Rack

& Pinion Steering

by Lorne Goldman

Safety

Every vehicle has the

same

three systems that are life sensitive.

These are tyres, the brakes and the steering. There can be no

compromises with ANY of them. Happily, Morgan classics, (at least

they were ended) are wondrously simple areas and the task to keep these

areas safe is not difficult or

cumbersome.

Morgans get silly (and have owners react the same way) when elementary

maintenance is not done. AND I cannot over-emphasize the need for

vigilance or the dangers

of getting the wrong advice (I have seen some horrid examples of the latter in the last decade!)

If you have any doubts whatsoever, consult an experienced Morgan dealer.

Happily, the key watchpoints are SO simple that common sense should

warn you away from any advice you cannot immediately judge as correct at

a glance, whether you are mechanically enabled or not.

History

In 1983,

the Morgan Motor Company approached Jack Knight Ltd., a noted British aftermarket

steering specialist, to design a rack and pinion steering system for the

Plus 8, the heaviest of the model line-up and accordingly the most in need

of a steering improvement. The resultant rack was a great step forward

and was first offered in 1984 as an optional extra at £250. It became

standard on all Plus 8s by 1986, unless a customer was crazy enough to

ask for the older system. By 1991, it became a free option for Plus 4s

and by the mid-1990s it was standard on all Morgans.

Though

the design falls far short of an ideal in areas, it is a vast improvement

on previous Morgan steering systems and has three great virtues; it is

simple, it is solid, (save for one BIG watchpoint) and it fits on the Morgan front end. There is little

that go wrong with it outside of the most basic human errors in fitting

and checking it. On  very rare occasion it can require adjustment,

which

is dealt with by David Poole in his great eMog posting, and after much mileage

the rack channel and spacers may require redressing, and easy job for any

machine shop. I have had a full refurbishing done in the UK for 75£s;.

very rare occasion it can require adjustment,

which

is dealt with by David Poole in his great eMog posting, and after much mileage

the rack channel and spacers may require redressing, and easy job for any

machine shop. I have had a full refurbishing done in the UK for 75£s;.

The Morgan

Motor Company had the stock rack's turns-to-lock changed a number

of times during its history.

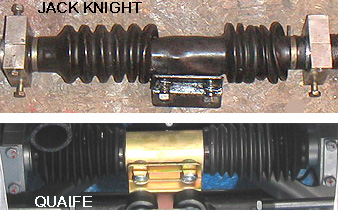

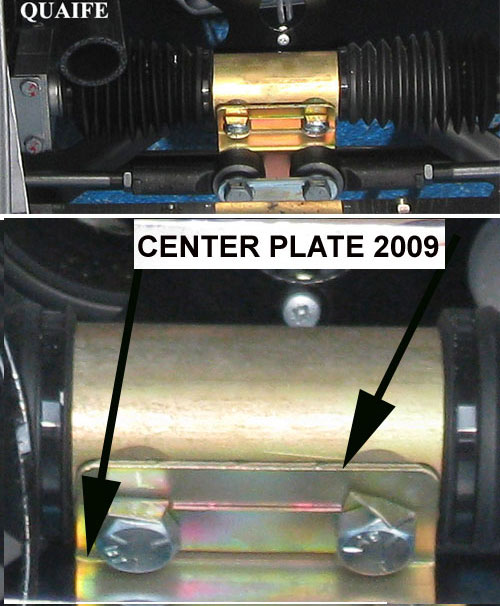

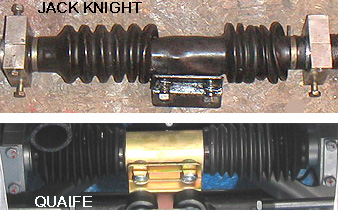

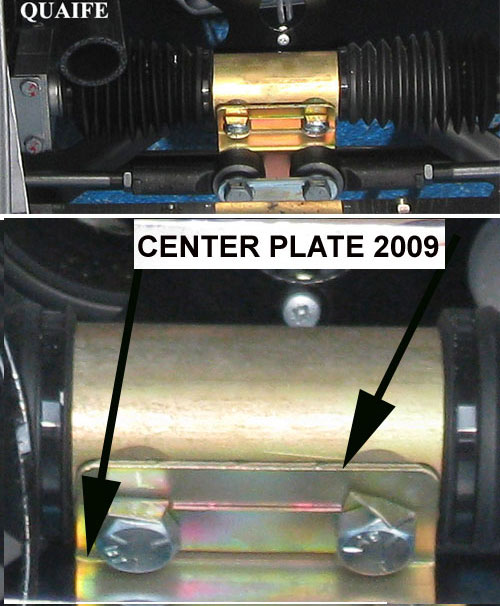

In 2007,

the original Jack Knight company fell into bankruptcy and the MMC asked

Quaife Engineering to supply the rack. For all intents and purposes, the

Quaife Morgan racks are the same and can be retrofitted to Jack Knight

cars. The Quaife racks can be distinguished only

by their different centre gaiters, a big improvement over the Jack Knight

gaiter. However, Jack Knight

has been reborn under the management of its former employees and an upgraded

gaiter, as good as the Quaife gaiter, can be had from them if you can get

them to call back.

The old style JK gaiter is

flimsy and inexplicably expensive, by a factor of 5 to 10 times. The flimsiness bothers more than the price. Once they are torn (a MOT issue), the wisest course

is to replace them with the new JK gaiter which is as good as the Quaife.

(The Quaife gaiter will not fit a Jack Knight rack.) Quaife parts can

only be ordered through the MMC, Jack Knight parts can be ordered from

Jack Knight directly, if you can find them. However, the parts in each are generic and can easily be found in the UK

|

WATCHPOINT

Tierods-to-Center-Plate Any time the tie rods are removed from the steering rack center plate,

the steering alignment should be verified. This is made more important

if the plate itself is removed and even doubled again if both clamps holding

the rack to the crossframe are removed, (Though this is not strictly necessary

to change the gaiter, many take both clamps off to remove the whole assembly.)

All or most of this must be done simply to change the center gaiter. The

play at each junction is sufficient to through your steering out of alignment.

Trust ME on this and not your local non-Morgan mechanic. Many owners have

found the steering canting off one way or another after a gaiter change.

|

Morgan Steering Rack Types

by Lorne Goldman

The Morgan steering

racks are produced by;

| YEARS |

1983

to 2007 |

2007

to date

|

| TYPE |

Jack Knight Engineering

(UK) |

|

| SOURCING |

will repair

and sell Morgan racks direct, multiple options for turns-to-lock

|

will not

sell Morgan rack direct

|

Please note that

neither of these Morgan Steering Racks are advanced rocket science. It is their saving grace. I have

had them fully rebuilt and/or repaired by a number of machinists or

specialists, at a small fraction of the price that either of these two

sources (or their agent, the Morgan Factory) insist on. Aside from the

major components (the rack and its pinion), their parts are commonly

available.

