#Pilot

REASONS FOR MORGAN CLASSIC DRIVETRAIN VIBRATION

This list of issues is not comprehensive.

I will keep adding to it as issues or contributions allow. However, it is a good start on the process that will end

your Morgan drivetrain vibration. Go to the diagnosis and checklist

section first. If the issue is in the front end..check out the FRONT END SECTION 12. And there is more remedial material within the Manual on each item mentioned here.

1. Motor

Accesories – Disconnect the belts of all motor accessories and run

motor. Many vibrations come from fans,

water pumps, etc. out of balance.

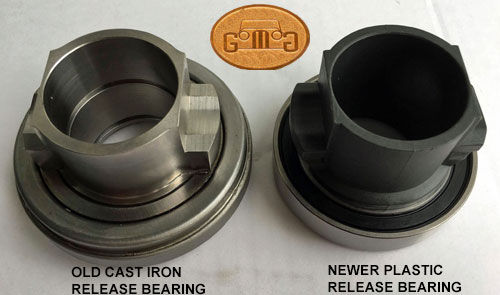

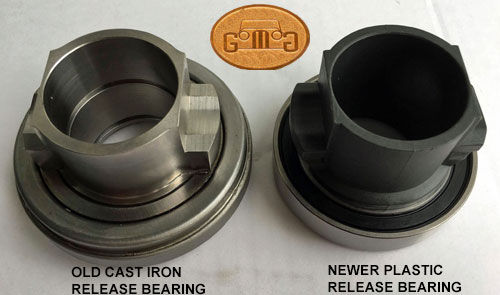

2. Clutch Throwout

or Release Bearing - When you install the (new) throwout bearing, remember that the

fork AND the springs go INSIDE THE GROOVE in the bearing - I see them installed

wrong all the time, with the curled ends of the spring capturing the flange on

the back end of the bearing - result is inability to get correct clutch

adjustment/free play.

2. Clutch Throwout

or Release Bearing - When you install the (new) throwout bearing, remember that the

fork AND the springs go INSIDE THE GROOVE in the bearing - I see them installed

wrong all the time, with the curled ends of the spring capturing the flange on

the back end of the bearing - result is inability to get correct clutch

adjustment/free play.

Install the flywheel (always have it resurfaced before this procedure), clutch

disc, pressure plate and clutch housing on the engine. Be advised that there

can be NO oil or grease on your hands, the flywheel or pressure plate friction

surfaces, or on the clutch disc. If there is, the clutch will grab (chatter)

when being engaged. Install the correct length clutch

fork on a 1½" long pivot that has the correct head type for the retainer

on the fork (refer to fork and pivot information previously discussed).

Position the fork so it sticks out of the clutch housing at about 4 or 5

degrees less than a right angle with the engine centerline (this would be when

looking down on the engine from above—the fork should be ahead of, or less than

a 90 degree angle by 4 or 5 degrees).

Install the transmission on the clutch

housing. The release bearing must be able to move away from the diaphragm

spring approximately 1/16 to 1/8" (this is the "free play"). At

this point you should be able to move the release bearing back and forward with

the fork. The bearing, when against the clutch, should leave the release fork

positioned at 4 or 5 degrees LESS than a right angle with the engine centerline

and allow it to be moved away from the clutch 1/16 to 1/8". If this

condition does not exists, do not install the assembly into the car until it

does. If not, you may need a different clutch release bearing or pivot or you

may have the wrong fork.

3. Motor

Mounts -

Morgan motor mounts are a wear part. The rubber interface dries,

cracks, deteriorates over time and must be replaced. Additionally,

bolts to other parts in the mount assembly, or to the frame or motor

will loosen and fall out.

