TRIUMPH TR ENGINES AND DIFFERENT CAMSHAFTS

by Anthony Rhodes

Here is a discussion regarding some of the issues involved

in selecting a new camshaft for your TR4/4A engine. The same issues apply

to the earlier engines, but variation in intake port design may alter

the balance point for trade-offs.

First, do you really need to change your cam? Maybe

not. The engine designers did a good job with balancing the trade-offs

of the camshaft. Certainly they knew how to make a "hot" cam, but chose

the one they did for very good reasons. A "hot" cam works at higher RPM,

but sacrifices low RPM flexibility (i.e low idle speed and grunt at low

rpm in higher gears. However, the hotter cam allows more power at

the upper rpm range. Unlike some modern short stroke engine designs,

our Triumphs are not able to get safely past what is now considered a mid-range

rpm range. So, the really hot cams that allow good power over 6000

rpm are not really useful here. The cams we  will

be working with are in the range of stock to mild to moderate. The choice

of cam will also be influenced by what other modifications have been made

to the engine to allow the cam to work the way it was intended. It

is almost like buying a person with a bad heart a racing bicycle.

Even though the bicycle can go very fast, the person using it can not sustain

the effort to make it go!

will

be working with are in the range of stock to mild to moderate. The choice

of cam will also be influenced by what other modifications have been made

to the engine to allow the cam to work the way it was intended. It

is almost like buying a person with a bad heart a racing bicycle.

Even though the bicycle can go very fast, the person using it can not sustain

the effort to make it go!

What does a "hot" cam do differently from a "stock" one?

It does nothing differently at all, it just does it at a different time.

Time is of the essence, particularly with cams. The cams open and

close the valves which allow the mixture to be drawn into the engine and

the spent exhaust to leave the engine. At low rpm, it is not hard

to get the mixture into, and the exhaust out of, the engine. As the

rpm gets higher it is progressively more difficult to get the gases in

and out due to drag throughout the system. At high rpm you have to wait

proportionally longer to get the gasses in and out. This wait is the time

that the intake or exhaust valves are open. That is the entire issue.

Higher RPM requires longer valve duration for good performance than low

RPM. In addition, when optimized for one range, it is not as good

for the other range.

As I said above, the use of the hotter cams requires other

modifications to the engine to put the cam to good use. Specifically, you

may need a "better flowing" head. This requires that the ports and

valves be treated to reduce low resistance. This will allow the gases

to move more easily so you get a larger volume in and out of the engine

in the same period of time. Again, there is a trade off here.

Very large ports allow huge slugs of gas to be expelled without having

a lot of drag induced by very high flow speeds. Unfortunately, the

flow can be too slow as well, so large ports can allow the gas to flow

so slowly that problems can occur. When these problems occur it may

be impossible to obtain a low idle speed.

Another modification that a hot cam often requires is

a higher compression head. With excessively low compression it may

not be possible to get the combustion efficiency that the engine requires.

So, is it reasonably possible to get a "better" cam without

having to modify the rest of the engine? The answer is a qualified yes.

Certainly you can get some more performance from the engine, but will the

cost of the cam removal and reinstallation be worth the 6-10hp difference?

Only you can answer that one. I, unfortunately, subscribe to the "more

is better", or "in for a penny, in for a pound" philosophy.

I

have not yet made the dive into the engine, but since my engine rebuild

will require at least new valve guides, why not shave the head to increase

the compression, and explore the cost of "porting and flowing" the head?

Once I spring for that cost, it would make sense to install larger intake

valves. Larger intake valves require that the head gasket and block be

relieved around the edge of the valve orifice. Since the engine has

quite a few miles on it, and the pistons and liners are aging fast, maybe

I should put in 89mm pistons to increase displacement from 2138cc to 2187cc.

Certainly after all these modifications the carburetors themselves are

causing a restriction, and some other carbs would be necessary. Maybe

2" (instead of the stock 1.75") SU's, but Webers or Weber-look alikes are

better. Webers make sense here because I have lost some of the low-end

anyway with a "hot" cam. Needless to say, I now need a better exhaust

manifold.

I

have not yet made the dive into the engine, but since my engine rebuild

will require at least new valve guides, why not shave the head to increase

the compression, and explore the cost of "porting and flowing" the head?

Once I spring for that cost, it would make sense to install larger intake

valves. Larger intake valves require that the head gasket and block be

relieved around the edge of the valve orifice. Since the engine has

quite a few miles on it, and the pistons and liners are aging fast, maybe

I should put in 89mm pistons to increase displacement from 2138cc to 2187cc.