Turns Lock-to-Lock

The

steering wheel lock-to-lock is the number of turns it takes for a

driver to get his steering wheel from its limit on one side to the

limit truned to the other side. Morgan changed these often

and Jack Knight offers many options.

Why is this important? The number of turns creates a mechanical ratio

that can help the driver with turning ease. The higher the number of

turns makes it easier to move the tie-rods the required amount to turn

at a certain angle. In other words, more turns lock-to-lock increases

the ease of turning the steering wheel at low to very low

speed, making it easier to park. Effort is only key at very low speeds.

On the other hand, fewer turns lock-to-lock makes the car more

sensitive to the steering wheel as it takes relatively less steering

wheel rotation to achieve movement to

They lesser the number of turns it takes, the

more sensitive the steering wheel is. Sensitive steering wheels provide

better responsiveness to steering inputs even at high speeds and driving

becomes instinctive. It's a simple result of mechanical advantage. The higher the ratio

(numerically), the easier it is to move the wheel, and more input at the

wheel is needed to move the tie rods a specific amount. That means

more steering wheel correction is needed when driving.

At the same time, too much wheel

sensitivity will make a car twitchy and hard to control. It's a very

fine balance that car makers and hobbyist owners have to deal with.

Changing the Jack Knight Center Gaiter (in 11 easy steps)

;)

by Lorne Goldman

If

you can, the gaiter is best changed with the rack in situ and wheels on

the ground. This may sound nutty, but if the rack is removed, it requires

so many items to be uninstalled that a full alignment and steering wheel

adjustment will be compulsory. This method will minimize the wheel alignment

issues when you re-assemble. If you raise the car, then try to brace the

wheels so that their relationship with the rack does not change during

the process. Secondly,

the gaiter CAN be changed with the rack in situ, no need to remove the

whole thing unless you really want to. With a RHD you can slip it

over the rack from the right hand side (as you are looking at the rack

from the front of the car) and the from the other side with a LHD.

For those who wish to remove the rack,

this can be done by removing the steering column at the rack rear and then

removing the two block brackets holding the rack to the crossframe.

1.

Open the lock tabs on the steering center plate, and unbolt the tie-rods

from the center plate (you will need a spanner to hold the nuts from the

back)

2. Let the tierods fall to the floor and

do NOT move them

3. Open the second set of lock tabs

and unbolt the center plate from the rack.

WATCHPOINT

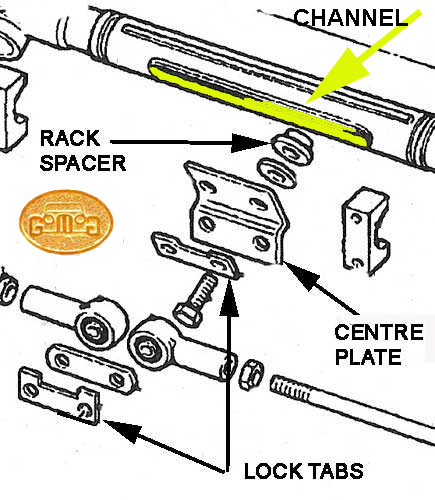

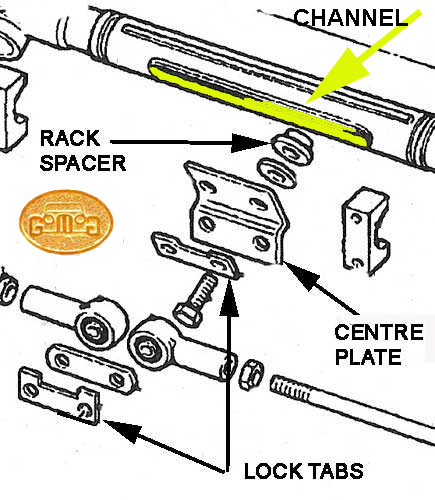

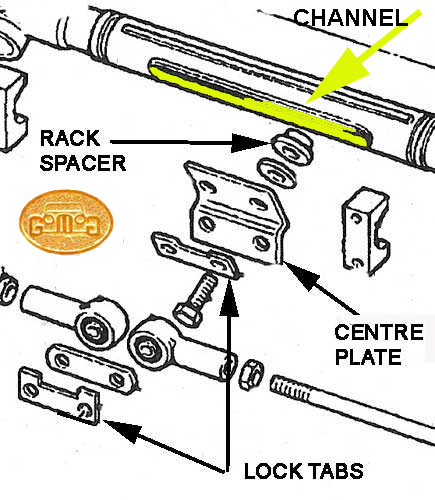

I: The center-plate-to-rack bolts go through two spacers that slide

in the rack. They are not visible as the gaiters hide them. They create

a snug fit in the channel, reduce the amount of horizontal play, which

in turn, steadies the entire steering, (ANY BIT OF MOVEMENT HERE WILL BE

MULTIPLIED BY THE LENGTH OF THE STEERING COLUMN BEFORE IT REACHES THE STEERING

WHEEL). More on this latter.

|

| WATCHPOINT

II: These rack

spacers are designed to serve another purpose. They protect the gaiter

at its weakest point. If you look closely, (when you can examine the spacers)

you will notice thatt they have a small raised circlet in their metal on

the side that faces the bolt entry. This raised area goes into the two

gaiter bolt holes and prevents the bolts from crushing the gaiter and splitting

it..as the split will grow over time. If you are not

aware of this, the overwhelming possibility is that you split the gaiter

at these points and yet pat yourself in the head for a "job well done". Owners

do it, dealers do it, and it is very sad event at 60

quid a pop. |

4.

Now you remove the the bolts from the right side aluminum block holding

the rack to the crossframe, split it into its two pieces with a light hammer

tap if necessary. You can cut (knife or scissors) the old gaiter from the

rack or slide it off the right side you opened up. Watch for the spacers

to fall out.

5.

Now, test something. Can you squeeze the oily spacers through the bolt

holes in the gaiter? You should be able to and I want you to be confident

of that. Next slide the new gaiter back onto the rack, like you were putting

nylons on your favorite lady (or man). Be careful not to snag it but it

will adapt and stretch. You want its front (the center section with the

two holes) to be facing forward and you want the two spacers to be in the

correct position in the channel and facing forward. Fiddling will be involved..a

Morgan tradition!

6.

Now fiddle in the plate-to-rack bolts. You must align the bolts, the lock

tabs, the gaiter bolt holes, the spacers and threaded holes in the rack

pinion..a screw drivers and you no-oily fingers can be used. Get each one

threaded loosely before you tighten anything. Please don''t forget anything

or their order. You do NOT want to get me upset.

7.

Once you tightened the bolts, lock the tabs. Only one bit need be touching

each bolts.

8.

Re-install the aluminum block on the right attaching the rack to the crossframe.

9.

Forget the silly metal bands they used to clamp the gaiter, use the

right-sized tie wrap and trim off the ends.

