Remove propane hardware and

lines:

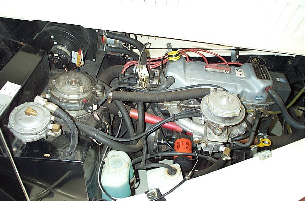

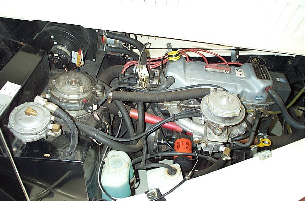

You

will probably find that the propane fuel line was routed into the passenger

area behind the right seat and then under the upholstery and up through

the scuttle. Shut the valve to the line that feeds the propane carb,

and then loosen the fuel line at the valve. There will be an escape

of pressurized propane for a few seconds. Disconnect the fuel line

from the valve. Note in the picture at right that the line has been

disconnected from the valve.

You

will probably find that the propane fuel line was routed into the passenger

area behind the right seat and then under the upholstery and up through

the scuttle. Shut the valve to the line that feeds the propane carb,

and then loosen the fuel line at the valve. There will be an escape

of pressurized propane for a few seconds. Disconnect the fuel line

from the valve. Note in the picture at right that the line has been

disconnected from the valve.

Remove the propane hardware from the engine compartment.

Note that there are coolant lines attached to one of the pieces.

Be prepared for the release of coolant. Then remove the propane tank.

Remove  all

eight bolts that secure the tank to the steel plates and the plates to

the chassis rails and the tank just rotates forward and down. It

is rather heavy, so it helps to have a jack under it. The fuel line

can then be removed by pulling the upholstery away from the passenger side

and disconnecting the clamps. You will need to remove the right side

seat.

all

eight bolts that secure the tank to the steel plates and the plates to

the chassis rails and the tank just rotates forward and down. It

is rather heavy, so it helps to have a jack under it. The fuel line

can then be removed by pulling the upholstery away from the passenger side

and disconnecting the clamps. You will need to remove the right side

seat.

That is the easiest way to route fuel lines. The originals

went through the drive shaft tunnel. Solid fuel lines (originals were rubber)

can be bent so that they can be routed from the tank all the way up and

through new holes in the firewall. Rubber grommets are an excellent.

Short pieces of flexible tubing and clamps can be used to connect the solid

lines to the fuel filter and pump. This is safer than under the chassis

where they can be smashed or ruptured...though racers keep them outside

to make the car safer. I briefly considered routing fuel lines through

the drive shaft tunnel, until I realized that if the drive shaft broke

there the remains would be thrashing around. Another expensive alternative,

is to consider Aeroquip lines. These have all the advantages of solid lines

but are far more flexible, safer and resistant.

Install new parts:

I won't go into installation of the carburettor and air

filter, fuel pump and fuel lines. Those should be  fairly

obvious. Rather Iíll deal with the fuel tank and wooden bits.

Since the fuel tank will go in from the bottom, this is a good time to

install the new wooden frame. Glue and screw the horizontal

members to the side members and slip these assemblies into place and secure

with the top bolts. Glue and screw the vertical members to the horizontal

members and glue and screw the horizontal members together where they overlap.

Glue the long horizontal pieces to the undersides of the assembled frame

and drive in all screws from the top. Drill pilot holes as close

to the ends as possible from the under side of the frame and drive in screws.

Install it from the bottom and bolt it to the sides of the wooden tub with

its top bolts only allowing you to pivot it upwards a bit on these two

bolts. Admire your work. The picture at right shows the frame with

the tank in place.

fairly

obvious. Rather Iíll deal with the fuel tank and wooden bits.

Since the fuel tank will go in from the bottom, this is a good time to

install the new wooden frame. Glue and screw the horizontal

members to the side members and slip these assemblies into place and secure

with the top bolts. Glue and screw the vertical members to the horizontal

members and glue and screw the horizontal members together where they overlap.

Glue the long horizontal pieces to the undersides of the assembled frame

and drive in all screws from the top. Drill pilot holes as close

to the ends as possible from the under side of the frame and drive in screws.

