and

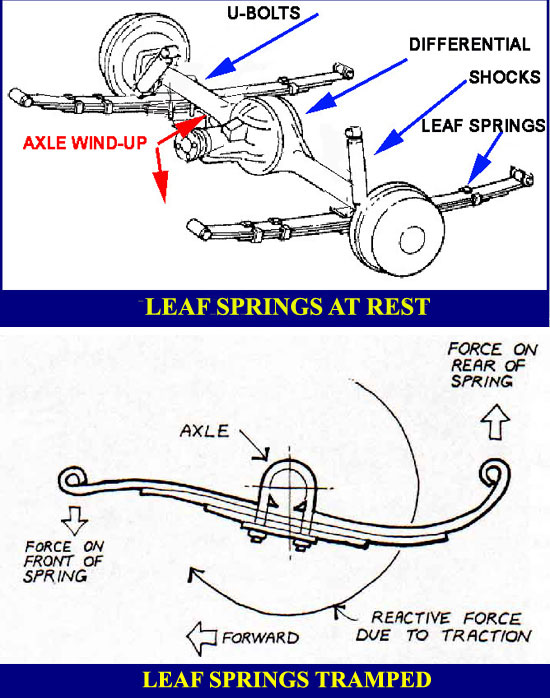

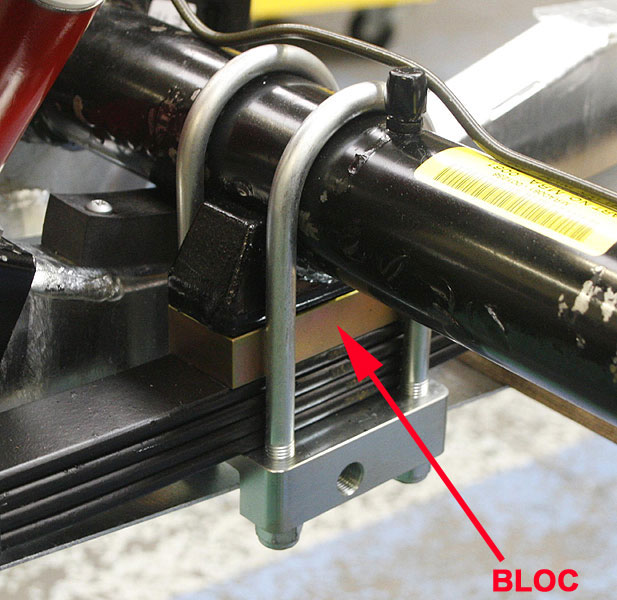

physics show that the use of such blocks encourage axle wind-up

and the need for panhard rods to stop the springs from moving sideways

as the blocks also create a smaller flat surface and encourage twisting

from side to side.

and

physics show that the use of such blocks encourage axle wind-up

and the need for panhard rods to stop the springs from moving sideways

as the blocks also create a smaller flat surface and encourage twisting

from side to side. In the distant past, GM, Ford and Chrysler and other manufacturers tried blocks on the rear of some of their trucks. Pay close attention to the next one you see traveling down the road. I have recently. (Older model trucks are easier to find in South America! :D) Follow one for a while and you will notice how the axle attempts to twist. This twisting happens on all vehicles as they accelerate and brake. However, the twisting is much more severe on lowering block-equipped vehicles.

The MMC used them to adjust trad ride height during their "hard times" (2000-2019). Through much of that period, Management focussed their best efforts on non-trad models. They apparently did not want to spend to match suspensions to their many different models during the period. Additionally, they were beset with inconsistent leaf springs quality, with leaves sagging to the unusable point in as little as 2 months. (I went through 4 sets in 3 years!)

For these reasons (and one more if you read a bit farther!), the use of blocks to change the ride height of any vehicle is NOT recommended.These blocks are no longer used by these or any other manufacturer I am aware of. They were an attempt to save money rather than fitting different springs to vehicles used for carrying different loads rather than fitting springs that suited the vehicle, the desired ride height and the load it is to be used for.

Most unfortunately, blocks also lead to unacceptable shortcuts in a vehicle as light and sensitive as a Morgan. Morgans are SO basic that any component or lack of maintenance that is not perfectly suited to it quickly manifests itself.

The saddest example of this in the Morgan world, outside the racing community where such usage is often acceptable, is the Morgan 4/4 Sport.This is/was aesthetically lovely entry level model, introduced a few years ago with a strictly limited option

range..with set colors and interior. It was stripped of bumpers,

overriders, spare tyre, etc and achieves a low weight reminiscent of

earlier eras, from 17% to 20% lighter than the other Classics, being

Plus 4 or the Roadster, with most of the weight saving at the rear.