10.

Then put on the tie-rods, this might require you to move the center plate

along the rack. It is better to move the rack than the rods. Now

close their lack tabs. Now get a bit of oil paint and make reference lines

from a corner of each of the four bolts. In the future, these lines will

allow you to see if any of these all important bolts have shifted at a

quick glance.

1.

The trick with the end cones is that people slide them on too far. First

deep turn and they pierce the cone with the rack without knowing it. The

rack does not require much lubrication. Almost anything will do, hypoy

oil (like you use in the axle) or chain saw oil or use the silly GoMoG

Manual https://www.gomog.com/allmorgan/r&p.html#lubricant

. Jack the car front on one side so it is atilt. Remove the cone. Fill

it up and fit it back on. Tie-wrap it. As you have taken the whole

center gaiter off, do it on the other side as well.

Otherwise, topping up one side is sufficent for maintenance purposes.

| WATCHPOINT

III: Yes. You're right. The JK gaiter is a fright. It is a flimsy

affair made by laminating (coating) silicone on a form. It is nowhere

near the quality of similar gaiters and its price is a function of

insane greed. ;) Jack Knight no longer supplies them.. I have heard they are

now made for Morgan directly by the old JK supplier. There are those looking

into a higher quality gaiter, easily sourced and reasonably priced. Perhaps

that will shame the company into being kinder. However, for those

of us in the UK, it is also a cause of a MOT failure. The examiners are

not happy with lubricant leaks next to disc brakes. So,

if you have one, do not demonstrate

your one-shot oiler to them either!!! |

|

WATCHPOINT IV - PLAY

AT THE STEERING WHEEL WATCHPOINT IV - PLAY

AT THE STEERING WHEEL

Morgan rack and pinion steering

systems should have NO play at the steering wheel. None. There are a number

of causes for play, but the most dangerous ones relate to the fitting of

the rack and its tie-rods. Be aware that the length of the steering column

will exaggerate any rack anomaly at the steering wheel. making the steering

wheel your best early warning system. As soon as play is noticed, three

areas MUST be checked before driving further.

1. the two bolts holding

the centre plate to the steering rack itself.

2. the two bolts holding

the tie-rods (those rods which connect the steering rack to the front stub

axles and therefore the wheels) to the steering rack centre plate.

3. the four bolts (2 each

side) running through the two blocks that hold the rack to the car frame.

(Consult the diagrams here).

Between

1-3 the rack is held to the car and the wheels to the rack. If they are

compromised, so is your steering and your safety. At one time or another,

I have seen each of these areas with loose bolts. Care can prevent this.

Many times a visual test

will locate the problem.especially if one removes the centre gaiter. To test, have someone at the steering wheel and

have them turn the wheel while you look at the three areas, #2 will be

difficult as the bolts are obscured by the #1 bolts. Do it with the front

tyres on the ground and then again with them off. The rack should NOT move

on the frame and the only movement of the rods should be from side to side. However..read here.

|

WATCHPOINT V- CENTRE PLATE

TO RACK

These two bolts go through

a lock tab, the centre plate, often a small washer and then through the

important rack spacers (that keep the assembly guided within the parameters

of the channel in the rack) and then thread into the pinion. Obviously,

if these bolts come loose, the rack is no longer fully secures the centre

plate and therefore the tierods. Effectively, the steering wheel is losing

its connection with the front wheels. There are supposed to be secured

by the lock tab..but this can be left off by forgetfulness, or the tabs

can be forgotten (not closed), or have a insufficient contact with the

bolts.)

It is hard to perfectly

ascertain the state as the tierods cover these bolts. The centre plate

tierod bolts, must be removed and the tierods moved away top allow these

inner bolts to be examined. Once this is done, pull back the tabs and try

to tighten the two bolts. Once tightened, carefully bend back the tabs.

|

| WATCHPOINT VI Use a white paint marker

to draw a reference line from a point on each bolt to places on the plate

of your choosing. This reference line will make future examinations easy

as you will know in an instant if the bolt has moved if the line on the

bolt and the plate are no longer aligned. |

| WATCHPOINT VII Wheel Alignment. If you remove the

bolts entirely, you will have to reposition them through the gaiter and

then the spacers (by fiddling with the spacers) and then find the correct

holes in the pinion. This will almost certainly change the alignment. Have it checked. |

| WATCHPOINT VIII With

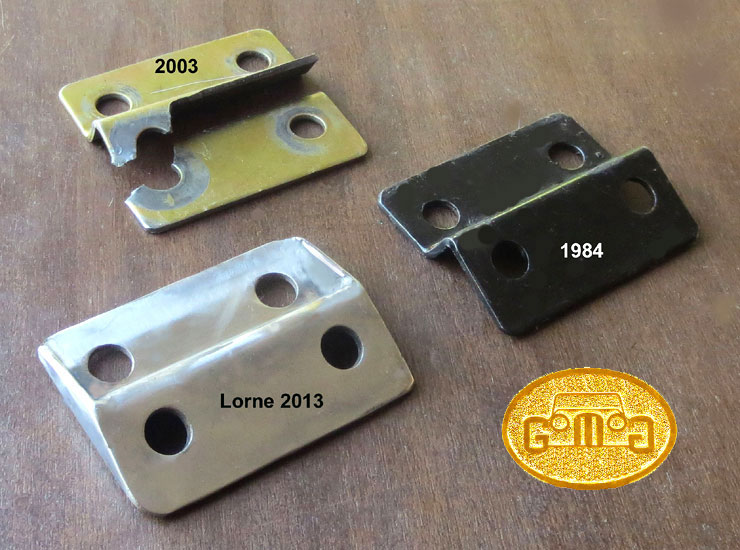

the older style Jack Knight gaiters (approximately 8000 Morgans from 1984

to 2007), close examination will show that the spacer has a round raised

area or that there is a small washer between the centre plate and the gaiter.

This was done to match the holes in the gaiter for the bolts. Without the

raised area or CORRECT sized washer, the plate will clamp the silicone

gaiter and the gaiter will split. If you replace your spacers. |

|

WATCHPOINT VI- TIERODS

TO CENTRE PLATE If you have properly dealt

with the Centre Plate to Rack bolts, you have removed the tierods from

the centre plate. Simply reassemble these, tighten and lock them with the

tabs. Use the paint mark system on these bolts

as well.

|

|

WATCHPOINT VII- BOLTS

THROUGH THE SECURING BLOCKS

Simple. There are two sets

of 2 half blocks that secure the rack to two L brackets on the car's crossframe.

(See the diagram above indicating "rack holder" & cross frame".) Each

half block has a half round centre that together match the rack and two

high grade long bolts going though the two halves into the L brackets.

When assembled the blocks clamp the rack onto the brackets and the frame.

If the bolts loosen, the rack loosens and moves askew with steering and

road anomalies. If the bolts fall out...

