How to Test an Ignition Coil

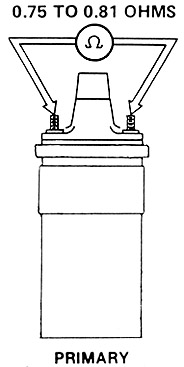

This testing procedure is valid for just about any automotive

coil. Using an ohmmeter, check the resistance between the side terminals

of the coil. Do this with all of the wires to the coil disconnected. You

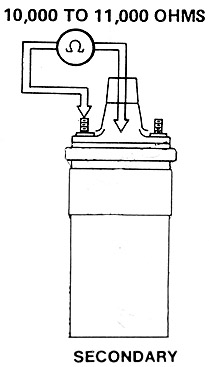

should see 0.75 to 0.81 ohm of resistance. Then check the resistance between

either side terminal and the center high tension terminal. The reading

should be 10,000 to 11,000 ohms. Any significant deviation from these numbers

would indicate that the coil is defective.