The saddest example of this in the Morgan world, outside the racing community where such usage is often acceptable, is the Morgan 4/4 Sport.This is/was aesthetically lovely entry level model, introduced a few years ago with a strictly limited option

range..with set colors and interior. It was stripped of bumpers,

overriders, spare tyre, etc and achieves a low weight reminiscent of

earlier eras, from 17% to 20% lighter than the other Classics, being

Plus 4 or the Roadster, with most of the weight saving at the rear. | WATCHPOINT: These blocks should not be confused with the centering blocks sold by Mulfab. Their purpose is to merely to center the rear wheels in their wheel wells for aesthetic reasons adopted by the Morgan company a few years ago. In the newer Morgan design, the wheels were centered by shifting the axle centering bolt rearward. The Centering block design has a negligible effect on either comfort or comportment. The lowering blocks at issue have an entirely different effect, as described here. |

| GoMoG Law of Replacement: Why Replace An Original Component That Has Proven Itself to Fail, Over and Over Again? The long list of such decisions, since the beginning of the Steve Morris era, has incrementally degraded the traditional Morgan to the point where its demise was sadly necessary. Prior to his regime, a new Morgan could be relied on to be trouble free for years and warranty claims were ALWAYS generously dealt with. I like Steve and wish him well. But production shortcuts, cheaper components and ridding the work force of expertise is not a recipe for long term profits no matter what they are making on Pickersleigh Road this week. Additionally, constant draconian untested changes, effectively Peter Principles the entire workforce and suppliers. |

| THERE IS SOME REALITY TO THIS SAGGING. The Factory has had sad experiences (and passed this on to buyers) finding reliable leaf springs since some point after 2002. As noted, my "old" supplier 2002 leaf springs (5 leafs) have lasted 18 years with negligible sagging (1 cm) (and great flexibility) just like those on my first Morgan. Yet just 2 years later, I went through 3 sets of new MMC-sourced 5 leafs in less than 18 months (under 5,000 miles) on the Morgan (also a Plus 8) we kept in the UK. This sagging only stopped when I switched to the newer 4 leafs from Peter Mulberry (the same as those used by the MMC after they stopped sourcing from their decades old orginal leaf spring maker. I heard that this supplier and others were also cancelled by Morgan after repeated sagging. THE FIX IS BETTER QUALITY LEAF SPRINGS..NOT SCOTCH TAPE SOLUTIONS. Focus on causes not symptoms. |

The ends of the leaves move about an inch with each press. Each leaf is re-arched separately. The technician avoids putting too much pressure at one point and breaking a leaf. At the end, each leaf will have the same arch. They will then be re-assembled in their original position and orientation with new center bolts and tie clamps. The cost is not terrible..about $200 for a pair. However, it only restores ride height for a short period as the leafs will "remember" their sag stat and return to it.

A pattern is used to re-shape the hot spring leaf to its correct arch. It is then quenched in special oil to cool it rapidly. It is now shaped correctly, but the heating and quick-cooling process creates hardness and brittleness that has to be removed. The leaf is re-heated to at least 950 degrees for a set time to draw out some of the hardness. It is cooled slowly and then shot-peened to relieve stress. Few companies have the equipment and know how required to heat-treat a spring. This makes the process much more costly than cold setting. A pair of leaf springs was recently re-arched by the cold setting process at a cost of $100. It would cost a minimum of $450 to have the same job done by the heat-treating method! (ugh)

The best solution would be to have a set of new springs, designed for YOUR trad and not another different model with different weight and weight disribution. However, this is not something we can look to the Factory for any longer. They have not been able to resolve these issues for almost two decades and there is less chance of this now than at any time since Morgans began. It is a given in the trucking industry that leaf springs will last an average of 100,000 miles (160,000 kms). This has also been the experience with properly maintained Morgans prior to the last 18 years.

| WATCHPOINT: I maintain my leaf springs with a spray of a silicone penetrating oil and by keeping the car on stands when it is not being used for more than a few days. The stands prevent the tyres from being boxed (becoming mis-shaped from too long in the same position with the car's weight on them) and also takes all pressure and wear off the suspension. Yes, suspensions deteriorate faster on the gorund without usage than they do when being used! |

| I hope I have not insulted or discouraged anyone. I have a great admiration for amateur Morgan fiddlers/gadgeteers. They have provided to only advances in trad technology in the last two decades, and now that Morgan Classic models have been cancelled, these are the people we need and that the old collegiate format used to provide. However, I no longer know of a Morgan forum that fills this need and that should be rectified, |