POWDER COATING AT HOME I

Pretreatment:

A) Sand Blast Parts with

fine or medium grade abrasive material.

1) You do not have

to blast if parts are raw material or have been previously powder coated.

2) Heavy blasting

abrasives leaves a poor profile on the metal for painting and can

actually

cause painting defects such as pinholes.

3) For best results

in final finish lightly sand parts to knock down profile from sand

blasting.

4) If previously powder

coated, sand down lightly with 220 grit sandpaper, or give a light

texture (By Rubbing) with course steel wool. This will allow the

powder paint to adhere to the previous powder coated part.

B) Wash raw parts with Columbia

Coatings Prep & Paint or a solvent base material such as lacquer thinner,

acetone, MEK or other Non-Petroleum Solvents.

C) Spray on Prep and

Paint and rinse after 30 seconds.

If rust is on parts a second application may be required.

Our Prep and Paint Turns Rust Back into Black Metal. DO NOT LET PREP

& PAINT DRY ON PARTS!!! IF SO SAND (SCUFF) DOWN OXIDATION LEFT

BEHIND!!!

Powder Painting:

A) Make sure gun is properly

color changed to color desired for coating. With a Chicago Electric Gun

make sure you remove plastic screw at bottom of shaft of gun (Between End

Of Gun And Trigger) and blow thoroughly as the screw sometimes holds powder

and can cause cross powder contamination.

B) Make sure gun has proper

air pressure. (Refer to Powder Gun Manual). We highly recommend

putting Air Regulator on gun itself and do not rely on

compressor to regulate because of actual volume that builds in air hose

itself is more than gun requires and can cause bursting of powder at

end of gun.

C) Make sure part is properly

grounded by gun clamp or through other grounding source. You can

also ground out to hook or wire that is touching part!!!

D) We suggest preheating parts

for 375-400 Degrees for 10 minutes to help outgas parts and kill any

material such as oils that could have been missed when cleaning parts.

E) Coat parts 3 to 5 minutes after

preheating (First Recommended By Columbia Coatings Only On All Powders

Including Competitors) as this helps in getting down in the areas powder

has a hard time getting to (Cracks and Creases) with the use of less powder.

Curing:

A) Single Coats, Secondary (Final Coat), Third (Final

Coats)

1) Light Parts: 375

degrees for 10-20 minutes. (Pulleys, Brackets and other small items.)

2) Heavy Parts:

385-400 degrees for 15-25 minutes. (Wheels, Intake Manifolds, Etc.)

B) Base Coats and Secondary

Mid Coats. (Such as Chrome base for Translucent Color and or with Clear,

White Base for Fluorescents and Neon's or Our Zinc Rich Coating.)

1) Partial Cure for

10 to 15 Minutes at 375 to 400 Degrees.

2) Remember: This

is for all base and or mid-coats that is going to have a final coat such

as clear on top for exception of chrome below.

3) Chrome as a final

coat !!! Chrome must be fully cured at 375 to 400 degrees for 15-20

minutes to get full luster of the chrome. After Chrome base cools

apply Clear for the Topcoat for Optimum Protection and Appearance!!!

Click http://www.columbiacoatings.com/

POWDER COATING AT HOME II

from the eMog

Pub and Richard Norman

I worked for a commercial operation that did this and

it ain't that easy!

First: You must clean the parts thoroughly of oil, grease,

dirt, oxidation (rust!), etc.

If you do not then the paint layer WILL bubble and lift,

(worst still the metal substrate will oxidise underneath) and as has been

said before, it is hell to remove the area that HAS adhered or to fill

in the dips (gaps) and the parts just have to be chucked away! (Simply

a drip of oil left will spread when the part is baked!)

Commercially this is done by dipping the parts in several

tanks of hot liquids, degreasing, caustic, etc. These tanks get contaminated

by the substances and grease, etc. and the liquids have to be replaced

else they get gunged up and then put gunge on to clean parts! Then you

have to dry it – do not touch it as you might just put some

gunge back on and clean dry hot air only! How will you jig/hang it?

So that the area where the jig masks the powder will not be seen on the

finished product?

Next: you will need to apply an even thickness of powder

and paint all over the part(s).

How do you plan to do this? Commercially this is achieved

by giving the parts a negative charge and and then owing at it. The positively

charged paint particles (powder) in to the booth around the parts. (Best

not to be there yourself even with a mask) The paint particles are attracted

to the part and adhere under the charge. Can you do that? If not how will

you get the even thickness – an uneven thickness can be seen

in the finished product even in mat finishes! As a second issue there are

problems with maintaining the charge on e.g. steel, iron, etc.

