Tuning Your Carbs with an Exhaust Gas Analyzer

Tuning Your Carbs with an Exhaust Gas Analyzer

... from Fred Sisson's "Bedside Reader"..

with an EFI Addendum by Lorne Goldman

PICK A NUMBER BETWEEN ONE AND THREE HUNDRED...

Did you know that there are 354 needles listed for

(the most common) .090 jet SU! To further compound the problem of choice-

your particular car will probably run lousy on 40% of them, OK on

30%, feel great on 20%, run really great on 5% and really kick

butt on 5%. No wonder so few people

change needles. Where do you start?

Other people's recommendations, even "factory" recommendations

are probably off somewhere in your driving range... maybe WAY off! Just

remember "different is not the same". Different car (and EVERY one is different)

- different requirements- different needles.... No one can "tell" you what

is the really proper needle for your own car. No matter how experienced

they are, it will only be an educated guess at best. We all know that

the big-bucks racers have their engines checked on a dynamometer, simulating

race conditions, with lots of very expensive instrumentation. This is a

bit beyond my modest means and... expertise. Still- there is a way to sort

through the haystack and find the right SU needle for your own particular

car. I guarantee that it will improve your engine's performance, it is

not too costly and it is very rewarding.

ARE YOUR NEEDLES CORRECT FOR YOUR ENGINE?

This is not about "thinking"- this is about "knowing".

How do you know? As far as I am concerned, the ONLY way to

tune SU carburetors is with an on-board exhaust analyzer ($100 bucks).

This way, you can check your car while you are driving it, on your roads

(or track). Anything else is groping in the dark.

Many companies make exhaust analyzers today. They run

somewhere around $100.00. They use an O2 sensor that fits into your exhaust

system and are described in the book. Racer Wholesale now offers

an analyzer that will read two sensors (and there is a decent one in

the J.C. Penny catalogue for $120. GoMoG Webmaster). This is

the really hot setup for twin carbs as you can exactly tune each carb (not

just the resultant combined mixture of the two.)

The analyzer itself is a 'bitty thing. Mine is about 1

½"x 2". It has a series of LEDs that instantly read the fuel/air

ratio- as you drive! Real world stuff here..... I doubt that

any standard carburetor will give the absolute perfect ratio at all times.

However, you can get darn close and the reward for your time and

effort might just be a very dramatic improvement in performance.

At the very least, you will have peace-of-mind, knowing that your engine

is not being hurt from the effects of a drastically rich or lean mixture.

Many of the hot sports racers have the analyzer permanently

mounted in their car. They "tune for the course". Exhaust analyzers are

available as in-dash instruments also. I personally use the analyzer with

the temporary mount as the in-dash units are a bit out of place in

a vintage car. There is also a choice of O2 sensors. I have been using

the cheap kind which runs around $30.00. The 70 buck O2 sensor is better

as it is electrically heated and comes to the initial readings quicker,

but the cheapy works fine once it gets hot. I tape the gage to the

windscreen with "racer tape" so that I can see it at all times while driving/testing.

It reacts instantly so you can even use it to set the power valve for a

Holley carb. Pretty neat. When I am done- remove the gauge and O2 sensor.

There is a blank plug that screws into the sensor hole.

AN ADDENDUM FOR EFI (FLAPPER SYSTEMS)

by Lorne Goldman

Fred's article points to one of the inexpensive devices

that the home mechanic can purchase to fine tune there engine as well or

better than most roadside professional garage. An exhaust gas analyzer

takes the guess work out of carburetor tuning.

It is also the only method of precisely tuning the Plus

8 Rover "flapper" EFI system that was optional between 1984 and 1986

and standard between 1986 and 1990. The later "Hotwire" system has the

ability to be "hooked-up" to a diagnostic unit but the flapper does not.

Tuning is done by attached a exhaust gas analyzer to the tail pipe and

turning the idle air bypass screw on the airflow meter until the analyzer

LED shows the correct CO2 level. (normally 1.5 to 2.5% for a Plus 8).

