1133 Chatmoss Dr., Va. Beach, Va. 23464; (757) 495-8229

1133 Chatmoss Dr., Va. Beach, Va. 23464; (757) 495-8229

Originally written: December 2007

Last update:  November 22, 2009.

November 22, 2009.

When we moved into our house, back in 1984, the porch did not have any railings. The porch is relatively high, 3 feet 6 inches from the ground, so we said we wanted to put some railing up someday. We had 2 small boys, JohnC - 4 yrs, and ScottE 3 months, a dog and a cat. As the kid grew older they enjoyed jumping off the porch over the shrubs into the front yard. Time has moved on since then, it’s now December 2007.

I was talking to my dad a few weeks ago (Oct 2007), and he told me that one of his neighbors had just had vinyl stair railings put on their porch and they looked very nice. So I went over and took a look at them, and boy were they nice. Dad got the name of the contractor that installed them for me and I gave him a call for an estimate. He quoted about $800 for labor. He had a few good ideas. To put up the railing on the right side of the stairs, I would need a post installed, as the first column is about two and a half feet to the right of the stairs. He also had one expensive one, he suggested I should replace all the columns with new vinyl ones as the existing wooden ones would not take the vinyl porch railing. I thanked him for his time and the estimate, and started thinking about the job.

He made it sound easy! I’m a pretty experienced do-it-yourselfer, have restored 4 cars, doing 90% of my own car maintenance, plumbing and electrical around the house. So I thought I’d give it a try.

My wife asked me if I’d looked at any of the houses in the neighborhood that had installed railings. I said No. So we started going around looking at all the houses. There were all kinds of railings, wood, vinyl, even a couple of metal ones. All kinds of different arrangements, some had extra posts installed in the run between columns, some butted posts up to the existing columns. I was surprised how many different installations I actually saw.

Next, I took a ride out to HomeDepot to see what they had. The sell a very nice vinyl railing system by YardSmart. HomeDepot also had a nice flyer that gave some general directions for how to install the products. But they were mostly for a wooden deck. I have a concrete porch with brick trim. So I wasn’t sure how to go about installing the railing. I ran into a gentleman there and we got talking about the railings, posts, etc. and he was telling me about what Lowe’s sold. I still really didn’t have a clue as to what I would be getting myself into. I take a drive over to Lowes and ask where their vinyl railing was, and I’m pointed in the right direction. Lowes sells a product by SevereWeather. I take a look around, no literature not much of a display. So I head home figuring I’d do some research on-line. Unfortunately, I didn’t really find a lot there. I did find YardSmart’s and SeverWeather’s web sites. Of the two, YardSmart seemed like the better choice and it had the same documentation as the had in the HomeDepot store.

Now I know a little, so I go out onto my porch and start taking measurements of the porch, the inside distance between columns, the height of the stairs, and their length or run.

Back to the hardware stores, to look at what they stock. HomeDepot has the Williamsburg style columns like what is currently on the house. And their deluxe railing was very nice. They even had a nice stair railing kit. But one big problem, the railing the stock is only 5 feet 7 inches in length, as is their stair railing kit. The distance between the columns on my porch are (starting from the left) 6 feet 4 1/4 inches, 6 feet 3 3/8 inches, and on the right side 7 feet 4 inches. Then I measured the stairs, the height is about 3 feet 6 1/2 inches and the run is about 62 and a half inches. This meant that the hand rail would have to be about 75 and a half inches long. Everything I needed was longer than what HomeDepot stocked.

So I head over to Lowes. I didn’t see the columns I needed, but I did see the railing. And guess what, they stocked 6 and 8 foot lengths. So I could get the 8 foot ones and cut them down to fit. Now I understand why some of the people had the additional posts between their columns. To handle the shorter, 6 foot railing lengths.

The post at Lowes, consists of a metal pipe with plates at the top and bottom. The bottom plate gets screwed to the concrete or wood, then you slide a 4x4 vinyl sleeve over the top plate. While it will be strong from the standpoint of the post attachment to the deck I don’t think that the railing will be too secure just screwing it into the vinyl sleeve. Not to mention that the post with mounting bracket at HomeDepot costs less than the ones from Lowes.

Now the fun starts, and the reason for writing this article. The following details the problems I had, the trial and error solutions, in an attempt to ease your pain and make your job go smoother.

I met my dad at HomeDepot. I had planned on doing this job in stages, the stair railings first. This would require about an 8’ stair railing, one column and one "newel" post. When we got to HomeDepot, dad suggested that I just get all the columns and hardware that I needed. So we picked up five columns, two 4x4 vinyl sleeves, three 4x4s (more on them later), the mounting plates and the caps for the 3 posts (2 at the bottom of the stairs, and one on the right side on the porch).

