DATSUN/ALFIN BRAKE DRUMS

by Lorne Goldman, Harald Sakshaug & the gang

at the eMog Pub

May 1998, updated December 2002, updated December 2005, March

2008, January 2009, October

2009, August 2012 December 2025

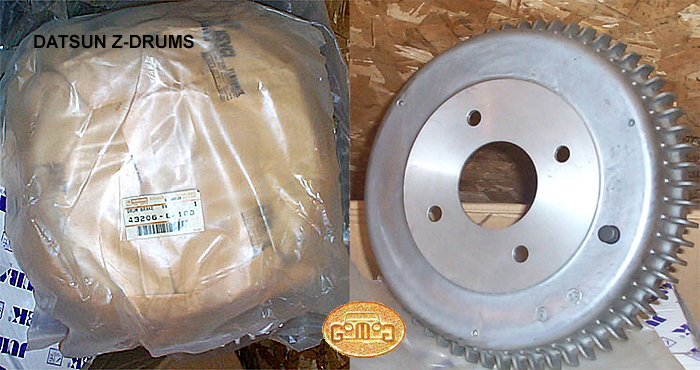

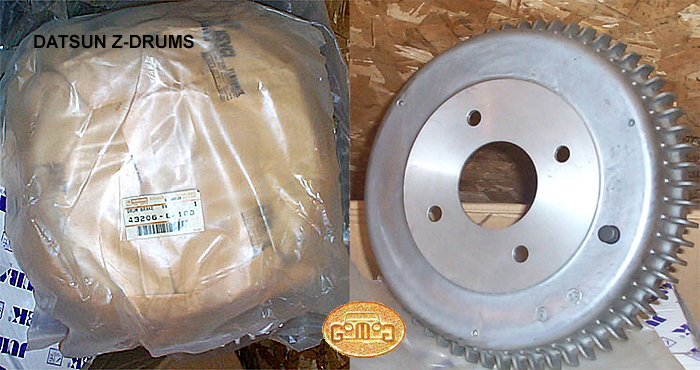

Datsun

Z drums, (designed along the same idea of the famous Alfin drums but frankly

MUCH better) were made in bimetal of cast aluminum with fins for extra cooling

and a steel insert and used on the famous Datsun Z sports cars series.

Datsun

Z drums, (designed along the same idea of the famous Alfin drums but frankly

MUCH better) were made in bimetal of cast aluminum with fins for extra cooling

and a steel insert and used on the famous Datsun Z sports cars series.

The advantages are much improved rear braking, cooler

drums, a big saving in unsprung weight and of course, the ability to shine them up to a

gleaming finish (smile)..all without modifying the car. When I tested them,

I tested them hard...yet when I stopped that car after some time of this,

the Datsun brake drums were only tepid to the touch. The used Alfins I had tried earlier ran hotter.

The

problem will be to find used Datsun

drums still in good condition with only acceptable wear. The maximum

wear

permissible is marked on each drum on their inner surface. I have seen

a good used set go for $850 USD without machining. I found my set

(s) , all dusty and covered with yellowed paper, at the

Nissan depot in Vancouver, Canada

for $92 CAN. Part number is 43206-E4100. I

bought all 7 sets they had (30 years ago). I kept what I need for

my Morgans, plus an emergency set and gave the others to Morgan friends

as Xmas as birthday presents.

Sadly, re-stocking was even then impossible for Datsun/Nissan.

They

switched to the aftermarket which supplied of lower quality

replacements and soon after, stop carrying them at all. Other attempts

to copy the originals did not turn out well in Europe.For a long time

everyone reported these new ones warped.

As

a comparison to Alfins (originals or copies), the original Datsun Z

drums are essentially a more modern, refined, and were a more

cost-effective application of the bimetallic braking drum technology

pioneered by Alfin. (Real Datsun drums are now even more expensive than repro Alfins.

