Morgan Gauge Restoration

by Alan Truax

One of the new

challenges my 1954 Plus 4 transition Morgan rebuild presented was the

restoration of the dash and instruments. The 4-1 cluster gauge was

in particularly bad condition. This, I think, was caused by the

release of the mechanical temperature gauge fluids. The paint on the

gauge faces were mostly gone and the temperature gauge itself was

missing. I replaced the missing gauge with an electrical temp gauge. What

little paint remained was loose and crumbling. There was no

possibility of restoration by just touching up the instruments

face. The gauges would need a total refinish.

One of the new

challenges my 1954 Plus 4 transition Morgan rebuild presented was the

restoration of the dash and instruments. The 4-1 cluster gauge was

in particularly bad condition. This, I think, was caused by the

release of the mechanical temperature gauge fluids. The paint on the

gauge faces were mostly gone and the temperature gauge itself was

missing. I replaced the missing gauge with an electrical temp gauge. What

little paint remained was loose and crumbling. There was no

possibility of restoration by just touching up the instruments

face. The gauges would need a total refinish.

There are two

methods I considered for the restoration, Decals and Silk Screening.

Decals seemed to be the easiest method so I opted to try that method

first. I do plan to further explore silk screening for future

projects because that method should be more durable.

1. Documenting the graphics

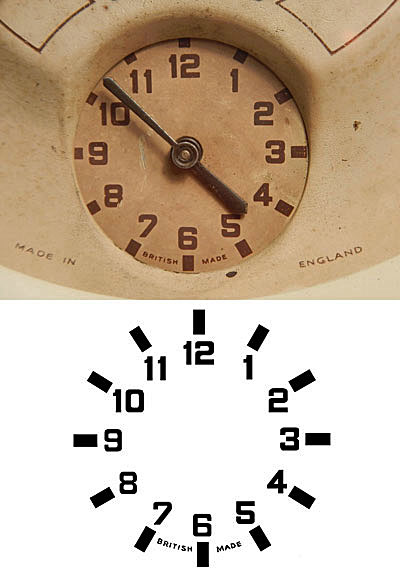

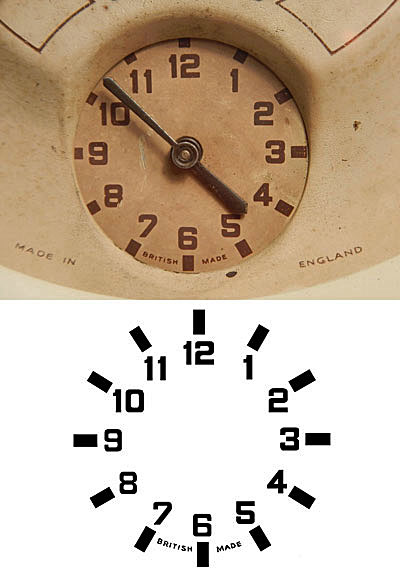

The first step

is to photograph the gauges. I took several photos of each of the

four gauges and the frame. I needed these photos to first

document the location and orientation of the graphics and second, to

provide the base photos for photo-shopping the artwork to print the

decals. Next, I measured and recorded the dimensions of the

existing graphics so that I could later exactly size the decals.

It is important to have the camera directly over the gauge and

perpendicular to it so that the image isn't distorted.

2. Refinishing the background color

When I was

satisfied that I had a good record of the old graphics, I was ready to

proceed with the stripping and refinishing of the gauge faces.

The faces of each of the four gauges were removed from the bodies and

the insides were carefully cleaned and tested. The finish on all

the gauge face plates washed off easily with acetone. I found

that all gauges were polished brass except the Amp gauge which was

aluminum. The Fuel and Temp Gauges have stop pins that need to be

removed in order to apply the decals. This was carefully done to

preserve the pins for re-installation after the decals are applied and

to not distort the plates. (I later decided that punching a hole in the

decal was a better option.)