LR/ROVER PLUS 8'S CLUTCH SLAVES

1. Mossbox Plus 8s, 1968-1972

1.01 the 1" bore Girling 64068329 (either 7/8 or 1" will do)

1.02 the 7/8" bore ? (checking possibly 64674336)

2. The Rover 4-Speed era 1972 to 1977

3. The LT77 era 1977-June 1993

4. The R380 era 1995ish-2004

5. Non-Morgan D&D

THE MOSSBOX ERAThe Mossbox Plus 8s

by Lorne Goldman with help/photos from Duncan Charlton, Tony McLaughlin & André Koopman

As you see above, these cars first used a

1" bore slave and then switched to a 7/8' both used by Austin. For

Morgan it was only important that they fit. The "feel" difference

between 1" and 7/8" should be negligible. The slaves are placed

both used on Austin: The Mini and the

| Duncan: I

have always found it tricky to get the slave cylinder adequately bled

on my 1971 Plus 8. The bleeder screw is not mounted at the highest

point, so I connect the hose but don't mount the slave cylinder to

bleed it. I clamp the piston so it can't exit the bore and then bleed

while I support it so that the bleeder is now at the highest point.

Only after bleeding in that position do I mount it to the car. |

Others, possessing a lift find access easier.

THE CLUTCH SLAVE Plus 8 FOR THE MAURICE OWEN SYSTEM

by Lorne Goldman

Plus 8s 1977-1994ish & Rover Plus 4s 1987-1994ish

A

right hand Girling Clutch Slave cylinder with either a 1" or 7/8" bore. Right hand

inlet and bleed nipple It has a short throw of 1 3/8" (35mm). Casting number as stamped on the base is 64673467 but the part number is .

The bleed nipple and hose inlet can be swapped around, they are both

3/8" UNF ports. Waiting time at this date (2024), if you find it,

is 50 days until shipping.