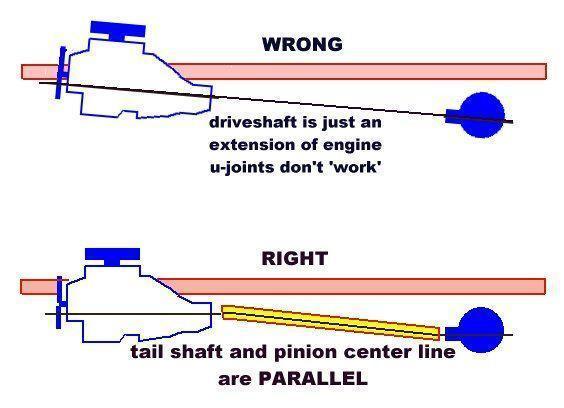

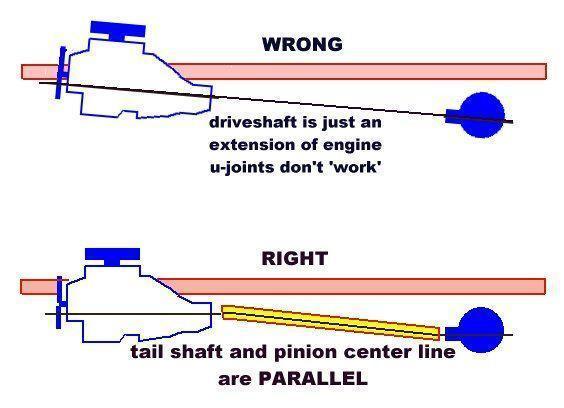

4. The Pinion

Angle

- This is tthe angle the pointy input shaft to the transmission makes

with its contact with the engine drive shaft. As a general rule, the

pinion angle shouldn't be set relative to the

ground, or exact level, but rather to the output shaft of the

transmission. The important thing is that the

two center lines are parallel.,

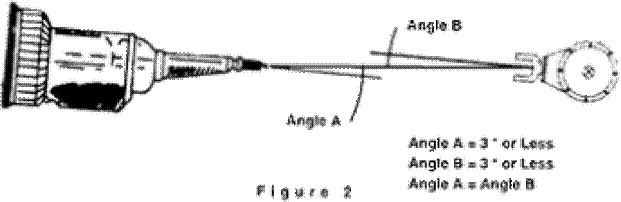

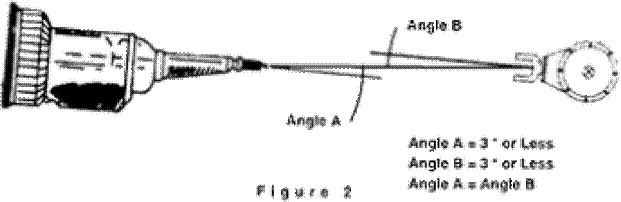

5. The Drive Shaft U-Joints

While it is possible to run at zero

degrees through the U-joints, something more than actual zero and less than

three degrees seems to run smoothest. Angle induced vibration will be

high frequency, twice engine RPM in direct drive. It may show up only on

acceleration or deceleration. Adjust the pinion down to correct acceleration

and up to correct deceleration vibrations, plus or minus one degree is usually

enough. Before adjusting anything, make sure the U-bolts holding the driveshaft

to the pinion yoke are not overtightened. Correct torque is 17 foot pounds and

no more.

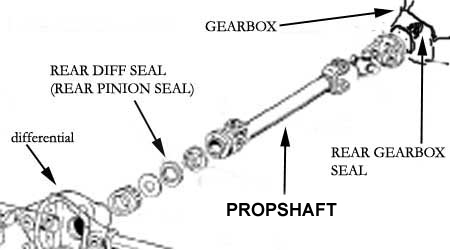

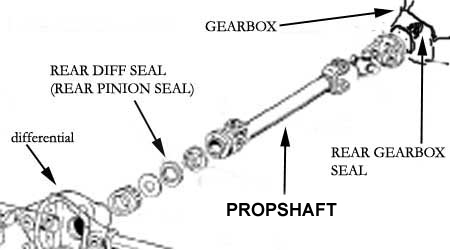

6. Driveshaft (Prop Shaft) Phasing

Everything in

the drive train must operate in "phase" in order to minimize vibration,

noise and component wear. This sounds complex but it isn't as the

universal joints of the prop shaft take care of most of the task.

1.Check your U-joints for proper alignment. The rotational

speed of a universal joint varies or cycles as it turns through 360 degrees.

Since universal joints are almost always installed in pairs, they are normally

"phased" so this difference is eliminated. being canceled out by the two

joints. (As one joint speeds the rotation up, the other slows it down so

the rotational speed of the output is fairly constant.) Many propshaft

come apart for easy assembly, usually a splined shaft is used to transmit

power from one piece to the next. If the splined parts are connected without

insuring that the U-joints are in phase, a tremendous vibration can result

at speed.

To check your U-joints, jack up your car and support it

on jack stands. (Never crawl under a car supported only by a jack.) A visual

check will tell you if your U-joints are lined

up correctly. Simply compare each end of the driveshaft to see if the yokes

on each end (the parts welded to the driveshaft tube itself) lie in the

same plane. (In a Morgan you may have to open the gear box cover access

panel). If they do not line up, or are at right angles to each other, it

is usually a simple matter to unbolt the propshaft and re-orient the splines

of the two pieces to bring the universal joints into proper phasing.