Check whether they are tight.

In the normal course, these bolts should not loosen as they are held with

nylocs. However, negligence is always possible and the re-use of nylocs

leads to their losing their ability to lock. One can use new nylocs, or

a bit of loctite blue or ultimately, stover nuts instead of nylocs. If

there is concern, use the same white line reference discussed above.

|

Lubricants

The approved lubricant (which was used in manufacture) is BP Energrease

FG 00-EP since it is a compatible with the application and gaiter material. By 2013 it was no longer available.

Here are alternatives.

Mobil Mobilux 2

SKF Alfalub LGMT

Shell Alvania R2 or G2

Esso Beacon 2

Actually..this

is for very anal sorts. I use any appropriate lube I have around. In my

case, in the Quebec mountains, it is chainsaw oil.

Adjusting

the Jack Knight Rack & Pinion Steering Rack

by David Poole at

the eMog

Pub

The rack is/was produced by Jack

Knight Engineering (UK) which now seems defunct

The following procedure should

be used to adjust the steering rack. There is no specified torque

setting for the adjustment locknut and the manufacturers specify that it

should be tightened “sufficiently to lock the adjuster in place”.

1. Thoroughly clean the area

around the adjustment assembly.

2. Remove the locknut, and

remove and discard the lock washer.

3. If the rack has a significant

mileage, unscrew the adjuster and remove it, together with the nylon follower

and spring.

4. Check that the nylon follower

is free to move within the bore of the adjuster, and that it is not damaged

or worn. If it is, replace it.

5. Replace the nylon follower

in the groove at the rear of the rack, followed by the spring and adjuster.

6. Gently screw in the adjuster

until it bottoms as it makes contact with the rack, and then unscrew it

¼ turn.

7. Place a new lock washer

over the adjuster, with the internal tongue engaged in the rebate on the

side of the adjuster, and the concave side down.

8. Hold the lock washer and

do up the locknut finger tight. Make sure that the adjuster does

not move.

9. Bend the outer tab of

the lock washer that is aligned with the gap at the front surface of the

rack towards the rack housing, so that it that locks the adjuster to the

rack body.

10. Tighten the locknut sufficiently

to lock the adjuster in place, and bend one of the tabs on the lock washer

away from the rack housing and over a flat on the nut.

LUBRICANT

The approved lubricant (which

is used in manufacture) is BP Energrease FG 00-EP since it is a compatible

with the application and gaiter material. The specifications for

the grease are defined below.

BP Energrease FG 00-EP

- Description

Energrease FG 00-EP is a

mineral oil based, polymer-thickened, stable, semi-fluid gear grease. It

contains an anti-oxidant additive and also a sulphur-phosphorous type EP

(extreme pressure) additive. It has excellent shear stability, load-carrying

ability and the coating characteristics that eliminate the risk of dry

start-up.

Application

This grease has been satisfactorily

used by many industries overseas and in South Africa in enclosed spur,

bevel, helical and worm gearboxes. The operating temperature range is -10°C

to 100°C.

Advantages

- Overcomes leakage of lubricant.

- Suitable for a wide range

of gearbox applications, irrespective of the attitude in which the gearbox

is mounted

- Eliminates dry start-up

- Allows extended maintenance

periods

- Exhibits excellent shear

stability, oxidation stability and load carrying ability

- Reduces noise

- Improves reliability

|

| N.B. Adjustment of the rack & pinion

is a rare procedure. Most racks are well set-up at the outset and will

stay that way for many years. Check other area for vibration first and

the bolts holding the rack and those to the center affixing plate. |

WATCHPOINT: On more used R&P Morgans, there

will be wear in the centre of the rack channel which will increase over time. My Jack Knight produced a steering wheel vibration and an up-and-down movement after

37,000kms (23,000 miles) and its seems Quaifes are exhibitting the same

issue. If the play is not attended to or the waer accelerates with the

movement that the owners are tolerating. In a bit, the feedback gets

worse and the rack is unrepairable. This was mentioned on a

mechanically-challenged UK forum but those who noticed it did not

investigate or even remove the gairter hiding the problem area. That

has many owners buy a new rack for

astronomical prices. (Morgan, though they abandonned this steering system (Jack KNight & Quaife) in 2019, the MMC still

has an exclusive with Quaife that prevents Quaife from selling to us

and many Quaife fitted cars are have wearing r&ps by now.

That keeps Morgans profit intact. R&P systems, generic or

otherwise, normally cost 20% of what MMC charge. The far more expensive

new cars (the Plus Four and Six, use these!

However, this wear can be dealt with for very little and

a 30 minute wait (my outlay was a 6 pack of beer) if you have a

decent machine shop nearby. I merely told him to widen the channel a

bit to even it out again and create spacers with a larger outer

diameter to fit as snuggly as the original spacer. That eliminated the

up and down movement and the vibration. It saves an owner many

hundreds, and after, all this is going to be happening again. The

current MMC has boasted that the new Morgans contain only 1.6% of the

components used in the cars up to 2020. Considering the MMC quickly

abandons support of non-current production within a VERY short

time..since the advent of the first Aero. it is prudent to either

stockpile parts you will need in the furture while you can, OR learn how to repair your Morgan.

SEE HERE.

|

Comparing the Jack Knight & Quaife Steering Racks

by

Lorne Goldman 2014

In

1983, Maurice Owen, the Morgan design chief, approached Jack Knight, a

small lot UK designer of automobile parts, to design a rack & pinion

steering system for the Morgan Motor Company. The first was fit, as an

option, in 1983. Some 24 years later in 2007, Jack Knight ran into business

problems suspended affairs for a time. Morgan approached Quaife Ltd, used for some Three Wheeler parts, to

provide a replacement. The newer Quaife unit can be swapped in, without

undue fiddling, to replace a Jack Knight. And the reverse will be true

as well. In recent years, Jack Knight returned to business under some former

employees and has become reliable supplier. That gives owners two options

for their Morgan R&P replacement or special needs.

In

1983, Maurice Owen, the Morgan design chief, approached Jack Knight, a

small lot UK designer of automobile parts, to design a rack & pinion

steering system for the Morgan Motor Company. The first was fit, as an

option, in 1983. Some 24 years later in 2007, Jack Knight ran into business

problems suspended affairs for a time. Morgan approached Quaife Ltd, used for some Three Wheeler parts, to

provide a replacement. The newer Quaife unit can be swapped in, without

undue fiddling, to replace a Jack Knight. And the reverse will be true

as well. In recent years, Jack Knight returned to business under some former

employees and has become reliable supplier. That gives owners two options

for their Morgan R&P replacement or special needs.

Being

interchangeable, it is an excellent time for a review and comparison to

help owners choose if a need presents itself.

