|

A quick guide to the terms used when talking to a “wheel guy.” |

|

|

|

|

|

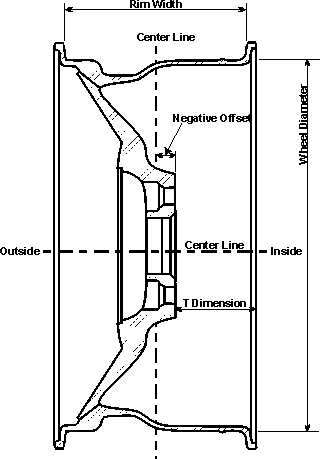

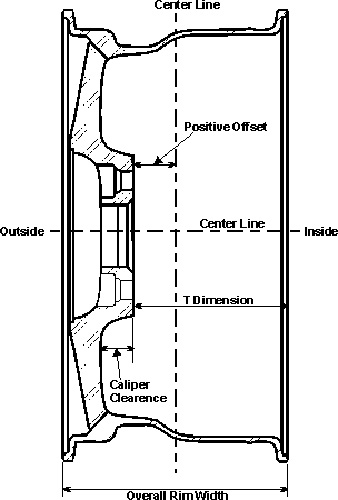

The offset of a wheel is the measurement of the hub surface contact area in offset from the center line of the overall rim width of the wheel.A wheel whose hub surface contact area sits further towards the outside of the wheel than the center line has a positive offset. A wheel whose hub surface contact area sits further towards the inside of the wheel than the centerline has a negative offset To determine the offset, the wheel must be measured accurately using the following steps: (1)measure the overall rim width of the wheel. (2)measure the T dimension (Backspace), which is the measurement from the hub surface contact area to the outside of the inner rim. (3)divide the overall rim width by 2 which gives you the center line. (4)subtract the center line (overall rim width/2) from the T dimension (Backspace). (5)a negative answer means the wheel has a negative offset and a positive answer means the wheel has a positive offset PCD The Pitch Circle Diameter is the diameter of the circumference of the center line of the lug nut holes, this can be four, five or six lug. The easiest way of measuring four or six lug wheels is take the diagonal holes and measure from the outer edge of one hole to the inner edge of the second hole.With five lug wheels this is not possible as there are not diagonal holes, therefore the simplified way would be to measure the outer circumference and inner circumference of the holes.The difference should be divided by two and added onto the smaller circumference or deducted from the larger circumference. CENTER BORE The center bore is the location hole machined in the center of the wheel and this varies from one vehicle to another.It is essential the wheels purchased have the correct center bore for the vehicle they are to suit, otherwise you may experience balancing problems. CALIPER CLEARANCE Some vehicles as standard are produced using large brake calipers, therefore our listings have taken this into account when advising fitments. You should advise your wheel supplierif you have modified the brakes on your vehicle. |

|

|

|

|

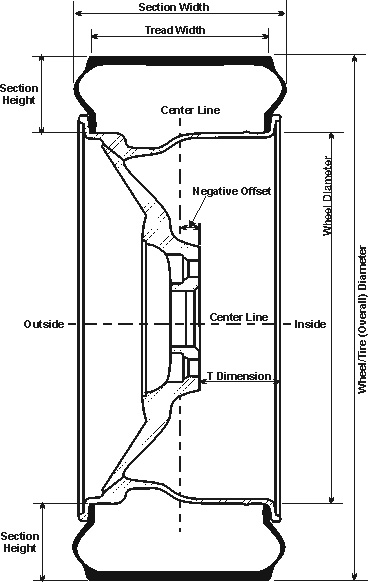

The overall width of the tire from outer sidewall to outer sidewall (tire mounted and inflated but not under load). section width measurement does not include sidewall protrusions such as raised letters. SECTION HEIGHT The height of the tire section, from the outer tread surface to the tire bead where it makes contact with the rim seat.Tire is mounted and inflated, but not under load. OVERALL WHEEL/TIRE DIAMETER The outer diameter of the tire (measured at the center of the tread) while the tire is mounted and inflated, but not loaded. The relationship of the section height to the section width.Divide the tire’s section height by the tire’s section width, then multiply the result by 100. CALCULATING TIRE OVERALL DIAMETER Example Tire: 205/45 16 235= Section width in mm 45%= Aspect Ratio 16= Rim Diameter in inches (1) Convert Tire Diameter to mm by multiplying by 25.4 25.4x16=406.4mm (2) Calculate section height in mm by multiplying the section width by the aspect ratio 205x.45= 92.25mm (3) alculate the Overall Diameter by multiplying the section height by 2 and adding that result to the wheel diameter (2x92.25)+406.4= 590.9mm |