Install it from the bottom and bolt it to the sides of the wooden tub with

its top bolts only allowing you to pivot it upwards a bit on these two

bolts. Admire your work. The picture at right shows the frame with

the tank in place.

There is no good way I know of to mark the spots where

you must drill the tank boards to bolt them to the chassis. To bolt the

tank to the boards, you can measure with a cut out, then assemble the boards

on the floor and drill.

Lift the tank up into the opening and slide the boards

into place under the tank. This is a two-person operation unless

you strap the tank to a ceiling member and lift it over the level of the

board placement. As noted Morgan uses three boards, some with the

corners cut to allow more more lateral movement. They then can use a determined

sequence to get the boards in place easily. Remember that the securing

plates for the tank is essential to the system. The boards are sandwiched

between the tank flange and securing plates. The tank cannot simply be

screwed into the boards. It will soon become adrift and will not have any

ability to move with the flexing frame.

Make sure the boards are snug against the back of the

chassis, the tank is snug against the back of the  chassis

and is centred on the boards. There should be no bolts or protrusions

between the back and the tank. Drill the holes where the boards will be

bolted to the chassis. Mark the locations of the holes where the

tank will be bolted to the boards. Remove the boards and the tank

and drill the holes you have just marked through board and tank fixing

flange and under the board metal piece. Should you wish, you can use an

angle iron (alloy) to the front of the tank to further inhibit fro and

aft movement.

chassis

and is centred on the boards. There should be no bolts or protrusions

between the back and the tank. Drill the holes where the boards will be

bolted to the chassis. Mark the locations of the holes where the

tank will be bolted to the boards. Remove the boards and the tank

and drill the holes you have just marked through board and tank fixing

flange and under the board metal piece. Should you wish, you can use an

angle iron (alloy) to the front of the tank to further inhibit fro and

aft movement.

Attach fittings to the tank for fuel feed (and return

if used), and install the sender unit and rollover check valve if used.

Note from the picture above that both of these can be accessed from above

with the frame in place.

Lift the tank back up and slip the boards in under it,

making sure the boards go back in the same  sequence

as before so the holes line up with the chassis holes. Secure the

boards and tank with stainless hardware, inserting a bolt and flat washer

from below and a flat washer, lock washer and nut from the top. Slender

arms and hands will be a big help here as there is not much room to work.

Hold a stabilizing strap up against the under side of the tank boards and

mark a screw hole location. Drill the pilot hole, making sure you

donít drill all the way through the boards and into the tank. Secure

the strap, drill the remaining holes and drive in the remaining screws.

Repeat for the other strap. The picture at right shows the tank and

boards in place and secured. The fuel outlet fitting is in the tank.

sequence

as before so the holes line up with the chassis holes. Secure the

boards and tank with stainless hardware, inserting a bolt and flat washer

from below and a flat washer, lock washer and nut from the top. Slender

arms and hands will be a big help here as there is not much room to work.

Hold a stabilizing strap up against the under side of the tank boards and

mark a screw hole location. Drill the pilot hole, making sure you

donít drill all the way through the boards and into the tank. Secure

the strap, drill the remaining holes and drive in the remaining screws.

Repeat for the other strap. The picture at right shows the tank and

boards in place and secured. The fuel outlet fitting is in the tank.

The

picture at left shows the fuel line connected to the filter and, in turn,

to the fuel outlet fitting. Short pieces of flexible hose and clamps

make the connections and the fuel line and filter are secured to the tank

boards with rubber insulated clamps. The tank had been given several

coats of shop primer and I decided to leave it that way for now.

I may eventually treat the tank and boards with waxoyl, but for now will

avoid the mess.

The

picture at left shows the fuel line connected to the filter and, in turn,

to the fuel outlet fitting. Short pieces of flexible hose and clamps

make the connections and the fuel line and filter are secured to the tank

boards with rubber insulated clamps. The tank had been given several

coats of shop primer and I decided to leave it that way for now.

I may eventually treat the tank and boards with waxoyl, but for now will

avoid the mess.

I found a rollover check valve that would provide venting

of the tank while filling. I supplied the tank  fabricator

with a nut with the proper threads and he cut a hole in the top of the

tank and welded the nut on the inside. The valve attaches to the

tank by threading into the nut. There is a nylon washer on to seal

the valve to the tank. The valve is open from bottom to top.

