Green Rouge

Primarily used in final finish buff operations on stainless steel, steel, brass, aluminum, nickel, and chrome. The green rouge is a chrome oxide, and is considered the best all around luster compound.

White Rouge

The white rouge is the softer than green rouge. Primarily used in the final finish of steel, stainless steel, and zinc. This compound is also a favorite in coloring aluminum and brass.

Red Rouge

Primarily used in the final finish of gold and silver, it is the finest of all rouges. It also produces an excellent finish on brass.

Stains &

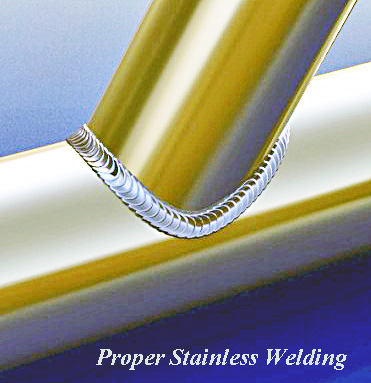

Rust with Stainless Steel Welds

by Lorne Goldman November 2009

I have often received inquiries

on why Morgan stainless steel (ss) welds discolor and can even rust at the

sites. The reasons are quite simple and well-known to most properly trained

welders. The surface discoloration on stainless steel after welding

or even after grindingis oxidation. At too high

a temperature, the stainless steel will combine with oxygen to form an oxide

layer on the metal surfaceor within the weld. The color of the "stain"

is a function of the layer thickness. This will also vary with the type

of stainless chosen. The oxidation indicates that the metal temperature

when welding was too high..probably in excess of 500C when 315C would have

done better, been much stronger and looked like a jeweler had a hand in

it. OR it could also be a unwise choise of stainless welding wire or a combination

of these factors. It is a simply matter to try different heat and stainless

types to determine what will be idea. Improperly chosen equipment can also

make a decent weld more difficult.

I have often received inquiries

on why Morgan stainless steel (ss) welds discolor and can even rust at the

sites. The reasons are quite simple and well-known to most properly trained

welders. The surface discoloration on stainless steel after welding

or even after grindingis oxidation. At too high

a temperature, the stainless steel will combine with oxygen to form an oxide

layer on the metal surfaceor within the weld. The color of the "stain"

is a function of the layer thickness. This will also vary with the type

of stainless chosen. The oxidation indicates that the metal temperature

when welding was too high..probably in excess of 500C when 315C would have

done better, been much stronger and looked like a jeweler had a hand in

it. OR it could also be a unwise choise of stainless welding wire or a combination

of these factors. It is a simply matter to try different heat and stainless

types to determine what will be idea. Improperly chosen equipment can also

make a decent weld more difficult.

Sadly, the high heat also destroys the anti-rusting

elements in the stainless and weakens the metal eventially causing rust

and breakage. Trying to grind off the

discoloration or rust makes the weld even weaker. Polishing can sometimes

correct the aesthetic effect but will not otherwise address the damage caused

by the welding.