The Datsuns provide better cooling due to the radial fins and improved

performance without requiring major modifications for many classic car

enthusiasts. Original Alfin drums are

primarily sought after for period-correct restorations or specific

racing classes where authenticity is a must.

As

a comparison to Alfins (originals or copies), the original Datsun Z

drums are essentially a more modern, refined, and were a more

cost-effective application of the bimetallic braking drum technology

pioneered by Alfin. (Real Datsun drums are now even more expensive than repro Alfins.

The Datsuns provide better cooling due to the radial fins and improved

performance without requiring major modifications for many classic car

enthusiasts. Original Alfin drums are

primarily sought after for period-correct restorations or specific

racing classes where authenticity is a must.

The rest of us in-the-know use Datsun drums. They run cooler and last

longer. They more than compensate for any difference in Morgan alloys

and Morgan wire wheels...bathroom scale tested! Both drums are

equally pretty. Both can be polished to a mirror shine which makes wire

wheels even more desirable.

| WATCHPOINT 1(weight) : Both Datsuns and Alfins

weigh 1/2 the weight of normal drums and this saving is with unsprung

rather than sprung weight!!!! (2.5 kilos for a 9 inch drum) Coupled

with Porterfield shoes the effect is noticeble with an Dastun advantage

as their fins keep the drum heat way down, something the Aflins

don't do. |

| WATCHPOINT 2 (trying to weld in the modification holes) Don't!!!!! I am a perfectionist. I tried twice to do this, once myself and once with the most professional welder

I could find. Disaster. The type of alloy and bimetal nature of the

Datsun drums causes them to be completely ruined. Unreparable. The good

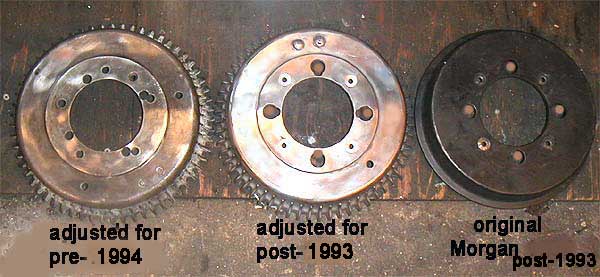

part is that using these adjusted drums, on both pre and post June 1993

Morgans, the modifcations have NEVER caused a problem. |

MORGAN TRAD REAR BRAKE TYPES EACH REQUIRES DIFFERENT MODIFCATIONS

Pre-7/1993 manually adjusted

rear brakes

Post-7/1993 self adjusting rear

brakes

SOURCES

DECEMBER 2025

SEE THE WATCHPOINT FOR NEW DATSUN DRUMS

| SUPPLIER |

PRICE IN BRITISH POUNDS |

COMMENT |

Rimmer Brothers (UK)

Part No. 210578UR |

£410

ex VAT (for non-UK buyers)

£492 (for UK buyers) |

call their Datsun copies "Alfins" |

Z-Car Depot (US)

Part #: 400-131 |

£330 |

likely the best source |

Moss Motors (US)

Part #: 586-160 |

£610 |

call their Datsun copies "Alfins" |

TORQEN (UK)

Part # 400-131 |

£550

ex VAT (for non-UK buyers)

£660 (for UK buyers) |

|

Typecast Engineering Ltd (UK)

(contact them) |

£790 |

Alfin Reproductions

|

| WATCHPOINT 3 (December 2025) The

drums show as and drilled for Morgan pre-7/1993s and Triumph TR3As

from Rimmer Brothers

I have no idea of their quality. However, Rimmer is a reputable supplier, merely expensive. (If anyone ties their drums, report to me please. Maybe the quality improved) |

| WATCHPOINT 4 (October 2009) There

have been Datsun-like drums for sale in Europe since 2007. At one time

there were available from Morgan suppliers. However, these drums reportedly

proved to be substandard, out-of-round and with unacceptable porosity in

the casting. The Morgan trade wisely ceased offering them. Buyer beware

as they are still being offered by other suppliers in the UK. |

MACHINING (pre- & post- June 1993 trads).