Certainly after all these modifications the carburetors themselves are

causing a restriction, and some other carbs would be necessary. Maybe

2" (instead of the stock 1.75") SU's, but Webers or Weber-look alikes are

better. Webers make sense here because I have lost some of the low-end

anyway with a "hot" cam. Needless to say, I now need a better exhaust

manifold.

You can see where this is going. Since I am not

looking for a ton of horsepower (its not a Corvette after all!!), I will

stick to a more mild cam where I do not have to worry too much about porting,

flowing, new manifolds and the like. I will run a moderately increased

compression, and moderately improve the head to go with the moderate cam

I will install. This will be only moderately expensive (I hope).

Which cam is which?

N.B. Send me more if you have them! Webmaster

VINTAGE/Old Style cams

| TYPE |

Duration |

Inlet/Exhaust |

Lift |

Comments |

| Stock |

254 |

17-57/57-17 |

0.375 |

|

| "D" |

284 |

33-71/71-33 |

0.393 |

Race/Street 10:1 compression required |

| "F" |

300 |

39-81/81-39 |

0.432 |

Full Race, 11.7:1 comp., 4000-6000 |

| G-3 |

309 |

51-79/79-51 |

0.499 |

Racing only, 11.7:1 comp., 4200-6500 |

| SAH #26 |

264 |

22-62/62-22 |

0.388 |

Mild Cam |

| Piper |

268 |

24-64/64-24 |

0.387 |

Mild Cam |

| Derrington |

280 |

30-70/70-30 |

0.435 |

Near limit for street use (see Elgin 7010-9 |

MODERN cams

| TYPE |

Duration |

Inlet/Exhaust |

Lift |

Comments |

| Elgin 6710-18 |

268 |

24-64/64-24 |

0.404 |

No major Mods req. Pulls Hard, good power (effectively

a "1/4 grind") |

| Elgin? |

274 |

27-67/67-27 |

? |

No description. Effectively a "2/4 grind" |

| Elgin 7010-9 |

280 |

30-70/70-30 |

0.375 |

"3/4 grind", Streetable with 87mm and header |

| BFE #260 |

260 |

? |

0.408 |

Mild Cam |

| BFE #148 |

282 |

? |

0.425 |

Slight lope @ idle, but low lift rate, so not as hot

as others |

How do all these variations make a difference? Well,

they vary the time that the valves open and close. To understand

why the timing is important, you have to understand a little of what is

happening inside the manifolds and cylinder.

In a model of engine function where the intake and exhaust

gases have no momentum nor and drag, then all you need to do is open the

intake valve at the beginning of the intake stroke and then close it at

the end of the intake stroke, then compress the mixture, fire when the

piston hits the top and then open the exhaust valve when the piston is

at the bottom.

In the real world the gases do have momentum and drag.

We can use momentum to our advantage so the engine does not have to do

all the work pumping the gases in and out. Using momentum, the gases will

(to a certain extent) blow themselves in and suck themselves out.

For the intake stroke, we can use the partial vacuum created

by the exhaust gases as they are shooting out of the cylinder to help suck

in the new mixture. In order to do this, we need to open the intake

valve before the exhaust valve is closed, and we can even open it before

the piston has come to the top of the exhaust stroke! At higher revs

we need to open the valves earlier and keep them open proportionally longer

in order for the same

amount of gas to be moved. At low revs, prolonged

valve overlap will cause some if the new mixture to be sucked out with

the exhaust, causing no end of problems, and reducing performance.

This is the first instance of why a cam timed for high revs does not work

well at low revs.

Now a little later into the intake stroke the exhaust

valve has closed and the mixture is being sucked into the cylinder as the

piston moves downward. When the piston hits the bottom of the intake stroke,

the incoming mass of mixture has momentum driving it into the cylinder,

so we can keep the valve open even after the cylinder has begun its upward

compression stroke and allow momentum to drive even more mixture into the

cylinder. The length of the intake runners will help in this matter

as the echo of the intake valve closing on the last stroke can come back

and compress even more gas into the cylinder. The echo is a wave

of gas bouncing back from the carburetor end of the intake runner just

as a wave bounces off a wall in a swimming pool. Again, at higher

revs we need to keep the valve open proportionally longer in the cycle

to get the full charge of mixture. The added charge of mixture entering

the cylinder is a poor man's supercharging.

On the compression stroke the valves are closed, so there

is no magic here as far as valves are concerned until near the end of the

firing stroke.