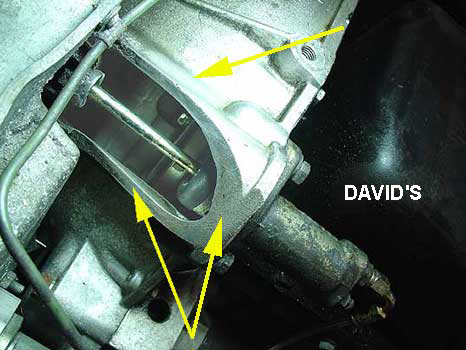

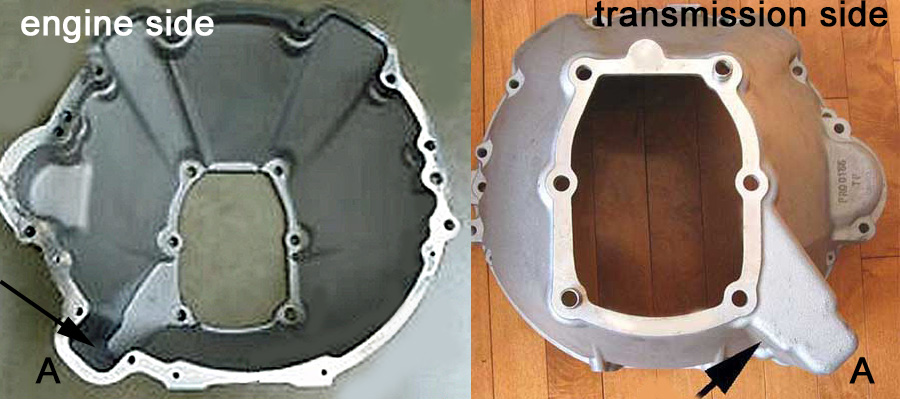

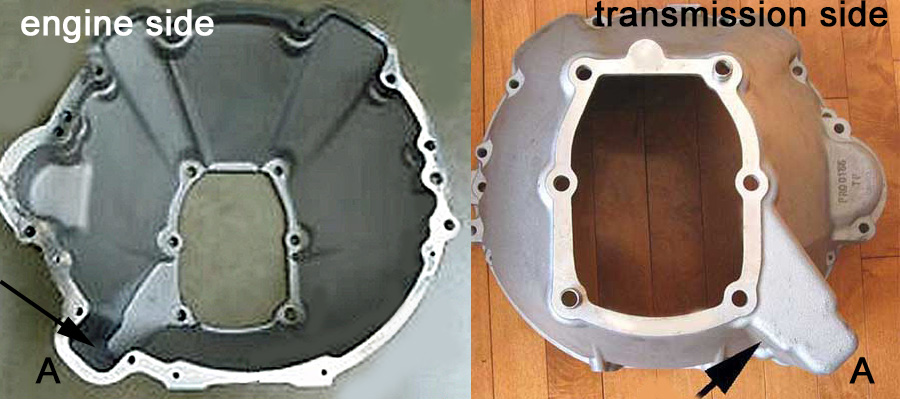

THE POST-1977 BACKGROUND

The

background is that the Sd1 bellhousing (the all-important part that

mates a transmission to the engine) used to fit the LT77 or R380

gearboxes to these cars for more than a quarter of century

(1977-2004) is not compatible with a Morgan trad, frame or body. It

and/or the frame HAS to be altered. Here is the offending part of the

bellhousing. It is the part that was designed by Rover to accommodate

the clutch slave.

The Morgan Company accomodated the clutch slave in two different configurations

which I have named after the two MMC design chiefs responsible for

them. All Plus 8s (1977 - 2004) and the Plus 4s (1987-2000) used

the LT77 or the R380 Gearbox SD1 bellhousings as their base. But the versions were modified differently.

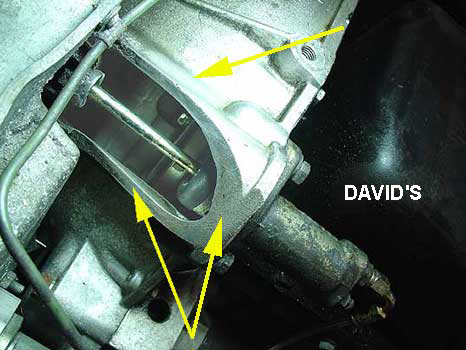

THE MAURICE OWEN SOLUTION

Maurice sheared the offending section for the Rover clutch slave off the

bottom of the bellhousing (left) and welded the section off (MMC metal

work shop). He then

opened the TOP of the bellhousing (right), and moved the release

bearing pivot

from its normal position on the gearbox to the top of the bellhousing.

He then found a tiny non-Rover generic much shorter clutch slave

to replace the now too

long original from Rover.

Bill Beck's

case, he had the

chassis crossmember altered to allow a

bit more bellhousing egress under the bulkhead, giving the

Plus 8 engine some

badly needed room at the front and allowing the engine to be a bit and

level, meaning that it cleared the bonnet hinge and cutting the hinge

or smashing down the SU air filter box was no longer necessary!

However, the outer side of the regular slave's protection had to be cut

off to allow sufficient spacing and debris easily enters these

bellhousings. On the other hand,

production was MUCH faster and the factory could save as the clutch slaves

were free with the engine/transmission purchase.

PROS:

1. It solved the fit problem without requiring a modification of

the frame or the firewall or the engine or its components. Earlier

models forced the hammering flat of the SU air filter housing and later

models a scoop out of the right side valence for the alternator. Early

EFI models required a cut out of the bonnet hinge.

2. It created a bit more clearance under the bellhousing.

CONS:

A. The shorter a clutch slave it the more susceptible it is to

wear. (as noted these little non-Rover/LR slaves are easily confused

and don't last long is the car is used at all).