MACHINING (pre- & post- June 1993 trads).

There is most likely some machining to do depending on what type

of wheels your car was made for.

There is most likely some machining to do depending on what type

of wheels your car was made for.

I tried both Alfins and Datsuns 30 years ago on

my made-for-alloy-wheels Plus 8. A decade later, I also fit them to the Phoenix which has post-June rear brakes. That meant these drums (which come with

4 holes) must be drilled to fit a Morgan trad. As well, the centre

hole must be enlarged to the Morgan standard and a small bit taken from

the dust flange on their rims which will then fit over the Morgan rear

back plate. It is much wiser for you to refrain from filling the

old holes with aluminum. This can be dangerous and it is not necessary.

The nature of the bimetal will cause 1 in 2 to crack if extraordinary precautions

are not taken. As there is far and away enough structural strength in the

modified drum and considering the holes will be cover by your wheel rim

or wire wheel adapter, there is no need to run the risk for aesthetics.

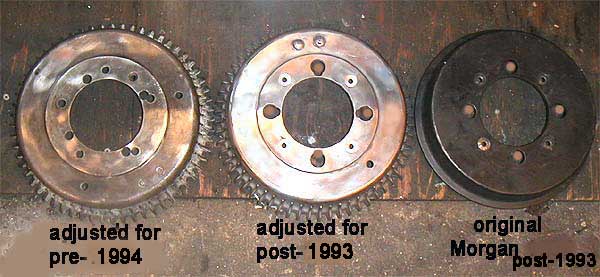

See the one at the bottom of the page..example on the far left..

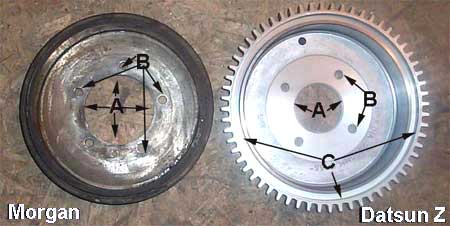

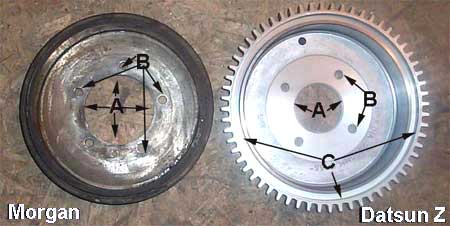

The picture below shows your Morgan drums and the untouched

Datsun beside it.

There are three mods necessary to get it to fit a car

made for bolt on wheels.

There are three mods necessary to get it to fit a car

made for bolt on wheels.

1.

Increase the size of centre holes "A" to match those on your Morgan drums.

You will find that the two sides of the car are possibly slightly different.

(smile)

2. Drill the new bolt holes "B" The Datsun comes with

four and none will fit. It is best to overlap one of the new holes as best

as possible over one of the old holes and then others will be clear

of the originals. It is a small thing but you can have him place the countersunk

fixing screw for the drum as close to the overlapping hole as possible.

One has to play a bit to get it all right.

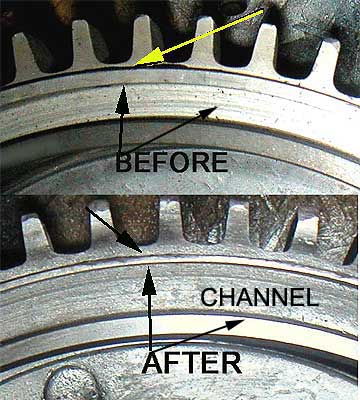

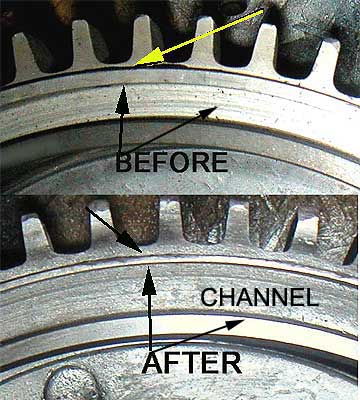

3. One must remove one half the thickness of the inner

side of outer edge of the groove around the perimeter of the drum. That

sounds complicated but it is clear when you are looking at the drum.

