IGNITION BALLAST RESISTOR AND/OR CONSENSOR/CAPACITOR

by Lorne Goldman & Ted Bridge

This can be a very frustrating issue for British cars fit with an ignition coil and distributor. Most Morgan Plus 8s (overseas excepted) were fit with distributors until 2000.

|

A. Foreword

B. Understanding a Ballast Resistor

C. Testing a Ballast Resistor

D. Advantages and Disadvantages of a Ballast Resistor Over a Capacitor/Condensor

E. Condensor Capacitors

FOREWORD

I have now run across three instances of a bad condenser or ballast resistor in Morgans up to the point their ignitition systems began to use coil packs (circa 1996-2002 from a faulty memory). If I am noticing that fault cropping up..it is the time for an article. It is very difficult to diagnose. The symtoms are varied:

1. The car can run for 20 minutes or so, but then stalls, Only

restarting after a rest. if you are lucky This is because the coil is

overheated and its internal oil is boiling.

2. The car will run unsteadily. This is because;

a: The lack of one (ballast resistor or condensor/capacitor

causes a too high voltage to run through the coil and the distributor,

damaging the coil (which will become EXTREMELY HOT) and the distributor

cap

3. The car will overheat, yes the coil becomes so hot that it heats the engine!!!.

Understanding a Ballast Resistor

A Ballast Resistor is an electrical device that reduces voltage to

the coil so that more energy is available for the spark plugs during

starting. Its resistance increases as current flows

through it is increased and its resistance reduces as current flows

through it drops. As a result, a device that helps to preserve voltage

stability. This added stability increases ignition and running stability. Additionally, their

usage reduces

the chances of coil failure by reducing coil voltage and

current, ensuring that the coil does not overheat as a result of the

addition. An overheated coil quite often causes damage to distributor

and its amplifier. The high heat of a over-heated coil also increases

engine bay temperatures to sad effect.

Traditionally, ignition systems didn’t use a ballast, meaning that

the ignition system used a 12v coil with a 12v feed from the battery via

the  ignition switch. This system is fine when the engine is running. However, it can be

problematic when starting because the starter motor draws a huge amount

of current from the battery, leaving the ignition system and the spark plugs with less energy

to create sparks. This is mad worse during colder starting temperatures or

when the starter motor is worn, requiring even more energy for the

starter motor and leaving less available for the spark plugs.

ignition switch. This system is fine when the engine is running. However, it can be

problematic when starting because the starter motor draws a huge amount

of current from the battery, leaving the ignition system and the spark plugs with less energy

to create sparks. This is mad worse during colder starting temperatures or

when the starter motor is worn, requiring even more energy for the

starter motor and leaving less available for the spark plugs.

To

counteract this distribution of energy, ignition systems were changed

to use a 9v coil instead of a 12v coil. A 9v coil gives the same output

as a 12v coil when provided with a 12v feed, resulting in a better

spark for starting with less energy draw on the starter motor. Once the

engine is running, the 12v feed is cut and the coil continues to run on

the 9v feed.

Which coil should I use if my car has a ballast resistor?

MAJOR WATCHPOINT: Never try to run a ballast resistor or condensor system

when a ballast resistor is not present in the ignition system unless

you have changed the entire system! Damage to all components downstream

of where these deviceswere placed which is before the coil, BEGINS IMMEDIATELY. In minutes, you have damaged anything there or newly put in. Coil, points, cap, electronics....

N.B. There ARE

internally ballast resisted coils. Mallory coils with red tops are one

such coil. However, I do not recommend them. Ballast resistors are

inexpensive and reliable. There are made of cermamic to absorb heat.