B. The placement at the

top means a releatively short push rod which usually prejudices the

entry angle and path which causes the slave cylinder to wear faster as

well.

C. As a general rule, it is unwise to place any

hydraulic cylinder BELOW its reservoir. This too accelerates

wear and makes bleeding more difficult.

D. Access to the slave became much more of a hassle in later EFI cars because of the complexity of the hoses and loom above it.

| These

cons makes the normal life span of this clutch slave of

this configuratrion decidedly short. You can expect only 12,000

to15,000 miles and must carry an extra one with you at all times. They can be changed roadside. However, I discovered a permanent solution 20 years ago. A used slave sent to an expert to be sleeved

in stainless steel lasts forever. The cost is the same as buying a new one with its limited lifespan. |

THE BILL BECK SOLUTION

Bill

Beck's solution is smarter and saved the MMC even more in cost and

labor. Bill made two changes so that the stock LR/Rover slave can

be used an no welding or patching is needed. Bill sliced the

bellhousing section housing the stock slave open.

PROS:

1. It

allows the standard Sd1 clutch

slave to be used which elminates parts confusion and makes

sourcing easier. Much cheaper in labour and parts than the Maurice Owen

solution. No welding involved.

2. It is easily accessible..

3. It is longer and allows for greater longevity

4. It is below its reservoir which increases longevity.

CONS:

A. It required

a modification of the crossframe piece below. The piece arcs

downward eliminating precious ground clearance at this point;

B. An open

bellhousing is unwise for obvious reasons. (Though I have seen

much worse design modifications in mating bellhousings to

gearboxes! See the

USA's

D&D's Bellhousing

USA's

D&D's Bellhousing

To the

right!! [shiver]) An open bellhousing collects

debris which inevitably effect the components inside and accelerates

rust. And in this case it is infinitely worse than the Bill Beck

solution which did save the MMC money while curing important earlier

issues.

N.B. To

date, the best bellhousing to mate a non-standard gearbox to a

Rover V8 I have seen in the Morgan world is that made by

J.E. Developments of the UK to fit a Tremec T-5 to a Plus 8. It

is bespoke and totally enclosed. It uses an internal concentric clutch release which eliminates the issues created by an external setup.

N.B. Like the John Eales, (who I recommend) T5 belhousing D&D uses a internal concentric clutch release.

SUMMARY:

I have

tried/used them all. I have come to the conclusion that the best option

for me is the Maurice Owen solution with a stainless sleeved slave. It

works and lasts forever while leaving a pristine interior for the

bellhousing. The ideal would be a bellhousing with a removeable side access panel that allows for clutch replacement without removing the engine. A right PIA!! The

MMC forgets that these cars are supposed to last forever. They merely

manufacture with the cars without a body on them!!