Simply put, the groove is not wide enough to accommodate the Morgan back

plate...with this mod it will be.

P.S. If you are using your old brake shoes, you will have

wait a bit of driving for the shoes to adjust to a new curvature of the

drums depending on the difference in wear between the Morgan and the Datsun.

If you are lucky enough to find new Datsun drums and the spirit so moves

you, have one of the companies (i.e.Porterfield) making carbon kevlar brake

shoes to make you up a set to match the curvature. You will be surprised

at the braking improvement.

NOTE: With the older brakes and brake adjusters you should

back off the brake shoe adjustment before fitting the z-drums as you would

with any new drums and then re-adjustment as you would normally. If the

brake shoes are still too tight you can remove the shoes (if you know how)

and file a tiny bit off the contact points at the ends to give you

a little more leeway.

.Post-1993 Self-adjusting rear

brakes (wires)

The post-1993 self-adjusting rear brake made-for-wire-wheels

Morgans have much less machining. The Morgan drums on these come already

made for 8 holes (four to give clearance to the bolts holding the assembly

to the axle and 4 to hold the drum on the assembly).

The post-1993 self-adjusting rear brake made-for-wire-wheels

Morgans have much less machining. The Morgan drums on these come already

made for 8 holes (four to give clearance to the bolts holding the assembly

to the axle and 4 to hold the drum on the assembly).

With the almost identical bolt pattern on both the Morgan

drum and the Datsun Z-drum there are no excess holes left as in the earlier

cars. That will leave you with a comparatively "clean" result.

| IMPORTANT WATCHPOINT 5:

I am a perfectionist. When I found my first set of new (from

Nissan) 30 years ago (then for a pre-June 1993 Plus 8, I had the holes

drilled as described here and asked the best professional welder I

knew, to fill in the old original holes. DISASTER!! Despite all

precautions the bi-metal nature of these drums runs a 50% risk of ruining the entire drum.

Do not try it. |

I should note that on three Morgans and 400,000kms I have

never had a problems with these modifications.