Then we headed to Lowes to pick up the 8 foot railings. As I started pulling the top and bottom rail sections, I noticed that most of them were broken. That’s when I realized that they weren’t vinyl, rather some composite. Not what I wanted!!! Especially if they are already broken.

Problem #1. What do I do now? Back to HomeDepot and talk to the people at the Contractors desk. I can special order hand railings that are just under 8 feet in length, but at a premium. So I order the 3 sections I will need. But I can’t get an 8 foot stair railing. So I have to change my plans on having the railing go all the way down to the sidewalk. It will have to be moved up somewhere along the stairs. I’ll have to see where when I get everything home.

We get all the material home and stored in my garage. I’m all set to start the project on Saturday. I’ve enlisted the help of a friend, Dennis, for brawn, the extra pair of hands, an extra brain, and some tools.

Saturday morning we start. We are going to try and replace the column on the left of the stairs (facing the house) and mount the front post for the stair railing.

I had talked to several people, and decided that we’d dig a hole about 2 to 3 feet deep and put a 4x4 in there and then fill it with concrete. So Dennis starts digging a hole in the flower bed, at the end of the stairs, for the front post, and I start mounting the "newel" post to the porch.

Part 2 is to get a 1/2” wedge anchor and run it into the concrete.

So off we got to the hardware store in search of the new parts required. Mission accomplished, and we’re back at work. We drill some holes in the concrete with the masonry bit and set the post anchor with some Tapcon screws.

We set a 4x4 post in the hole and into the anchor and adjust it for vertical using a post level. We attached the base of the post to the post anchor using 4 #10 by 1 1/2” sheet metal screws. We measure and mark where we should cut the post so it is the same height above the ground as the "newel" post I mounted on the porch. We remove the screws, lift the post out and cut it. I used a reciprocating saw similar to a Sawzall to cut the post, but found the saw to be very difficult to control for a clean cut. I’ll have to use a different saw for cutting the railings and the columns.

When we set the cut off post back in hole, we find out that the 4’ sleeve (remember I cut an 8’ sleeve in half) is too short.

Sunday morning I get up and get started. I’ve got to pull the post. So I do. We are planning on reusing the same post and sleeve. But I have to move the hole back towards the house a little. I mark a new location for a new wedge anchor in the post, drill the sleeve and post so I can mark the brick. I remove the post to see where to drill the new anchor hole and realize I‘m on the back edge of the same brick I had been anchored to. To make matters worse, we cracked the brick. I don’t think this is going to work.

I guess I should mention that trying to get the screws I was using started through the vinyl proved to be a bit of a problem also. Especially the ones that we used at the base of the post to hold it to the post anchor. Remember this is in a hole, and we can’t get the drill down in the hole. I tried using the ratchet from my 1/4” drive socket but couldn’t get the screw to bite. So I used my 1/4” air ratchet. This gave enough speed and constant turning, that the screw bit into the vinyl and then the wood. A couple of other options might be to use a drill but try driving the screws in a an angle, or using a 90 degree adapter on the drill.

Problem #7. Another problem we ran into was cutting the top railing for the stair rail. It has an aluminum I beam in it for support. So we originally used a saws-all to cut it. Big mistake. We didn’t have enough control over the saw. This may be why we ended up sort. At least it’s a good excuse. So now we are using a hack saw and the old manual mode to cut the vinyl rails. This can be a chore, so we found an easier way, described later in Tip #7.

Needless to say, I was very disappointed. Maybe I should have let the contractor do the job. But tomorrow is another day. We'll see what happens.

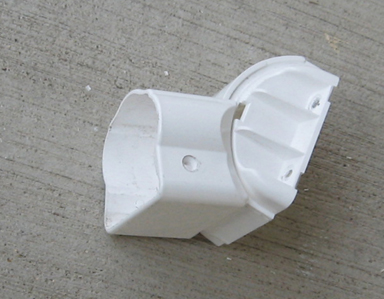

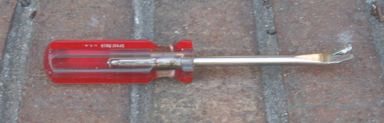

Tip 2. If not, remove the balusters. To remove the balusters, he suggested standing on the bottom railing and using a rubber mallet knock the top and bottom rails off the balusters.

I found a better way to remove the balusters. Years ago I needed to pry the crankshaft gear off an engine. I’d gone to a hardware store looking for some sort of a small pry bar. What I found was a “cat’s claw” or wood workers nail removing tool. Simply slide it the hole on the side of a baluster, where the tab is and press down a little. The curve on the cat’s claw will let the tab on the baluster slide under the cat’s claw and depress the tab so you easily can pull and wiggle the baluster from the rail.