Okay so now you have a part with some paint powder loosely

attached, you have to get it up to temperature fairly quickly! True the

metal will (sorry should) be hot, as it has just left the hot dips and

the dryer but still you need to get the temperature hot (correct for the

paint that you have purchased, for the product that you are coating and

for the thickness of layer you have or want.)

I do not want to put you off, just prepare you for the

failures that you will have in the early days. Toxic fumes and ruined ovens

will not be your worst things to contend with!

BTW hand painting also has its problems with badly mixed

paints, colour match, continual rubbing down, thin layer upon layer,

keeping brushes clean, etc.; so does spraying and it is true that PC is

a really hard finish and when/if you achieve it please can we all have

a look at the photo of you with the Cheshire cat grin on your face?

Best of luck {8-)) Richard, R1

POWDER COATING III

from the eMog

Pub and Mike Miles

Powder coating the drums black is good for radiation heat

transfer but it may not improve the overall heat transfer very much, since

it adds a lower conductivity 'skin' on the drum which slows down the ability

to transfer heat from the shoe contact surface to the outside surface.

As a really rough estimation it could reduce the overall heat transfer

by up to 10% (which means the drums stay hotter, fade happens more quickly).

While we're on the subject - when something is being cooled

by moving air (forced convection) the typical proportion of heat transferred

by radiation is fairly low (usually less than 10%) assuming it has something

to radiate to. When it is subject to natural convection (non-forced

air motion, also known as bouyancy), the radiation proportion can be as

much as 30%.

As some of you will be quick to point out - there are

exceptions due to geometry, nature of the surface, working temperatures,

etc which is all true, however as a rule of thumb, forced convection heat

transfer tends to dominate the balance.

In the situation with brake components, radiation heat

transfer is from one body (the drum) to any other bodies in direct line

of sight (wheel rim predominantly) whereas the forced convection occurs

during vehicle motion (transfer to the air passing by). When you

stop there are natural convection currents that begin to establish but

by then you've most likely zoomed off again. Again, making them black

won't add greatly to the overall efficiency - but they may LOOK like they're

doing the job...

Drum coatings:

There are (at least) two other alternatives for putting

a nice coating on the drums however. There are high-solids zinc and

high-solids stainless steel sprays (available in rattle-cans believe it

or not - Seymor and Krylon brands). They CLAIM they are 100% solids

however they are actually slightly less due to having a binder in them.

They are an enamel that helps the metal stick to the surface being sprayed

on. When you have really clean parts (drums, calipers, etc)

you can apply the coating and then bake it for about an hour at 350 °F

(180 °C). The baking drives off all the aromatics so the coating

won't discolor or flake under stress and heat.

Regarding the oven baking - a friend of mine has a second

hand oven in his shop so he can bake the parts per the above description.

It is also well ventilated with an exhaust fan beside the oven. The

odor is not overpowering but is similar to any hot plastic (but watch that

temperature! Too hot and it will start smelling charred - ask Dick

Dice about his first Cajun cooling experience sometime...). The dominant

chemicals driven off are polyester however there was a powder coating supply

company that was heavily fined in 2001 because there were trace amounts

of heavy metals in the powder (no evidence they were airborne but caution

is the watchword).

REMOVING POWDER COATING

from Format January 2013 edition

Ever wonder about that frame or car part that was power

coated and now might have a hidden crack that need attention ? Or, as we

found, a part was powder coated and it was not fully disassembled and two

pieces were then inseperable ? Well, what is needed is a method to separate

the two powder coated pieces now locked together – and we found it through

the internet. The magic is not heating to over 400 deg in your home oven,

nor sanding, nor abrasive blasting - rather a small can of Permatex Gasket

Remover #80646 will do the job. Spray it on, wait 10 minutes and the powder

coating become soft and gel-like. Scrape that off and repeat 4 or 5 times.