To check your U-joints, jack up your car and support it

on jack stands. (Never crawl under a car supported only by a jack.) A visual

check will tell you if your U-joints are lined

up correctly. Simply compare each end of the driveshaft to see if the yokes

on each end (the parts welded to the driveshaft tube itself) lie in the

same plane. (In a Morgan you may have to open the gear box cover access

panel). If they do not line up, or are at right angles to each other, it

is usually a simple matter to unbolt the propshaft and re-orient the splines

of the two pieces to bring the universal joints into proper phasing.

2. The major components at each end of the propshaft must be parallel to each other Think

about a complete automotive drivetrain from the side -this includes

engine, transmission, driveshaft and rear axle assembly. Part of the

"phasing" procedure includes making sure that the center lines of the

transmission and the rear axle input shaft are parallel. If the axis of

the pinion gear is parallel with the ground, then tail shaft of the

transmission must also be parallel to the ground. They can be

higher or lower than the other but they MUST be parallel to the ground.

And when these two components havedifferent centerlines to the any reference point (i.e. the ground) vibration must result!!! . Everything in the drive train must operate in "phase" in order to minimize vibration, noise and component wear.

Think about a

complete automotive drive train from the side -this includes engine,

transmission, driveshaft and rear axle assembly. Part of the "phasing"

procedure includes making sure that the center lines of the

transmission and the rear axle drive shaft are parallel. If the axis of

the pinion gear is parallel with the ground, then tail shaft of the

transmission must also be parallel to the ground. It can be higher or

lower but it MUST be parallel.

7. Driveshaft (Prop Shaft) Balance

If your shaft is not balanced with the actual

end yoke and U-joints, you have not fixed the potential vibration problems. A

driveshaft will not run  smooth and vibration-free unless it is straight and in

balance. The

smooth and vibration-free unless it is straight and in

balance. The  recommendation is to have shaft

dynamically high speed balanced at 10,000 rpm by a driveshaft professional. Typically, if the shaft is out of balance it will start to vibrate (and

make a droning sound) somewhere around 50-60 mph and then get worse as speed

increases to a point, and then get somewhat better at even higher speed...much like the vibration effect with a problematic Morgan front end.

recommendation is to have shaft

dynamically high speed balanced at 10,000 rpm by a driveshaft professional. Typically, if the shaft is out of balance it will start to vibrate (and

make a droning sound) somewhere around 50-60 mph and then get worse as speed

increases to a point, and then get somewhat better at even higher speed...much like the vibration effect with a problematic Morgan front end.

If making a new driveshaft correctly, measuring is done by putting the yoke in until it bottoms out and pull it back

3/4 of an inch. Measure the length of the U Joint centerlines and have a shaft

made with that length. If the yoke is too short to accomodate this correctly

you will have a stange vibration so check your drive shaft for proper

fit. Put the car on a drive on rack or on jack stands. With the car's weight on

the suspension as you would drive it, disconnect the shaft from the pinion

yoke. Push the drive shaft forward until it bottoms into the transmission. You

should be able to drop the rear u-joint cleanly past the pinion yoke without

resorting to a tool of any kind. Any clearance up to 3/8 inch is fine.

8. An Engine Anomally

Lean misfire or bad/fouled plug. A

very common cause of vibrations is a misfiring cylinder. A cracked spark plug insulator, smashed gap

or broken ground strap, are some of the causes. If you suspect a misfiring

cylinder, the best was to isolate it is to pull each spark plug wire one by

one, at idle, and note if/when there is a resulting rpm drop. Ten browse the GoMoG Manual for help.