Ballast resisted coils give OFF heat.

|

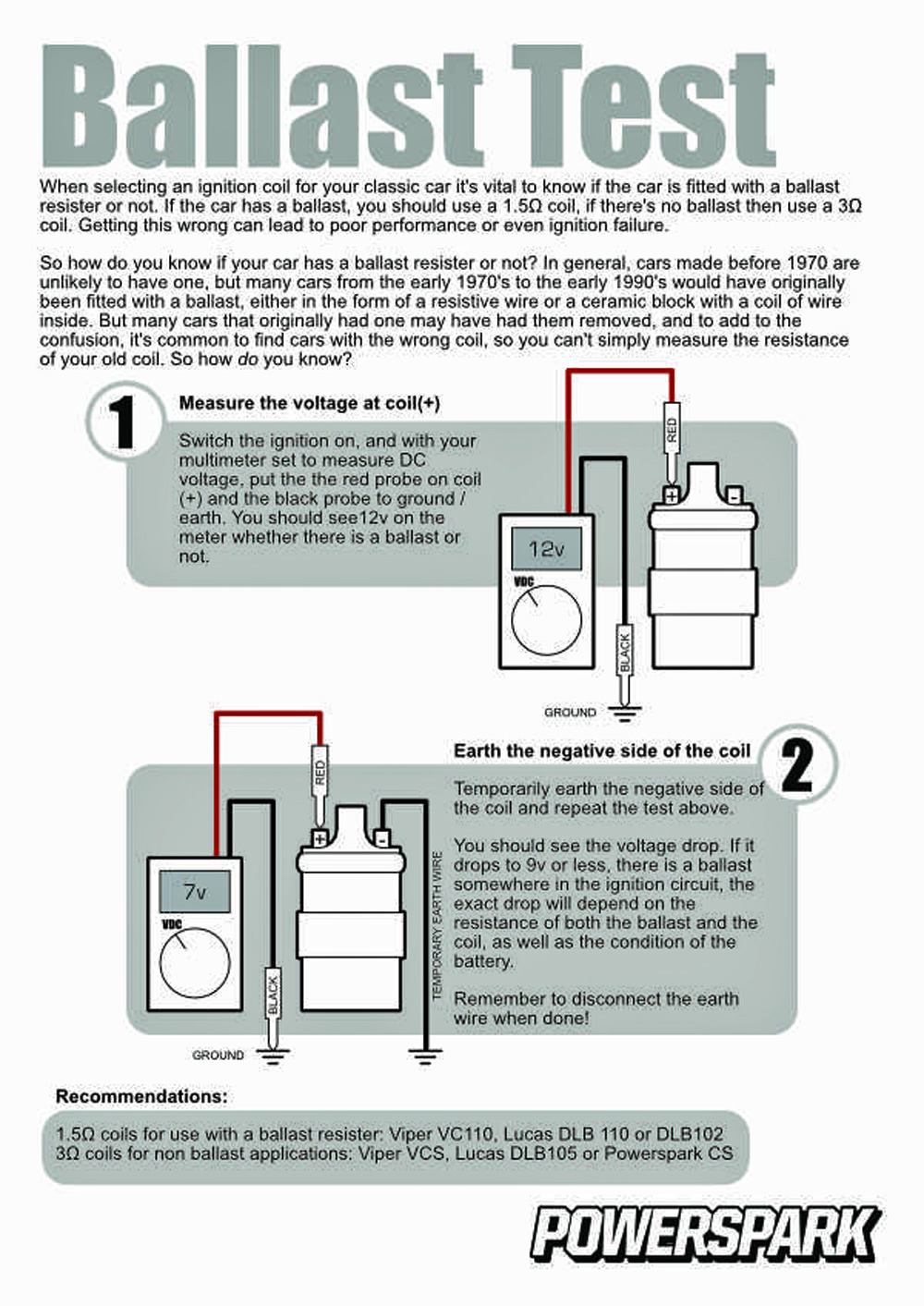

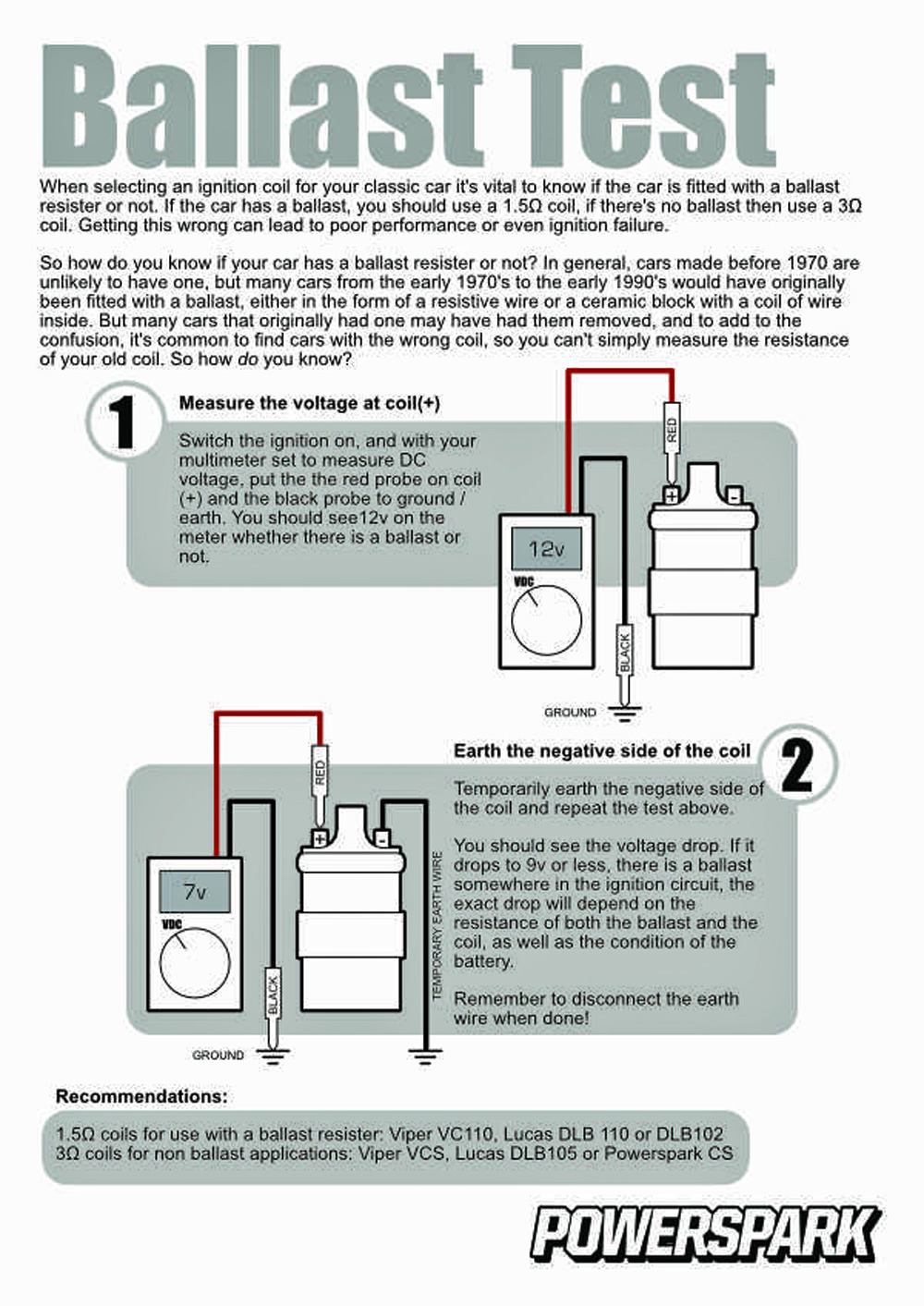

Testing a Ballast Resistor

To test the ballast resistor in automotive applications an ohmmeter or a multimeter is needed.

If the ignition

coil is not linked to the ballast resistor, the ignition coil receives

the entire supply voltage. The battery is usually utilized to power  the

ignition system. The battery voltage will most likely be 12V in most

circumstances. If the voltage level decreased to 7-8V after connecting

the ballast resistor, then the ballast resistor will be in good

condition. However, if the voltage level of the ignition coil will be

high it means the ballast is damaged. So, to extend the life of the

ignition coil we need to lower the voltage and for this purpose we

connect a ballast resistor to the ignition coil to decrease the

voltage. Test for voltage at the power entry side..should be 12+Volts.