There is a ball bearing that is held in by a circlip. Air can escape

past the ball and out through the hoses shown. Should the car roll

over the ball bearing forms a seal against the top of the valve.

The hoses are setup so that fuel may slosh up and into the first section

of hose, and may even make it through the tee and up over the first loop.

There it will encounter a second tee and will drain back down into the

tank. The hose that goes up from the second tee loops up and back

down and out into the back of the right side wheel well.

fabricator

with a nut with the proper threads and he cut a hole in the top of the

tank and welded the nut on the inside. The valve attaches to the

tank by threading into the nut. There is a nylon washer on to seal

the valve to the tank. The valve is open from bottom to top.

There is a ball bearing that is held in by a circlip. Air can escape

past the ball and out through the hoses shown. Should the car roll

over the ball bearing forms a seal against the top of the valve.

The hoses are setup so that fuel may slosh up and into the first section

of hose, and may even make it through the tee and up over the first loop.

There it will encounter a second tee and will drain back down into the

tank. The hose that goes up from the second tee loops up and back

down and out into the back of the right side wheel well.

All

that remains of the tank installation is to attach the fill hose to the

neck on the tank and to the neck on the fuel cap. You will have to

work with this a bit to try to minimize the kink in the fill hose.

I have found that I can usually lock the gas pump filler nozzle on while

filling the tank, but it must be positioned correctly or it will shut off

too readily. I have only once had a problem with fuel sloshing back

up out of the filler hose, and I chalked that up to operator error.

All

that remains of the tank installation is to attach the fill hose to the

neck on the tank and to the neck on the fuel cap. You will have to

work with this a bit to try to minimize the kink in the fill hose.

I have found that I can usually lock the gas pump filler nozzle on while

filling the tank, but it must be positioned correctly or it will shut off

too readily. I have only once had a problem with fuel sloshing back

up out of the filler hose, and I chalked that up to operator error.

Some Morgans have an aluminium plate that fits in the

centre of the hole with a lip that fits over the top  wood

member and 4 small screw into the member and held at the centre by the

three bolts holding the tripod spare wheel bracket. These bolts go through

the bracket, the plate and the wooden members. Some of us change the plate

to polished stainless, others extend the plate so they can screw it into

the wooden piece at the bottom to prevent vibration and others use a plate

large enough to cover the whole space top and bottom and side to side.

It is your option.

wood

member and 4 small screw into the member and held at the centre by the

three bolts holding the tripod spare wheel bracket. These bolts go through

the bracket, the plate and the wooden members. Some of us change the plate

to polished stainless, others extend the plate so they can screw it into

the wooden piece at the bottom to prevent vibration and others use a plate

large enough to cover the whole space top and bottom and side to side.

It is your option.

Test and adjust as necessary:

Once everything is installed you will want to check the

emissions levels. You may find that the car runs clean enough that

a Ďcatí is not needed. Emission inspection requirements in your area

will be the determining factor. In my case the carburettor could

be adjusted to burn clean enough without a cat. The other question

will be the usable capacity of the fuel tank and what the new sender and

fuel gauge show you. I took one gallon of fuel in a can and ran the

car out of fuel. I poured the one gallon in and made it to the nearest

station and filled the tank. I found the total capacity of the tank

to be 16 gallons. I then ran it until the gauge just read empty and

filled it again. I found that the gauge reads empty when 12.3 gallons

have been burned. I operate on the assumption that I have 15 gallons

and leave that one last gallon as emergency reserve. When the gauge

reads empty I have 2.7 gallons to get me to the next station. On

the highway that would yield a range of about 450 miles. Your mileage,

as the saying goes, may vary.

If using a Centroid unit, you can adjust the empty and

full readings to suit.

If you get a smell of petrol check it out. If it comes

from the vent get a small charcoal cannister from a friend and connected

the end of the vent hose to it. That'll cure the problem.