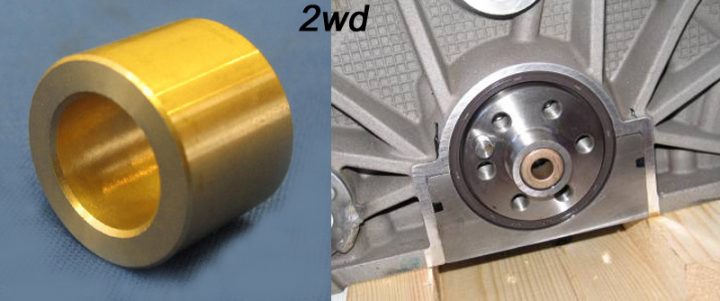

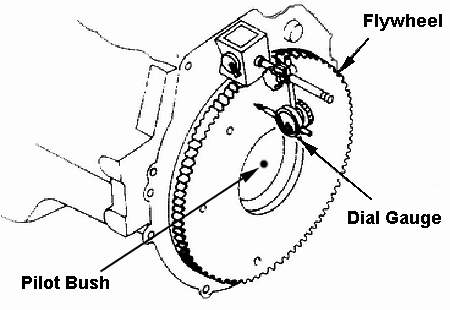

9. Pilot (or Spigot) Bush

- Clutch pilot bearing or bushings: Pilot bearings or bushings began as bronze bushings placed at the end of the crankshaft

or in the center of the flywheel to support the

outboard end of the transmission input shaft. With Morgans, this

continued well into the 2000s. However, for most cars since the

1970s, pilot bearings are the ball bearing type

|

The

pilot

bushing is seldom thought of as a part of the clutch system but it is

one of

the most vital parts of the system. It holds and pilots the end of the

transmission input

gear into the crankshaft. It holds the input gear steady as its "nose"

twirls inside the bushing. If it is worn or not running "true", it

can

cause serious clutch problems or transmission failure. Pilot bushing

bore

runout should always be checked with a dial  indicator and should be within .002

total. The bronze bushing type should be a press fit into the crankshaft bore. It

must be installed carefully. It should have between .001 and .003 clearance on

the transmission shaft when installed.

indicator and should be within .002

total. The bronze bushing type should be a press fit into the crankshaft bore. It

must be installed carefully. It should have between .001 and .003 clearance on

the transmission shaft when installed.

So the

job of the pilot bushing is to support the end of the input (main

drive) gear in the crankshaft. It only acts as a bushing when the

clutch is

depressed. This pilot bushing should be a light drive fit into the

crank bore.

Care should be taken when installing any pilot bushing as they are soft

and

easily damaged. A damaged pilot bushing can

bind on the input gear giving symptoms of clutch drag. Transmission

damage and early failure can be caused by a pilot bushing or crankshaft bore that

"runs out" in relation to the transmission locating bore in the

bellhousing. A slight scratch on the bushing will

cause a mild noise when the clutch is not enaged. This is annoying but

not harmful. Plus 8s are infamous for this.

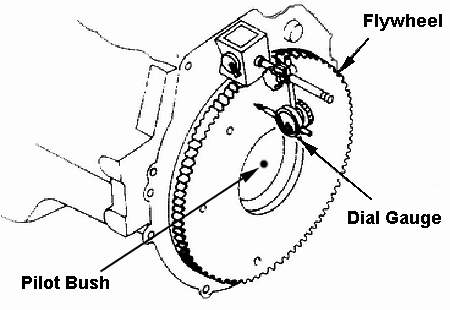

It is advisable to check the bore

of the crank with a dial indicator before installing the pilot bushing (see

below). If the bore runs out more than .003 total, the crank should be set up

in a lathe and the bore trued up OR a special pilot bushing should be made that

runs out the same amount as the crank bore.

To check alignment, use a dial

indicator with the base mounted to the crank flange to check the transmission

pilot hole for concentricity to the crankshaft center line with +/- .010”. Check the face of the bellhousing (where the

transmission bolts up) for squareness to the back of the block. Variance should be no more than +/- .010”

side-to-side and top to bottom. Also check the

fit of the transmission to the bellhousing

and the fit of the pilot bushing to the

transmission input shaft.

| WATCHPOINT: There are sad rumors that these bushes are

very difficult to remove. Ignore them. Simply fill the hole with grease and use a

clutch alignment tool end or similar OD bolt, tap it into the hole and the grease

will force the bush out. When it works, you owe me a pint! |

9. Flywheel Runout

Check the face of the flywheel for runout

with a dial indicator. Runout should not exceed .005". If it does, the

flywheel should be resurfaced. If runout exists after resurfacing, the fault is

either in the resurfacing job or there are burrs, dirt, or dings on the

crankshaft or flywheel hub. Remember there is end play in the crankshaft

bearings and this must be held in one direction when checking flywheel runout

(or bellhousing face runout).

To check a

bellhousing, mount it on the engine it's going to be used with, make sure there

are no burrs or dirt on the block or bellhousing. All bellhousing to block

bolts should be in and tight. Mount the dial indicator on the crankshaft of the

engine using a suitable magnetic base attachment or mechanical clamping means.