Firstly,

both racks are very simple and solidly made. I have never heard of a

Jack Knight (JK) or a Quaife (Q) failure and if someone out there has..please

write

me. Ergo, there is

no known difference in reliability. Amongst

other JKs, I have my original 1984 in spares. At 100,000 miles (with my

first Morgan) I did have to straighten the pinion passage and make two

new spacers to match the widened passage but other than that, it served

me without a problem for over 150,000 miles. However, Qs have

presented no issues either in

the seven years (at the time of this writing) they have been around. I

know only of one failure and it was attached to a bent crossframe.

Of

course, there is a lot of lore available for the JK and none for the Q

as yet. The Q is a factory part and the Morgan world is therefore not informed

of much from them these days. However, the similarities between the two units are

such that a Quaife should not be a problem for a skilled amateur or machinist

to deal with..and that is unlikely to be necessary.

Quaife

Ltd will not supply the the rack to anyone other than Morgan. However,

Jack Knight has lost its Morgan trade and like many of former Morgan suppliers

in that position, they now supply the community direct. Though the quality

of the two racks is comparable, JK units can be had at a fraction of the

Quaife cost, and if JK has its act together when you call, you will receive

it in much less time. (They now have a well laid out web

site with online buying.

Quaife

comes in one version..3 turns to lock. A Jack Knight R&P can be had in many

versions to better suit each driver, 2.3, 2.7, 3.0 or 3.5.

And for the many Superform

wing cars where the front wheels rub and blister the paint, Jack Knight

can customize a rack to prevent the wheels from doing so.

A JK can also be easily converted from RHD to LHD or vice

versa. We are told that, so far, the Quaife cannot be converted. That doubles

the potential market for a JK over a Quaife. N.B.

Morgan's new dealership

contract prevents dealers from selling any other rack than a Quaife.

July 2020. I have the necessary information now to write and article on

how to do the swap. Watch this space.

One advantage of the Quaife over the JK is the gaiter. Morgan

used a flimsy silcone gaiter for the JK for many years. They can split

if you stare angrily at them! (wry smile) Quaife's come with a large metal

center plate and gaiters that are tougher. However, Jack Knight designed

a similar gaiter to that of Quaife for their units. I suggest you buy it for your

JK, (if you can find and convince JK to produce one for you.

R&P Watchpoint

(1984 - present) Updated January 5, 2018

Revisited 2023

from Lorne Goldman on Morgan Addicts

THE TWO PART PROBLEM

Please

read other R&P articles

PART 1 The most crucial parts

in a car are NOT the most expensive ones. Those can only hurt your

pocket book. The crucial parts are the ones that most effect the safety of

the occupants. Normally, they are found in the following assemblies, tyres, brakes and steering. These are the systems that preserve your control of your car and therefore your life.

Of these, of all of these, it would be difficult

to argue that there is any as critical as the cheap little plate at the center

of the Morgan Rack & Pinion steering.