You

will probably find that the propane fuel line was routed into the passenger

area behind the right seat and then under the upholstery and up through

the scuttle. Shut the valve to the line that feeds the propane carb,

and then loosen the fuel line at the valve. There will be an escape

of pressurized propane for a few seconds. Disconnect the fuel line

from the valve. Note in the picture at right that the line has been

disconnected from the valve.

You

will probably find that the propane fuel line was routed into the passenger

area behind the right seat and then under the upholstery and up through

the scuttle. Shut the valve to the line that feeds the propane carb,

and then loosen the fuel line at the valve. There will be an escape

of pressurized propane for a few seconds. Disconnect the fuel line

from the valve. Note in the picture at right that the line has been

disconnected from the valve.

all

eight bolts that secure the tank to the steel plates and the plates to

the chassis rails and the tank just rotates forward and down. It

is rather heavy, so it helps to have a jack under it. The fuel line

can then be removed by pulling the upholstery away from the passenger side

and disconnecting the clamps. You will need to remove the right side

seat.

all

eight bolts that secure the tank to the steel plates and the plates to

the chassis rails and the tank just rotates forward and down. It

is rather heavy, so it helps to have a jack under it. The fuel line

can then be removed by pulling the upholstery away from the passenger side

and disconnecting the clamps. You will need to remove the right side

seat.

fairly

obvious. Rather Iíll deal with the fuel tank and wooden bits.

Since the fuel tank will go in from the bottom, this is a good time to

install the new wooden frame. Glue and screw the horizontal

members to the side members and slip these assemblies into place and secure

with the top bolts. Glue and screw the vertical members to the horizontal

members and glue and screw the horizontal members together where they overlap.

Glue the long horizontal pieces to the undersides of the assembled frame

and drive in all screws from the top. Drill pilot holes as close

to the ends as possible from the under side of the frame and drive in screws.

Install it from the bottom and bolt it to the sides of the wooden tub with

its top bolts only allowing you to pivot it upwards a bit on these two

bolts. Admire your work. The picture at right shows the frame with

the tank in place.

fairly

obvious. Rather Iíll deal with the fuel tank and wooden bits.

Since the fuel tank will go in from the bottom, this is a good time to

install the new wooden frame. Glue and screw the horizontal

members to the side members and slip these assemblies into place and secure

with the top bolts. Glue and screw the vertical members to the horizontal

members and glue and screw the horizontal members together where they overlap.

Glue the long horizontal pieces to the undersides of the assembled frame

and drive in all screws from the top. Drill pilot holes as close

to the ends as possible from the under side of the frame and drive in screws.

Install it from the bottom and bolt it to the sides of the wooden tub with

its top bolts only allowing you to pivot it upwards a bit on these two

bolts. Admire your work. The picture at right shows the frame with

the tank in place.

chassis

and is centred on the boards. There should be no bolts or protrusions

between the back and the tank. Drill the holes where the boards will be

bolted to the chassis. Mark the locations of the holes where the

tank will be bolted to the boards. Remove the boards and the tank

and drill the holes you have just marked through board and tank fixing

flange and under the board metal piece. Should you wish, you can use an

angle iron (alloy) to the front of the tank to further inhibit fro and

aft movement.

chassis

and is centred on the boards. There should be no bolts or protrusions

between the back and the tank. Drill the holes where the boards will be

bolted to the chassis. Mark the locations of the holes where the

tank will be bolted to the boards. Remove the boards and the tank

and drill the holes you have just marked through board and tank fixing

flange and under the board metal piece. Should you wish, you can use an

angle iron (alloy) to the front of the tank to further inhibit fro and

aft movement.

sequence

as before so the holes line up with the chassis holes. Secure the

boards and tank with stainless hardware, inserting a bolt and flat washer

from below and a flat washer, lock washer and nut from the top. Slender

arms and hands will be a big help here as there is not much room to work.

Hold a stabilizing strap up against the under side of the tank boards and

mark a screw hole location. Drill the pilot hole, making sure you

donít drill all the way through the boards and into the tank. Secure

the strap, drill the remaining holes and drive in the remaining screws.

Repeat for the other strap. The picture at right shows the tank and

boards in place and secured. The fuel outlet fitting is in the tank.

sequence

as before so the holes line up with the chassis holes. Secure the

boards and tank with stainless hardware, inserting a bolt and flat washer

from below and a flat washer, lock washer and nut from the top. Slender

arms and hands will be a big help here as there is not much room to work.