Now test for voltage at the end wired directly to the positve side of

the coil. It should be lower.

the

ignition system. The battery voltage will most likely be 12V in most

circumstances. If the voltage level decreased to 7-8V after connecting

the ballast resistor, then the ballast resistor will be in good

condition. However, if the voltage level of the ignition coil will be

high it means the ballast is damaged. So, to extend the life of the

ignition coil we need to lower the voltage and for this purpose we

connect a ballast resistor to the ignition coil to decrease the

voltage. Test for voltage at the power entry side..should be 12+Volts.

Now test for voltage at the end wired directly to the positve side of

the coil. It should be lower.

Ballast Resistor in a LED Circuit

The LED bulb may

be damaged if the source voltage in an LED circuit is higher than the

rated voltage of the LED bulb. To avoid this, a ballast resistor should

be connected in series with the bulb. The voltage across the LED is

decreased to a safe level by connecting the ballast resistor in this

manner.

Advantages & Disadvantages

1. They both assist in the regulation of voltage and current in electrical systems.

2. They both safeguard the coil, the amplifier, the points, the

electronics and the distributor from overvoltage and overcurrent.

3. In the rest of an electric circuit, these resistors diminish variations in current and applied voltage. As

a result, a ballast resistor is mostly utilized for over-voltage,

current, or protection inside various automobile and light circuits in

order to provide circuit stability.

4. Maintenance.

Condensor-capacitors rust over time, most often on their unseen side. By that time, they have damaged the rest of the ignition system

Ballast Resistors None. They should last forever.

5. A disadvantage is that with a ballast resistor you may need Radio

Frequency Interference (RFI) Suppression spark plug wires as without

them your sound system may have static. However, almost all new spark

plug wires are Radio Frequency Interference (RFI) Suppressant except the very cheap ones.

Cost & Availability

Condensor: At

a UK automobile store. I would suggest carrying on with you, but by the

time you see a problem..more damage has been caused. 2-4 British pounds

Ballast Resistor: At any auto store in the world. As above. 10-20 British pounds.

Capacitor (aka a Condenser)

Understanding Ignition Capacitor/Condensers

Though

the end result is the same. However, rather than being wired in

series and reducing the battery voltage before it reaches the coil as a ballast resistor does, a capacitor/condenser DRAWS the unneeded voltage from the positive (+) coil post !

Though

the end result is the same. However, rather than being wired in

series and reducing the battery voltage before it reaches the coil as a ballast resistor does, a capacitor/condenser DRAWS the unneeded voltage from the positive (+) coil post !

Maintenance.

They should be changed every 2 years as they will fail without a

warning sign. As noted above, they will then proceed to damage your

distributor and its amplifier. They are even cheaper than ballast resistors, costing a couple of £s at most. Sadly, Land Rover used them for a short period on LR and Morgan Plus 8s until they learned better. Frankly, the best idea to avoid inevitable sadness is to replace them with a ballast resistor. A one-pint job. Here is an excellent article more fully detailing the curse of a Lucas igntion coil condensor/capacitor.

Way of Testing a Capacitor Condenser

TEST ONE. 1.)

Remove the condenser from the engine (or at least disconnect the lead

wire). Note the small metal connector located on the end of the

condenser. This connector is the "hot" or power connection. The metal

case of the condenser is the grounding point. Discharge the condenser

by shorting the lead wire to the case.

2.) Switch the

meter to the ohms position. Place the red lead into the "ohm" connector

on the meter. Insert the black lead into the "com" or common connector

on the meter. Set the resistance range to the highest available setting

(if it is selectable). Connect the test leads together and zero the

meter. If the meter won't zero replace the battery. (Yes, an ohm meter

has a battery).

3.)