After the spark has fired and the mixture combusted, the

piston is driven downward and eventually it is time to open the exhaust

valve. We can open the exhaust valve before the piston hits the bottom

of the stroke without losing much power. The early opening of the

valve gives more time for the exhaust to leave the cylinder. The

early opening also allows the exhaust to be shot out of the cylinder with

a little more force and speed. This is important later in the exhaust

stroke. Again, at higher revs it is necessary to open the exhaust

valve proportionally earlier, but at lower revs, that will result in noticeable

loss of power.

Now the piston is moving upward expelling the exhaust

gases. The length of the exhaust runner is important since the blast of

exhaust has momentum and can help suck the exhaust out of the cylinder

at the end of the exhaust stroke, and can even help suck in some of the

new mixture. The length of the runner is important since if it is

too short it will develop less suction (extractor effect) than it should.

If it is too long then it will cause excessive back pressure. This

is how "tuned pipes" work, and why they are a mixed blessing. If

you are going the right (high, usually) RPM, then the extractor effect

is very useful (as long as your cam is timed appropriately). At lower

RPM, the pipes are too short and you lose the extractor effect.

Now we have been through the entire four strokes of the

engine, and it is more clear why cam selection is important and such a

difficult decision.

What is an "asymmetrical" cam? In the old days,

and even today, cams were usually symmetrical. (E.G. the 17-57/57-17

stock TR4 cam) This means that the intake valve opens 17 degrees

BTDC of the intake stroke, and closes 57 degrees ABDC of the intake stroke.

In this case the exhaust valve opens 57 degrees BBDC of the exhaust stroke

and 17 degrees ATDC of the exhaust stroke. Why are the numbers the

same? I am not sure, but I suppose it was easier to machine that

way (before computer controlled machines) and with an infinite number of

possible asymmetric settings, they stuck with the more limited choices

of the symmetrical style. Nowadays we have computers! This allows

us to make any cam profile we want with very little extra effort.

We just type in a different set of numbers into the computer and let it

make the machine run. In addition, we have supercomputers to do advanced

modeling of the complex flows in the engine. In my description of

the 4 strokes above I never said anything about the exact time the valves

were supposed to open. There is no special reason why you should

open the exhaust valve 17 degrees BBDC just because you opened the intake

valve 17 degrees BTDC. As a matter of fact, there is every reason

to suspect they should NOT open at the same number. It would be a

mighty coincidence if the optimal numbers were the same. More of

a coincidence than you having the same phone number (except area code)

as your sister living in another state! Advanced computer modeling

allows designers to discover the optimal timing of all valve opening and

closings. Actually, the most advanced engines have no cam at all,

instead, the valves are solenoid actuated and can be opened at varying

times based on engine demands. We do not have that luxury.

Note: I have found that the asymmetry can

be in the ramp profile of the lobe. It can open and close at different

speeds. I.E. It can open fast with a steep ramp, then

close more slowly to minimize valve bounce by using a more shallow ramp

angle.

Well, that is it. I hope this explanation helps

you understand cams and cam selection a little better. I still have

not decided which cam will be the best for me. Probably unless I

make a BIG mistake, any cam I choose (even the stock one) will keep me

happy.

Starting Up a Long Dormant One

by Lorne Goldman May 2020

I stumbled across this today. I found it charming. So I am placing a link to it HERE. It also illustrates a primary principle that you can always rely on: The GoMoG Law of Starting an Engine: An Internal Combustion Engine Will Always Start If It Has Fuel And A Spark. That

leads to other ancillary helpful laws..such as, if you confirm

one of two is present, then the other has to be the area where

the problem will be found. For example, I run with a

permanently installed fuel pressure gauge (early fuel EFI system)

and I have altered the wiring to allow the pump to run as soon as the

ignition is turned (after making other, much better provisions for my safety). That means I can diagnose which of the two areas is causing me grief at a glance.

| P.S. I was also amused at the fellow in the video puzzling over the eMog badge (minute 8:00) and what it was about! The

intention behind the eMog badge and pins was merely to allow emoggers

to discretely recognise each other without seeming to advertise for more

adherents at club events we were at. We hoped that without anything

written on this insignia, they wouldn't act as a billboard. In the

internet age, we were concerned about the survival of the traditional

clubs. That is the reason the eMog Moderators never encouraged Meets of

our own,. though some did, indeed happen. :) Sadly, we were prescient.

