Dear JC,

You asked in the right place! I have been dealing with such questions for 28 years. Ron also has a L-Jetronic.

I adore them. A wonderful owner-friendly step between carbs and the now complex EFI types. Everyone used them..all them

based on the same AFM..the adorable flapper. With all the hype these

days, the principle advantage of fuel injection is the injector

spray..which has never changed since Bosch discovered it in the 1920s.

Most everything else about it now is government regulation and

manufacturer protections!

There was a time 25 years ago, when I used to collect such things.

Like all other parts at the time, AFMs used to cost me 5£ off

ebay.co.uk! I used to take them apart and see how they worked rather

than attack the working one on the car. I also find that the ultimate

test for any company is to swap in a known good one. So I kept one I

have tested on the car as my reserve. Here is part of my stash, but it

is back in Canada, 9000 kms away.

Eventually I switched to the larger Jaguar version with their 34%

more airflow. They are more common than the Rover ones and can provide

you with noticeably more power, even on a 3.5 engine. I have not used my

3.5 version for 20 years..so it is yours as a gift, but very hard to

access even when I am back in Quebec which will not be until next

summer.

However, I can help you. I also know of place on the US that can

fully restore them at a reasonable price..and bead blasts them to make them prettier than new. They are also easy to test or

to adjust. Even the best of them has the all import spring tension

become too slack over time and requires tightening. All the instructions

are up on GoMoG, but I have not reviewed them in a LONG time and they

might need re-editing. This will make me look over them again.

Do you have a Gunsen CO2 reader? It is the best tool for tuning L-Jet

AFMSs and carburetors.. They used to be cheap but everything has

tripled in price.

If needed the

part you are looking for goes by many designations, the Bosch numbers

will get you the most success as the device was used on MANY cars..

Ignore the Land Rover number unless you want to pay enormously. ERC5198

Use Bosch 0 280 202 008

I never look under the Rover numbers but they begin with ERC..I can find it if you want it. Somewhere in my archives.

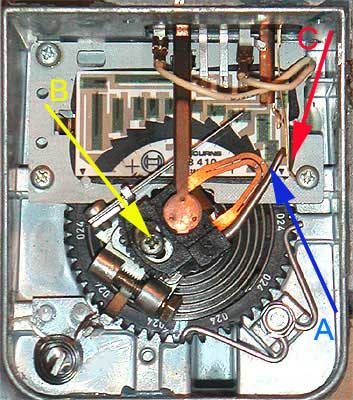

1. In any adjustment of the spring, you MUST make sure that;

a. the armature centre pointer (you can just see a tiny

little dot at the end) is precisely pointed at the bottom left corner of

the tiny shaded rectangle you see at the arrow "A" If it is not,

you can adjust the angle of the armature, by loosening the screw indicated

at "B" You will notice that the screw does not enter a hole but rather

an wide slot allowing for this adjustment.

b. You should place the idle air bypass screw (not shown)

about 1/2 way down in adjustment. If the adjustment screw cannot be turned

or has been cross-threaded..do not buy the unit.

2. Though it would seem that the large toothed wheel adjustment is simple, you must consider that there are 50 teeth in its 360 degrees and the wheel can turn completely about 4-5 times (by my bad memory) ..creating 200-250 possible air/fuel combinations. Each tooth, (within a range the car will start at all) represents a 1% CO2 adjustment! You CANNOT adjust the AFM without a CO2 analyzer. (Gunsen makes the cheapest home version..about 100 GBP). You can get what seems a smooth idle without..and then find under load and normal speed that you have caused some prejudice to the engine by running far too lean..or, less seriously, far too rich).

The best procedure is to turn the adjustment wheel until the spring (with in the black wheel) looks pproximately like the picture below and try to start the car. If it doesn't start, loosen the spring a bit. (If your engine pulses...the spring is too loose).

Once started, turn the spring incrementally until your CO2 analyzer reads 2%. You can then refine the idle mixture later, after you close up, by using the idle air bypass valve.

3. The arrow "C" point to the fuel pump contact...a weak point on the L-Jetronic. In a eMog survey two years ago, we discovered that 8 of 12 of them here had failed and been bypassed. In my experience, it is the single most oft-asked thing that stumps the Agents on these flapper Morgan. The innards of the L-Jetronic are delicate.... use the wrong sealant and the fumes corrode the contacts and they fail. Clean with alcohol and air before resealing.

Additionally, the fuel pump contact is a tiny wire going

to a red relay-like affair called the "steering module" and then on to

the fuel pump relay with a more robust wire. Forget it. Have your fuel

pump function with the ignition interrupted by an inertia switch..(I use

one from a Jag). This is far more reliable, simplifies the standard system

and acts as an ignition cut off..so your insurance company will pay for

it AND reduce your premiums. (smile)

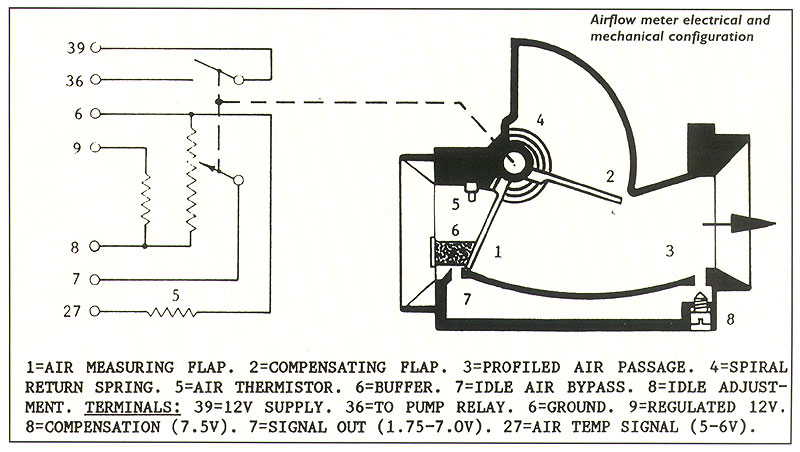

The key component in L Jetronic is undoubtedly the airflow meter. It is composed essentially of a graduated air passage containing a hinged flap which deflects against a spring according to the flow of air through the passage. The flap is mounted on a spindle and directly controls the position of a sliding contact along a resistive track.

