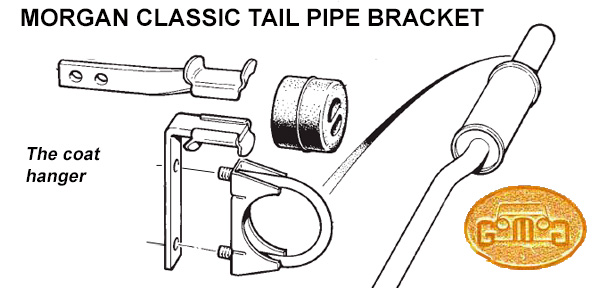

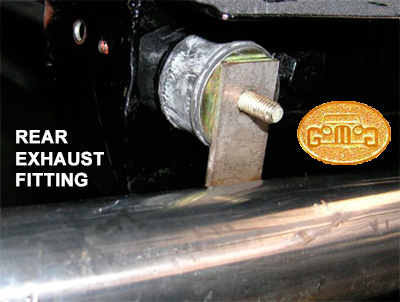

bracket attached to the chassis

through a large rubber doughnut that is forced onto both pieces. For those of you unfamiliar with the system, I have

attached a diagram to the right.

bracket attached to the chassis

through a large rubber doughnut that is forced onto both pieces. For those of you unfamiliar with the system, I have

attached a diagram to the right.

Happily, common sense is/was common in Market Drayton, UK, the home of the restorer of one of my Plus 8s,

Kevin Vernon of Tudor Motor Body Repairs Ltd. Kevin, like yours truly,

enjoys simple solutions. Simplicity, reliabilty and functionality are

the highest accolades for anyone who deals with

machines, especially Morgans! Where other owners seem to enjoy making

their Morgans more complex and less reliable with addons, I choose to go in the other direction, upgrading

bracketry and making the car simpler, distilling its essence.

After 200,000 miles of such an attitude, my Morgans finally became the most reliable vehicles I have ever known. Kevin's idea is bullet-proof, lasts forever, and is easy to remove or install. As

Happily, common sense is/was common in Market Drayton, UK, the home of the restorer of one of my Plus 8s,

Kevin Vernon of Tudor Motor Body Repairs Ltd. Kevin, like yours truly,

enjoys simple solutions. Simplicity, reliabilty and functionality are

the highest accolades for anyone who deals with

machines, especially Morgans! Where other owners seem to enjoy making

their Morgans more complex and less reliable with addons, I choose to go in the other direction, upgrading

bracketry and making the car simpler, distilling its essence.

After 200,000 miles of such an attitude, my Morgans finally became the most reliable vehicles I have ever known. Kevin's idea is bullet-proof, lasts forever, and is easy to remove or install. As  well,

it uses parts that can also be used in other areas of the Morgan, at the silencers and to hold the radiator. That cuts down

on needed spares one must carry on long distance mogging! Please don't

replace the doughnuts. Save yourself the hassles and do the

modification.

well,

it uses parts that can also be used in other areas of the Morgan, at the silencers and to hold the radiator. That cuts down

on needed spares one must carry on long distance mogging! Please don't

replace the doughnuts. Save yourself the hassles and do the

modification.  For

those without the skills, the contacts necessary to align their tailpipes or have a tab spot welded to

tailpipe, this may be the cheapest solution.

Librands, an aftermarket supplier (now under new management

rather than the founders, the Bourne/Wells aka BHM/LibraMotive design team) sells a copy of the Kevin Vernon idea I use

combined with a variation on the original Morgan Factory system. It

allows for the pipes to remain splayed outboard and involves and amazing nine (9) parts

for each tailpipe (nuts, bolts, adjusting plates, clamps, outboard

brackets)! See the image to the left. HOWEVER, it does get rid of the doughnut (s). 50£ in stainless steel plus shipping.

For

those without the skills, the contacts necessary to align their tailpipes or have a tab spot welded to

tailpipe, this may be the cheapest solution.

Librands, an aftermarket supplier (now under new management

rather than the founders, the Bourne/Wells aka BHM/LibraMotive design team) sells a copy of the Kevin Vernon idea I use

combined with a variation on the original Morgan Factory system. It

allows for the pipes to remain splayed outboard and involves and amazing nine (9) parts

for each tailpipe (nuts, bolts, adjusting plates, clamps, outboard

brackets)! See the image to the left. HOWEVER, it does get rid of the doughnut (s). 50£ in stainless steel plus shipping.| GoMoG Law of Invention: The more parts your invention has, the more likely the risk of breakage and aesthetic prejudice. |