OIL PRESSURE

GAUGE AND SENDER

by Lorne Goldman

Until the late 1980s, Morgan

used Smith's Oil Pressure gauges. Then they switched to VDO. Both of these were mechanical

units until some time in the 1990s when the MMC wisely switched to oil pressure gauges that operate with an electrical

sender rather than a mechanical system.

MECHANICAL SYSTEMS

The mechanical systems were accurate. They received the pressure through a tube from

the oil pump. But sadly, like the one-shot oiler, the systems are inherently super risky as the plastic tubing is vulnerable

to heat and other causes of breakage. When this happens, they cause pressurized oil to spray about and empty the engine of

motor oil (with dire consequences) in

no time..putting the engine (and yourself) at dire risk from an engine seizure. Without oil, engine parts expand and

lock. When traveling, it is a pain to address this issue and clean up its mess.

However, there are fittings

that can "splice" the tube together with the appropriate pressure fitting.

The systems come from the home oil furnace industry and are still used

theough they have long since been outlawed for cars. So they can be had

if you find a specialist in home oil furnaces. They are little brass fittings

consisting of two pressure dowels (inside), a male threaded fitting and

two fmeal threaded fittings. To repair, one must make clean cut ends, then

take the fitting apart, slide the male fittings on each side of the tube,

then place a dowel on a side, push a bit of the tube into the male

threaded fitting and thread the female bit on over the dowel and onto the

male fitting. Now do the same on the other side and you have your splice.

If there is insufficient length, then buy a bit of an extension from the

same source you got the fitting and buy two fittings, one for each end

of the splice. If securely attached to the car or motor, it makes a permanent

repair...albeit with the same risks as the original.

THE OLD TUBES FOR THE OLD PRESSURE GAUGE

Subject to

the warning and codicils above, the tube from the oil pump to the oil

pressure gauges are made of the same tubing used in the home oil

furnace industry. Simply go to the nearest heating specialist and buy the

length you need.

The smart owner swaps in an electric oil pressure gauge. They can be had in whatever gauge maker/type

you have. Failing that, send them to SpeedyCables (aka Caerbont) and they will modify them from mechanical to electrical.

ELECTRICAL

GAUGES

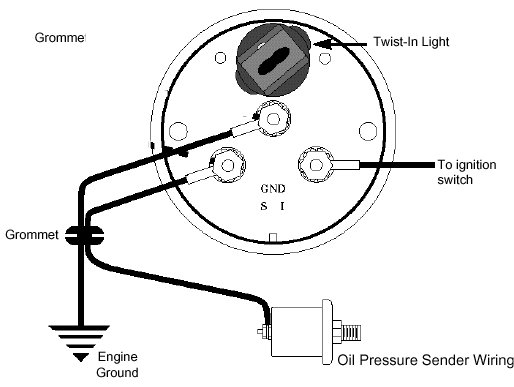

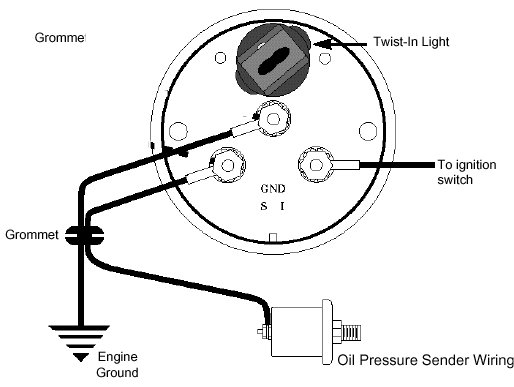

These consist of a gauge

which measures the resistance from sender (normally at the pump) which

transforms varying pressure into  varying

resistance. This eliminates the tube filled with pressurized oil so

varying

resistance. This eliminates the tube filled with pressurized oil so  that

risks and consequence of that type of breakage is eliminated. Replacements

gauge can be had, indistinguishable from the originals, that function electrically

rather than mechanically. However, there are some issues that must be checked

and confirmed. The sender, the oil pump and the gauge must match or be

made to match so the readings make sense, the range of readings span the

specific motor pressures, and the threads in the oil pump and sender fit

(which can be done with adapters if necessary. These senders have all sorts

of shapes..most often like a mushroom. Some will have two posts for

wires (a ground/earth feed and a wire to the gauge) or one post (only a

wire to the gauge as it assumbed the sender is grounded/earthed by the

contact of the threads with the oil pump).

that

risks and consequence of that type of breakage is eliminated. Replacements

gauge can be had, indistinguishable from the originals, that function electrically

rather than mechanically. However, there are some issues that must be checked

and confirmed. The sender, the oil pump and the gauge must match or be

made to match so the readings make sense, the range of readings span the

specific motor pressures, and the threads in the oil pump and sender fit

(which can be done with adapters if necessary. These senders have all sorts

of shapes..most often like a mushroom. Some will have two posts for

wires (a ground/earth feed and a wire to the gauge) or one post (only a

wire to the gauge as it assumbed the sender is grounded/earthed by the

contact of the threads with the oil pump).

If the wire is broken or detached, the

pressure will read very high or not at all depending on the car type. Simply repair it or run a new one.

varying

resistance. This eliminates the tube filled with pressurized oil so

varying

resistance. This eliminates the tube filled with pressurized oil so  that

risks and consequence of that type of breakage is eliminated. Replacements

gauge can be had, indistinguishable from the originals, that function electrically

rather than mechanically. However, there are some issues that must be checked

and confirmed. The sender, the oil pump and the gauge must match or be

made to match so the readings make sense, the range of readings span the

specific motor pressures, and the threads in the oil pump and sender fit

(which can be done with adapters if necessary. These senders have all sorts

of shapes..most often like a mushroom. Some will have two posts for

wires (a ground/earth feed and a wire to the gauge) or one post (only a

wire to the gauge as it assumbed the sender is grounded/earthed by the

contact of the threads with the oil pump).

that

risks and consequence of that type of breakage is eliminated. Replacements

gauge can be had, indistinguishable from the originals, that function electrically

rather than mechanically. However, there are some issues that must be checked

and confirmed. The sender, the oil pump and the gauge must match or be

made to match so the readings make sense, the range of readings span the

specific motor pressures, and the threads in the oil pump and sender fit

(which can be done with adapters if necessary. These senders have all sorts

of shapes..most often like a mushroom. Some will have two posts for

wires (a ground/earth feed and a wire to the gauge) or one post (only a

wire to the gauge as it assumbed the sender is grounded/earthed by the

contact of the threads with the oil pump).