Although the track itself incorporates a complex array of laser trimmed resistors the principle is very simple: just a potentiometer producing an output voltage according to the deflection of the flap (see diagram). Like most things of course the satisfactory operation of the airflow meter involves some sophistication in its design features. For instance a simple flap pivoting in the air-stream would be overly-sensitive to any resonant pulses in the induction tract and any spit-back from the engine would be likely to blast it back violently against the incoming flow to the limit of its travel. To resolve these problems a second flap was added at 90 degrees to the first, pivoting within a damping chamber. The idea was that any pulse or spit-back striking the two flaps would be largely balanced either side of the pivot point and any sudden movements would be resisted by the damping chamber.

This worked quite well for pulse absorption but the much stronger shock wave generated by a spit-back could still blast the flap onto its closed stop with such severity that the spindle bearings could be knocked out of alignment causing the flap to jam. Originally a spring loaded relief valve was built into the flap to relieve such pressure waves but did not react quickly enough so was superseded by the simple expedient of a small rubber buffer at the entrance to the air passage.

The Air Flow Meter or AFM is one of the most expensive components of the L-Jetronic system. Fortunately they rarely wear out or fail and there are plenty of inexpensive used ones available. The AFM is simple in operation. Air entering from the air filter side pushes a little door open. As the volume of air increases it pushes the door open farther. The AFM measures how far the door opens to determine the volume of air. The AFM also measures the temperature of the air. These two bits of information are combined to determine the total number of air molecules entering the engine and that information is sent to the ECU. The ECU then uses this information to help decide how much fuel the engine needs and adjusts injector duration accordingly. Of course the ECU gets information from many sensors but at full throttle the AFM's signal is primary. That means if you want max power a properly operating AFM is critical.

* A bad AFM can cause the following problems: Difficult or impossible hot or cold starting, the starts and stalls syndrome, lack of power, high emissions, and irregular idle.

I am afraid the official Bosch procedures for checking

these things are not too good.

There can be no doubt that many L Jetronic problems involve

the airflow meter, not that it is particularly troublesome but it does

have several key functions and a fault in any of them is equally inconvenient.

One of the most common is for the fuel pump relay switch ceasing to close

properly. The cure is usually just to remove the black plastic cover (which

involves some patient work with a sharp knife to gradually break the glue

joint) and gently bend the switch contact arms until they close as the

flap  opens.

However, if the switch is broken then the airflow meter will usually have

to be replaced. Franky I do not trust the switch. On eMog, we found that

50% of them fail over time and that is a silly reason to go searching for

a AFM that has not been produced in 20 years, espcially when you are a

1000 miles from home. I wire the fuel pump into the ignition with a modern

impact inertia switch inline.

opens.

However, if the switch is broken then the airflow meter will usually have

to be replaced. Franky I do not trust the switch. On eMog, we found that

50% of them fail over time and that is a silly reason to go searching for

a AFM that has not been produced in 20 years, espcially when you are a

1000 miles from home. I wire the fuel pump into the ignition with a modern

impact inertia switch inline.

The wiper arm is secured to the flap spindle by a clamping screw and the wiper itself is adjustable on the arm, being locked in place by a small screw and washer. There is a slender possibility of either clamp screw slipping, perhaps after some sort of shock or backfire. If this should happen it does not take much movement to upset the fueling considerably and if this symptom is observed, and no other fault is apparent, it can be worth experimenting carefully with the slider alignment.

The resistance track sometimes wears through, usually around the much used first third of the wiper travel. This will obviously cause erratic fueling and whilst a track from an airflow meter which has failed for other reasons, from a similar car, could be substituted, some trial and error might be needed to set the slider position satisfactorily.

Resistance measurements do not provide an accurate means of assessing the serviceability of an airflow meter - it is a potential divider and the system depends on voltages not resistance. There should be smooth transition of voltage on terminal 7 as the flap is moved. Typical airflow meter terminal voltages are:-

Pin 6 0v

Pin 7 2.25v - flap fully closed

Pin 7 7.5v - flap fully open

Pin 8 7.6v

Pin 9 12v - nominally 2v below battery

A quite common occurrence is that slight wear in the spindle bearings allows the flap to rub on the housing. This can appear serious but in the majority of cases the flap functions quite normally when the engine is running. Occasionally one finds an airflow meter, or its connector, with a large (100 Mf) capacitor soldered across terminals 6 & 8. This was supposed to be a cure for a drivability problem during warm-up but how effective it was is a matter for conjecture.

If a new meter is needed, or you wish to refurbish your

own, contact Fuel Injection Corp.

| FLAPPER PLUS 8S | GoMoG MANUAL | GoMoG MAIN PAGE |