BATTERY CUT OFF SWITCH

by George Dow and Lorne Goldman

The Factory has been installing battery cut-off or "Isolator"

switches for some time...either as an option or standard fare. These switches

are designed to cut off all power to  car's

electrical system, thus making electrical work much easier and the risks

inherent to it much less. In principle, they are an excellent idea for

any Morgan! However, the component Morgan uses and their installation creates

some problems which should be addressed or avoided.

car's

electrical system, thus making electrical work much easier and the risks

inherent to it much less. In principle, they are an excellent idea for

any Morgan! However, the component Morgan uses and their installation creates

some problems which should be addressed or avoided.

Over time, the Morgan switches often fail. This can be

a sad event as they invariably do so while the car is being used, sometimes

very far from home. The uninitiated can often be flummoxed at the suddenly

(or intermittently) unresponsive car. I have frequently heard of ruined

trips or large towing invoices. None of this is necessary. See the following

watchpoint for a quick temporary fix.

| WATCHPOINT: These

switches simply interrupt the current from the battery to the starter.

Therefore, the only thing necessary to re-complete the power route is to

secure the two cables going to the two switch posts to the same post (it

doesn't matter which one.) This will bypass the faulty switch. As a precaution,

remove the red (+) cable at the battery while you work. |

These

switches are not especially high quality (rated to 60 amps) but do have

a decent track record in sailboat applications for which they were originally

made ( in the UK) Ergo the plastic construction. Their primary advantage

is that they are very cheap..costing as little as 2.99£ on ebay.co.uk.

At that price, Morgan dealers will understandably not try to convince a

mogger that something better is a wise decision. However, what is the cost

and hassle of a roadside breakdown worth? The switches come with a big

plastic red key which is a doubtful security measure as they are all identical.

These

switches are not especially high quality (rated to 60 amps) but do have

a decent track record in sailboat applications for which they were originally

made ( in the UK) Ergo the plastic construction. Their primary advantage

is that they are very cheap..costing as little as 2.99£ on ebay.co.uk.

At that price, Morgan dealers will understandably not try to convince a

mogger that something better is a wise decision. However, what is the cost

and hassle of a roadside breakdown worth? The switches come with a big

plastic red key which is a doubtful security measure as they are all identical.

The switch is fit through the rear (wooden) bulkhead behind

and between the seats. There is a wooden spacer, to either give it greater

support or to account for the extended neck version that have chosen (this

switch type comes in a number of neck lengths). Ideally the battery cables

running to and from it should both also be secured solidly nearby, but

this is often not the case. As for the battery switches.. given the reported

failure rate I am inclined to ask just what is causing the failures.

(Has anyone taken a failed switch apart to trace the cause of the failure?

If so please contact us.

. When you ponder a bit, it is foolish to simply just fit a replacement.

of course, the cable run to/from these switches should be consideration

in that the cable weight is considerable and as such should be supported

by some means other than just by the terminal screws at the switch, if

it ain`t, then failure at the terminals and their mounting into the switch

seems a possible source of failure.. It might be reasonable to point

out that such switches carry the full load of the battery that a starter

motor is a dead short when the key is first turned. So those switches may

be exposed to shock loading of over one thousand amps for a period of time,

and a car that is ever hard to start will put rather a lot of strain on

such switches over TIME. Yup a higher rated switch is an improvement though

has to be also designed for the purpose in that it can withstand the necessary

starter motor loadings which far exceed 180 amps.

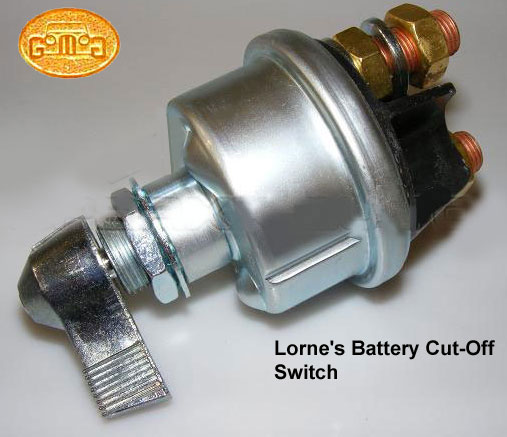

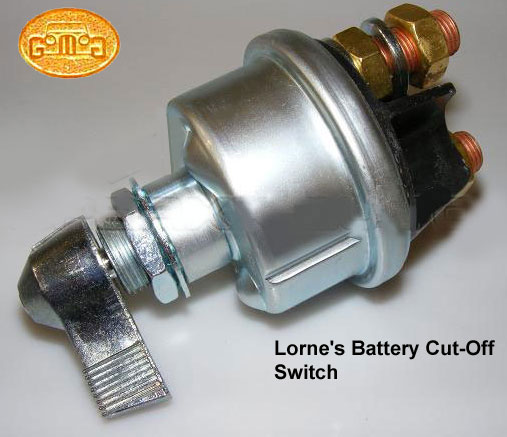

| My (Lorne) solution was to fit a solid metal switch rated to 180 amps.