The contact point of the indicator should be touching the bore of the

bellhousing. The indicator must be mounted rigidly enough so it does not move

on its mounting to prevent false readings. Rotate the engine by hand with the

spark plugs removed and observe the reading on the dial. The total number of

thousandths misalignment of the bore relative to the crankshaft is read

directly on the dial. Total runout should not exceed .007", with

.010" being maximum. The greater the misalignment, the sooner transmission

problems and failure will occur. A symptom of misalignment is unusual wear of

the pilot bushing. We have checked stock Chevy bellhousings on engines that

were out more than 1/32" (.032"). Some Ford one are reportedly worse.

Anything over .010" runout must be corrected before the engine and

bellhousing are put in service or you can count on pilot bushing, transmission,

and clutch problems, followed by transmission failure. The simplest way to

correct misalignment is to try another bellhousing or bellhousings. Machining

the bellhousing is the best cure but offset dowel pins are simpler. Shims

between the block and bellhousing will also work if you have the patience to

use this method. Offset dowel pins are sometimes available from "speed

shops."

Vehicle Drive Train Vibration Diagnosis Checklist

|

PART

|

POSSIBLE PROBLEM

|

| BODY |

|

|

|

Body

|

Loose

Body Mounts

|

|

|

Body

|

Rusted

Body Mounts/Brackets

|

|

|

BRAKES

|

|

|

|

Brakes

|

Calipers

|

Loose

Caliper Bolts

|

| CLUTCH |

|

|

|

Clutch

|

Pilot

Bushing

|

Loose,

Worn

|

|

Clutch

|

Flywheel

|

Out of

Balance

|

|

Clutch

|

Flywheel

|

Out of

Balance, Surfaced too much, Loose, No Dowel Pin

|

|

Clutch

|

Clutch

Pressure Plate

|

Plate Off

Center, Out of Balance, Bent Housing

|

|

Clutch

|

Clutch

Disk

|

Out of

Round, Dropped, Out of Balance

|

|

Clutch

|

Bellhousings

|

Cracked

or Hole not Concentric to Crankshaft

|

|

ENGINE

|

|

|

|

Engine

|

Water

Pump Shaft

|

Bent,Loose Bearing

|

|

Engine

|

Fan

Clutch

|

Loose,

Bad

|

|

Engine

|

Fan Blade

|

Bent, Out

of Balance

|

|

Engine

|

Balancer

|

Loose,

Spun on Rubber, Bad Keys

|

|

Engine

|

Motor

Mounts

|

Cracked

|

|

Engine

|

Tune-up

|

Misfiring

|

| Engine |

Engine timing off |

|

| Engine |

Carb |

Misfiring |

| Engine |

Crankshaft Rear Flange |

Bent loose flytwheel bolts, worn dowel pin |

| FRAME |

|

|

|

Frame

|

Cracked

Bent or Rusted Frame or Crossmembers

|

|

|

Frame

|

Cracked Front Frame Extensions

|

|

|

Frame

|

Loose Bumper Brackets,

Impact Bars

|

|

| REAR AXLE |

|

|

Rear Axle

|

Flanges

|

ent

Flange or Loose Bolts

|

|

Rear Axle

|

Flanges,

Half Shafts

|

Wrong

Combination, Wrong Alignment

|

|

Rear Axle

|

Half

Shafts

|

Bent, Out

of Balance, Loose UJoint Holes

|

|

Rear Axle

|

U-Joints

|

Not

Seated Properly, Off Center, Wrong Caps, Clips Missing

|

|

Rear Axle

|

Axle

Yokes

|

Bent, Not

Seated U-Joints, Not Machined Correctly, Loose Bolts

|

|

Rear Axle

|

Pinion

Flange

|

Bent,

Machined Wrong, Loose Bolts

|

|

Rear Axle

|

Pinion

Snubber Bushings

|

Loose or

Worn Out Cushions or Loose Bolt

|

|

Rear Axle

|

Pinion

Snubber Bracket

|

Slotted

Bracket Holes or Loose Bolts

|

| STEERING |

|

|

Steering

|

Wheel

Bearings

|

Loose or

Bad Bearings

|

|

Steering

|

Steering

Gearbox or Rack

|

Loose

Internally or Loose from Frame

|

|

Steering

|

Steering

Column

|

Loose,

Bent

|

| Steering |

Column Bush compromised |

Replace |

| Steering |

Column Adjuster untightened |