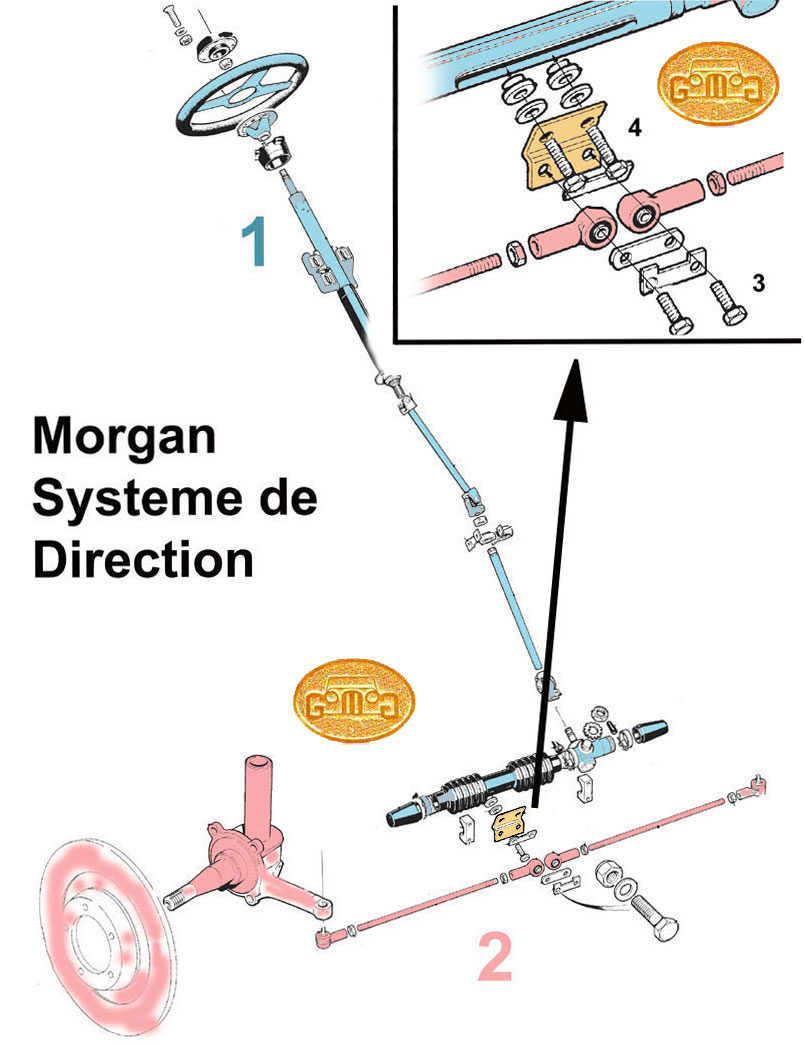

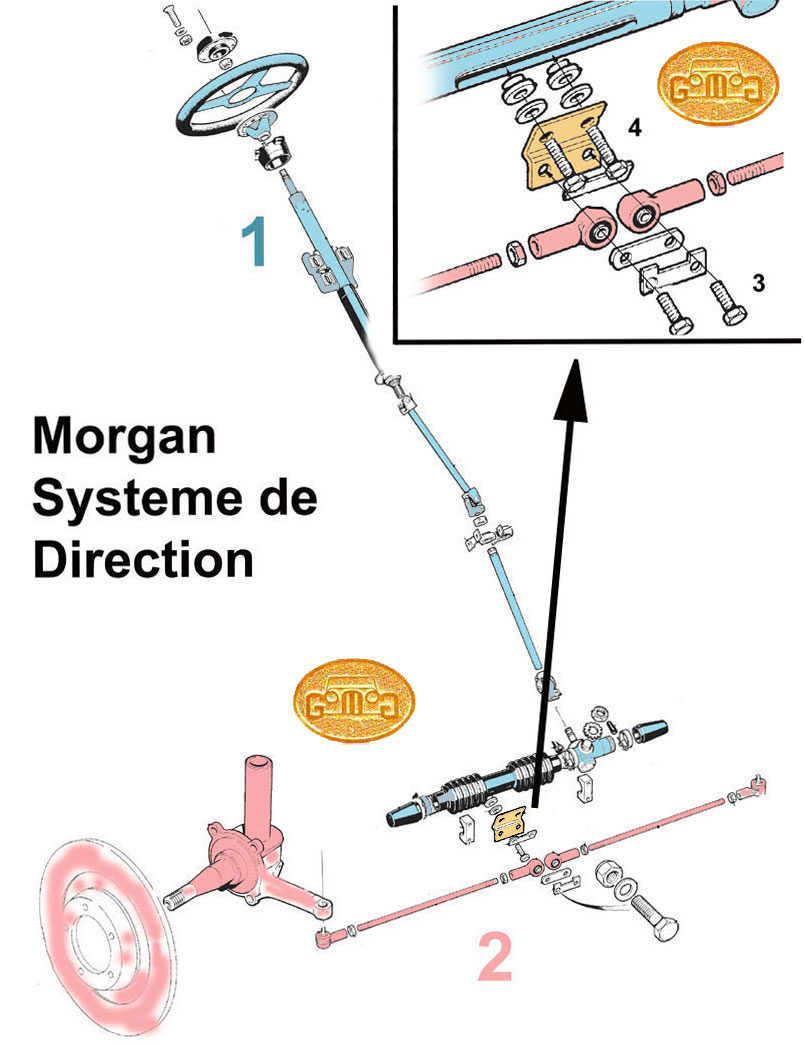

Examine the Jack Knight R&P steering

system to the right. The front wheel assemblies (tyres, wheels, brakes,

bearings, stub axles, tie rods (#2

shaded red) are all bolted (#3) by a single plate (#4

shaded brown) to the steering rack (#

1 shaded blue) , column and the steering wheel. On the Jack Knight cars (1984-2007)

it is part # MSR0287 and they call it the "steering rack mounting

bracket". On the Quaife R&P (2007 to present) it is part # H-2M1-05 which is identical, so the problem

seems to have been inherited from one steering system to another, unchanged in 35 years and counting. Sad stuff, but there you have it. Here are diagrams for the Quaife.

Examine the Jack Knight R&P steering

system to the right. The front wheel assemblies (tyres, wheels, brakes,

bearings, stub axles, tie rods (#2

shaded red) are all bolted (#3) by a single plate (#4

shaded brown) to the steering rack (#

1 shaded blue) , column and the steering wheel. On the Jack Knight cars (1984-2007)

it is part # MSR0287 and they call it the "steering rack mounting

bracket". On the Quaife R&P (2007 to present) it is part # H-2M1-05 which is identical, so the problem

seems to have been inherited from one steering system to another, unchanged in 35 years and counting. Sad stuff, but there you have it. Here are diagrams for the Quaife.

A

quick examination of the diagram shows that this little bent plate (an

in-house part) is the heart of the system's security and integrity. A. If

even one of the inner plate bolts break, the plate will only be held to the

rack by a single remaining bolt and the steering will be prejudiced. B. If

one of the outer bolts holding the tie rod ends, one wheel will not longer

be attached to the steering system. C. Happily the newer bolts are graded and held with

with lock tabs and nylocs. However, the plate itself has been known

to sheer along the fold lines without any prior indication. The result will most likely be horrific as one or both front wheels will detach from the steering system and splay outward. It

happened

to me at the end of one of the finest Morgan days I ever had! A

fantastic 780 mile drive and just as I was entering my

garage! I finished the trip with my wife and daughter at each of the

front wheels steering them by hand into my workshop. I do not recall

any extraordinary impact on that trip but I did notice the steering had

become sloppy in the last 30 miles (by that time the plate was likely

held together by bolt pressure only. However, it was night time by then

and I was close to home. That was a stupid mistake..only covered by

insanely

good luck! And I do NOT like relying on luck.

REDUX I was told once that my dear friend Button has mused publicly that something has to be amiss in this watchpoint.

Namely that my photos are suspect as he has never experienced this

phenomena with his r&p. Bill has never had an R&P. :) Button has offered this sort of

thing before with other of GoMoG watchpoints

that have saved people's lives. He does not do this with ANY malice and

I only wish dear Button was herel! The fact is that I do not

recall any event on that trip which was unusual to my 250,000 miles of

mogging on two continents (Europe and America). Of course, I had a road

clunk or two over the 1800 miles of back roads on that trip but nothing

out of the ordinary, and the state of my suspension is

legendary...(though achievable by anyone with a standard Morgan who

wishes to follow this manual.) In any event, this plate should

never fail NO MATTER WHAT the road anomaly. Of course, I have run

across this mishap with others since..and, as well, it must be

pointed out that dealers are always reluctant in this new era to get in

trouble with the Factory by going on the record. I cannot count the

times over the last 25 years, the more concientious Agents have

enlisted me to speak for them. Many of these warnings have now been

incorporated into Morgan lore and the production line.

This is time for remembering one of the most important GoMoG Laws.

| THE GOMOG LAW OF WARNINGS: As I taught my beloved chidlren (now adults), there

are warnings you can question and ignore because even if they occur they

can only cause annoyance. Then there are other warnings, if ignored, that can

cause dire tragedy with one incident. If there is no downside, always

believe and act upon the latter when it causes you no effort or cash

to respect. After all, what is the downside? Just adding the gussets is virtually costless. |

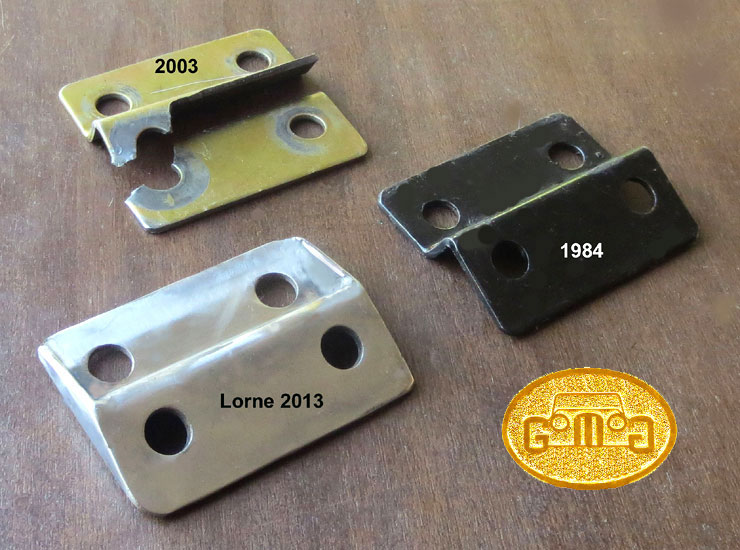

With the help of metal and mechanical experts and MMC dealers, I found out the cause. These plates likely break because they are improperly cold-bent and subsequently become vulnerable at the bend. When steel is cold

bent, its yield stress increases and its ductility decreases. Ductility

is a metal's ability to deform under tensile stress. Residual stresses,

enbrittlement, spring-back, reduction in toughness and curl are also common

problems of cold-bending metal. Cold bending can cause strain-aging. Dynamic

strain aging occurs during bending. But

whether hot or cold bent at Morgan, it sheared. And this is

not something that has to be brought my attention twice. There are

parts that can fail many times and merely cause annoyance. This is not

one of those. It must be addressed.