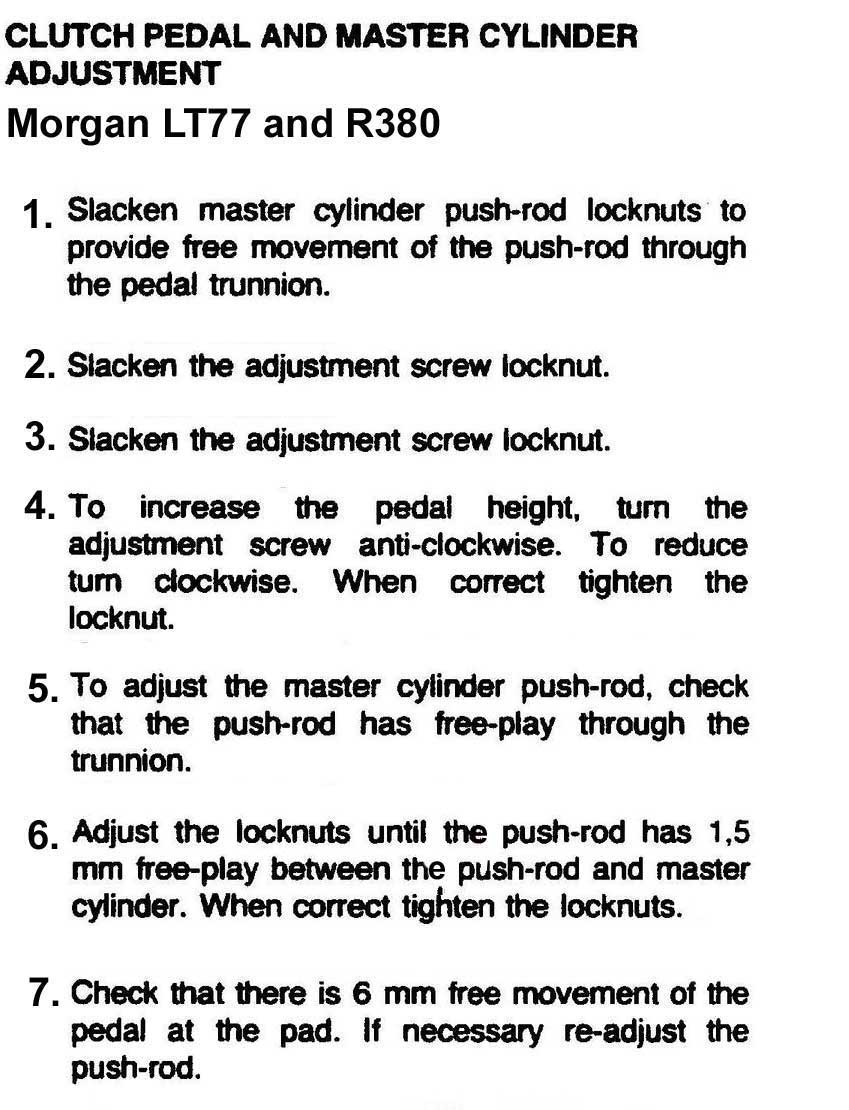

Clutch Pedal Adjustment

(LT77 and R380 Plus 8s (1977 to 1996) and Plus 4s (1987-1996)

Clutch Pedal Adjustment

(LT77 and R380 Plus 8s (1977 to 1996) and Plus 4s (1987-1996)

Replacing the Clutch Slave (LT77 and R380 Plus 8s (1977 to 1996) and Plus 4s (1987-1996)

A local garage will not have an advantage over you here, especially. The area is Morgan-configuration only. Part

of the neverending odd modifications needed to keep fitting later

motors to an engine bay designed in the Thirties for a 36bhp tractor

engine. ;) That task constantly exhibits a GoMoG Law I call the Deadly

Domino Effect. In this case, the bellhousing doesn't quite fit far

enough into the car because of the:

1. the width of the area for

bellhousing,

2, the crossmember at the bulkhead underneath

3. and the

bellhousing casting placement for the regular LR clutch slave.

Two Morgan designers, Maurice Owen and the Bill Beck, (1967-2002)

addressed the issue differently. Both designs have

issues.

You and I could

have come up with a better design. But these these designers were given

priorities and instructions and attitudes from on high. You would be

wrong to think that they were incompetent. The sad pity is that, as these cost priorities are indulged and such designs are currently multiplying,

the cars are becoming less and less reliable. (Do not confuse aging and

poor maintenance with bad design They are separate issues.)

We will be deal here with replacing the slave in the Maurice Owen

system. Look at the area atop your engine. I have found some piccies

(above If that is what you have on your car, go pump your clutch

vigorously a bit and then go check if you can see/feel any brake fluid.

(If you get

clutch fluid on your hands, wash it off quickly. I use spray brake cleaner.)

To change the clutch slave shown above.

1. with a 7/16 spanner, remove the line to the clutch master. I find

this makes the rest of the job easier as you can tighten the line at

the slave without twisting the line.