The surfaces to

be refinished were then either scuffed with 220 wet and dry paper or

bead blasted to provide a substrate that the new finish will adhere

to. I used a beige lacquer that looked to me to be a good

match of the Morgan gauge color. The script "Morgan" in the center is

printed in white. I do not have the capability to print white on

the decal so I needed to paint the center of the gauge beneath the

Morgan script white and make a decal with a transparent "Morgan"

graphic.

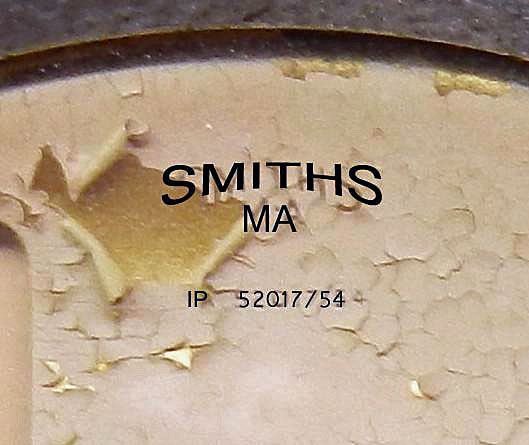

3. Producing the graphics

I used

Adobe Photoshop to modify the base photos to produce a decal

graphic. First I cropped the photo to just the area of the decal

and next photoshopped the following steps;

Step 1 - convert the photo to black & white

Step 2 - increase contrast

Step 3 - adjust threshold levels to decrease and eliminate unnecessary gray tones

At this point the photo is mostly pure black and pure white but still has many areas that need work.

Step 4 - fill in areas of paint loss and missing graphics

Step 5 - improve edge definition and correct any remaining flaws

Step 6 - convert back to color and fill with appropriate colors

That may sound simple, but hours of work were required to get the graphics up to a good standard. Some

of the instrument faces had text graphics that were mostly

missing. For these I used Photoshop's text insertion methods

choosing a font that matched the damaged text. I did this by

simply using the base photo as a reference background and creating a

new Photoshop text graphic over it.

4. Scaling the graphics

Once the

graphics were deemed good enough to use, they were printed on plain

paper at a known size to compare to the recorded sizes required of the

decal. For  example, I might have printed the Fuel

Gauge graphic out at a 2" width and found that the measurement across

the outside edges of the O and the F was 1.3 inches and the actual

measurement of the gauge that I recorded before stripping the finish

was 0.95 inches, I would need to correct the print size to (.095/1.3)X

2".

example, I might have printed the Fuel

Gauge graphic out at a 2" width and found that the measurement across

the outside edges of the O and the F was 1.3 inches and the actual

measurement of the gauge that I recorded before stripping the finish

was 0.95 inches, I would need to correct the print size to (.095/1.3)X

2".

5. Printing the decals

I printed

sample decals using the corrected size to verify the scaling and

color. The actual color of the decal on the decal stock will

differ slightly from that printed on paper and some did require color

correction. My printer is an inkjet type and the inks used will

run when exposed to water. The solution is to coat the decals

with lacquer to seal the inks. I used two coats of a satin

lacquer to seal the ink before cutting them out to size. If you

cut to size and then lacquer, you will have difficulties in sliding

them off the paper backing. It is important that you keep the

decal stock clean and do not touch the film surface. Your

fingerprints on the film will affect the uniformity of the printed

colors.

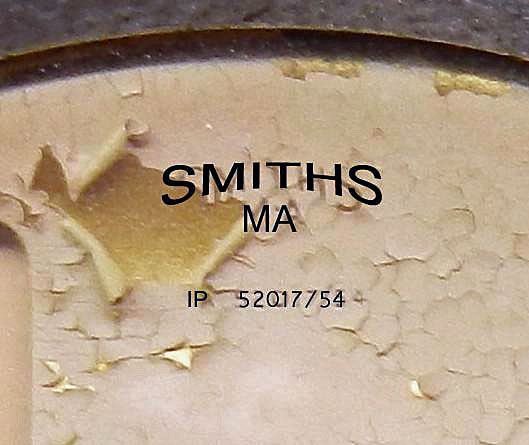

6. Trimming the decals

The four

gauges are framed by the large round plate with the Morgan insignia in

the center. I made a template in the shape of the frames that was

slightly larger than the gauge frame and used that to outline where I

trimmed the decal to get proper positioning while having the plastic

film of the decal filling the full frame. The purpose is to hide

the edge of the decal film from view when positioned properly.

