TOP

OF TIMING CHAIN COVER

TOP

OF TIMING CHAIN COVER

Let's examine this very important component of the engine for weaknesses and possible solutions. The Rover V8 timing chain cover is not simply a cover but a component frame. It holds the distributor, its shaft, the oil pump and is the place where the water pump is affixed to. The more you ask a component to do the greater the likelihood of problems and the higher the cost of the item. This timing chain cover has a new replacement cost of approximately $700.00 US. On the other hand, considering it is made of cast alloy I cannot see a reason for replacement beyond the damage caused from an accident and that would have to be a bad one.

THE TIMING CHAIN

The standard Rover timing chain is not good. It's one virtue is that it is quiet. It is a single chain system with a nylon cam gear and one keyway on the crank gear. They ALL stretch and after 50-70,000 kilometers it can hang like a wet rag. A stretched and loose timing chain makes timing imprecise, combustion less than optimal and you will have difficulties finding a smooth idle. It also does nothing to help restrict camshaft "walk" which in turn creates a situation where either the distributor drive gear on the camshaft or the matching distributor gear chips which throws off the timing even further or can even cause your distributor to fail.

Your solution here is to upgrade the timing chain system. You can cheaply change the cam gear to an all steel version or upgrade even further to an all steel "vernier" version which makes camshaft phasing very easy. Your best bet is to replace gears and chain. Cloyes, Kent Cams, and J.E. Engineering all have excellent products with duplex (double) pre-stretched chains. Some of these may require a slight modifications to the timing chain cover to alloy for the slightly wider width.

TOP

OF TIMING CHAIN COVER

TOP

OF TIMING CHAIN COVER

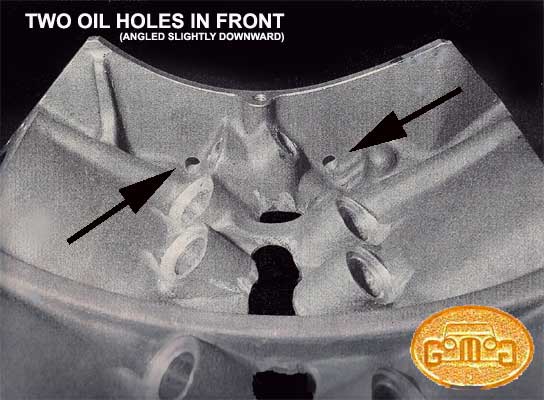

The arrow from the left points to a small (16mm) node that must be ground down normally 2mm. Supposedly this node rests on the camshaft gear rim and holds the gear in place. I have doubts as to the success of this design and there is a better solution in this article further on.

CAMSHAFT "WALK"

There is obviously no problem with movement of the timing

chains crankshaft gear which is bolted firmly in place. However, if one

looks at the larger camshaft gear this is bolted to the camshaft itself

which has nothing to restrict its lateral movement saving the lifters and

the timing gears. The little node shown above is supposed to restrict movement

but it was never precise especially when you start cutting to accommodate

a better timing chain. The best solution to this is a camshaft thrust button

which takes  the

place of the bolt locking the camshaft gear onto the camshaft. It has an

adjustable-length and a nylon or polished steel "face" which can be easily

adjusted to act against the inside of the front of the timing chain cover

to limit any camshaft walk.

the

place of the bolt locking the camshaft gear onto the camshaft. It has an

adjustable-length and a nylon or polished steel "face" which can be easily

adjusted to act against the inside of the front of the timing chain cover

to limit any camshaft walk.

OILING

Perhaps as a result of the search for solutions to the effects of design and component flaws described above, there have been methods discovered to improve the timing cover oil flow and the oiling of the distributor gears in the timing chain cover.

The first (and the most popular because it is costless) is to drill two holes in the front of the lifter gallery. These holes pass directly through into the timing chain area and all for a better flow of oil. The second is to drill a hole in the oil pump cover for an external oil feed and pass the feed into a like hole drilled to the side of the timing chain cover to feed oil to the distributor drive gears.

Both seem good ideas and harmless if not.

This was written by a man named Jim Allen (jimallen@onlinecol.com). It is an excellent and authoritative description of the cam wear problem in our stock 3.5 liter Rover V8s. It's worth reading.

For about 4 years, while I worked at a Rover dealership ('87-93), we had a cam wear problem on 3.5L engines. It dated back a ways (prior to the USA intro), according to many sources, and was common on any engine with the "detox" or "low lift" cams (the NAS '87-88 3.5L had the low lift cams). To a much lesser degree, the other 3.5Ls were affected as well.

| WEBMASTER: These models were fit with a nylon timing chain. Though they were very quiet, they quickly stretched and caused and variety of problems..excessive cam wear, cam gears would break, the timing would be uncertain. I recommend replacing the stock timing chain.You are better off to consider a duplex chain, but one other than Cloyes. (here have been issues reported.) I use a JP DUPLEX TIMING CHAIN SET. |

Most engines affected

We discovered the problem while repairing a rash of intake manifold coolant leaks. The bad lobes were often readily visible. After that we started checking when the engine was down. The earliest cam failure I saw was at 1,100 miles but I have torn apart about 50 NAS 3.5L engines in my career and only a handful did not show abnormal wear.

The 3.9, 4.0, 4.2 and 4.6L engines seem immune to the problem to a large degree, due to better designs and manufacturing. In the course of doing an article on cams a few years back, I queried 8 cam manufacturers, including some in the UK, about the problem. I was told it was due to two situations; the small diameter of the cam (which leaves less surface area when the profile is ground) and poor heat treating. Lack of maintenance, internal coolant leaks or subgrade oil made the problem worse. The surface area problem was solved by using more of the material in the blank when the cam was ground and the heat treating was improved.

Check with dial indicator

As to checking, the bad lobes can be identified visually but if you don't know what to look for by experience, you will only spot it when it gets very bad. The best method with an assembled engine is via a dial indicator. You will need to remove the rocker arms to do this, as the lifters will bleed down via valve spring pressure and give inaccurate readings. You can use the pushrods to measure from. Put the cam on the center of the heel to zero the dial and then rotate the engine to the peak lift point and record the results. Test each lobe a couple of times until you can dublicate the results exactly each time. Since the hardening is little more than .010-012" thick, if the readings vary more than that, lobe to lobe, you are into the soft stuff somewhere. Also, you can compare the reading to the lift specs in the manuals. If you have a cam out, you can mike the lobes, compareing differences between the lobes or to a new cam of the same grind.

Bad timing!

from Century Rover

As to checking timing chains, I tested the cam timing of about 30 vehicles in the course of my Rover dealership work. Any time I had the front cover off and had a few extra minutes, I checked with a degree wheel.

I was curious as to why one engine could be a rip-snorter and the next a dog. I found that only five or six of the engines I tested were at, or close enough to, the factory spec. About a third were advanced a few degrees (up to about 4 degrees- making them the rip-sporters) and the rest were retarded (the dogs) to varying amounts (up to 8 freaking degrees). Going farther, I checked to find where the errors came from and found that every cam I checked was dead on and the end result was that the timing gears were the cause. The keyways were machined incorrectly. After that, I did not trust the factory timing gear. The few (maybe two) I replaced under warranty (no, they would not replace the units for timing errors unless the engine was grossly effected), I checked for accuracy and swapped sets with the parts dept to get a good set. If the customer was buying, I installed a Cloyes True Roller set**. I know of one customer who could feel the difference, seat of the pants!

| WEBMASTER: You are best to consider a duplex chain, but one other than Cloyes. There have been issues reported. I have tried four and now use a JP DUPLEX TIMING CHAIN SET. |