I also secured both cables next to the switch, minimizing the cable

movement effect on the switch posts. I also ran a wire directly from the

"input" post to the fuses to the clock, radio etc that I do not want to

lose power. |

BATTERY NUMBERS, AND

DIMENSIONS

Find the code number of the battery you need and google a local

source

and supplier using the terms "car battery and the code" you found.)

WATCHPOINT

| BCI NUMBER |

Maximum Overall Dimensions

WATCHPOINT |

| Millimeters |

Inches |

| L |

W |

H |

L |

W |

H |

| PASSENGER CAR AND LIGHT COMMERCIAL_BATTERIES

12-VOLT (6 CELLS) |

| 21 |

208 |

173 |

222 |

8 3/16 |

6 13/16 |

8 3/4 |

| 22F |

241 |

175 |

211 |

9 1/2 |

6 7/8 |

8 5/16 |

| 22HF |

241 |

175 |

229 |

9 1/2 |

6 7/8 |

9 |

| 22NF |

240 |

140 |

227 |

9 7/16 |

5 1/2 |

8 15/16 |

| 22R |

229 |

175 |

211 |

9 |

6 7/8 |

8 5/16 |

| 24 |

260 |

173 |

225 |

10 1/4 |

6 13/16 |

8 7/8 |

| 24F |

273 |

173 |

229 |

10 3/4 |

6 13/16 |

9 |

| 24H |

260 |

173 |

238 |

10 1/4 |

6 13/16 |

9 3/8 |

| 24R |

260 |

173 |

229 |

10 1/4 |

6 13/16 |

9 |

| 24T |

260 |

173 |

248 |

10 1/4 |

6 13/16 |

9 3/4 |

| 25 |

230 |

175 |

225 |

9 1/16 |

6 7/8 |

8 7/8 |

| 26 |

208 |

173 |

197 |

8 3/16 |

6 13/16 |

7 3/4 |

| 26R |

208 |

173 |

197 |

8 3/16 |

6 13/16 |

7 3/4 |

| 27 |

306 |

173 |

225 |

12 1/16 |

6 13/16 |

8 7/8 |

| 27F |

318 |

173 |

227 |

12 1/2 |

6 13/16 |

8 15/16 |

| 27H |

298 |

173 |

235 |

11 3/4 |

6 13/16 |

9 1/4 |

| 29NF |

330 |

140 |

227 |

13 |

5 1/2 |

8 15/16 |

| 33 |

338 |

173 |

238 |

13 5/16 |

6 13/16 |

9 3/8 |

| 34 |

260 |

173 |

200 |

10 1/4 |

6 13/16 |

7 7/8 |

| 34R |

260 |

173 |

200 |

10 1/4 |

6 13/16 |

7 7/8 |

| 35 |

230 |

175 |

225 |

9 1/16 |

6 7/8 |

8 7/8 |

| 36R |

263 |

183 |

206 |

10 3/8 |

7 1/4 |

8 1/8 |

| 40R |

277 |

175 |

175 |

10 15/16 |

6 7/8 |

6 7/8 |

| 41 |

293 |

175 |

175 |

11 3/16 |

6 7/8 |

6 7/8 |

| 42 |

243 |

173 |

173 |

9 5/16 |

6 13/16 |

6 13/16 |

| 43 |

334 |

175 |

205 |

13 1/8 |

6 7/8 |

8 1/16 |

| 45 |

240 |

140 |

227 |

9 7/16 |

5 1/2 |

8 15/16 |

| 46 |

273 |

173 |

229 |

10 3/4 |

6 13/16 |

9 |

| 47 |

246 |

175 |

190 |

9 11/16 |

6 7/8 |

7 1/2 |

| 48 |

306 |

175 |

192 |

12 1/16 |

6 7/8 |

7 9/16 |

| 49 |

381 |

175 |

192 |

15 |

6 7/8 |

7 3/16 |

| 50 |

343 |

127 |

254 |

13 1/2 |

5 |

10 |

| 51 |

238 |

129 |

223 |

9 3/8 |

5 1/16 |

8 13/16 |

| 51R |

238 |

129 |

223 |

9 3/8 |

5 1/16 |

8 13/16 |

| 52 |

186 |

147 |

210 |

7 5/16 |

5 13/16 |

8 1/4 |

| 53 |

330 |

119 |

210 |

13 |

4 11/16 |

8 1/4 |

| 54 |

186 |

154 |

212 |

7 5/16 |

6 1/16 |

8 3/8 |

| 55 |

218 |

154 |

212 |

8 5/8 |

6 1/16 |

8 3/8 |

| 56 |

254 |

154 |

212 |

10 |

6 1/16 |

8 3/8 |

| 57 |

205 |

183 |

177 |

8 1/16 |

7 3/16 |

6 15/16 |

| 58 |

255 |

183 |

177 |

10 1/16 |

7 3/16 |

6 15/16 |

| 58R |

255 |

183 |

177 |

10 1/16 |

7 3/16 |

6 15/16 |

| 59 |

255 |

193 |

196 |

10 1/16 |

7 5/8 |

7 3/4 |

| 60 |

332 |

160 |

225 |

13 1/16 |

6 5/16 |

8 7/8 |

| 61 |

192 |

162 |

225 |

7 9/16 |

6 3/8 |

8 7/8 |

| 62 |

225 |

162 |

225 |

8 7/8 |

6 3/8 |

8 7/8 |

| 63 |

258 |

162 |

225 |

10 3/16 |

6 3/8 |

8 7/8 |

| 64 |

296 |

162 |

225 |

11 11/16 |

6 3/8 |

8 7/8 |

| 65 |

306 |

190 |

192 |

12 1/16 |

7 1/2 |

7 9/16 |

| 70 |

208 |

179 |

196 |

8 3/16 |

7 1/16 |

7 11/16 |

| 71 |

208 |

179 |

216 |

8 3/16 |

7 1/16 |

8 1/2 |

| 72 |

230 |

179 |

210 |

9 1/16 |

7 1/16 |

8 1/4 |

| 73 |

230 |

179 |