Workes

really well and costs less than $10.00

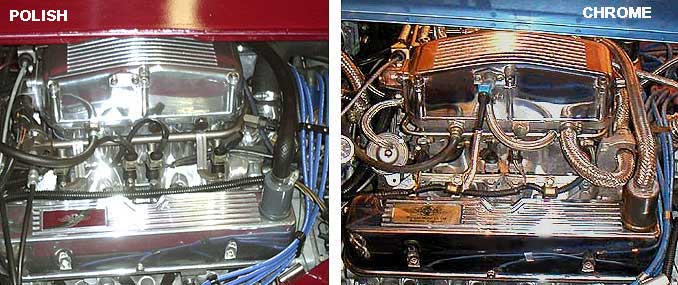

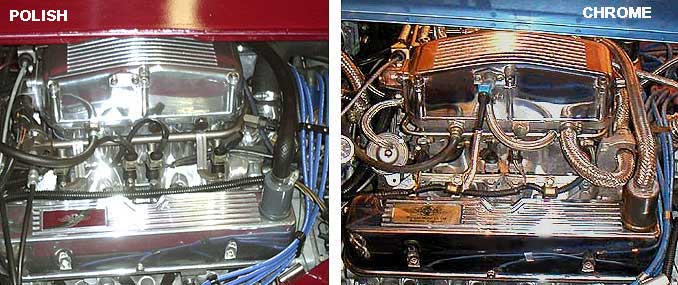

CHROMING VERSUS POLISHING

ALUMINIUM

from the eMog

Pub and Lorne Goldman

The advantage with chrome over high gloss polishing (also

very attractive) is the reflective quality and the lack of maintenance

after. I had my valve covers chromed here some years ago. Rpi's prices

for chrome valve covers are far better than what I paid here because of

the volume they do.

I

have only seen two chromed plenums, (both my own) though a goodly number

of polished ones. Most of the UK Agents can have the polishing done for

you. The problem with chroming a plenum is that it is a very porous cast

alloy piece. It requires much sanding and polishing to obtain a perfectly

smooth surface in order to chrome. This must go beyond the normal polishing

as EVERY flaw shows up on a chrome surface. The advantage with polishing

is that you can do it at home. Simply sand the plenum with progressively

fine sandpaper until it is satin smooth. It will take a while.

I

have only seen two chromed plenums, (both my own) though a goodly number

of polished ones. Most of the UK Agents can have the polishing done for

you. The problem with chroming a plenum is that it is a very porous cast

alloy piece. It requires much sanding and polishing to obtain a perfectly

smooth surface in order to chrome. This must go beyond the normal polishing

as EVERY flaw shows up on a chrome surface. The advantage with polishing

is that you can do it at home. Simply sand the plenum with progressively

fine sandpaper until it is satin smooth. It will take a while.

After that, there is the standard problem that alloy cannot

be directly chromed. It must be plated three times with different metals

to obtain a chrome finish. Between the sanding the polishing and the plating,

all of this is extremely costly.

Polishing aluminum produces a shiny opaque surface while

chroming produces a mirror reflective surface (with different undertones

depending on its quality and the chromer. "Show" chrome, with black undertones

is the best.) Being virtually a mirror finish makes people think it shiny..especially

as it reflects camera flash and light. However, it is not "shiny" and much

less than you would have through polishing. Chrome doesn't diffuse light,

it reflects it. The view changes as you move around it. It seems to shine

in a photo because of the light effect. It is as hard to photograph as

a mirror. If you hold your old polished valve covers next to your new chrome

ones you will see what I mean.

As well, take a look at the photo. Photos poorly show

shiny metal but you can see the differences. The chrome shows far more

areas black. It was a kind gift from a number of friends in the UK. I can

inquire on the technique if you are interested and get back to you off-emog.

I

have only seen two chromed plenums, (both my own) though a goodly number

of polished ones. Most of the UK Agents can have the polishing done for

you. The problem with chroming a plenum is that it is a very porous cast

alloy piece. It requires much sanding and polishing to obtain a perfectly

smooth surface in order to chrome. This must go beyond the normal polishing

as EVERY flaw shows up on a chrome surface. The advantage with polishing

is that you can do it at home. Simply sand the plenum with progressively

fine sandpaper until it is satin smooth. It will take a while.

I

have only seen two chromed plenums, (both my own) though a goodly number

of polished ones. Most of the UK Agents can have the polishing done for

you. The problem with chroming a plenum is that it is a very porous cast

alloy piece. It requires much sanding and polishing to obtain a perfectly

smooth surface in order to chrome. This must go beyond the normal polishing

as EVERY flaw shows up on a chrome surface. The advantage with polishing

is that you can do it at home. Simply sand the plenum with progressively

fine sandpaper until it is satin smooth. It will take a while.