baby

cheap M80 with cones centre not the expensive hydratrak. Most 6 cylinder

cars used an M75 beam or M76 IRS while most v8 cars use an M78 Beam

axle. There is little difference to the LSD centre in any of these axles.

baby

cheap M80 with cones centre not the expensive hydratrak. Most 6 cylinder

cars used an M75 beam or M76 IRS while most v8 cars use an M78 Beam

axle. There is little difference to the LSD centre in any of these axles.

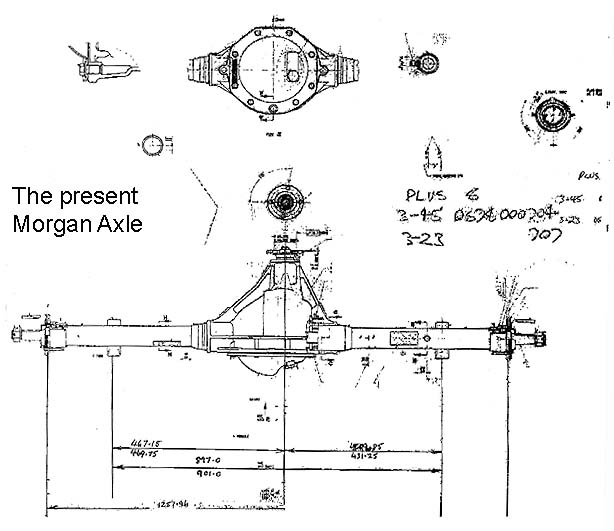

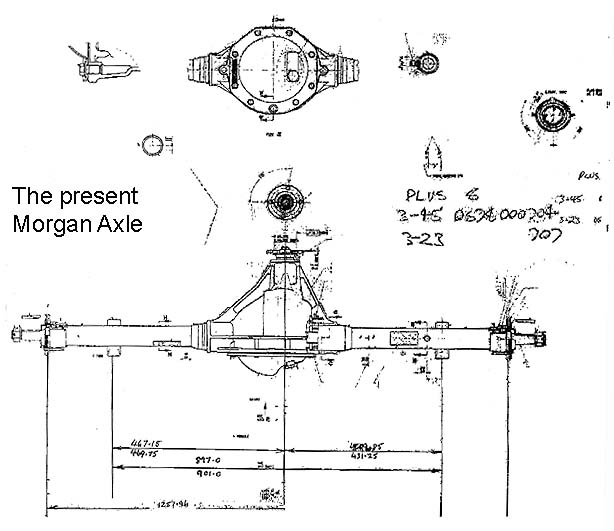

The BTR axle in the

Morgan

cars has been used by every manufacturer of cars in Australia from

about

1966 onwards. It is a bit misunderstood by many in markets where it

wasn't

as common. Its inherent strength comes from excellent materials used in

manufacture rather than over engineering and bulk. There have

been many takeovers and restructuring that some Morgan people

cannot get confused about where they are made. Click here. These axles are from their

M range. The Morgan uses an M76. This is a misnomer as its an M78 housing

with an M75 sized ring gear as far as I can tell, the usual M76 is

an IRS unit like a  baby

cheap M80 with cones centre not the expensive hydratrak. Most 6 cylinder

cars used an M75 beam or M76 IRS while most v8 cars use an M78 Beam

axle. There is little difference to the LSD centre in any of these axles.

baby

cheap M80 with cones centre not the expensive hydratrak. Most 6 cylinder

cars used an M75 beam or M76 IRS while most v8 cars use an M78 Beam

axle. There is little difference to the LSD centre in any of these axles.

The M75 and the M76 both use a 7.5 inch crown wheel. The M78 uses a 7.75 inch crown wheel but the inside diameter of the crown wheel is the same and the LSD unit is the same apart from ring-gear bolt handedness and size. The LSD unit is a cone unit designed by Borg Warner in the 60s in the US and manufacturered in both the US (Chrylser/Dana) and Australia (Borgwarner/BTR/Spicer) under different guises. Borg Warner Australia Ltd became BTR engineering and then became part of Spicer Axle Australia who are part of Dana Corp just like Salisbury in the UK now is Motospecs Sydney and are the world wide distributors of Spicer Axle Australia parts, they employ a number of ex-BTR and Borg-Warner people and have agents around the world, including the UK. The same design of LSD centre was used by Chrysler during the 60s and 70s for their 7 ¼ 8 ¼ and 8 ¾ inch differentials.