216 |

9 1/16 |

7 1/16 |

8 1/2 |

| 74 |

260 |

184 |

222 |

10 1/4 |

7 1/4 |

8 3/4 |

| 75 |

230 |

179 |

196 |

9 1/16 |

7 1/16 |

7 11/16 |

| 76 |

334 |

179 |

216 |

13 1/8 |

7 1/16 |

8 1/2 |

| 78 |

260 |

179 |

196 |

10 1/4 |

7 1/16 |

7 11/16 |

| 85 |

230 |

173 |

203 |

9 1/16 |

6 13/16 |

8 |

| 86 |

230 |

173 |

203 |

9 1/16 |

6 13/16 |

8 |

| 90 |

246 |

175 |

175 |

9 11/16 |

6 7/8 |

6 7/8 |

| 91 |

280 |

175 |

175 |

11 |

6 7/8 |

6 7/8 |

| 92 |

317 |

175 |

175 |

12 1/2 |

6 7/8 |

6 7/8 |

| 93 |

354 |

175 |

175 |

15 |

6 7/8 |

6 7/8 |

| 95R |

394 |

175 |

190 |

15 9/16 |

6 7/8 |

7 1/2 |

| 96R |

242 |

173 |

175 |

9 9/16 |

6 13/16 |

6 7/8 |

| 97R |

252 |

175 |

190 |

9 15/16 |

6 7/8 |

7 1/2 |

| 98R |

283 |

175 |

190 |

11 3/16 |

6 7/8 |

7 1/2 |

| PASSENGER CAR AND LIGHT COMMERCIAL BATTERIES

6-VOLT(3 CELLS) |

| 1 |

232 |

181 |

238 |

9 1/8 |

7 1/8 |

9 3/8 |

| 2 |

264 |

181 |

238 |

10 3/8 |

7 1/8 |

9 3/8 |

| 2E |

492 |

105 |

232 |

19 7/16 |

4 1/8 |

9 1/8 |

| 2N |

254 |

141 |

227 |

10 |

5 9/16 |

8 15/16 |

| 17HF |

187 |

175 |

229 |

7 3/8 |

6 7/8 |

9 |

| 4D |

527 |

222 |

250 |

20 3/4 |

8 3/4 |

9 7/8 |

Note 1: The complete BCI listing includes

several categories not included here: Heavy-Duty motor Coach and Bus batteries,

and Special Tractor Batteries (6 and 12-volt). BCI provides configuration

diagrams and performance ratings as well. Contact BCI, 401 N. Michigan

ave, Chicago IL 60611-4267, (312) 644-6610 for more information.

Note 2: The maximum height includes the terminal

posts. Width and length measurements are generally to the widest point,

including protruding flanges, except for hold-down flanges at the bottom

of the battery. See the diagrams in the BCI battery Replacement Data Book

for full details.

car's

electrical system, thus making electrical work much easier and the risks

inherent to it much less. In principle, they are an excellent idea for

any Morgan! However, the component Morgan uses and their installation creates

some problems which should be addressed or avoided.

car's

electrical system, thus making electrical work much easier and the risks

inherent to it much less. In principle, they are an excellent idea for

any Morgan! However, the component Morgan uses and their installation creates

some problems which should be addressed or avoided.

These

switches are not especially high quality (rated to 60 amps) but do have

a decent track record in sailboat applications for which they were originally

made ( in the UK) Ergo the plastic construction. Their primary advantage

is that they are very cheap..costing as little as 2.99£ on ebay.co.uk.

At that price, Morgan dealers will understandably not try to convince a

mogger that something better is a wise decision. However, what is the cost

and hassle of a roadside breakdown worth? The switches come with a big

plastic red key which is a doubtful security measure as they are all identical.

These

switches are not especially high quality (rated to 60 amps) but do have

a decent track record in sailboat applications for which they were originally

made ( in the UK) Ergo the plastic construction. Their primary advantage

is that they are very cheap..costing as little as 2.99£ on ebay.co.uk.

At that price, Morgan dealers will understandably not try to convince a

mogger that something better is a wise decision. However, what is the cost

and hassle of a roadside breakdown worth? The switches come with a big

plastic red key which is a doubtful security measure as they are all identical.