In many cases forums have virtually destroyed their local clubs. No

secret in that. The marque has become much less known to the young

because of that. We must all come up with a format that allows both to

flourish. Those "old days" were great! I will now get off this podium! |

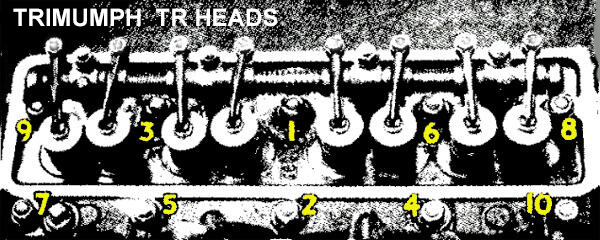

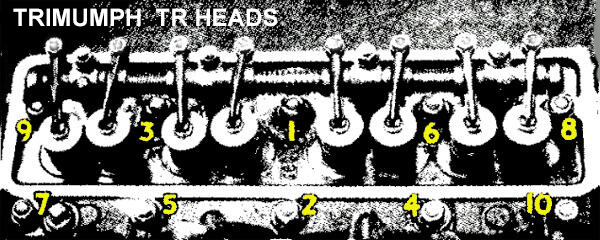

Rope Trick for Removing the TR Head

from the Triumph Experience Forum (Mickey) September 2024

| GoMoG Webmaster Note: It is advisable to remove or loosen the head bolts in the reverse of the torquing sequence. |

The rope trick helps to break the cylinder head seal on the block.

Remove the rocker shaft complete with it's rockers and then the spark

plugs, and feed in a length of thin soft rope (maybe 5mm dia) into the

cylinder chamber, and with the head nuts removed turn the engine over a

couple of times on the starter. The rope is compressed up and fills the

cylinder head chamber and the piston crown pushes it up against the

cylinder head lifting it maybe 3mm.

You can be hopeful and try the double nut on the studs and try turning out the

studs in reverse. Some may come out dry, if not use your best quality

anti seize fluid and pour into little reservoirs made by using

plasticine or other sticky pliable putty substance around each stuck

stud, diesel works really well. Leave it for a day or so to disappear

down the stud and then try the double nut method on the stud...wiggling

it both tighten (to break the seal) and then try to undo. If the double

nut won't break it maybe a more professional stud remover might do the

job, and then of course warming the stud (careful if you've used anti

size or diesel on the head) can help when used in the process.

If you get the studs all but one out, then an overhead crane or lift

onto the head along with a twisting motion helps screw the head up a

stuck stud. Perseverance pays off in the end, I've rebuilt over 20 of

these engines, some which obviously came off the Titanic ! and although

they threaten resistance the normally give up begrudgingly.

A little idiosyncrasy of the engine are their wet cylinder liners which

should protrude between 3-5 thou above the block surface, make sure you

follow the workshop manual and get used to fitting and pulling the

cylinder head whilst you juggle the clearances and machine. An area

where many "pro" workshops fail, they do one build and measure and then

strip and machine components and refit ...bish boff biff done...wrong.

The clearances are dynamic and change orientations so build, measure,

strip, machine and BMSM again, until you get them correct.

TR Four-Cylinder Series Torque Sequence

Torque Values

by Greg Solow from the Engine Room

First make sure the head and block surfaces are clean and

flat and that all of the threaded holes in the block have good clean

threads. With studs, screw in the studs hand tight only. Do not tighten

studs into a block unless you are sure that the bottom of the stud can

hit the bottom of the hole. On a TR4 type engine, the studs do not have

as long a bottom as the hole is deep, the stud will thread into the

block stop where the threads on the stud end. If you continue to torque

the stud into the block, the threads will try to pull the stud down into

the hole and the stud will act like a wedge. It will cause the block to

crack from the stud hole to whatever the nearest open area is. This is

the reason most "tractor" blocks have cracks at the left rear stud hole

going to the water jacket. There are improvements to be made here, but

that is another story. So just tighten the studs hand tight.

We have found Permetex "Anti-Seize" when used as a

lubricant on the head bolt thread, washers and nuts, does not change the

torque that is applied, but does help prevent the "sticktion" mentioned

in the earlier posts, so that it becomes less necessary to loosen the

nuts first during re-torquing. So on a TR-4, we apply the anti- seize to

the fine threads on the top of the stud, to the top surface of the

washer and to the inside of the nut and its' bottom surface. Tighten the

nuts using a normal torquing sequence to about 30 lbs. ft., then 50,

then 70, then we go to 85 or 90. We use this as a maximum torque. WE

no longer torque heads to 105 lbs. ft. as we have not found it

necessary, and it only leads to broken and stripped studs and head nuts.

Run the engine to get it fully up to operating temperature,

then retorque the head hot, to the same torque figure as the initial

torque. With a solid steel head gasket, you can try again, but we have

found nothing will tighten any more. With a composite (copper/asbestos)

or other "non solid sheet" gasket, we hold re-torque the head again after

a couple of heat cycles. If you wish to loosen each nut before

retorqing, there is certainly no harm in doing so. It is good to mark

each nut with a scribed line before you loosen it up, so you can tell if

it tightened to a position that is tighter than it was in the begining.