Tip 3. The rail swivel caps can be mounted 2 ways on their bases. One way there is a stop that limit’s the angle. If you remove the end cap from the base and turn the base over you can get a lot more angle out of it. When you attach the swivel to the post, the post will limit how far the end cap can swivel so it won‘t fall off.

Tip 4. If you still can’t get enough angle by turning the swivels over, then you need to remove the balusters and enlarge the holes. Pat recommend cutting 1/8” from the front and back of the baluster slots.

Armed with this knowledge I decided to go out and play with the stair railing a little. Well this stair railing kit is now a throw away, so I figure I’ll play with it and see if I can‘t get it to work.

First I turned the swivels over to allow maximum angle at both ends. Then I pulled all the balusters out of the top and bottom rails. I set the top rail in the swivel on the porch, and found I could get the rake I wanted from the swivels! Now the top of the top rail is about 39” above the first step, the same height as it is at the porch. I'm finally getting there!

I installed only the first and last baluster to the top and bottom rail and see if I can still get the angle I need. Nope! So using a Dremil tool with their rotary saw blade, I cut an 1/8” off the front and rear of the first and last balusters holes (in both the top and bottom rails) and reassembled. I set the assembled rail in the swivels, and it fits! There was a pretty large gap now around the balusters So I tried only cutting 1/16” off the front of the 2 middle baluster holes, installed these two middle balusters and test fit. It still fit and the baluster holes were a lot cleaner looking. So I suggest removing only 1/16” at a time.

When my wife came home from work and saw the new height she really liked it. She was happy! Even though this was just a mock up. I’d have to use the other stair rail kit I’d purchased to finish this side and then get another stair rail kit for the other side. But if fit!!!

Wednesday I got brave and took out the other stair railing kit and decided I‘d mount it.

Tip 5. I started by writing the words “yard” and “house“ on the bottom, ends, of the top and bottom rail. So I’d always have a reference as to which way the railing should be going.

Tip 6. I don’t recommend installing the "locking" screws until the job is done. I had to pull the “locking” screws out to adjust my swivels a little more.

Measure the distance from the baluster to the posts to center the railing to center it and adjust as necessary. Mark the railings as per the instructions.

It was time to make my cuts on the top and bottom rails. I held my breath, and decided not to take as much off the rail as was indicated. I’d rather make a few more cuts than take too much off and ruin another stair rail kit. That can get real expensive. I used my hack saw to cut the bottom rail. Cutting just the vinyl on the bottom railing was easy, and I had very good control over the saw. Then I started to cut the top rail. Remember there’s an aluminum “I” beam inside. So that means 2 cuts of the “I” beam. But cutting the “I” beam is a little tough and you loose control of the saw. I light bulb went off in my head!

Tip 8. After my final cuts, the top rail was about 1/8” from touching the front post. To me this is the most critical fit. You want the top rail as tight as you can get it as it will be taking all the force of someone pulling on it. I would have to raise the rail to get it to meet the post just a little. So I cut a 1/16” off the bottom rail, and fit again. Both of the swivels met the post nicely. The top of the swivel for the top railing on the porch is about 39 1/2” above the porch. The top of the swivel at the bottom of the steps is about 40 1/4” above the stair. Not bad, and you’d be hard pressed to see this 3/4” difference.

Tip 9. Now is the time to install the "locking" screws into the swivels. Mark the swivel brackets for position by marking a line with a pencil across the tops of all 4 of the mounting brackets at the swivels. Remove the railing, and the swivel brackets. Align the swivel to your mark and mark the base with a pencil. Use a center punch to highlight you mark and to give the drill bit something to bit and center on. Drill a small pilot hole, and then screw the screws in to lock the swivels.

Problem #9. In the screw package for the lower swivels, there are 8 screws for attaching the swivels to the end posts and an additional 4 flat head screws with the head painted white. According to the instructions there are supposed to be used to lock the swivels in place. But there are 2 counter sunk holes in each top rail. Assuming that these are to lock the hand rail to the end caps, there should be 4 more screws in the kit. Not so.

Tip 10. You’ll have to come up with something, or leave the 4 counter sunk holes in the 2 top rail caps with nothing in them. Or what I think I’m going to do is: use four 3/4” dry wall screws in these holes and put some white nail polish on them. But first I’ll have to run a small drill bit through the holes to create a pilot hole in the Aluminum “I” beam.

With one railing under our belt, my youngest son, ScottE, and I tackle the 2nd railing. It took us about 3 1/2 hours to install. It went pretty much without a hitch. We purposefully left the post sleeves a little long to allow us to trim them to the same length.

Continue on to Part 2 - Replacing the columns and installing porch railings

Return to the Main page

To email me with comments or questions.