The "Smiths" , "Made in England", and "Morgan/AMPS/OIL/WATER/FUEL" for

the frame were trimmed slightly beyond the graphics and trimmed with

rounded edges avoiding sharp corners.

7. Applying the decals

The

decals have a water soluble adhesive factory applied. The decals are

released from their paper backing by soaking in room temperature

water. If the decals are left in the water too long, the adhesive

will be lost. About 20 to 30 seconds is usually enough time

loosen the decals from their paper backing and be ready to slide them

on the gauge plates. Keep the gauges, water and decals clean

because it would be all but impossible to remove any dirt under the

decal. Slide the decal off onto the gauge plate and position it

properly by referring to your record photos. Once the decal is in

position, gently but thoroughly force out all the water and air bubbles

using a wadded paper towel. Set aside until completely dry.

The

decals have a water soluble adhesive factory applied. The decals are

released from their paper backing by soaking in room temperature

water. If the decals are left in the water too long, the adhesive

will be lost. About 20 to 30 seconds is usually enough time

loosen the decals from their paper backing and be ready to slide them

on the gauge plates. Keep the gauges, water and decals clean

because it would be all but impossible to remove any dirt under the

decal. Slide the decal off onto the gauge plate and position it

properly by referring to your record photos. Once the decal is in

position, gently but thoroughly force out all the water and air bubbles

using a wadded paper towel. Set aside until completely dry.

Restored 4-1 Gauge

8. Materials used:

Krylon MAXX Almond Satin spray paint

Deft Clear Wood Finish Satin Lacquer

Rust-Oleum Automotive Enamel Gloss White

World of Paper Inkjet/Clear Waterslide decal paper

9. ADDITIONAL WATCHPOINTS:

The main face surrounding the individual 4 gauges is keyed and you must maintain the orientation.

If you opt for a

white script "Morgan", I suggest that you first prime the main face

with a white lacquer primer and then mask off the area under the

"Morgan" before applying the beige lacquer. After the

lacquer is completely dry, use an abrasive pad, the type that is

used between coats of finish, to lightly smooth the transition between

the white and beige areas.

Removing the stop pins may not be necessary.

I did not use

any additional coating after applying the decals. To Improve the

durability of the restored gauges, you want to apply an additional

coating of lacquer after applying the decals. It would be prudent

to test on a sample first to be certain of material compatibility after

allowing the finishes to cure a week or two. I found that the lacquer I

used for sealing the decals was compatible with the beige lacquer only

after two weeks. Testing indicated that applying a sealing coat of that

lacquer too soon would cause the finish to lift.

One of the new

challenges my 1954 Plus 4 transition Morgan rebuild presented was the

restoration of the dash and instruments. The 4-1 cluster gauge was

in particularly bad condition. This, I think, was caused by the

release of the mechanical temperature gauge fluids. The paint on the

gauge faces were mostly gone and the temperature gauge itself was

missing. I replaced the missing gauge with an electrical temp gauge.

One of the new

challenges my 1954 Plus 4 transition Morgan rebuild presented was the

restoration of the dash and instruments. The 4-1 cluster gauge was

in particularly bad condition. This, I think, was caused by the

release of the mechanical temperature gauge fluids. The paint on the

gauge faces were mostly gone and the temperature gauge itself was

missing. I replaced the missing gauge with an electrical temp gauge.

example, I might have printed the Fuel

Gauge graphic out at a 2" width and found that the measurement across

the outside edges of the O and the F was 1.3 inches and the actual

measurement of the gauge that I recorded before stripping the finish

was 0.95 inches, I would need to correct the print size to (.095/1.3)X

2".

example, I might have printed the Fuel

Gauge graphic out at a 2" width and found that the measurement across

the outside edges of the O and the F was 1.3 inches and the actual

measurement of the gauge that I recorded before stripping the finish

was 0.95 inches, I would need to correct the print size to (.095/1.3)X

2".