Touch the red lead to the hot connector on the condenser. Place the

black lead to the metal case on the condenser. The meter's needle

should jump slightly to the right (toward 0-ohms), then should drop

back to the left towards infinite resistance). Hold the leads in place

for 15 to 20 seconds. This action places charge in the condenser. If

the test shows any reading other than infinity, the condenser is

leaking and needs to be replaced.

3.)

Touch the red lead to the hot connector on the condenser. Place the

black lead to the metal case on the condenser. The meter's needle

should jump slightly to the right (toward 0-ohms), then should drop

back to the left towards infinite resistance). Hold the leads in place

for 15 to 20 seconds. This action places charge in the condenser. If

the test shows any reading other than infinity, the condenser is

leaking and needs to be replaced.

4.) Remove the

leads and reverse the placement to the condenser. Move the red lead

from the hot connector to the metal case, and move the black lead from

the metal case to the hot connector. At the moment where both leads are

touching the correct points, the meter should jump towards the right.

The second time the needle may move twice as far, as this action

discharges the condenser. Holding the leads in contact should again

result in movement of the needle back toward infinite resistance.

5.) Movement of

the meter's needle indicates the condenser is good. If no movement was

indicated on the meter in any circumstance, the condenser is bad and

must be replaced. Retest the condenser several times for a consistent

reading.

In operation the

condenser will "ring" at up to 300 volts, so the condenser needs to be

rated much higher, no less than 600 volts DC. The ignition will likely

work with any capacitance value between 0.05 and 0.6 microfarad. Too

high or too low value may eventually transfer metal from one side of

the contact points to the other side leaving a pit and a point.

Capacity of spark coil capacitors ranges from 0.2 microfarad to 0.33

microfarad. Almost all automotive coils use a 0.25-0.29 microfarad

capacitor.

A capacitor may

absorb moisture over a long period of time, and moisture will cause

failure of the condenser. So it is possible that a condenser stored for

10 years or so might be bad or might fail prematurely in service. It is

a good idea to check your traveling spare condenser occasionally.

TEST 2 Video

WATCHPOINT. The

logic here is merely mine. The advantage of is that it works. I have

had much success helping my brethren with it. Good Luck!

|

ignition switch. This system is fine when the engine is running. However, it can be

problematic when starting because the starter motor draws a huge amount

of current from the battery, leaving the ignition system and the spark plugs with less energy

to create sparks. This is mad worse during colder starting temperatures or

when the starter motor is worn, requiring even more energy for the

starter motor and leaving less available for the spark plugs.

ignition switch. This system is fine when the engine is running. However, it can be

problematic when starting because the starter motor draws a huge amount

of current from the battery, leaving the ignition system and the spark plugs with less energy

to create sparks. This is mad worse during colder starting temperatures or

when the starter motor is worn, requiring even more energy for the

starter motor and leaving less available for the spark plugs. the

ignition system. The battery voltage will most likely be 12V in most

circumstances. If the voltage level decreased to 7-8V after connecting

the ballast resistor, then the ballast resistor will be in good

condition. However, if the voltage level of the ignition coil will be

high it means the ballast is damaged. So, to extend the life of the

ignition coil we need to lower the voltage and for this purpose we

connect a ballast resistor to the ignition coil to decrease the

voltage. Test for voltage at the power entry side..should be 12+Volts.

Now test for voltage at the end wired directly to the positve side of

the coil. It should be lower.

the

ignition system. The battery voltage will most likely be 12V in most

circumstances. If the voltage level decreased to 7-8V after connecting

the ballast resistor, then the ballast resistor will be in good

condition. However, if the voltage level of the ignition coil will be

high it means the ballast is damaged. So, to extend the life of the

ignition coil we need to lower the voltage and for this purpose we

connect a ballast resistor to the ignition coil to decrease the

voltage. Test for voltage at the power entry side..should be 12+Volts.

Now test for voltage at the end wired directly to the positve side of

the coil. It should be lower.  Though

the end result is the same. However, rather than being wired in

series and reducing the battery voltage before it reaches the coil

Though

the end result is the same. However, rather than being wired in

series and reducing the battery voltage before it reaches the coil