

Fix Two

FIX THREE

There is an ignition expert in California by the name of Bob

Ashlock who makes an adapter he calls TACHADAPT that would be suitable.

Cheap adapters will merely multiply whatever voltage they see, but

Bob's is regulated. Additionally, being a small operation you will have

more backup than MSD,. The MSD/Holly/Mallory service is not great.

|

Smiths Tachometer Calibration and Repair

I got interested in calibrating the Smiths electronic tachometer some time

ago when I realized that my tach was completely out of calibration. I used a

technique similar to the one described in Tom Ballous 1975 Tech Tip to calibrate

my tach at about 1200RPM using my dwell/tach meter. I began to wonder, however,

how well calibrated my dwell/tach meter was and how well my Smiths tach was

at high RPM. This curiosity led me to analyze how the Smiths tach works and

to design a personal computer based tach calibration tool. This paper is intended

to explain how the tachometer works, to explain how my tach calibrator works,

and to update Tom Ballous Tech Tip with my opinions and advice.

Tachometer background information:

I know of two types of electronic tachometers in cars, inductively coupled

and direct coupled.

Direct connect electronic tachs have a direct electrical connection to the

ignition circuit. These tachs use voltage signals in the ignition circuit to

drive the tach.

The inductively coupled type of tach such as the Smiths electronic tachs of

the 1960s uses a one turn loop of the ignition wire as the primary side of a

transformer that couples the current pulses caused by the cars ignition circuit

into the inside of the tach. The timing of those current pulses are used to

drive the tach. These tachometers were used in Sunbeam Tigers and Alpines as

well as in Shelby Cobras and other British cars of the period. Since this is

the tach Ive had the most experience with, this is the tach I will describe

in detail.

The Smiths tach must be disassembled in order to calibrate or repair it. Carefully

rotate the chrome bezel until the tabs on the bezel line up with the slots on

the case. This can be a very difficult job if the seals have aged badly and

stuck. Whatever you do, DON'T pry up the tabs on the bezel or youll ruin it.

If you need to, you can CAREFULLY pry a tiny bit around the bezel in an attempt

to break it loose. Don't tap the edge as the meter is very fragile.

Once you get the chrome bezel off the tach, the face glass and inside bezel

must come out, if they didn't come out with the chrome bezel. Carefully pry

the inner bezel from the case. It is not necessary to separate the glass from

either bezel if it is stuck to one of them. Be careful prying on anything, especially

if the glass is still in place, as it is very easy to damage it or the bezels.

I have not been able to locate a source for the seals, so I just try to be very

careful, and reuse what I can with whats left of the seals. I always use a lint

free cloth and glass cleaner to clean the glass while the tach is apart.

Once the meter face is exposed, be very careful not to mar or get finger prints

on the face or break the needle. The next step is to remove the tach innards

from the case.

There are four screws on the back of the case, two of which are recessed in

holes in the case and two of which are not. The two in the recessed holes hold

the innards of the tach together so don't take them out. Put the tach case face

down on the bench. While pinching the U bracket stud with one finger and the

power spade lug with another to hold up the tach innards, remove both of the

non-recessed screws. The tach innards are now being held in the case by your

two fingers. Pick up the case and cup your other hand under the face of the

case. Carefully let the stud and spade lug slide out of your fingers and catch

the face of the tach by the edges in the cup of your hand. You can then pull

the case off of the tach innards and turn it over. You are now ready to calibrate

or debug the tach.

This is a good time to slide a shield under the needle to shield the face and

repaint the needle if you can find appropriate paint. (My artistic talents arent

very good, so I never try that step myself.)

Reassembly is the reverse of this process.

Electronically, the Smiths tach is a relatively simple two Germanium transistor

inductively coupled electronic tach. The following diagram shows the schematic

of the tach: (I think I may have the Zener symbol upside down, BTW.)

The two transistors together form a monostable multivibrator, or one-shot.