Not all Mopars got a plate clutch LSD unit. On the other hand, the cone units are all the same Borg warner design inside. As such you can use the Chrysler/Mopar Sure Grip additive available from any Chrylser main dealerin any standard differential oil and NOT have a chattering LSD.

The M75, M76 axles used in

Ford Falcon and Holden Commodore (from model VN to VS series one, 6 cylinder

cars) is a good source of crown wheel and pinions and LSD centres.

The M75 was used in Australian Ford Cortina, the Ford Escort and the Australian

Nissan Pintara. The 28 spline 4 spider gear LSD unit M78 was also used

in the Camaro IrocZ from 86-92 . The Camaro people in the US call

it a GM 9 Bolt Diff. The M78 was used in Ford Chrylser valiant and GM Holden

V8 cars.

| Any M75, M76, or M78 housing can be cut to length and fitted to your Morgan if you use your original axles and the LSD unit you choose is a 28 spline half shaft unit. |

You won’t fit M78 crown wheel and pinion in an M75 housing easily although it can be done. You can, of course fit, the M75 and M76 gears into an M78 housing. Gear sets fit series 2 LSD unit 2.77:1 and some 3.08:1

Or

In the Series 3 unit: 2.92:1 some 3.08:1 3.23:1 3.45:1 3.5:1 3.89:1 3.9:1 4.11:1 (but some use smaller crown wheel bolts than others.)

The Series 2 unit has 1 mm tall pedestals for the LSD case half bolt heads to clamp down onto (check the rear of the ring gear mounting flange for the case half bolt heads).

Series 3 units have a 5 mm pedestal. Check before purchasing a new one so you get the correct one for the gear set you want as the series 2 ring gear flange is offset 5 mm to the left from the rear of the car to fit in the big pinion gear on a 2.77:1 gear set

| BTR Units, RATIOS & OFFICIAL LIMITS | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

G & J Differential Services in Dandenong Victoria can supply spares

Craft Differentials in Sydney supply spares

9bolt.com in the US supplies spares

Yukon & Strange in the US supply master install kits and 3.7:1 aftermarket Ring and Pinion

TA Performance supplies a cast alloy cover and girdle

SAA Spicer Axle Australia expanded diagrams of both M80 and the M78. As stated your Morgans seem to have the M78 beam axle housing with an M76 centre making it an M78 28 spline axle with a M75 7.5 inch crown wheel

http://www.motospecs.com.au/ parts distributor to OEM and aftermarket for SAA

http://www.gjdiffs.com.au/ helpful guys that sell uprated cones side gears spring packs and reconditioned LSD units

Camaro Board Page four and include details of part numbers, my name on that site is Dave999

Further information about these axles can be sort from http://www.moparmarketforum.com/forum/index.php. The happy Chrysler chaps there will answer questions as well. Kind Regards.

Filling

a BTR Axled Morgan

(4/4s, Plus 4s, Plus 8s, Roadsters

)

by Lorne Goldman at

the eMog Pub March 2001 (update

5 May 29, 2012)

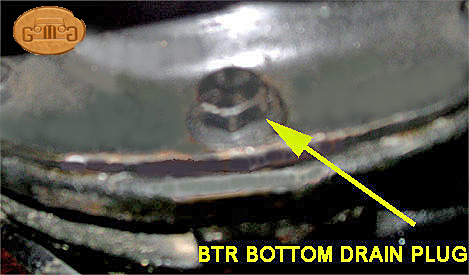

| N.B. Salisbury (until 1995) and BTR axles (from 1996) are very different. Do NOT confuse them as they MUST also be treated differently. The BTR is a noticeably bulkier axle with two plugs, one at the rear and another (the drain) at the bottom. The Salisburys have three square plugs (14mm). One at the top, one at the bottom and one at the rear. If you have doubts on which you have, contact the webmaster. |

Take the car (if possible) on a short run to warm the lubricant a bit.

1.

Place the car on a level surface.

1.

Place the car on a level surface.

2. Jack up the rear and remove the level plug. Nut socket size is 1&5/16" AF, 3/4 W or 33mm

[A BTR has only two plugs, one is at the bottom rear and often ignored by the uninitiated as they mistake it for a rear cover bolt). It is used to drain the lubricant. The other is a threaded plug a bit offset to the right in the middle of the rear cover. This one acts as a filler and level indicator.]