Hold a stabilizing strap up against the under side of the tank boards and

mark a screw hole location. Drill the pilot hole, making sure you

donít drill all the way through the boards and into the tank. Secure

the strap, drill the remaining holes and drive in the remaining screws.

Repeat for the other strap. The picture at right shows the tank and

boards in place and secured. The fuel outlet fitting is in the tank.

The

picture at left shows the fuel line connected to the filter and, in turn,

to the fuel outlet fitting. Short pieces of flexible hose and clamps

make the connections and the fuel line and filter are secured to the tank

boards with rubber insulated clamps. The tank had been given several

coats of shop primer and I decided to leave it that way for now.

I may eventually treat the tank and boards with waxoyl, but for now will

avoid the mess.

The

picture at left shows the fuel line connected to the filter and, in turn,

to the fuel outlet fitting. Short pieces of flexible hose and clamps

make the connections and the fuel line and filter are secured to the tank

boards with rubber insulated clamps. The tank had been given several

coats of shop primer and I decided to leave it that way for now.

I may eventually treat the tank and boards with waxoyl, but for now will

avoid the mess.

fabricator

with a nut with the proper threads and he cut a hole in the top of the

tank and welded the nut on the inside. The valve attaches to the

tank by threading into the nut. There is a nylon washer on to seal

the valve to the tank. The valve is open from bottom to top.

There is a ball bearing that is held in by a circlip. Air can escape

past the ball and out through the hoses shown. Should the car roll

over the ball bearing forms a seal against the top of the valve.

The hoses are setup so that fuel may slosh up and into the first section

of hose, and may even make it through the tee and up over the first loop.

There it will encounter a second tee and will drain back down into the

tank. The hose that goes up from the second tee loops up and back

down and out into the back of the right side wheel well.

fabricator

with a nut with the proper threads and he cut a hole in the top of the

tank and welded the nut on the inside. The valve attaches to the

tank by threading into the nut. There is a nylon washer on to seal

the valve to the tank. The valve is open from bottom to top.

There is a ball bearing that is held in by a circlip. Air can escape

past the ball and out through the hoses shown. Should the car roll

over the ball bearing forms a seal against the top of the valve.

The hoses are setup so that fuel may slosh up and into the first section

of hose, and may even make it through the tee and up over the first loop.

There it will encounter a second tee and will drain back down into the

tank. The hose that goes up from the second tee loops up and back

down and out into the back of the right side wheel well.

All

that remains of the tank installation is to attach the fill hose to the

neck on the tank and to the neck on the fuel cap. You will have to

work with this a bit to try to minimize the kink in the fill hose.

I have found that I can usually lock the gas pump filler nozzle on while

filling the tank, but it must be positioned correctly or it will shut off

too readily. I have only once had a problem with fuel sloshing back

up out of the filler hose, and I chalked that up to operator error.

All

that remains of the tank installation is to attach the fill hose to the

neck on the tank and to the neck on the fuel cap. You will have to

work with this a bit to try to minimize the kink in the fill hose.

I have found that I can usually lock the gas pump filler nozzle on while

filling the tank, but it must be positioned correctly or it will shut off

too readily. I have only once had a problem with fuel sloshing back

up out of the filler hose, and I chalked that up to operator error.

wood

member and 4 small screw into the member and held at the centre by the

three bolts holding the tripod spare wheel bracket. These bolts go through

the bracket, the plate and the wooden members. Some of us change the plate

to polished stainless, others extend the plate so they can screw it into

the wooden piece at the bottom to prevent vibration and others use a plate

large enough to cover the whole space top and bottom and side to side.

It is your option.

wood

member and 4 small screw into the member and held at the centre by the

three bolts holding the tripod spare wheel bracket. These bolts go through

the bracket, the plate and the wooden members. Some of us change the plate

to polished stainless, others extend the plate so they can screw it into

the wooden piece at the bottom to prevent vibration and others use a plate

large enough to cover the whole space top and bottom and side to side.

It is your option.