If I try to tighten a nut or stud, and it will not move, then it is

definitely good practice to loosen and then re-torque. These general

instructions ( except for the torque figures quoted) will hold true for

any cast iron block and head combination. Using ARP moly based

assembly lube paste on the head nuts and studs will require a reduction

in torque of over 30% because it is so slippery. We have tried using the

ARP lube and one time actually crushed the raised boss on a TR-4 head

above the intake ports. The Anti-Seize works very well.

On modern engines the manufacturers no longer (generally)

use torque figures for head tightening. The engineers have calculated

how much "stretch" on the head bolts they need to get the clamping

pressure on the head gasket that they want & the procedure is to

torque to 20 lbs, ft.or less, then use a protractor and tighten the

bolt a certain number of degrees from that point, the desired pre-load is

calculated by the pitch of the threads of the bolt. This procedure

avoids the variables caused by the friction of the bolt or nut on the

threads or the washer and achieves a more consistent clamping force on

the gasket.

I forgot to mention a couple of things. Make sure that the

fine threads on the studs are not distorted. Wire brush them clean and

then inspect them under bright light against a white wall. The threads

should not tilt upward, but should be nice and uniform. After 50 years

of head gasket replacements the threads will eventually become distorted

and will bent upwards. Any studs like this should be discarded. Another

way to check them is to take two studs and fit the threads together.

Hold them up to the white wall and there should be no light visible

between the threads of the two studs. If the threads of one stud are

distorted, light will be visible. Check the bottom of each nut. feel the

inside of the hole. The threads should not be pulled downwards. When a

nut is machined, there is always a little bevel on the inside of the

hole leading into the first thread. As the nuts are torque again and

again, the thread will pull downwards. If these threads are distorted,

discard the nuts. Replacing the nuts with good Grade 8 "high nuts" is a

good idea. A "high nut" is a nut that is about 1 1/4 times taller than a

normal nut of the same size. Curtiss Industries makes good ones that

are heat treated to have a tensil strength of 180,000 psi. Lawson

Industries also distributes similar nuts. Of course all ARP hardware is

top notch, but I do not like the look of 12 point head nuts on a

Vintage race car, they just don't look right. I do not believe that ARP

make a hex "high nut" Finally make sure that the nuts will spin on to

the studs easily with your fingers before using them.

will

be working with are in the range of stock to mild to moderate. The choice

of cam will also be influenced by what other modifications have been made

to the engine to allow the cam to work the way it was intended. It

is almost like buying a person with a bad heart a racing bicycle.

Even though the bicycle can go very fast, the person using it can not sustain

the effort to make it go!

will

be working with are in the range of stock to mild to moderate. The choice

of cam will also be influenced by what other modifications have been made

to the engine to allow the cam to work the way it was intended. It

is almost like buying a person with a bad heart a racing bicycle.

Even though the bicycle can go very fast, the person using it can not sustain

the effort to make it go!

I

have not yet made the dive into the engine, but since my engine rebuild

will require at least new valve guides, why not shave the head to increase

the compression, and explore the cost of "porting and flowing" the head?

Once I spring for that cost, it would make sense to install larger intake

valves. Larger intake valves require that the head gasket and block be

relieved around the edge of the valve orifice. Since the engine has

quite a few miles on it, and the pistons and liners are aging fast, maybe

I should put in 89mm pistons to increase displacement from 2138cc to 2187cc.

Certainly after all these modifications the carburetors themselves are

causing a restriction, and some other carbs would be necessary. Maybe

2" (instead of the stock 1.75") SU's, but Webers or Weber-look alikes are

better. Webers make sense here because I have lost some of the low-end

anyway with a "hot" cam. Needless to say, I now need a better exhaust

manifold.

I

have not yet made the dive into the engine, but since my engine rebuild

will require at least new valve guides, why not shave the head to increase

the compression, and explore the cost of "porting and flowing" the head?

Once I spring for that cost, it would make sense to install larger intake

valves. Larger intake valves require that the head gasket and block be

relieved around the edge of the valve orifice. Since the engine has

quite a few miles on it, and the pistons and liners are aging fast, maybe

I should put in 89mm pistons to increase displacement from 2138cc to 2187cc.

Certainly after all these modifications the carburetors themselves are

causing a restriction, and some other carbs would be necessary. Maybe

2" (instead of the stock 1.75") SU's, but Webers or Weber-look alikes are

better. Webers make sense here because I have lost some of the low-end

anyway with a "hot" cam. Needless to say, I now need a better exhaust

manifold.