3. Remove the drain plug. (As a precaution, you can strain the lubricant to see if any debris is present.)

4. Replace the drain plug.

5. If you are adding Friction Modifier, pour it into the differential first. (from the MMC)

6. Using a container or funnel/tube that allows access to the rear filler hole, now fill the differential until the lubricant runs out of the filler hole.

7. Replace the filler plug.

8. Clean the differential and check for leakage at both plugs after your first run.

BMW and BTR recommend that

the fluid level be confirmed regularly but it need only be changed every

50,000 miles.

| WATCHPOINT Later BTR are technically spec'ed to last 40000-80,000 miles without a fluid change (I change mine every 25,000 miles). The level should be checked at every service however (every 3000-5000 miles). If "chattering" noises occur, it is time to refresh your friction modifier. Read on. |

For the lubricant, the

only

supplier they recommended was Castrol SAF-XJ. Sadly, this lubricant

is easily sourced in the UK and Europe but is not available in North

America

and some other countries through Castrol. However, a BTR was used by

BMW (3000s) and it can be sourced under their part number 83 22

2 282 583 (see the label) at any BMW dealer. This product already

contains

the necessary "Friction Modifier" (aka Sturaco) so it is unnecessary to

add anything.

The friction modifier can be

found separately and is used by EVERYONE under different names but

always saying "Friction Modifier". You have a choice, you can pick it

up at any Ford or GM dealer or spend mich more for the same thing

buying it from a specialist like Demon Tweaks. :(

I used

to recommend alternative fluids, gleaned from Morgan in Malvern and its

dealer network (i.e. Mobil SHC 80w140 ID. I

now recommend nothing but the BTR real thing listed above. Sadly I

still cannot not find it available outside of Australia, NZ

and Europe. Rely on the BMW fluid above which you can obtain at any of

their dealers. Yes, it is expensive but it

needs to be changed so rarely (officially 50,000 miles) that it is not

worth the trouble to find something cheaper. Better to spend an extra

$50 once every decade than risk a problem with your differential.

| WATCHPOINT: Should you read or hear of any advice of ANY other lubricant for these axles, ignore it and sue the writer. (sad smile) In all the years of BTR use, the only failures heard of is from people who ignored this rule.The first sign of failure will be a clicks or light clunk with attitude changes. Damage will commence as soon as the wrong lubricant is used and will continue spreading at a rate depending on what was wrongly chosen. |

The BTR, especially later versions, can make an unpleasant chattering sound. We corresponded extrensively with both the Australian manufacturers of the axle and the Morgan/BTR specialists in the UK and were told that this sound occurs when the wrong lubricant is used and/or that the lubricant chosen does not have a special friction modifier added.

For the lubricant, the only supplier they recommended was Castrol SAF-XJ. Sadly, this lubricant is easily sourced in the UK and Europe but is not available in North America and some other countries throigh Castrol. However, a BTR was used by BMW in their 3000 series and it can be sourced under their part number 83 22 2 282 583 (see the label) at any BMW dealer. This product already contains the necessary "Friction Modifier" (aka Sturaco) so it is unnecessary to add anything.

The Morgan Motor Company also uses and recommends this lubricant rather than using their normal supplier of lubricants, Morris. However, we have found that Morris has often dated ideas of what should be used in Morgan axles and gearboxes. They will also not give us a comprehensive fluids' constituent list so their is no way of checking what is or isn't in them. Considering the incidence of chattering BTRs filled at the Factory (cured by the simple addition of 2-3 onzes of FM) and R380s gearboxes filled with ATF (unwise) We prefer to pay it safe and go with what the component manufacturers insist on.

Here

are "possible" alternatives for those of us in North America and elsewhere.

(I play it safe and buy at BMW.)

| Should you read or hear of any advice of ANY other lubricant for these axles, ignore it and sue the advisor. (sad smile) In all the years of BTR use, the only failures heard of is from people who ignored this rule. The first sign of failure will be a clicks or light clunk with attitude changes. Damage will commence as soon as the wrong lubricant is used and will continue spreading at a rate dependant on what was wrongly chosen. |

Greasing

a BTR Axle

by Lorne Goldman

The BTR axles are closed end systems. There is no need to grease them for normal maintenance as is required for the Salisburys.