Normally, the collector of Q1 is at 6V. An ignition pulse couples through the

transformer to trigger a one-shot voltage pulse to 12V on the collector of Q1

for a set amount of time. Every time an ignition pulse is detected through the

transformer, the collector of Q1 will pulse from 6V to 12V for a fixed amount

of time. While the collector of Q1 is at 12V, the top of the meter is held at

6V by the Zener diode, so current will flow through the meter, causing the needle

to deflect. The width of the voltage pulse is determined by the combination

of the 0.25uF capacitor C2 and the combination of resistors R3, R4 and pot.

R5. The one-shot is triggered by every ignition pulse, so the voltage waveform

looks like a series of pulses when the engine is running. Since the pulses are

fixed in width and the frequency of the pulses is determined by the engine speed,

the ratio of the time the waveform is at 12V vs. 6V goes up with increases in

engine speed and down with decreases in engine speed. The way the meter works,

the more time the waveform is at 12V, the more the needle is deflected and the

less time the waveform is at 12V, the less the needle is deflected.

As the meter movements wear, lose their lubrication or get dirty, they require

more energy to deflect the meter. On many older tachs, I have found that

widening the one shot pulse width works to add the required energy. However,

the one shot pulse will be terminated early if the ignition pulse gets shorter

than the one shot pulse. I have found that many older tachs can't be adjusted

enough to compensate for the required extra energy. The symptom of this

problem is a tach that will not register above a certain RPM. I have tried

sewing machine oil to improve the meter movement as recommended by my jeweler,

but to no avail. Untill I am able to identify a lubricant or a cleaner/lubricant

combination that works, I add energy by cutting down on the resistance of the

55 ohm resistor/thermistor combination.

To calibrate the meter, you want to drive the tach with a very accurate, known

signal at the correct frequency for the RPM reading that you want on the meter.

Once you are driving the tach with the accurate frequency, you can adjust the

needle deflection to the proper place by turning the calibration pot. R5. The

tach can only be calibrated at one RPM. After that, all you can do is check

to see how close you are at other RPMs.

It is possible to recalibrate the 7,000RPM Alpine 4 cylinder tachs to work

in V8 Tigers using this method.

These tachometers contain electronic parts that are about 30 years old. The

characteristics of all the internal components are likely to slowly change as

they age, and I have found a number of tachs that have become uncalibrated,

and many fail.

The most common failure modes I have seen are failure of the main timing capacitor

C2. Failure of this cap. has caused tachs to be erratic, temperature sensitive

or just plain dead. If you suspect your tach to have this problem, locate the

capacitor, carefully unsolder the capacitor, and replace it with a new one.

I have been occasionally able to locate a supply of 0.25uF capacitors, but available

0.22uF to 0.27uF capacitors work fine. I also come across numeraous tachs with

a failed transistor input transistor. The symptom of that failure is that

the tach will not work in cars with lower ignition current. One way to

diagnose this problem is to temporarily pull the plastic block off tha back

of the tach, move the wire a bit and put two or three loops of wire through

the metal "U" bracket that goes over the plastic block and put that

on the back of the tach. If the added magnetic flux gives you enough signal

to trigger the tach, then the input transistor is failing. This could

also be an indication of problem with your coil circuit as well, however.

The other major failure mechanism I have seen is a broken meter spring. The

meter needs to be replaced in this case. Replacement meters must be gotten from

a parts tach. As a matter of course, the tach will have to be recalibrated if

any of the parts are replaced. I use an ohm meter to test for meter

movemement continuity. A good meter movement will give a reading of about

70 ohms in our out of the circuit, iwth the ohmneter positive to the red wire

and negative to the black.

All of the broken meter movements I have seen exhibit an open circuit.

All of the Smiths tachs of this era use the same electronic and mechanical

design, regardless of number of cylinders, positive or negative ground or the

make of the car. The power and ground wires are reversed between tachs for positive

or negative ground cars. The only other thing that changes is the face used

on the meters. So don't throw away any vintage Smiths tachs or tach parts, even

if they are dead. They can be used to resurrect any other one.

Calibration:

After learning how the Smiths tach works, I set about to develop a highly accurate

personal computer based calibration tool, as I didnt trust any other dwell/tach

meter any more than I did my Smiths. The calibration tool I designed is conceptually

quite simple. I designed a unit that plugs into the serial port of an Intel

compatible personal computer and will generate a current pulse through the ignition

wire that simulates the current pulse that happens when a spark plug is fired.