1955 Plus 4

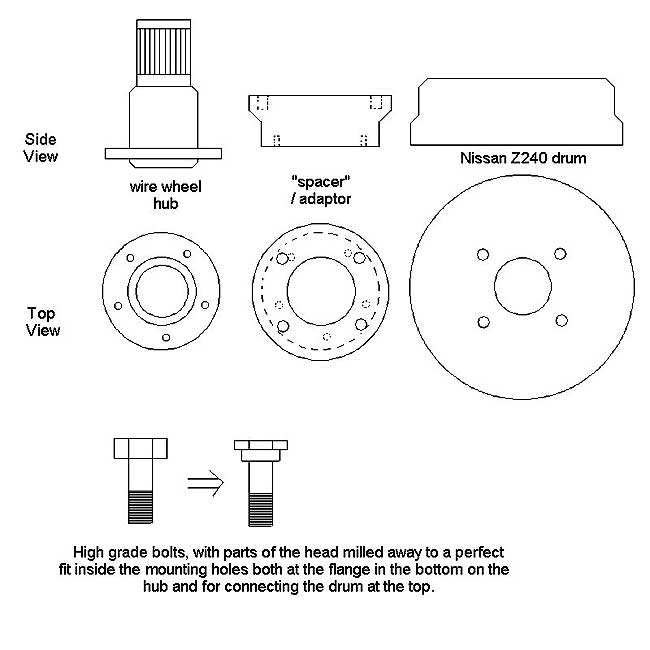

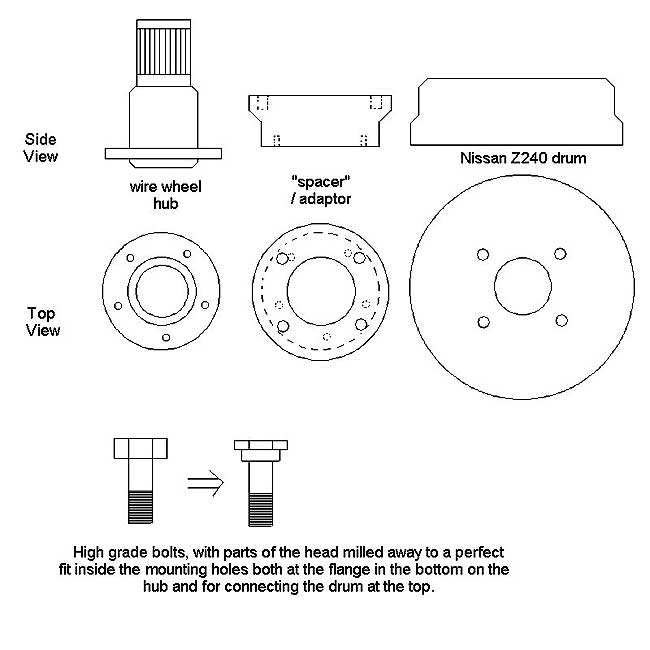

by Harald Sakshaug

Pulled the front brake drum off my 55 +4 yesterday, and

preliminarily fitted the disk wheel hub with the drum back plate and shoes

in situ. It fits. Then took the front drum brake, disk wire wheel hub and

the Nissan Z240 aluminum drum to my workbench. Lads and ladettes, it is

indeed possible to make a spacer which will fit on the disk wire wheel

hub so I can mount the Nissan drum to it.

Hey presto, I have wire wheels on my +4 without having

to convert to disk brakes. Much cheaper, and much less altering to the

original layout. When I want to go stud wheels again, I just pull the wire

wheel

hub and remount the studded one.

I'll pop down to the local metal wizard shop for some

lathe work to the drum itself, and have them to make two cylindrical spacer

rings (one for each side) to fit over the wire wheel hub. This spacer will

be mounted on the flange of the wire wheel hub with the 5 connecting holes.

Then the Nissan drum will be connected on the top of that spacer with the

four bolting holes in the drum.

The room behind the wire wheel hub is an issue, and I

have a general idea how to make the connections, which is attached to this

email as an image.

If anyone out there has ideas, opinions or just want to

address me for advice, please do. It would be welcome. Harald

BACK

Datsun

Z drums, (designed along the same idea of the famous Alfin drums but frankly

MUCH better) were made in bimetal of cast aluminum with fins for extra cooling

and a steel insert and used on the famous Datsun Z sports cars series.

Datsun

Z drums, (designed along the same idea of the famous Alfin drums but frankly

MUCH better) were made in bimetal of cast aluminum with fins for extra cooling

and a steel insert and used on the famous Datsun Z sports cars series.

MACHINING (pre- & post- June 1993 trads).

MACHINING (pre- & post- June 1993 trads).

There is most likely some machining to do depending on what type

of wheels your car was made for.

There is most likely some machining to do depending on what type

of wheels your car was made for.

There are three mods necessary to get it to fit a car

made for bolt on wheels.

There are three mods necessary to get it to fit a car

made for bolt on wheels.

The post-1993 self-adjusting rear brake made-for-wire-wheels

Morgans have much less machining. The Morgan drums on these come already

made for 8 holes (four to give clearance to the bolts holding the assembly

to the axle and 4 to hold the drum on the assembly).

The post-1993 self-adjusting rear brake made-for-wire-wheels

Morgans have much less machining. The Morgan drums on these come already

made for 8 holes (four to give clearance to the bolts holding the assembly

to the axle and 4 to hold the drum on the assembly).