|

|

Steering

|

Tie Rod

Ends

|

Loose

|

| SUSPENSION |

|

|

|

Suspension

|

Front

Stub Axles

|

Bent

Spindles, Loose Bolts

|

|

Suspension

|

Anywhere |

Loose or Missing Bushings

|

|

Suspension

|

Ball

Joints

|

Loose,

Not Lubricated, Need Replacement

|

|

Suspension

|

Shocks

|

Worn, Loose, Fit too tight, Leaking, Bolt

or Grommets

Missing

|

| TRANSMISSION |

|

|

|

Transmission

|

Trans

Input Shaft

|

Bent

|

|

Transmission

|

Trans

Output Shaft

|

Bent

|

|

Transmission

|

Trans

Tailhousing Bushing

|

Worn

|

|

Transmission

|

Trans

Mounts

|

Cracked or rubber worn/missing

|

|

Transmission

|

Driveshaft

|

Bent, Out

of Balance, Balance off or Weight Missing

|

|

Wheels/Tires

|

Wheels

|

Bent,

Loose Lug Nuts, Wheel Adapters

|

|

Wheels/Tires

|

Tires

|

Bad, Out

of Round, Out of Balance, Broken Cords

|

| TESTING & DIAGNOSIS |

|

|

|

Test

Drive

|

Check at

what speed vibration comes in

|

|

|

Test

Drive

|

Check whether it is MPH of RPM related

|

|

|

Test

Drive

|

Check

whether it goes away with clutch disengaged

|

|

|

Test

Drive

|

Get up to speed where vibration is the greatest,

Then:

|

|

| DIAGNOSIS |

|

|

|

Diagnosis

|

Disengage Clutch, Does Vibration Go Away?

|

|

|

Diagnosis

|

With Clutch Disengaged, Rev Motor Up & Down

|

|

|

Diagnosis

|

Does the Vibration Relate to Engine or Road Speed

|

|

|

Diagnosis

|

With Car Sitting Still, Rev Up Engine to Check for

Vibration

|

|

|

Diagnosis

|

Short Out Cylinders one at a time

|

|

|

Diagnosis

|

Disconnect All Belts to Eliminate Front Engine

Accessories

|

|

|

Diagnosis

|

Install a Different Set of Wheels and Tires to

Eliminate Them as a cause

|

|

|

Diagnosis

|

Run the Vehicle on the Hoist with Jack Stands at Rear to

Load Suspension properly

|

|

|

Diagnosis

|

Spin

Balance Wheels on Vehicle

|

|

|

Diagnosis

|

Hoist Testing will Eliminate Front Suspension, Steering, and

Road Vibration

|

|

|

Diagnosis

|

Using a Stethoscope or

Wooden Dowel on Components will Amplify Noises and Vibrations

|

|

| NOTES |

|

Notes:

|

Clutch & Flywheel Problems Tend to Be Felt at

around 1800 and 3600 RPM

|

|

|

Notes:

|

Tire Balance Problems Tend to Get Worse With

Speed

|

|

|

Notes:

|

Front End Problems Can Come and Go With Different Speeds.

|

|

|

Notes:

|

Front End Problems Tend to be Felt in the Steering

Column

|

|

|

Notes:

|

Clutch, Flywheel, and Trans Problems Tend to be Felt

in the Shifter

|

|

|

Notes:

|

Rear End Problems Tend to be Felt in the Seat

Bottom

|

|

|

Notes:

|

Body, Frame and Bumper Problems Tend to be Felt in

Body Vibrations

|

|

|

Notes:

|

Vibrations Tend to Come

From Items With Great Mass at a Great Distance from Centerline

|

|

|

Example:

|

You Can Get a Vibration

from a Tire, But You Wouldn't Get One From a Spindle Nut

|

|

2. Clutch Throwout

or Release Bearing - When you install the (new) throwout bearing, remember that the

fork AND the springs go INSIDE THE GROOVE in the bearing - I see them installed

wrong all the time, with the curled ends of the spring capturing the flange on

the back end of the bearing - result is inability to get correct clutch

adjustment/free play.

2. Clutch Throwout

or Release Bearing - When you install the (new) throwout bearing, remember that the

fork AND the springs go INSIDE THE GROOVE in the bearing - I see them installed

wrong all the time, with the curled ends of the spring capturing the flange on

the back end of the bearing - result is inability to get correct clutch

adjustment/free play.