2. Remove the fluid line from the clutch slave.

3. Now the big bolts. These often are unwilling as they are steel and

the bellhousing is aluminium. That creates a galvanic reaction (aka

metal rot) that seizes these bolts. Use the correct socket and if the

two bolts seem reluctant, take some time and use a penetrating oil,

even many times over a few days.

4. When they loosen, do not remove them right away.

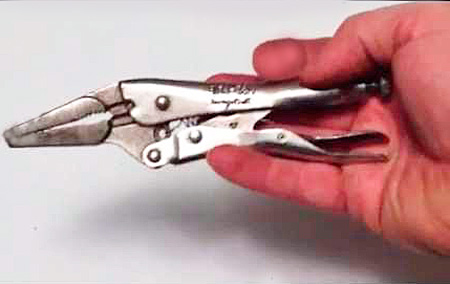

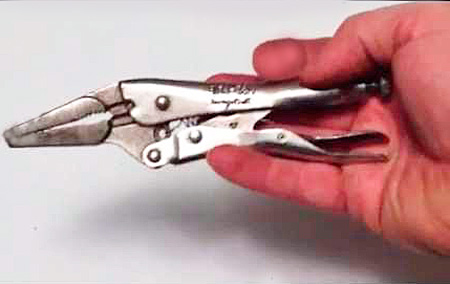

| WATCHPOINT: the

only annoying danger in this task is losing the cylinder's actuating

rod...which can be a pain in the butt. What I do is grab it with a

small needlenose vice grips as you are removing it then lock

it the vice grips and secure the grips at the side. |

5. Once the rod is secure, remove the big bolts by hand, and

slowly draw the slave towards the engine and, if necessary, a bit

upward until it is free from its actuating rod.

5. Once the rod is secure, remove the big bolts by hand, and

slowly draw the slave towards the engine and, if necessary, a bit

upward until it is free from its actuating rod.

6. Check the new cylinder. You do not

need a rod (assuming it came with one). You should use the old rod

as it has likely been adjusted to the right length for your car. Additionally, this little cylinder, even if it is the correct one, must have had its rear ground/filed to fit a Morgan.

7. Now you must reverse the procedure with the new slave. Carefully

position the slave on the engine side and angle/slide it onto the rod,

only removing the vicegrips when the rod slides in and is captured into

the cylinder and the rubber!

8. Now (after covering the bolts with a little silicone to prevent the

same galvanic reaction mentioned above), thread in the big bolts. Then

tighten them firmly with your socket and ratchet. You can now breath.

9. Now you must reconnect the line to the master clutch cylinder. Use the bottom fitting on the slave for this as you need access to the top one. (there

is no difference between the two but easy access to the top is

necessary for bleeding the system which is next up).

10. Remove the top fitting to allow you access to tighten the line and tighten the line.

11. Thread on the fitting into the master clutch cylinder and tighten after you are assured it is not cross-threaded.

12. Now you must refill and bleed the system. We all have different systems for that. I use any glass jar that happens to be around... with a tube connected between the bleeding nipple and with the other end submerged in brake/clutch fluid.

Make sure the reservoir never empties or you will pumping air rather

than fluid into the system. On which brake fluid to use, CLICK HERE.

BACK

Tuning Your Carbs with an Exhaust Gas Analyzer

Tuning Your Carbs with an Exhaust Gas Analyzer

USA's

D&D's Bellhousing

USA's

D&D's Bellhousing

Clutch Pedal Adjustment

(LT77 and R380 Plus 8s (1977 to 1996) and Plus 4s (1987-1996)

Clutch Pedal Adjustment

(LT77 and R380 Plus 8s (1977 to 1996) and Plus 4s (1987-1996)

5. Once the rod is secure, remove the big bolts by hand, and

slowly draw the slave towards the engine and, if necessary, a bit

upward until it is free from its actuating rod.

5. Once the rod is secure, remove the big bolts by hand, and

slowly draw the slave towards the engine and, if necessary, a bit

upward until it is free from its actuating rod.