More importantly. Now I know

that these plates can break BEFORE any other part in the entire steering

assembly, belying the basic design principle that the most crucial part

in any assembly should be the one that fails last. On the other hand, as

it should be the last to fail, it can be strengthened to any degree without

effecting other parts or the Sequence of Failure.

MY SOLUTION:

Unlike so many of the Morgan aftermarket predators that have

appeared in the last decade, I favor simple bullet-proof

non-invasive solutions, in keeping with a 1930s (Golden Age of Automolbiling) technology car.  I

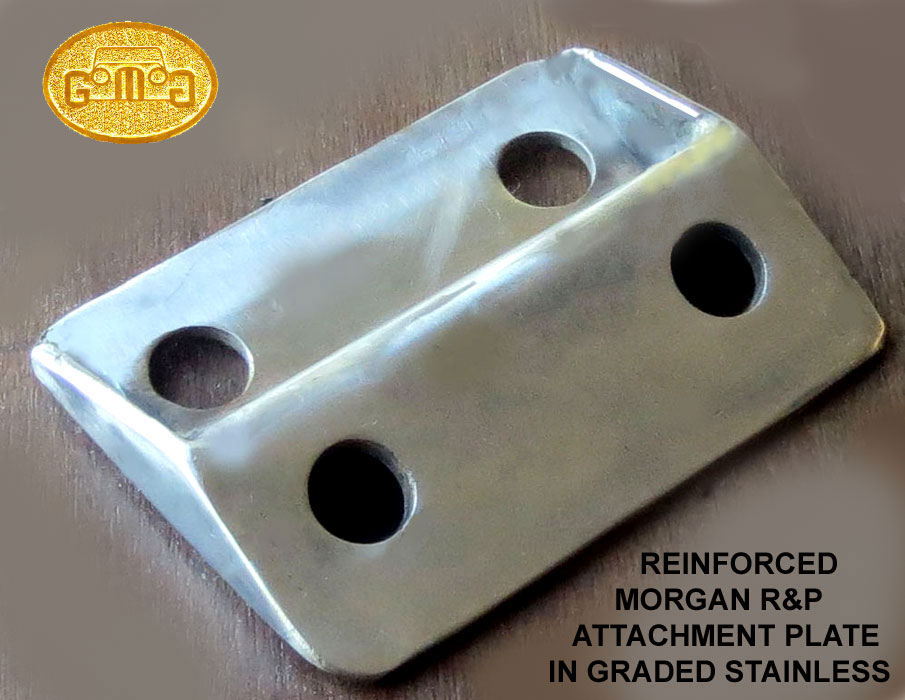

had an extra center plate left from an earlier R&P Morgan but I

intensely

dislike using a part that I know now is capable of failing,

disasterously. How many times does a disaster have to occur to be

tragic?!!!) So I designed

something more far more substantial and smarter and made it up. I replaced the

plate with a new center

I

had an extra center plate left from an earlier R&P Morgan but I

intensely

dislike using a part that I know now is capable of failing,

disasterously. How many times does a disaster have to occur to be

tragic?!!!) So I designed

something more far more substantial and smarter and made it up. I replaced the

plate with a new center  plate

using a stainless steel grade more capable of sustaining ANY possible stress or

impact that the steering assembly could possibly encounter or produce over time or wear. .

plate

using a stainless steel grade more capable of sustaining ANY possible stress or

impact that the steering assembly could possibly encounter or produce over time or wear. .

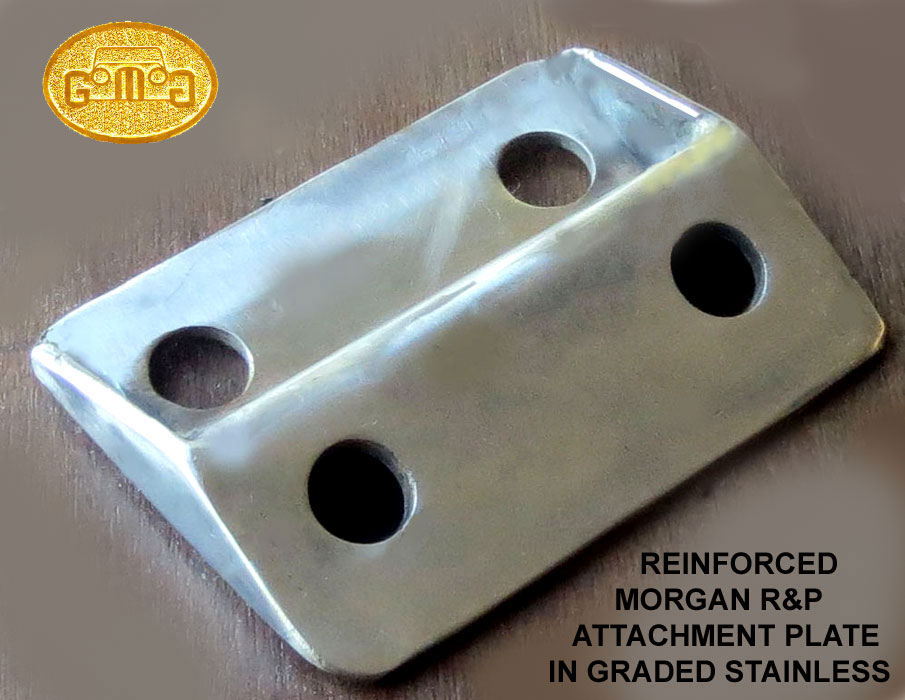

I

chose Type 304 stainless steel as it is rust

resistant, durable and far more likely to bend than shear like the

Morgan part. It is easy to make at home or small machine shop

fabrication. It is easy to clean. It can be polished to a mirror finish.

I

also increased the stock used to 4 mm rather than the 3 mm (1/8"?)

stock Morgan used for the original.

I also reinforced the plate I by welding on side gussets to reinforce the

bends and I heated the bends before shaping them. My end product is

MUCH stronger than

the MMC affair. I no longer worry about a reoccurence.

Lastly, I tapped the lower holes and welded graded stainless steel stoffer nuts at the rear of the holes. See Below. This is a foolproof way of preventing the plate from losing its bolts.

It is overbuilt, but that is what common sense dictates with any

component that is as life-important. That will eliminate the need

for lock tabs or wire on the lower bolts but I will still use Loctite

Red or Green. Please

note that even the smallest movement of the bolts within the plate bolt

holes can affect your wheel alignment. Please have checked them any time

your remove the plates or its bolts.