I then wrote a program that causes the current pulses to occur at very precise

times based on the RPM desired by the user. The timing is based on the highly

accurate crystal used for timing on the computers serial port. This crystal

controlled circuit must be highly accurate, or computers would not be able to

communicate with one another. This device and software will convert your personal

computer into a highly accurate tach calibrator that works from 500 to 10,000RPM,

in the car or on the bench.

For the curious, I found that my 1200RPM dwell/tach meter was over 100 RPM

off at 1200 RPM and my tach was off about 1000RPM at 5000RPM even after my dwell/tach

calibration effort.

Here are the three Youtube videos he published regarding his conversion:

https://www.youtube.com/watch?v=WAuFgzDS5zE&t=2s

https://www.youtube.com/watch?v=LHjlNvzZX6I&t=24s

https://www.youtube.com/watch?v=TBS119WwHg0

I especially wouldn't calibrate my tach at high RPM using Tom's method, since

the risk to the engine is not necessary anymore.

It is not often obvious by external inspection if the 0.25uF cap has failed.

If the tach is not functional or temperature sensitive, it is the first thing

I would replace to see if that is the problem.

The germanium transistors used in the Smiths design have a very low threshold

voltage. Silicon transistors have a much higher threshold voltage. It is likely

that replacing the germanium transistors with silicon transistors could really

change the characteristics of the tach. However, I would stick with the germanium

transistors. The HEP 253 number is still a good number for finding a germanium

replacement, although they are hard to find. You sure can't get them from Radio

Shack any more. There are some small electronics distributors who still do carry

them. Another good part number is NTE158.

You can live with more turns of the ignition wire through the metal loop, which

will give you a higher flux density for coupling the ignition signal to the

tach. However, I wouldn't do it unless absolutely necessary, as removal of the

nylon block on the ignition wire makes me worry about chafing the insulation

off the ignition wire, shorting 12V to the tach and stalling the car, if not

causing an electrical fire. I'd replace the input transistor if you have

this situation.

To Obtain a Tach Calibrator:

In order to allow Sunbeam enthusiasts to accurately calibrate their tachs,

I have started manufacturing the PC peripheral calibration units plus software

for sale.

The calibrator consists of a unit that amplifies a signal coming out of the

computer's serial port so it will emulate the ignition current pulses of your

car. There is also PC software that drives the serial port to produce

highly accurate timing pulses. This, in conjunction with an external

power supply (such as your car's battery) allows you to debug tach problems

and c4510155027117370alibrate funtional tachs.

Mallory

began in the early in the 20th century. They supplied Ford for many

years

until Ford moved to a cheaper supplier. They produce fine

simple-to-deal-with

product based on photo optics called the Unilite. The also make other

distributors

based on other technology. When the UK racers and tuners became

frustrated

a couple of decades ago, this is where they turned to for a solution.

Carson

City, Nevada. They are available in the UK from Real Steel, Rimmer

Brothers, and John Wolfe Racing. (Check the prices as they vary a lot!)

Mallory

began in the early in the 20th century. They supplied Ford for many

years

until Ford moved to a cheaper supplier. They produce fine

simple-to-deal-with

product based on photo optics called the Unilite. The also make other

distributors

based on other technology. When the UK racers and tuners became

frustrated

a couple of decades ago, this is where they turned to for a solution.

Carson

City, Nevada. They are available in the UK from Real Steel, Rimmer

Brothers, and John Wolfe Racing. (Check the prices as they vary a lot!)

cover.

This cover had an oil pump with a female drive gear driven by a male distributor

shaft. The second generation, (1977-GEMS cars), had a better oil pump

with a male drive gear driven by a female fitting on the distributor shaft.)

You must choose your Mallory model to match your generation.

cover.

This cover had an oil pump with a female drive gear driven by a male distributor

shaft. The second generation, (1977-GEMS cars), had a better oil pump

with a male drive gear driven by a female fitting on the distributor shaft.)

You must choose your Mallory model to match your generation.

British cars)...

British cars)...