PART 2

This was added after the part of the article above brought the customary

wave of article feedback. It allowed some light to shine on why plate shearing

is rarer than one should have thought it would be. It showed that there

IS a possible spot that will fail before the plate and is likely inter-related.

The feedbackers, who had rushed to check their plates, did not notice anything

amiss with any. Of course, it would be only by very lucky coincidence

that someone would catch a plate before in the process of shearing. It

is a process that takes very little time from start to finish so there

is normally little if any warning. However, many souls have reported that

there was play at the steering wheel and/or they discovered their lower

bolts on the plate, those holding the tierods, had loosened significantly,

despite the lock tabs being installed properly. Here is an example.

Video

1

Video

2

The

sequence seems apparent. If the nylocs ARE capable of holding (with the

application of the right loctite or with lock tabs of their own)

then the entire stress is transferred to the plate itself, and, in some

cases, it shears. Neither event are happy results as the control of the

car is lost.

Stover

Self-Locking Nut Stover

Self-Locking Nut

Stover Nuts are vibration

resistant self locking nuts. Stover Nuts are vibration

resistant self locking nuts.

Advantages:

1. The self locking function

of the Stover Nut is still effective after a number of applications, hence

it can be used many times.

2. The Stover Nut is an

all

metal Stiff Nut (available in graded metal).

3. It is resistant to shocks,

vibration and dynamic loads.

4. The locking function

of the Stover nut is achieved by the deformation of part of the nut and

it does not rely on nylon.

5. It has a much lower profile

than nylocs or regular nuts with lock washers.

I use stoffer nuts to replace

the untorquable nylocs the MMC use in critical areas. These include the axle u-bolts

(where proper axle nuts cannot be be used for clearance reasons and the

nylocs loosen as a sad tradition. I also use them at the propshaft.

N.B. A stoffer nut will run smoothly

until it reaches the deformed part after which the clamping force will

subsequently increase and require effort to thread.

|

|

SEQUENCE

of FAILURE: All

moving parts fail..eventually. So ideally, parts in any assembly (and each

individual assembly itself) should be designed and made to fail in a specific

sequence, with the most critical parts failing last. In this way, safety

is enhanced and damage pre-controlled. That is why we are so often instructed

to replace many parts in an assembly when one fails. In doing so,

we are trying to preserve the proper sequence of failure.

However, amateur (and often

"professional" mechanical designers will often replace a failed part with

something much stronger they have made themselves. Without careful examination

and understanding, that replacement can change the sequence of failure

and increase the risk of much greater damage.

|

Bump

Steer

by Lorne Goldman

I

imagine this bit will also cause protests in some corners. I acknowledge that there have been many

who have written sagely and with great solemnity on this subject. They

have pondered for decades on such sundries as to whether the tie-rods

should be afixed atop or below the stub axle arms, or how much longer

the rods should be to minimize bump steer.I am sorry for them for this bit. Indeed, many in the new predatory

aftermarket have convinced owners to spend silly sums of money and

effort curing it. Even the older significantly more honest aftermarket will sell cures (much less

expensive) to those that have been convinced

to fret about it. But they confide to me that their cures are out of

kindness and a recognition of the psychological relief they provide.

(wry smile)

However, the truth

of the matter is that the famous flexing of the Morgan chassis makes

bump steer unimportant..a non-issue..or at least impossible to deal with aside from car by car.

Whenever

they-who-wish-to-apply-other-automotive-technology consider the

Morgan suspension

and steering, they omit to factor in the impossible-to-quantify, namely

the flexing of the chassis.

This flexing not only varies from chassis

to chassis, car to car, it also changes with each model and each car

over time/usage. Measures that are designed for one car will not help

another except by coincidence. It may even cause a prejudice.

Imagine designing something for an old well-used 4/4 and

transferring it to a later heavier Plus 8 or Roadster!! However,

the newer "experts", are reluctant to admit or even acknowledge

the most salient and influential component on the car. The chassis and

the open top which have to individualize every car. But individual cars

cannoit generate one-size-fits-all profits...so the convince the market

that all Morgans are identical.c They

plunge

ahead, trained and limited by an education and training that applies

to the type of chassis

of other vehicles use.

Indeed, sometimes their kit will be an improvement to a varying degree

from car to car, sometimes it will add nothing and just as often it

will prejudice the suspension.

It

is for you to decide, for yourself, whether you think all Classic

Morgans are a bit different or identical. Ask THAT question of your

peer group! Sadly, these things have become "poltical" rather than

decided by common sense. Too little savvy and too much money.

:(

There

is a wonderful Peter Morgan anecdote that is germane. Some 70 years ago

he fit shocks to the Morgan front, fit alongside the kingpin springs,

just as they are today unchanged since then. When asked whether

they improved the handling or the ride, PM shrugged, indicating they

had no effect that he could discern. But he confided that buyers were

concerned as they saw them on other, different cars..so he slapped

them on. ;)

One day, for your own amusement and in memory of Peter Morgan, remove your front dampers and go for a test drive.

very rare occasion it can require adjustment,

which

is dealt with by David Poole in his great eMog posting, and after much mileage

the rack channel and spacers may require redressing, and easy job for any

machine shop. I have had a full refurbishing done in the UK for 75£s;.

very rare occasion it can require adjustment,

which

is dealt with by David Poole in his great eMog posting, and after much mileage

the rack channel and spacers may require redressing, and easy job for any

machine shop. I have had a full refurbishing done in the UK for 75£s;.

Examine the Jack Knight R&P steering

system to the right. The front wheel assemblies (tyres, wheels, brakes,

bearings, stub axles, tie rods (#2

shaded red) are all bolted (#3) by a single plate (#4

shaded brown) to the steering rack (#

1 shaded blue) , column and the steering wheel. On the Jack Knight cars (1984-2007)

it is part # MSR0287 and they call it the "steering rack mounting

bracket". On the Quaife R&P (2007 to present) it is part #

Examine the Jack Knight R&P steering

system to the right. The front wheel assemblies (tyres, wheels, brakes,

bearings, stub axles, tie rods (#2

shaded red) are all bolted (#3) by a single plate (#4

shaded brown) to the steering rack (#

1 shaded blue) , column and the steering wheel. On the Jack Knight cars (1984-2007)

it is part # MSR0287 and they call it the "steering rack mounting

bracket". On the Quaife R&P (2007 to present) it is part #  I

had an extra center plate left from an earlier R&P Morgan but I

intensely

dislike using a part that I know now is capable of failing,

disasterously. How many times does a disaster have to occur to be

tragic?!!!) So I designed

something more far more substantial and smarter and made it up.

I

had an extra center plate left from an earlier R&P Morgan but I

intensely

dislike using a part that I know now is capable of failing,

disasterously. How many times does a disaster have to occur to be

tragic?!!!) So I designed

something more far more substantial and smarter and made it up.

Stover Nuts are vibration

resistant self locking nuts.

Stover Nuts are vibration

resistant self locking nuts.